13

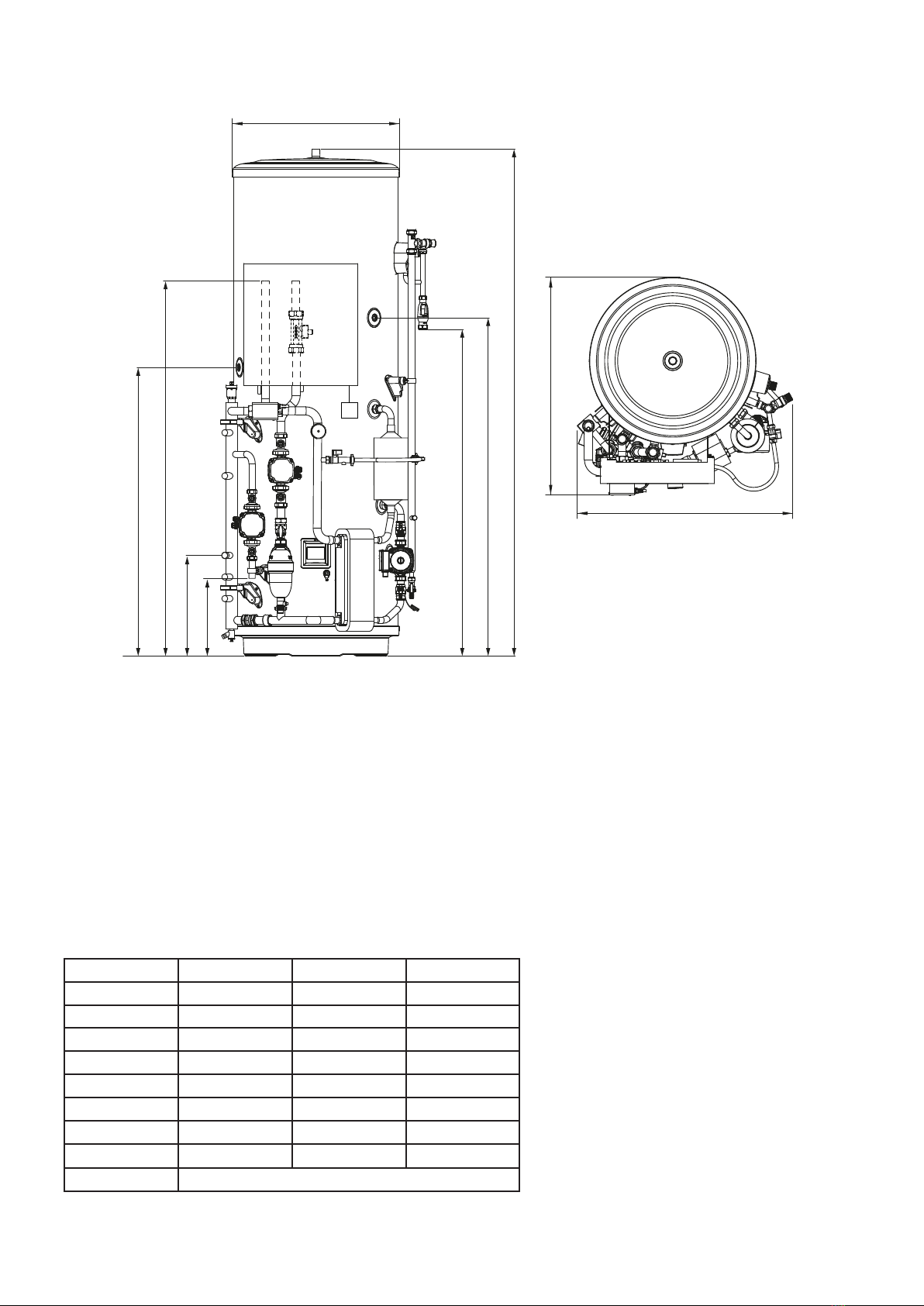

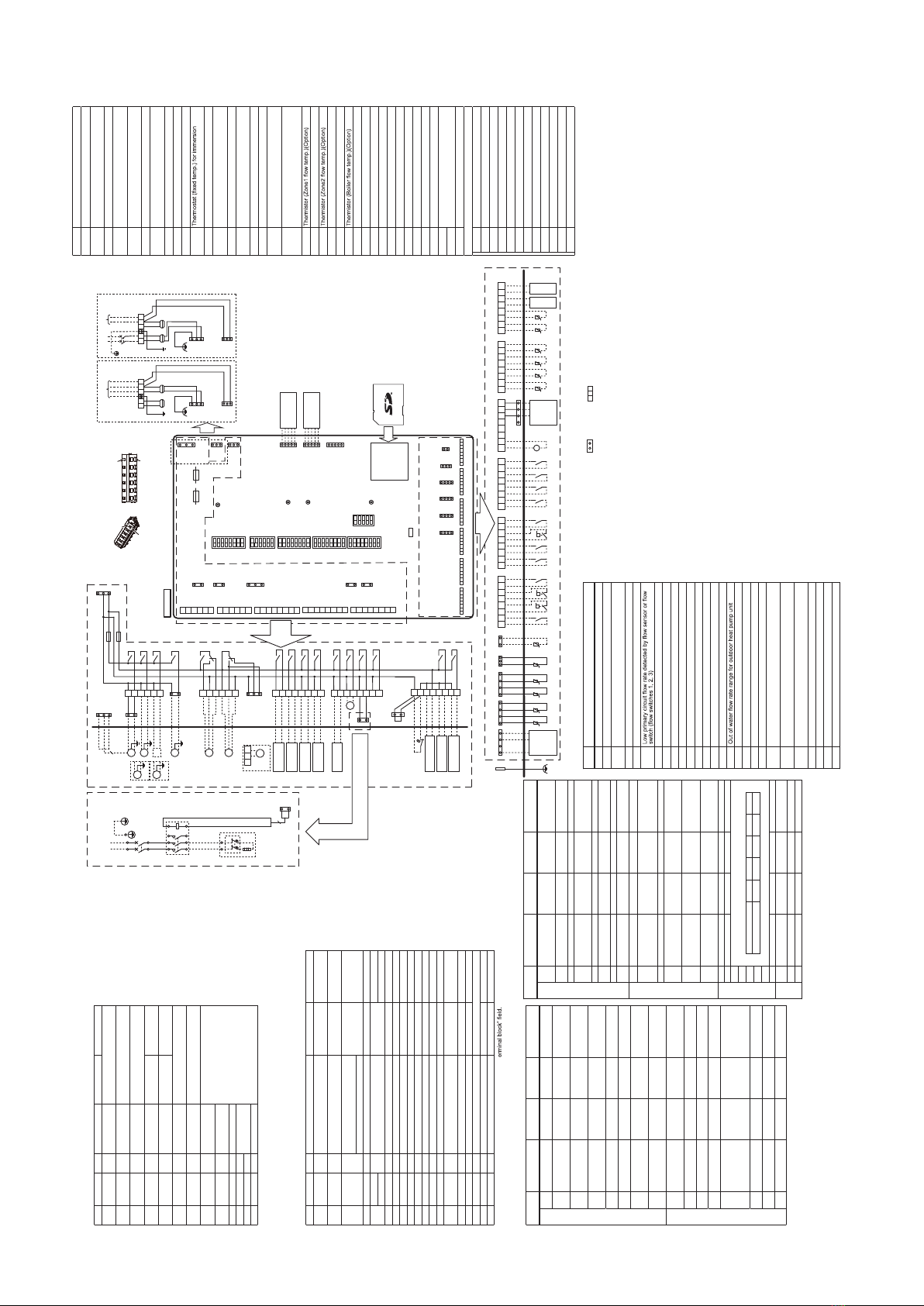

