Ecoflo ESE50WB1830 User manual

Owner’s Manual

Pre-Plumbed

Sewage Basin System

Features. . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation . . . . . . . . . . . . . . . . . . . . . .4-5

Safety Information. . . . . . . . . . . . . . . . 6-7

Warranty . . . . . . . . . . . . . . . . . . . . . . . . .8

TABLE OF CONTENTS

RSE50WB1830ESE50WB1830

Features and Benets

• Features an 18 in. x 30 in., 30 Gal.,heavy duty sewage basin with a water-tight

snap-in molded inlet hub

• Ultrastrongcovercomeswith2in.threadeddischargeandventanges,amoldedcordgrommet,amolded

reusable cover seal and eight stainless screws and washers to secure the cover to the basin

• Automatic, all cast-iron sewage pump passes 2 in. solids

• System pumps up to 7,500 GPH, (ESE50W) and 5700 GPH (RSE50W)

• Ultraquiet,heavydutyABSslipt,exibleunioncheckvalvepassesafull2in.solid

• Moldedinlethubcomeswithastainlesssteelclampforsecuringtheinletpipe

Performance (Gallon Per hour) Float Switch

Model 0’ 5’ 10’ 15’ shutoff On Off

Solids

Handling Warranty

RSE50WB1830 5700 5980 4020 2520 18’ 15.5” 7.5” 2” 1

ESE50WB1830 7500 6960 5880 4500 24’ 15.5” 7.5” 2” 2

• Thankyouforpurchasingthispumpsysyem.Takethetimetoreadtheinstructionscarefullybeforeusingthis

product.Westronglyrecommendthatyoukeepthisinstructionmanualinasafeplaceforfuturereference.

2

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

FEATURES

3

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

FEATURES

Features and Benets

Pre-Plumbed Sewage System (Basin and Pump)

• 30 U.S. gallon capacity options

• Heavydutystructuralfoaminjectionmolded

construction

• Pre-drilled inlet hole at 10-1/2” cL depth

• 100%testedwithitsownperformancecurve

• Ratedforcontinuousduty

• Rugged cast iron construction

• Solids Handling Vortex impeller

• Highefciencypermanentsplitcapacitormotor

with automatic reset thermal overload protection

• Ballbearingsforquietoperation

• Handles 2” solids

• Easilyreplaceable20footpowercord

• Mechanicalshaftsealforlonglife

• Support 400 lbs. + Sewage Pump

Basin Cover

• 2”Threadeddischargeandventanges

• Custom, molded, reusable PVC seal

• Heavydutystructuralfoaminjectionmolded

construction

2” Check Valve

• Passesafull2”solid

• Stainless steel hose clamps

• Industry’smostdurableapper

• Strong, durable ABS body

• Flowarrowsclearlymarked

• Fits2”black,galvanizedandPVCSchedule

40 pipe

Basin Inlet Hub

• Water and vapor-tight seal

• Fits 4” DWV SCH.40/80

• Built-in “O” rings

• Stainless steel clamp

Components

INSTALLATION

1. Preparing the Basin for Installation

• Remove the basin cover by removing the basin cover

fasteners.Removethepackagecontainingtheinlethub

(D),checkvalve(C)andcordgrommet(B).

• Removethepumppowercordandoatswitchcord

(ifnecessary)fromtheinsideofthebasin,removingall

slackfromthecord(s).Ensurethecord(s)arenottangled

aroundthepumporoatswitch.Verifytheoatswitchis

abletomovefreely.

• Feed the cord(s) through the cord grommet hole (4) on

the basin cover, place the cover on the basin ensuring the

dischargeangeandthedischargepipingareinthe

correct orientation.

• Press each cord through the slit and into the hole on the

cordgrommet(B),2holecordgrommetforpumpswitha

oatcordanda1holegrommetfor1cordsystems.Press

the grommet (B) into the grommet hole (4) to provide a

tight seal.

• Secure the basin cover onto the basin with the basin cover

fastenersremovedintherststep.

