Ecodyne Water Systems IDP30S User manual

7371046 (Rev. A 6/5/18)

Designed, Engineered &

Assembled in the U.S.A.

Manufactured by

Ecodyne Water Systems

1890 Woodlane Drive

Woodbury, MN 55125

OWNER’S MANUA

How to install, operate

and maintain your

Models

IDP30S Water Softener

IDP40S Water Softener

IDP40CC*Chloramine

& Chlorine Water Conditioner

IDP50CC*Chloramine

& Chlorine Water Conditioner

Models IDP30S & IDP40S tested and certified by

NSF International against NSF/ANSI Standard 44

for hardness reduction and efficiency and the

reduction of barium and radium 226/228,

and certified to NSF/ANSI Standard 372.

Models IDP30S & IDP40S tested and certified by

the Water Quality Association against CSA 483.1.

ÙModels IDP40CC & IDP50CC have not been

tested or certified by NSF International or the

Water Quality Association.

2

SAFETY GUIDES

Follow the installation instructions carefully. Failure to

install the water filtration system properly voids the

warranty.

efore you begin installation, read this entire manual.

Then, obtain all the materials and tools you will need to

make the installation.

Check local plumbing and electrical codes. The

installation must conform to them.

Use only lead-free solder and flux for all sweat-solder

connections, as required by state and federal codes.

Use care when handling the water filtration system. Do

not turn upside down, drop, or set on sharp protrusions.

Do not locate the water filtration system where freezing

temperatures occur. Do not attempt to treat water over

120°F. Freezing, or hot water damage voids the

warranty.

Avoid installing in direct sunlight. Excessive sun heat

may cause distortion or other damage to non-metallic

parts.

The water filtration system requires a minimum water

pressure of 30 psi at the inlet. Maximum allowable

inlet water pressure is 125 psi. If daytime pressure is

over 80 psi, nighttime pressure may exceed the maxi-

mum. Use a pressure reducing valve if necessary

(Adding a pressure reducing valve may reduce the flow).

The water filtration system works on 24V DC electrical

power, supplied by a direct plug-in power supply

(included). e sure to use the included power supply,

and plug it into a nominal 120V, 60 Hz household outlet

that is in a dry location only, grounded and properly

protected by an overcurrent device such as circuit

breaker or fuse.

This system is not intended to be used for treating water

that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

European Directive 2002/96/EC requires all

electrical and electronic equipment to be dis-

posed of according to Waste Electrical and

Electronic Equipment (WEEE) requirements.

This directive or similar laws are in place

nationally and can vary from region to region.

Please refer to your state and local laws for

proper disposal of the equipment.

TAB E OF CONTENTS Page

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Performance Claims & Dimensions . . . . . . . . . . . . . . 4

efore Starting Installation . . . . . . . . . . . . . . . . . . . . 5

Typical Installation Illustrations . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Programming the Water Softener . . . . . . . . . . . . 12-25

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adding Salt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . 26-27

Service Information . . . . . . . . . . . . . . . . . . . . . . 23-24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 28-31

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-37

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table of Contents, Unpac ing & Safety Guides

UNPACKING

Models IDP30S, IDP40S and IDP40CC are shipped

from the factory in one carton. The carton also includes

a bag of small parts needed to assemble and install the

unit.

Model IDP50CC is shipped from the factory in two car-

tons. One contains the resin tank/controller assembly,

plus a bag of small parts needed to assemble and

install the unit. The other carton contains the assem-

bled brine tank.

Thoroughly check the water softener for possible ship-

ping damage and parts loss. Also inspect and note any

damage to the shipping carton.

Remove and discard (or recycle) all packing materials.

To avoid loss of small parts, we suggest you keep the

small parts in the parts bag until you are ready to use

them.