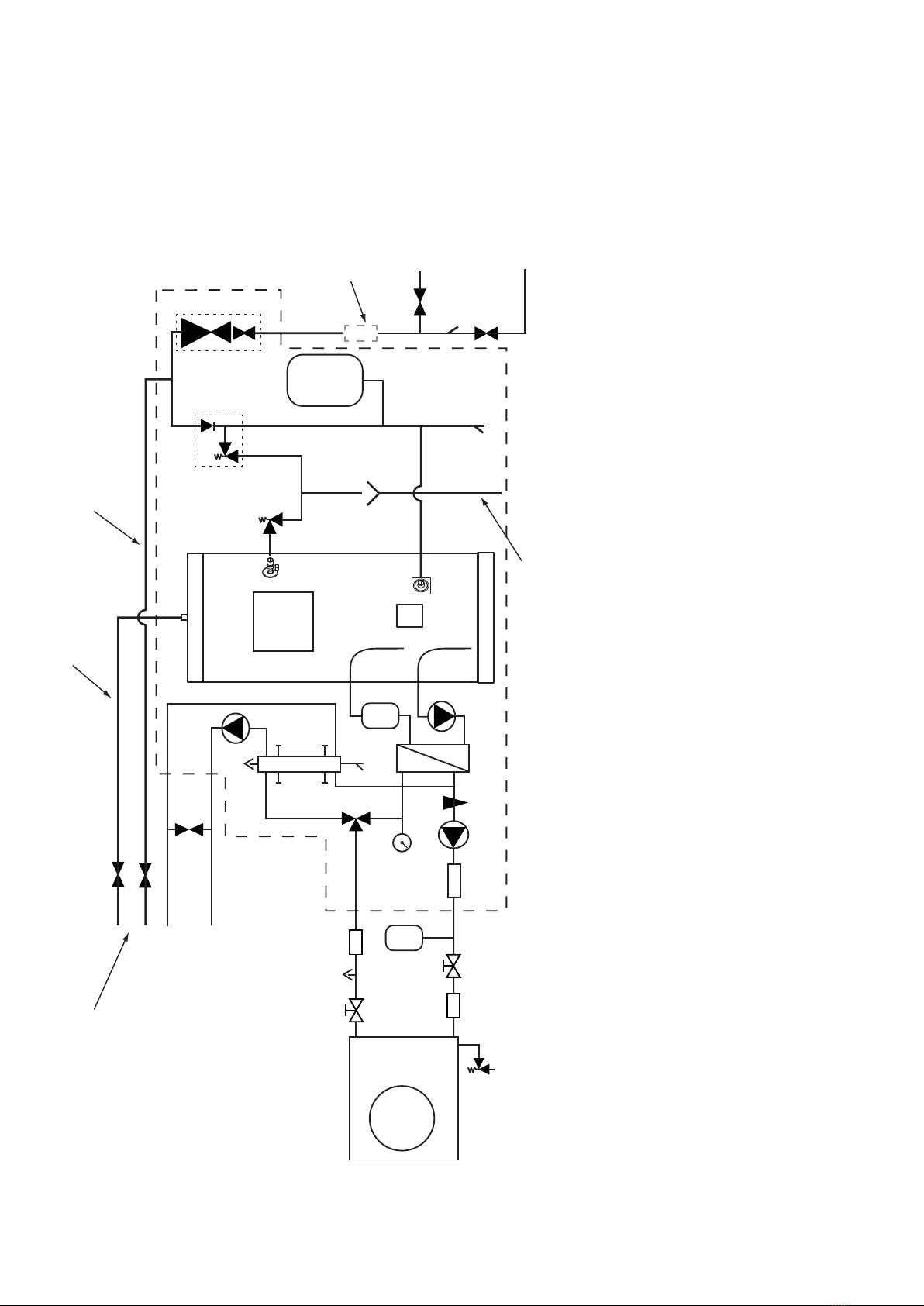

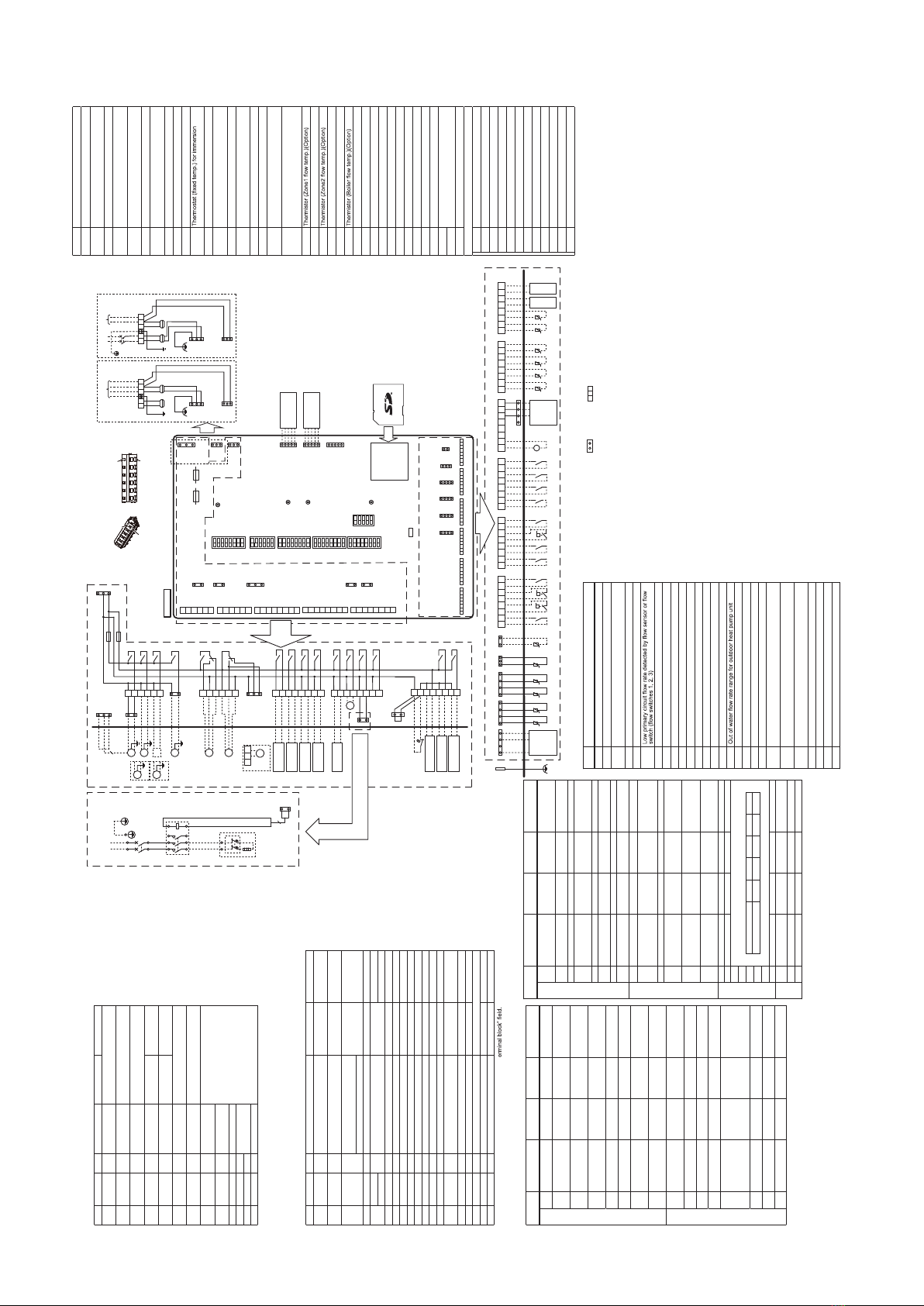

FTC WIRING DIAGRAM <PAC-IF07*B-E> Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB2