2.Preparing the installation location

• Excavate a hole large enough to accommodate the

basin(A),backllmaterial(1)andinletpiping(2).

• Add4–6in.ofcleansub-basematerialorconcrete

(3)tothebottomofthehole.

• Assure that it is level, compacted, and smooth.

• Place the basin (A) in the hole and ensure that it

is level.

3.Connecting the inlet piping

• Connect the inlet piping (1) as required by code

using the 4 in. snap-in inlet hub (D). Hand-Tighten

the hose clamp.

• Carefullybackllwithnaturallyroundedgravelor

stone, larger than 3/8 in. and smaller than 3/4 in.

diameter,aroundtheperipheryofthebasin(A).

4

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

4.Connecting the discharge piping

• Install a 2 in. PVC Schedule 40 threaded male adapter

(1)(notincluded)intothedischargeange(2)asshown.

UseTeontape,siliconsealant,orplumber’spipedope

to seal the threads. Ensure that you are connecting to

the sewage pump discharge and not the vent port.

• Connect discharge pipe (3) (not included) to the 2 in.

PVC Schedule 40 threaded male adapter (1) (not

included) using PVC primer and solvent cement to

properly seal the connection.

• Installthe2in.compressiontcheckvalve(EFSWCV200)

(C) to the discharge line at the appropriate location.

Ensuretheowarrowonthecheckvalve(C)ispointed

intherightdirection.Tightenttingstoensurea

watertight seal.

• Install 2 in. PVC Schedule 40 pipe (4) (not included) into

the2in.compressiontcheckvalve(C)andconnectthis

pipetotheappropriatesewermainpipefordischarge.

Handtightenthettingstoensureawatertightseal.

5. Attaching the vent connection

• Install a 2 in. PVC Schedule 40 threaded male adapter

(1) (not included) into the vent hole (2) as shown. Use

Teontape,siliconsealant,orplumber’spipedopetoseal

the threads.

• Connect a vent pipe (3) (not included) to the 2 in. PVC

Schedule 40 threaded male adapter (1) using PVC primer

and solvent cement to properly seal the connection. Connect

the vent pipe to the sewer’s vent system. We suggest that a

unionbeinstalledonthislinetoallowforeasypumpservice

or removal.

6. Connecting the power and verifying proper operation

• Makesurethatthecordgrommetisproperlyinsertedinto

the lid. This assures a water and gas tight seal.

• Checkthepumpbyllingthebasinwithwaterandobserve

the pump’s operation through one complete cycle.

INSTALLATION

5

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

6

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

SAFETY INFORMATION

PRECAUTIONS

1. This document serves only as an installation guide.

Refertoyourstateand/orlocalplumbingoronsite

wastewatertreatmentanddisposalregulationsforde

tails pertaining to your systems design, installation

and maintenance requirements.

2.Keepthisinstructionmanualinasafeplaceforfuture

reference.

3.Themotorofthispumphasathermalprotectorthat

willtripifthemotorbecomestoohot.Theprotector

willresetitselfoncethemotorcoolsdownandan

acceptable temperature has been reached. The

pumpmaystartunexpectedlyifitispluggedin.

4.Ensuretheelectricalpowersourceisadequateforthe

requirementsofthepump.

5.Thispumpismadeofhigh-strength,corrosion-

resistantmaterials.Itwillprovidetrouble-freeservice

foralongtimewhenproperlyinstalled,maintained,

and used. However, inadequate electrical power to

the pump, dirt, or debris may cause the pump

tofail.Pleasecarefullyreadthemanualandfollowthe

instructions regarding common pump problems and

remedies.

DANGER:Donotpumpammableorexplosive

liquidssuchasoil,gasoline,kerosene,ethanol,etc.

Donotuseinthepresenceofammableorexplosive

vapors.Usingthispumpwithornearammableliquids

cancauseanexplosionorre,resultinginproperty

damage,seriouspersonalinjury,and/ordeath.

DANGER: ALWAYS disconnect the power to the pump

beforeservicing.