3

SPECIFICATIONS

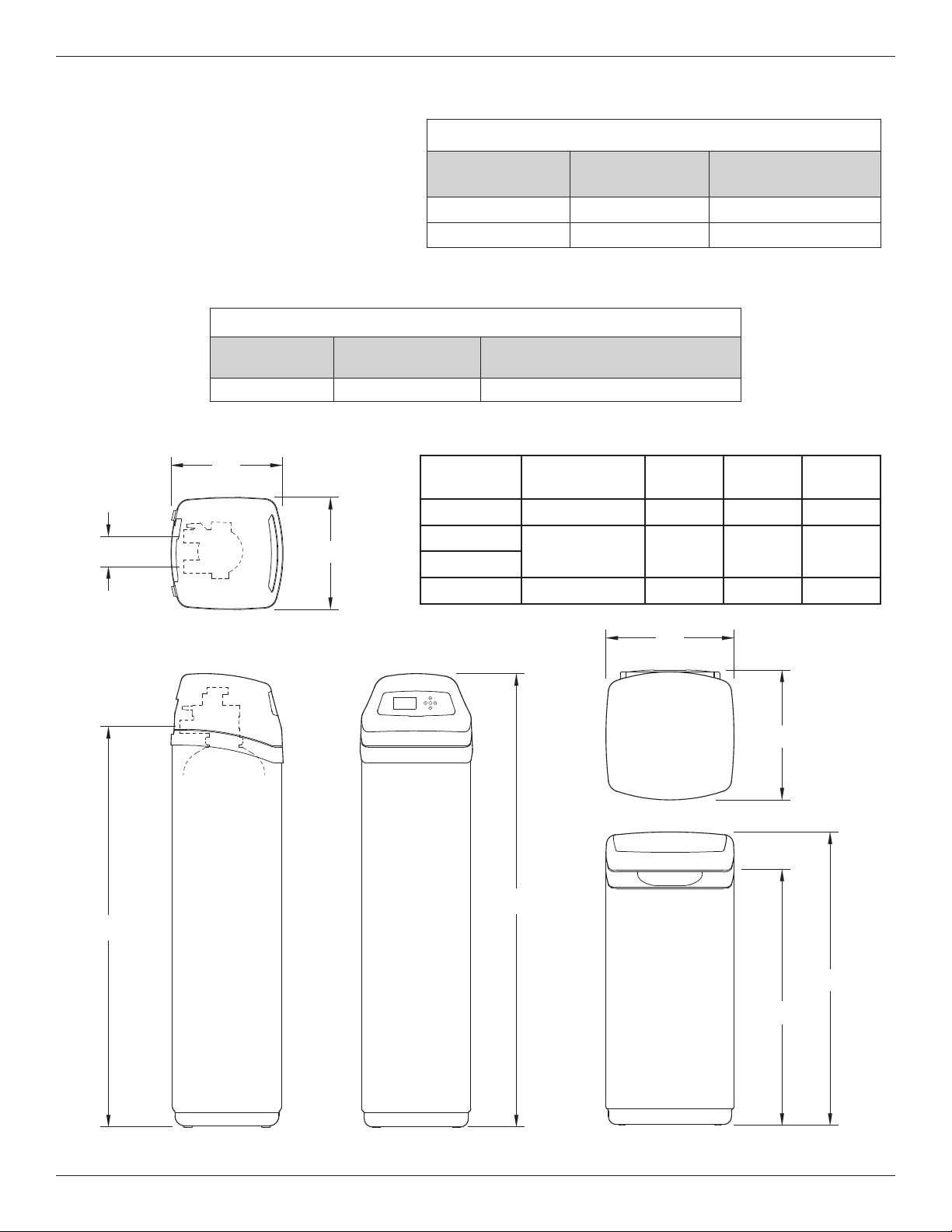

Model IDP30S IDP40S IDP40CC*IDP50CC*

Model Code ID30S ID40S ID40C ID50C

Rated Softening Capacity

(grains @ lb. salt dose)