Earth leakage circuit breaker for immersion heater

(Except PAC-IF071B-E)

MP1

Water circulation pump 1(Space heating & DHW)

MP2 Water circulation pump 2

(Space heating for Zone1)(Local supply)

MP3 Water circulation pump 3

(Space heating for Zone2)(Local supply)

MP4

Water circulation pump 4 (DHW)(Local supply)

3WV

(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

IHT

heater(Except PAC-IF071B-E)

IH Immersion heater(Except PAC-IF071B-E)

IHC Contactor for immersion heater

(Except PAC-IF071B-E)

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

(Included in PAC-IF071B-E)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5A Thermistor (DHW tank upper water temp.)

(Included in PAC-IF073B-E)

THW5B Thermistor (DHW tank lower water temp.)

(Included in PAC-IF073B-E)

(Option for PAC-IF071/072B-E)

THW6

THW7 Thermistor (Zone1 return temp.)(Option)

THW8

THW9 Thermistor (Zone2 return temp.)(Option)

THW10 Thermistor (Mixing tank temp.)(Option)

THWB1

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

IN11 Smart grid ready input (Local supply)

IN12

INA1 Flow sensor (Option)

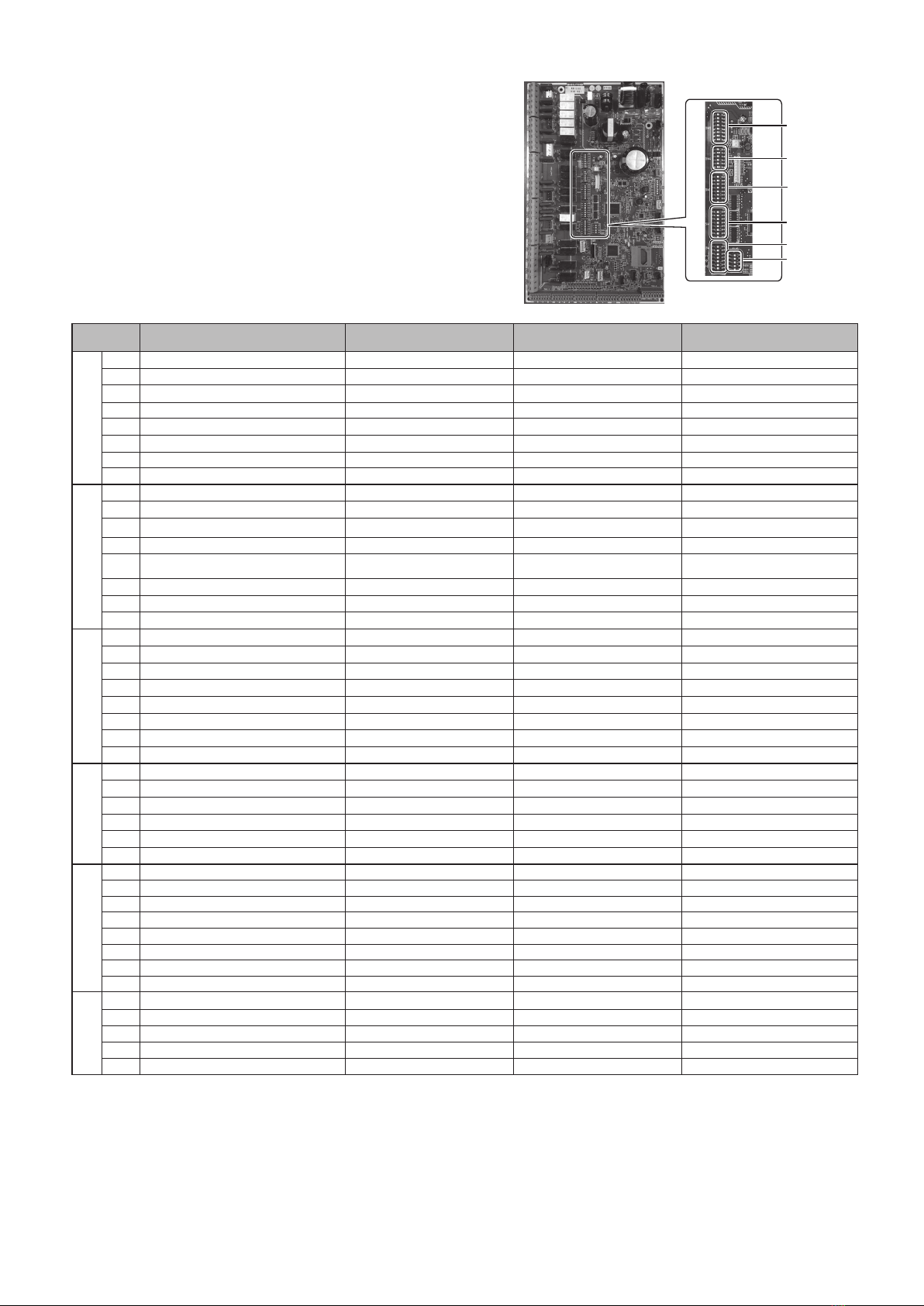

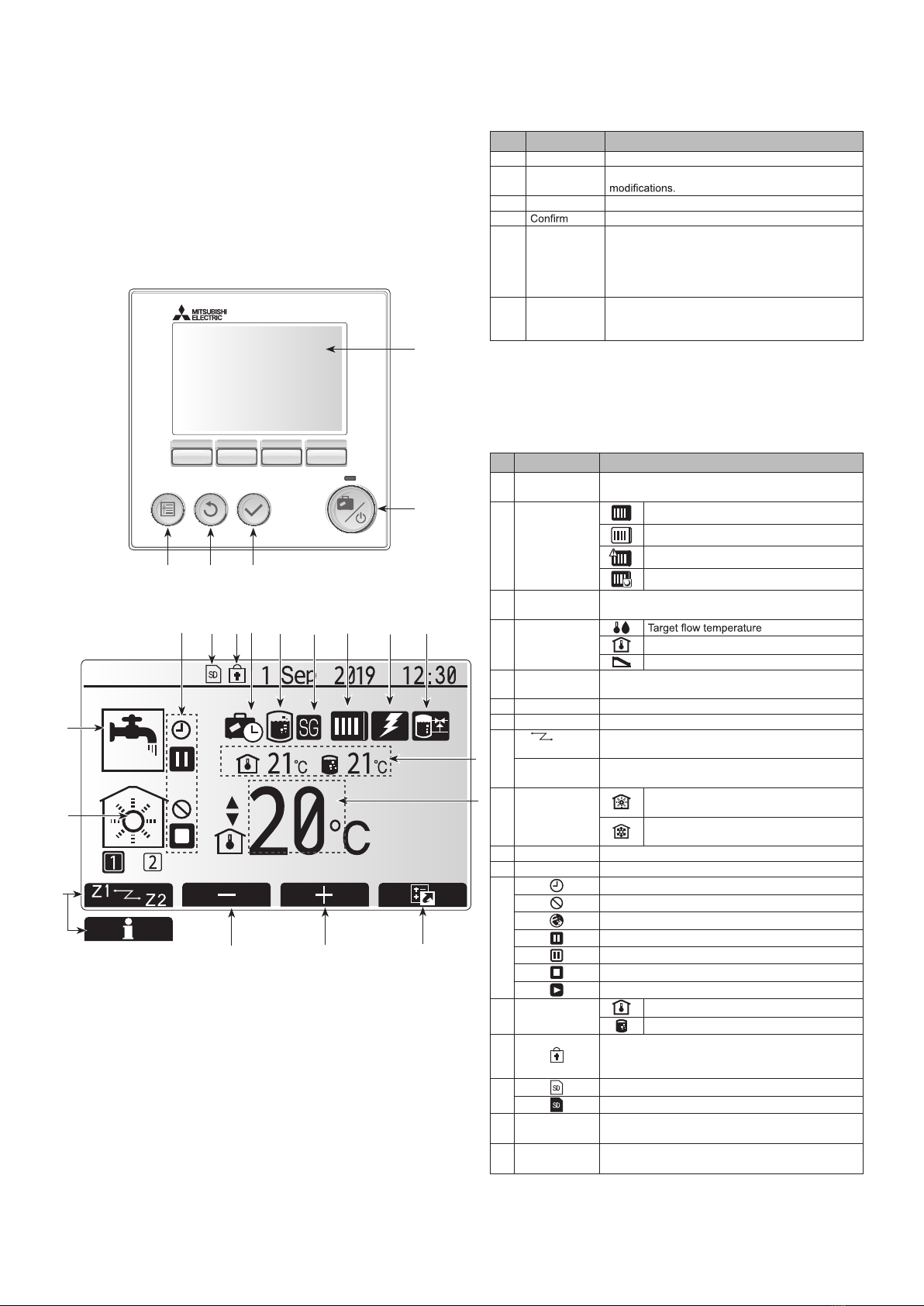

FLOW TEMP. CONTROLLER (FTC)

TBO.1-5

Terminal block <Outputs>

TBI.1-6 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (IEC T10AL250V)

F2 Fuse (IEC T6.3AL250V)

SW1-6 DIP switch *See Table 3

X1-16 Relay

LED1 Power supply (FTC)

LED2 Power supply (Main remote controller)

LED3 Communication (FTC-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

1. Symbols used in wiring diagram are, : connector, : terminal block. Function with asterisk (*) may not be available depending on model types.

2. Indoor unit and outdoor unit connecting wires have polarities, make sure to match terminal numbers (S1, S2, S3) for correct wirings.

3. Since the outdoor unit side electric wiring may change, be sure to check the outdoor unit electric wiring diagram for service.

4. When connecting a booster heater, the wiring method is different according to the type of built-in thermostat.

Please refer to the installation manual for details.

Table 4 Error Codes

Code Error

L3 Circulation water temperature overheat protection

L4 DHW tank water temperature overheat protection

L5 Indoor unit temperature thermistor (THW1, THW2, THW5B,

THW6, THW7, THW8, THW9) failure

L6 Circulation water freeze protection

L8 Heating operation error

L9

LA Pressure sensor failure

LB High pressure protection

LC Boiler circulation water temperature overheat protection

LD

Boiler temperature thermistor (THWB1) failure

LE Boiler operation error

LF Flow sensor failure

LH Boiler circulation water freeze protection

LJ DHW operation error (type of external plate HEX)

LL Setting errors of DIP switches on FTC control board

LP

P1 Thermistor (Room temp.) (TH1) failure

P2 Thermistor (Ref. liquid temp.) (TH2) failure

P6 Anti-freeze protection of plate heat exchanger

J0 Communication failure between FTC and wireless receiver

J1 - J8

Communication failure between wireless receiver and

wireless remote controller

J9

Communication failure between FTC (Master) and FTC

(Slave)

E0 - E5 Communication failure between main remote controller and

FTC

E6 - EF

Communication failure between FTC and outdoor unit

E9 Outdoor unit receives no signal from indoor unit.

EE Outdoor unit incorrect connection

U*, F*,A*

Outdoor unit failure

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 7-8 — Room thermostat

1 input *1

Refer to SW2-1 in

<Table 3 DIP Switch Functions>.

IN2 TBI.1 5-6 — Flow switch 1

input

Refer to SW2-2 in

<Table 3 DIP Switch Functions>.

IN3 TBI.1 3-4 — Flow switch 2

input (Zone1)

Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN4 TBI.1 1-2 — Demand control

input Normal Heat source OFF/

Boiler operation *3

IN5 TBI.2 7-8 — Outdoor thermo-

stat input *2

Standard opera-

tion

Heater operation/

Boiler operation *3

IN6 TBI.2 5-6 — Room thermostat

2 input *1

Refer to SW3-1 in

<Table 3 DIP Switch Functions>.

IN7 TBI.2 3-4 — Flow switch 3

input (Zone2)

Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN8 TBI.3 7-8 — Electric energy

meter 1

Refer to installation manual.

IN9 TBI.3 5-6 — Electric energy

meter 2

IN10

TBI.2 1-2 — Heat meter

IN11

TBI.3 3-4 — Smart grid ready

input

IN12

TBI.3 1-2 —

INA1

TBI.4 1-3 CN1A Flow sensor

*1. Set the ON/OFF cycle time of the room thermostat for 10 minutes or more;

otherwise the compressor may be damaged.

*2. If using outdoor thermostat for controlling operation of heaters, the lifetime of the

heaters and related parts may be reduced.

*3. To turn on the boiler operation, use the main remote controller to select “Boiler” in

“External input setting” screen in the service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output

(Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output

(Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output

(Space heating/cooling for Zone2) *1 OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2 — Mixing valve output *1 Stop Close

TBO.2 2-3 Open

OUT6

TBO.5 5-6 — Booster heater 1 output OFF ON

OUT7

TBO.5 7-8 — Booster heater 2 output OFF ON

OUT8

TBO.4 7-8 — Cooling signal output OFF ON

OUT9

TBO.4 5-6 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 5-6 — Error output Normal Error

OUT12

TBO.3 7-8 — Defrost output Normal Defrost

OUT13

TBO.4 3-4 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output

(DHW) OFF ON

OUT15

TBO.4 1-2 — Comp. ON signal OFF ON

OUT16

TBO.3 3-4 — Thermo ON signal OFF ON

OUTA1

TBI.4 7-8 — Analog output 0V-10V

BC

TBO.5 3-4 — Booster heater protection output

OFF(BHT Open) ON(BHT Short)

BHT

TBO.5 1-2

CNBHT

Thermostat for booster heater

Thermostat normal: Short High temp. open

Do not connect to the terminals that are indicated as “—” in the “T

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

CN108

CN01

(BK)

1

3

CN3C

(BU)

1

3

CNPWM

(WH)

1

5

CNRF

(WH)

Wireless receiver

(Option)

1

5

CN105

(RD)

WiFi adapter

(Option)

1

5

CNIT

(BU)

1

2

CN20

(RD)

1

3

CN21

(YE)

1

4

CNW12

(RD)

CNW5

(BU)

1

4

CN1A

(WH)

TBI.1

LED1

LED2

LED3

LED4

TAB1

1

8

1

8

1

8

1

8

1

6

SW1

SW2

SW3

SW4

SW5

F1

IECT10AL250V

F2

IECT6.3AL250V

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

3

1

3

CNBHT

(BK)

CNIH

(OG)

CNV1

(WH)

CNP4

(RD)

CNP1

(WH)

TBO.1

TBO.2

TBO.3

TBO.4

1

2

3

4

5

6

7

8

TBO.5

1

3

5

1

3

CNP4

(RD)

F1

F2

CN01

(BK)

TBO.1

X1

X2

X3

X14

1

3

3

CNPWM

(WH)

CNP1

(WH)1

3

M

1~

2WV2b

MP3

MP4

1

2

3

4

5

6

TBO.2

1

3

5

CNV1

(WH)

3WV

1

2

3

4

5

6

7

8

TBO.3

X4

X10

X16

X11

X12

TBO.4

1

2

3

4

5

6

7

8

TBO.5

X15

X13

X9

X8

Signal output

(Boiler)

Signal output

(thermo on)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp. on)

CNIH

(OG)2WV2a

1

3

X6

X7

N

(3)