DANGER: Do not touch the motor housing during

operation. The motor is designed to operate at high

temperatures. Do not disassemble the motor housing.

DANGER: Do not handle the pump or pump motor with

wethandsorwhenstandingonawetordampsurface,

orinwater.lfbasementooriswet,donotwalkonwet

areauntilallpoweristurnedoff.Ifshut-offboxisin

basement,calltheelectriccompanytoshutoff

servicetothehouse,orcallyourlocalredepartment

forinstructions.

Removepumpandrepairorreplace.Failuretofollow

thiswarningcanresultinfatalelectricalshock.

WARNING:Extensioncordsmaynotdeliversufcient

voltage to the pump motor. Extension cords present

alifethreateningsafetyhazardiftheinsulationbe

comesdamagedortheconnectionendsfallinto

water.Theuseofanextensioncordtopowerthis

pump is not permitted.

WARNING:Securethedischargelinebeforestarting

the pump. An unsecured discharge line will whip,

possiblycausingpersonalinjury,and/orproperty

damage.

WARNING: Release all pressure and drain all water

fromthesystembeforeservicinganycomponent.

WARNING:Wearsafetygogglesatalltimeswhen

workingwithpumps.

WARNING:Thisunitisdesignedonlyforuseon115

volts(singlephase),60Hz,andisequippedwith

an approved 3-conductor cord and 3-prong

grounded plug. Do not remove the ground pin under

any circumstances. The 3-prong plug must be

directly inserted into a properly installed and

grounded 3-prong, grounding-type receptacle. Do

not use this pump with a 2-prong wall outlet. Replace

the 2-prong outlet with a properly grounded 3-prong

receptacle (a GFCI outlet) installed in accordance

with the National Electrical Code and local codes

andordinances.Allwiringshouldbeperformedbya

qualiedelectrician.

WARNING:Protecttheelectricalcordfromsharp

objects,hotsurfaces,oil,andchemicals.Avoid

kinkingthecord.Donotusedamagedorworncords.

WARNING: Failure to comply with the instruction and

designedoperationofthisunitmayvoidthewarranty.

ATTEMPTING TO USE A DAMAGED PUMP can result

inpropertydamage,seriouspersonalinjury,and/or

death.

WARNING: Ensure that the electrical circuit to the

pumpisprotectedbya15Ampfuseorcircuit

breaker.

CAUTION:Donotliftthepumpbythepowercord.

CAUTION: Know the pump and its applications,

limitations,andpotentialhazards.

CAUTION: Periodically inspect the pump and system

componentstoensurethepumpintakeisfreeofmud,

sand,anddebris.Disconnectthepumpfromthe

powersupplybeforeinspecting.

CAUTION:Followallsafetystandardsandalllocal

electrical codes.

ELECTRICAL SAFETY WARNING: Do not splice the

electrical power cord.

WARNING: Do not allow the electrical cord plug to be

submerged.

WARNING:Donotuseextensioncords.Theyareare

hazardandcanreducevoltagesufcientlytoprevent

pumping and/or damage the motor.

WARNING: Do not handle or service the pump while it

is connected to a power supply.

WARNING: DO NOT remove the grounding prong

fromtheplugormodifytheplug.Toprotectagainst

electricalshock,thepowercordisathree-wire

conductor and includes a 3-prong grounded plug.

Plug the pump into a 3-wire, grounded, grounding

type receptacle. Connect the pump according to

electrical codes that apply.

SAFETY INFORMATION

7

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

8

Retain Original Purchase Receipt for Warranty Eligibility

Limited Warranty

Manufacturerwarrantstotheoriginalconsumerpurchaser(“Purchaser”or“You”)thatitsproductsarefreefromdefects

inmaterialandworkmanshipforaperiodoftwo(2)years(ESE50WB1830)andone(1)year(RSE50WB1830)fromthe

dateoftheoriginalconsumerpurchase.If,withinone/twoyearsfromtheoriginalconsumerpurchase,anysuchproduct

shallprovetobedefective,itshallberepairedorreplacedatmanufacturer’soption,subjecttothetermsandconditions

setforthherein.Notethatthislimitedwarrantyappliestomanufacturingdefectsonlyandnottoordinarywearandtear.

Allmechanicaldevicesneedperiodicpartsandservicetoperformwell.Thislimitedwarrantydoesnotcoverrepairwhen

normalusehasexhaustedthelifeofapartortheequipment.

Theoriginalpurchasereceiptandproductwarrantyinformationlabelarerequiredtodeterminewarrantyeligibility.

Eligibilityisbasedonpurchasedateororiginalproduct–notthedateofreplacementunderwarranty.Thewarranty

islimitedtorepairorreplacementoforiginalpurchasedproductonly,notreplacementproduct(i.e.onewarranty

replacementallowedperpurchase).

Purchaserpaysallremoval,installation,labor,shipping,andincidentalcharges.

Claimsmadeunderthiswarrantyshallbemadebyreturningtheproducttotheretailoutletwhereitwaspurchasedorto

thefactoryimmediatelyafterthediscoveryofanyallegeddefect.Manufacturerwillsubsequentlytakecorrectiveactionas

promptlyasreasonablypossible.Norequestsforservicewillbeacceptedifreceivedmorethan30daysafterthewarranty

expires.Warrantyisnottransferableanddoesnotapplytoproductsusedincommercial/rentalapplications.

General Terms and Conditions; Limitations of Remedies

Youmustpayalllaborandshippingchargesnecessarytoreplaceproductcoveredbythiswarranty.Thiswarrantydoes

notapplytothefollowing:(1)actsofGod;(2)productswhich,inmanufacturer’ssolejudgment,havebeensubjectto

negligence,abuse,accident,misapplication,tampering,oralteration;(3)failuresduetoimproperinstallation,operation,

maintenanceorstorage;(4)atypicalorunapprovedapplication,useorservice;(5)failurescausedbycorrosion,rustor

otherforeignmaterialsinthesystem,oroperationatpressuresinexcessofrecommendedmaximums.

Thiswarrantysetsforthmanufacturer’ssoleobligationandpurchaser’sexclusiveremedyfordefectiveproducts.

MANUFACTURERSHALLNOTBELIABLEFORANYCONSEQUENTIAL,INCIDENTAL,ORCONTINGENTDAMAGES

WHATSOEVER.THEFOREGOINGLIMITEDWARRANTIESAREEXCLUSIVEANDINLIEUOFALLOTHEREXPRESS

ANDIMPLIEDWARRANTIES,INCLUDINGBUTNOTLIMITEDTOIMPLIEDWARRANTIESOFMERCHANTABILITY

ANDFITNESSFORAPARTICULARPURPOSE.THEFOREGOINGLIMITEDWARRANTIESSHALLNOTEXTEND

BEYONDTHEDURATIONPROVIDEDHEREIN.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorlimitationsonhowlongan

impliedwarrantylasts,sotheabovelimitationsorexclusionsmaynotapplytoYou.ThiswarrantygivesYouspeciclegal

rightsandYoumayalsohaveotherrightswhichvaryfromstatetostate.

1899 Cottage Street, Ashland, Ohio 44805

Telephone: 1-877-326-3561

Fax: 1-877-326-1994

www.ecooproducts.com

WARRANTY

EF-0172 rev 6/21

This manual suits for next models

1

Table of contents

Popular Water System manuals by other brands

APEC

APEC ULTRA REVERSE OSMOSIS SYSTEM installation instructions

Grundfos

Grundfos RMQ A Installation and operating instructions

AutoAqua

AutoAqua Smart AWC touch SAWC-200P manual

AmeriWater

AmeriWater CENTURION 1500+ operating manual

AMK

AMK OWR 20 Planning, installation and commissioning

Schwan

Schwan SC80 Installation & user guide

ENERGY KINETICS

ENERGY KINETICS EK-Pak Owners and installation manual

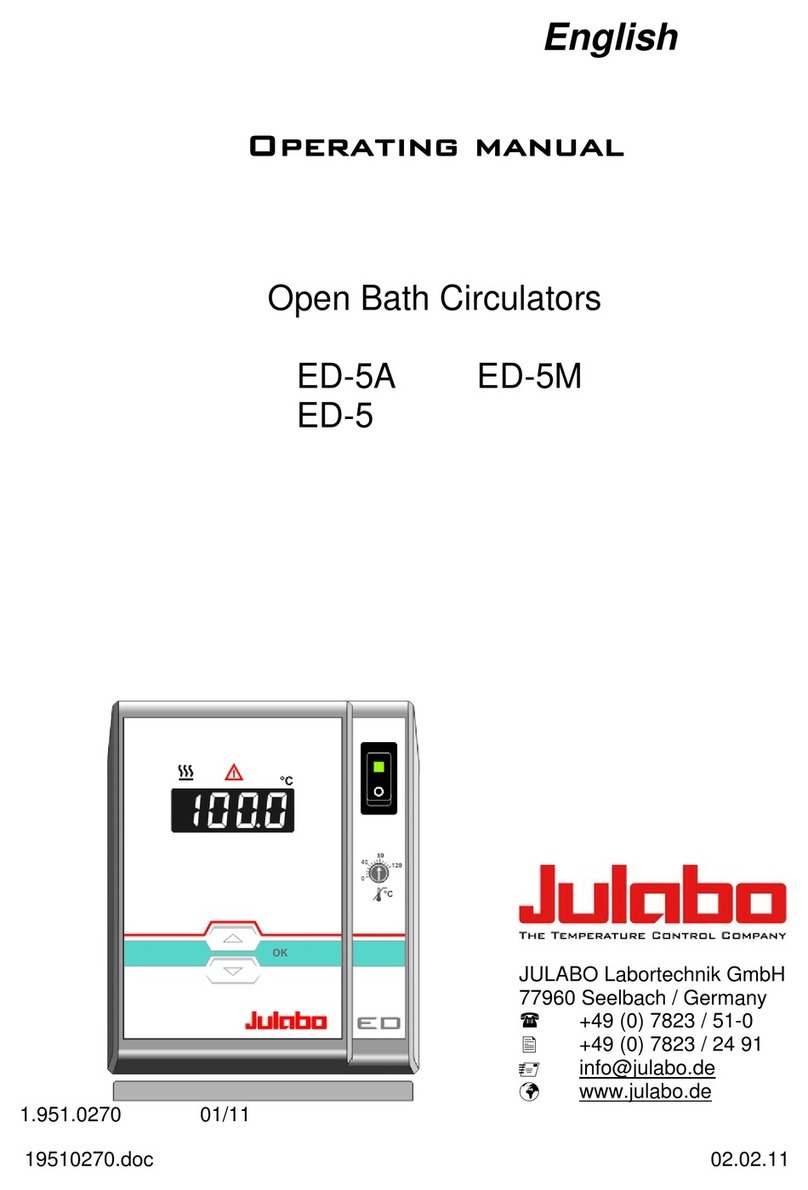

Julabo

Julabo ED-5A operating manual