12,000 @ 2.4

25,600 @ 7.5

30,600 @ 12.6

11,800 @ 2.4

31,600 @ 9.0

40,000 @ 15.5

11,800 @ 2.4

31,600 @ 9.0

40,000 @ 15.5

16,600 @ 3.3

44,300 @ 12.3

56,300 @ 21.3

Rated Efficiency

(grains / lb. @ minimum salt dose) 5,090 @ 2.4 4,950 @ 2.4 4,980 @ 2.4 5,090 @ 3.3

Water Used During Regeneration @

Minimum Salt Dose

2.5 gal. /

1,000 grains

3.1 gal. /

1,000 grains

4.1 gal. /

1,000 grains

4.5 gal. /

1,000 grains

Amount of High Capacity Resin 0.79 cu. ft. 1.13 cu. ft. 1.13 cu. ft. 1.56 cu. ft.

Amount of Catalytic Carbon ––0.40 cu. ft. 0.57 cu. ft.

Amount of Gravel –––12 lbs.

Service Flow Rate 7.2 gpm 8.0 gpm 4.0 gpm 5.0 gpm

Pressure Drop at Rated Service Flow 15.0 psig 8.5 psig 10.0 psig 10.0 psig

Intermittent Flow @ 15 psi p7.2 gpm 11.7 gpm 15.0 gpm 15.0 gpm

Intermittent Flow @ 30 psi p11.0 gpm 18.1 gpm 21.0 gpm 21.0 gpm

Water Supply Maximum Hardness 50 gpg 65 gpg 65 gpg 85 gpg

Water Supply Maximum

Clear Water Iron ¢6 ppm 8 ppm 8 ppm 10 ppm

Min. - Max. Water Supply Pressure u20 - 125 psi

Min. - Max. Water Supply Temperature 40 - 120 °F

Minimum Water Supply Flow Rate 3 gpm

Max Drain Flow Rate 2.0 gpm

pIntermittent flow rate does not represent the maximum service flow rate used for determining the unit’s rated capacity

and efficiency. Continuous operation at flow rates greater than the service flow rate may affect capacity and efficiency

performance.

¢Capacity to remove clear water iron is substantiated by independent laboratory test data. State of Wisconsin requires

additional treatment if water supply contains greater than 5 ppm clear water iron.

uCanada working pressure limits: 1.4 - 7.0 kg/cm².

ÙModels IDP40CC & IDP50CC have not been tested or certified by NSF International or the Water Quality Association.

These units conform to NSF/ANSI 44 for the specific performance claims as verified and substantiated by test data.

These models are efficiency rated. The efficiency rating is valid only at the minimum salt dose and the service flow

rate. The softeners have a demand initiated regeneration (D.I.R) feature that complies with specific performance

specifications intended to minimize the amount of regenerant brine and water used in their operation.

These softeners have a rated softener efficiency of not less than 3,350 grains of total hardness exchange per pound

of salt (based on sodium chloride) and shall not deliver more salt than their listed rating or be operated at a sus-

tained maximum service flow rate greater than their listed rating. These softeners have been proven to deliver soft

water for at least ten continuous minutes at the rated service flow rate. The rated salt efficiency is measured by lab-

oratory tests described in NSF/ANSI Standard 44. These tests represent the maximum possible efficiency that the

system can achieve. Operational efficiency is the actual efficiency after the system has been installed. It is typically

less than the rated efficiency, due to individual application factors including water hardness, water usage, and other

contaminants that reduce a softener's capacity.

While testing was performed under standard laboratory conditions, actual performance of the system may vary

based on local water conditions.