L

(1)

42

BU

RD

31 5 A1

42 6 A2

IHT

IH

BA

BU

RD

1

3

2

CNIH

(OG)

OG

OG

Power supply

to Immersion heater

(Except PAC-IF071B-E)

~/N230V 50Hz

ECB2

IHC

1

5

3

1

5

3

1

3

1

3

FTC board

X5B

X5A

MXV

Close

N

Open

MP2

MP1

M

1~

M

1~

TBI.2TBI.3TBI.4TBI.5TBI.6

12345678 12345678 12345678 12345678 12345678 12345678

1

2

3

4

5

6

1

4

t° t° t°

12345678

IN4IN3IN2IN1

12345678

IN10IN7IN6IN5

12345678

IN12IN9IN8 IN11

12345678

OUTA1

Flow

Sensor

12345678

t°

THW6 THW7 THW8 THW9

t° t°

12345678

THWB1 THW 10

Main remote

controller

FTC

(Slave)

TBI.1 TBI.2 TBI.3 TBI.4 TBI.5TBI.6

CN20

(RD)

t°

CN21

(YE)

1 3 1 2

CNW12

(RD)

1 4

CNW5

(BU)

t°

TAB1

THTH1TH2 *

THW5B *

- + + -

V

- + - +

14

t° t°t°

THW2THW1

1

5

SW6

M

1~

M

1~

M

1~

M

1~

M

1~

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

OG OG

YE

YE

GNYE

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

OG

BU

RD

BU

RD

YE

GNYE

1

3

1

3

OG

BN

OG

BN

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

5

CN3C

(BU)

CN3C

(BU)

CN01

(BK)

OG

YE

1

3

5

CN01

(BK)

2WV1

M

1~

4 5 6

TBO.2

1

2

3

4

5

6

7

8

Signal output for booster

heater protection

Signal output

(booster heater 1)

Signal output

(booster heater 2)

CN1A

(WH)

1 4

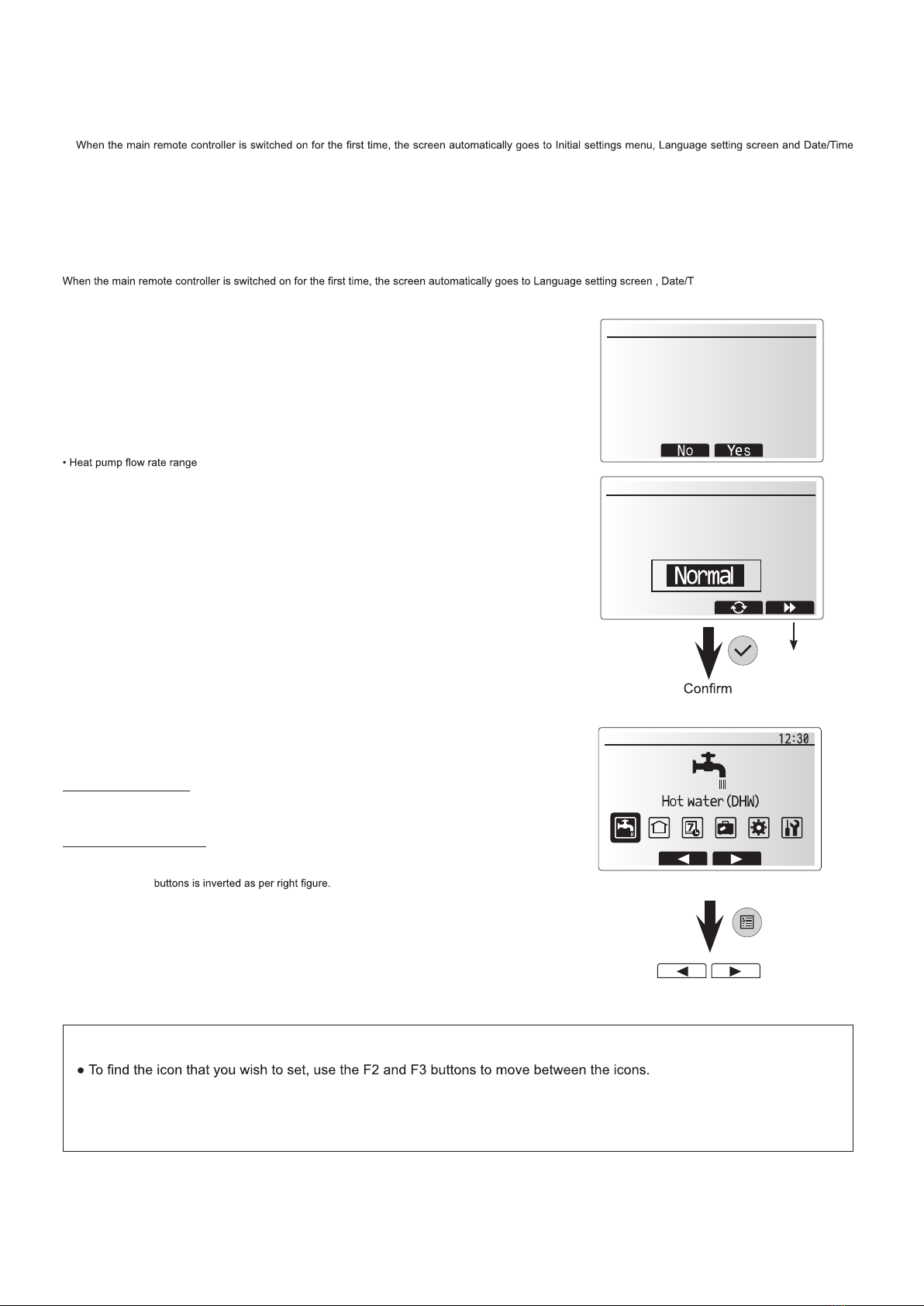

<How to use TBO.1 to 5>

1 4

Pressre

Sensor *

CN401

(WH)

1

4

CN401

(WH)

t°

THW5A *

1

BHT

CNBHT

(BK)

3

Tool

Tool

Conductor Conductor

Outline view Top view

Connect them using either way as shown below.

*1. External output (OUT11) will be available. For safety reasons, this function is not available for certain errors. (In that case, system operation must be stopped and only the

water circulation pump keeps running.)

*2. This switch functions only when the FTC unit is connected with a PUHZ-FRP outdoor unit. When another type of outdoor unit is connected, the heating mode function is

active regardless of the fact that this switch is ON or OFF.

*3. Space heating and DHW can be operated only in indoor unit, like an electric heater.

*4. If emergency mode is no longer required, return the switch to OFF position.

*5. Active only when SW3-6 is set to OFF.

*6. Active only when SW4-1 is set to ON.

Table 3 DIP switch functions

DIP switch Function OFF ON Default settings:

Indoor unit model

SW1

SW1-1

Boiler WITHOUT

Boiler WITH Boiler OFF

SW1-2

Heat pump maxi-

mum outlet water

temperature

55ºC 60ºC ON

SW1-3

DHW tank WITHOUT

DHW tank

WITH DHW

tank

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-4

Immersion heater WITHOUT Im-

mersion heater

WITH Immer-

sion heater

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-5

Booster heater WITHOUT

Booster heater

WITH Booster

heater

OFF

SW1-6

Booster heater

function

For heating

only

For heating

and DHW

OFF

SW1-7

Outdoor unit type Split type Packaged type

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-8

Wireless remote

controller

WITHOUT

Wireless re-

mote controller

WITH Wireless

remote control-

ler

OFF

SW2

SW2-1

Room thermostat 1

input (IN1) logic

change

Zone1 opera-

tion stop at ther-

mostat short

Zone1 opera-

tion stop at ther-

mostat open

OFF

SW2-2

Flow switch 1 input

(IN2) logic change

Failure detec-

tion at short

Failure detec-

tion at open OFF

SW2-3

Booster heater

capacity restriction Inactive Active OFF

SW2-4

Cooling mode func-

tion Inactive Active OFF

SW2-5

Automatic switch to

backup heat source

operation (When

outdoor unit stops

by error)

Inactive Active *1 OFF

SW2-6

Mixing tank WITHOUT Mix-

ing tank

WITH Mixing

tank OFF

SW2-7

2-zone temperature

control Inactive Active *5 OFF

SW2-8

Flow sensor WITHOUT

Flow sensor

WITH Flow

sensor OFF

DIP switch Function OFF ON Default settings:

Indoor unit model

SW3

SW3-1

Room thermostat

2 input (IN6) logic

change

Zone2 opera-

tion stop at ther-

mostat short

Zone2 opera-

tion stop at ther-

mostat open

OFF

SW3-2

Flow switch 2 and 3

input logic change

Failure detec-

tion at short

Failure detec-

tion at open OFF

SW3-3

— — — OFF

SW3-4

Electric energy

meter

WITHOUT

Electric energy

meter

WITH Electric

energy meter OFF

SW3-5

Heating mode function *2

Inactive Active ON

SW3-6

2-zone valve ON/

OFF control Inactive Active OFF

SW3-7

Heat exchanger for DHW

Coil in tank

External plate HEX

OFF

SW3-8

Heat meter WITHOUT

Heat meter

WITH Heat

meter OFF

SW4

SW4-1

Multiple outdoor control

Inactive Active OFF

SW4-2

Position of multiple

outdoor units

control *6

Slave Master OFF

SW4-3

— — — OFF

SW4-4

Indoor unit only

operation (during

installation work) *3

Inactive Active OFF

SW4-5

Emergency mode

(Heater only opera-

tion)

Normal

Emergency mode

(Heater only

operation)

OFF *4

SW4-6

Emergency mode

(Boiler operation) Normal

Emergency

mode

(Boiler operation)

OFF *4

SW5

SW5-1

— — — OFF

SW5-2

Advanced auto adaptation

Inactive Active ON

SW5-3

Capacity code

SW5-3 SW5-4 SW5-5 SW5-6 SW5-7

PAC-IF07*B-E OFF OFF OFF OFF OFF

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8

— — — OFF

SW6

SW6-1

— — —

OFF : PAC-IF071/072B-E

ON : PAC-IF073B-E

SW6-3

Pressure sensor Inactive Active OFF

SW6-4

Analog output Inactive Active OFF

WIRING DIAGRAM