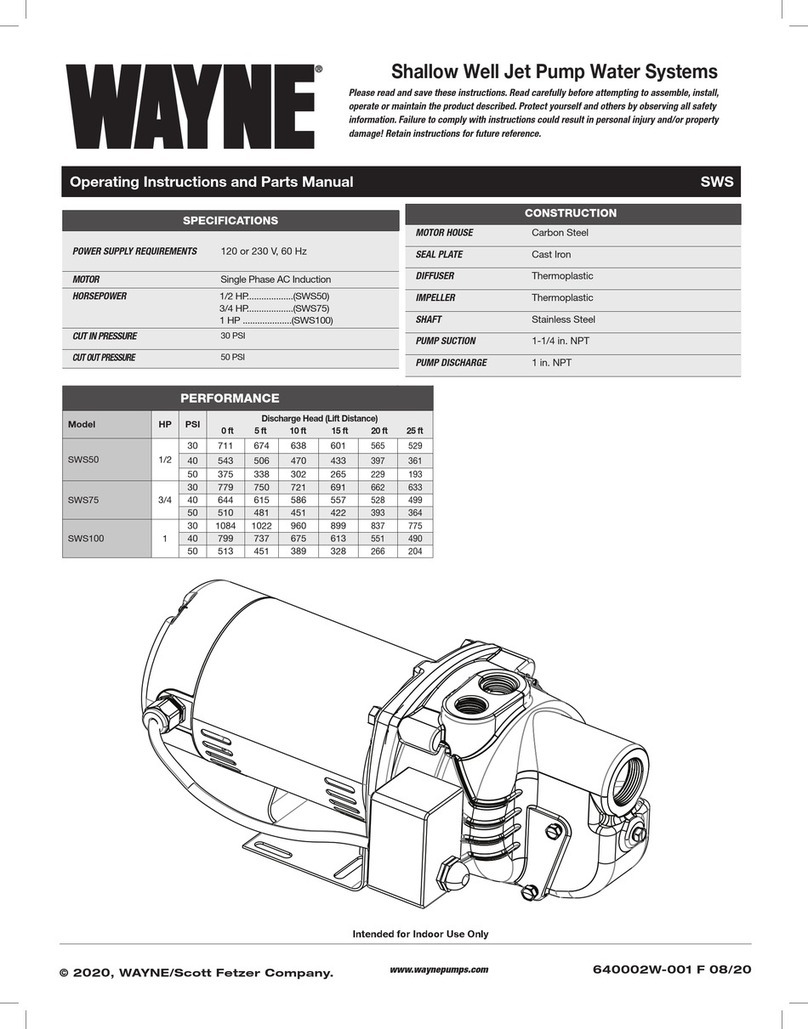

Wayne

Wayne SWS Series Operating instructions and parts manual

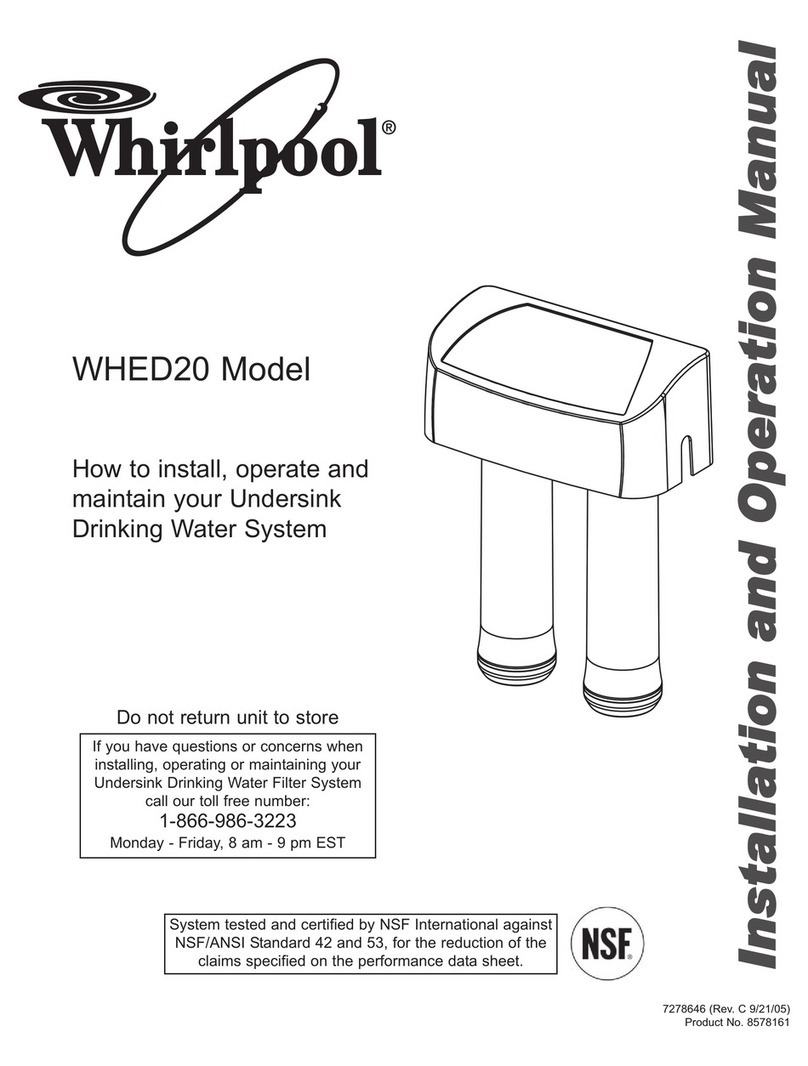

Whirlpool

Whirlpool WHED20 Installation and operation manual

Franke

Franke Irena Series Installation and user manual

Honeywell

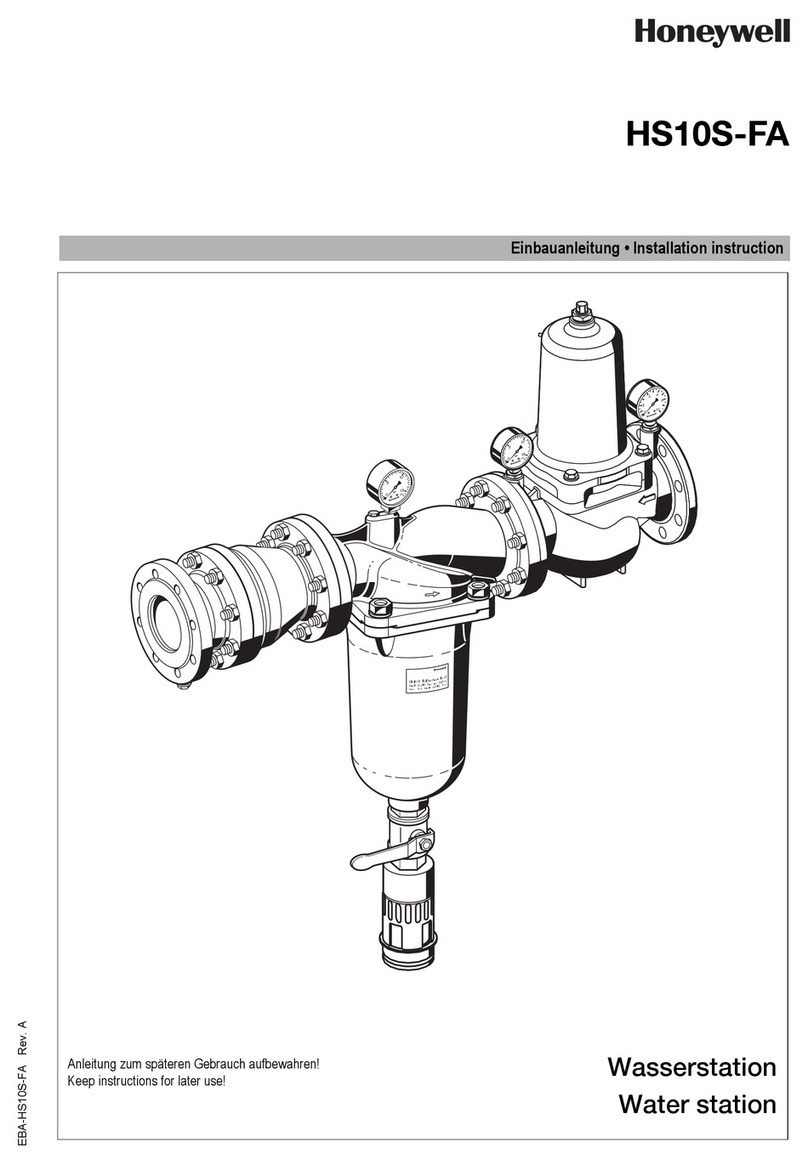

Honeywell HS10S-FA Installation instruction