Specifications

4

FRONT VIEWSIDE VIEW

IN - OUT

TOP VIEW

14"

14"

IN

OUT

A

16-1/4"

16"

36-9/16"

32"

BRINE TANK

B

C

14”

FIG. 1

SIDE VIEW FRONT VIEW

TOP VIEW

IN

OUT

IN - OUT

A

14”

Model Nominal Resin

Tank Size

Dimension

A

Dimension

B

Dimension

C

IDP30S 8” dia. x 40” 48-3/4” 42“ 3-3/8“

IDP40S 10” dia. x 47” 56-3/4“ 50” 3-3/4“

IDP40CC

IDP50CC 12” dia. x 54” 62-1/2” 55-3/4” 3-3/4“

C

B

16”

16-1/4”

32”

36-9/16”

RINE TANK

PERFORMANCE C AIMS

Contaminant Influent

Challenge evel

Maximum Allowable

Product Water evel

arium 10 ±10% mg/L 2.0 mg/L

Radium 226/228 25 pCi/L 5 pCi/L

Test parameters include: pH = 7.5 ±0.5

flow rate = 7.5 gpm

dynamic pressure = 35 ±5 psig

MODE S IDP40CC & IDP50CC PERFORMANCE C AIM

Substance Influent

Challenge evel Reduction Requirement

Chloramines 3 mg/L >70% @ 10 gpm for 34,000 gal.*

*From manufacturer’s test data.

Models IDP40CC & IDP50CC have not been tested or certified by NSF International or the Water Quality Association.

Performance Claims & Dimensions

5

WHERE TO INSTA THE SOFTENER

= To soften all water in the home, install the water

softener close to the water supply inlet, upstream

of all other plumbing connections, except outside

water pipes. Outside faucets should remain on

hard water to conserve salt and softening capacity.

= Place the softener near a floor drain, or other

acceptable drain point (laundry tub, sump, stand-

pipe, etc.) to carry away regeneration discharge

water.

= Connect the softener to the main water supply

pipe UPSTREAM OF the water heater. DO NOT

RUN HOT WATER THROUGH THE SOFTENER.

The temperature of water passing through the sof-

tener must be less than 120°F.

= Do not install the softener in a place where it could

freeze. Damage caused by freezing is not cov-

ered by the warranty.

= Put the softener in a place water damage is least

likely to occur if a leak develops. The manufactur-

er will not repair or pay for water damage.

= A 120V, 60 Hz electrical outlet, to plug the included

power supply into, is needed near the softener.

e sure the electrical outlet and power supply are

in an inside location, to protect from wet weather.

= If installing in an outside location, you must take

the steps necessary to assure the softener, instal-

lation plumbing, wiring, etc., are as well protected

from the elements, contamination, vandalism, etc.,

as when installed indoors.

= Keep the softener out of direct sunlight. The sun's

heat may soften and distort plastic parts.

TOO S, PIPE & FITTINGS,

OTHER MATERIA S YOU WI NEED

= ALWAYS install a single bypass valve, or a 3-valve

bypass system. ypass valves let you turn off water

to the softener for repairs if needed, but still have

water available to the house pipes.

= Plastic inlet and outlet fittings are included with the

softener, which allow water flow equivalent to 1 inch

nominal pipe. To maintain maximum valve flow, 1”

pipes to and from the softener fittings are recommend -

ed. Do not reduce the pipes to less than 3/4” size.

= Use copper, brass or PEX plastic pipe and fittings.

= Drain hose, 1/2” inside diameter minimum, is needed

for the valve drain.

= If a rigid valve drain is needed, to comply with

plumbing codes, you can buy the parts needed to

connect a 1/2” minimum copper tubing drain.

NOTE: The Commonwealth of Massachusetts plumbing

code 248-CMR shall be adhered to. A licensed plumber

shall be used for this installation.

THE PROPER ORDER TO INSTA WATER TREATMENT EQUIPMENT

FIG. 3

Pressure

Tank

City Water Supply

Well Water Supply

Well

Pump

OR

Optional

Sediment

Filter

Water

Heater

Water

Softener

Untreated Water to

Outside Faucets

Hot Water

to House

Cold Water

to House

FIG. 2

SING E BYPASS VA VE

Pull out for “Service”

(Soft water)

Push in for

“ ypass”

Before Starting Installation

This manual suits for next models

3

Table of contents

Other Ecodyne Water Systems Water Dispenser manuals

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual