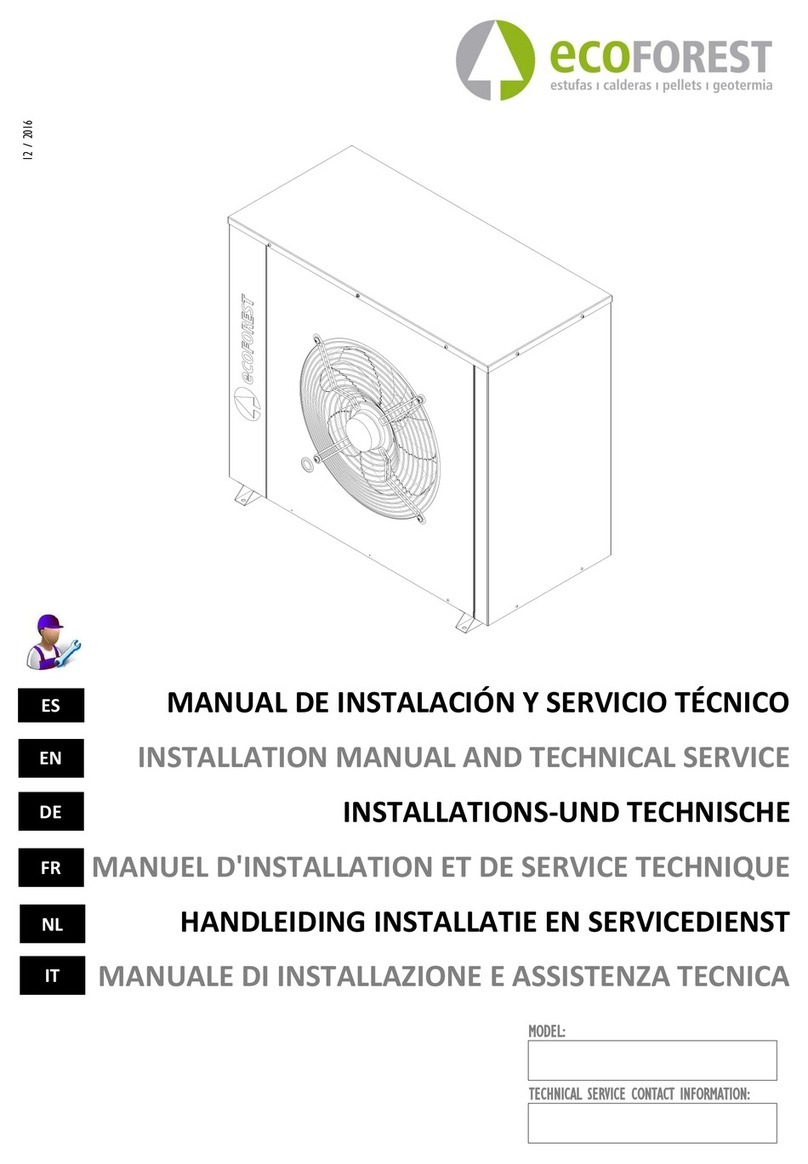

ECOFOREST ecogeo basic User guide

MANUAL INSTALADOR

INSTALLER MANUAL

INSTALLERHANDBUCH

MANUEL DE INSTALLATION

INSTALLATIE-HANLEIDING

ES

EN

DE

FR

NL

ecoGEO Basic

MODEL:

04 / 2016 SOFTWARE VERSION v01_B23

SERVICE CONTACT:

ecoGEO Compact

Installer manual ecoGEO

34

EN

2. Heat pump installation

2.1. Transport and handling

The heat pump must be transported vertically and not exposed to adverse weather conditions. It can be lain carefully on its rear side

to facilitate transportation to the installation site.

NOTE

Do not tilt the heat pump more than 45º, since this could impair proper equipment operation.

Due to its heavy weight, the heat pump should be handled by two workers using a forklift for heavy

loads.

2.2. Dimensions and connections

The overall dimensions and hydraulic connections of the ecoGEO Compact and ecoGEO Basic heat pumps are described below.

Figure 1.1. Overall dimensions and hydraulic connections of the ecoGEO Compact model (Amounts in mm).

56

1736

64

139

462

537

282

720

63

175

300

425

1

2

8

7

3

4

9

10

11

12

1812

600

Installer manual ecoGEO

35

EN

Figure 1.2. Overall dimensions and hydraulic connections of the ecoGEO Basic model (Amounts in mm).

No.

Description

No.

Description

1

Heating / cooling supply; G1-1/4” Male

7

Tap water inlet; G1" Female

2

Heating / cooling return; G1-1/4” Male

8

DHW outlet (G1" Female)

3

Brine supply; G1-1/4” Male

9

DHW recirculation return; G3/4” Female

4

Brine return, G1-1/4 Male

10

Drain; φ16 mm

5

DHW exchanger intake; G1” Male

11

Power cables inlet

6

DHW exchanger return; G1” Male

12

Control cables inlet

Table 1.1. Hydraulic connections key.

All the models are prepared for pipe connection both at the top and at the rear.

The factory installation is prepared for connection at the top. To connect at the rear, the connection fittings installed at the top must

be exchanged with the blind cable glands installed at the rear.

2.3. Unpacking

To unpack the heat pump, remove the wooden box carefully, remove the pallet anchoring screws and perform a check to make sure

the heat pump has not been damaged during transportation.

710

53

950

538

82

157

273

348

463

1

2

3

4

5

6

10

11

12

600

1060

Installer manual ecoGEO

36

EN

Figure 1.3. Removing the screws fastening the heat pump to the pallet.

2.4. Assembly and disassembly of the covers

A Torx T20 screwdriver and a 10 mm wrench are needed to assemble and disassemble the covers.

ecoGEO Compact Models

1. Disassemble the top front cover. Remove the screws located at the upper part and pull the cover upwards.

2. Disassemble the bottom front cover. Remove the screws located at the upper part and pull upwards.

3. Disassemble the side covers. Loosen the screws and nuts located at the front and rear and remove the cover.

4. Once the covers have been removed, the acoustic insulation panels can be removed by pulling them outwards.

Figure 1.4. Disassembly of the covers of the ecoGEO Compact models.

ecoGEO Basic Models

1. Disassemble the top cover. Remove the screws located at the rear and pull the cover upwards.

2. Disassemble the front cover. Remove the screws located at the upper part and pull the cover upwards.

3. Disassemble the side covers. Loosen the screws and nuts located at the front and rear and top and remove the cover.

4. Once the covers have been removed, the acoustic insulation panels can be removed by pulling them outwards.

Installer manual ecoGEO

37

EN

Figure 1.5. Disassembly of the covers of the ecoGEO Basic models.

NOTE

During cover disassembly, take care to remove the control panel cable without damaging it.

2.5. Recommended positioning

Choose a dry place where there is no risk of frost. Avoid installation against bedroom walls or walls of other rooms where noise

emissions can be annoying. If possible, install the heat pump with the rear part pointed toward an exterior wall. Avoid installation

near a corner, since this can amplify noise emission levels.

The heat pump should be installed on a stable base that can support the total weight of the equipment and the operating fluids in its

interior. Use the adjustable legs to compensate for possible irregularities on the supporting surface.

Figure 1.6. Positioning and levelling the heat pump.

2.6. Service areas

The minimum recommended distances to be left around the heat pump to facilitate installation, start-up and maintenance work are

indicated below.

Installer manual ecoGEO

38

EN

Figure 1.7. Minimum recommended service areas around the heat pump (amounts in mm).

The space needed at the back of the heat pump can be either 50 mm or 300 mm, depending on which pipe connection alternative is

chosen, top or rear, respectively.

3. Hydraulic installation

NOTE

The installation schemes included from here on should be considered simply as a guide.

The design of the hydraulic installation must be performed by qualified personnel and in accordance

with applicable local regulations.

3.1. General instructions

The following recommendations should be taken into consideration for proper hydraulic installation.

Avoid excessive strain between the pipes and the heat pump connections to prevent leaks and/or transmission of vibrations.

Flexible hoses should be used for heat pump connections.

Install cut-off valves at all the hydraulic connections to facilitate future maintenance tasks.

Install traps at all the installation points where air pockets can form.

Place heat insulation on all circuit pipes to prevent unnecessary heat loss. Pay special attention to the heating insulation on

the brine circuit pipes, since these can reach temperatures below 0ºC, causing condensation and/or frost.

DANGER!

During installation work on the hydraulic circuits, take special care to prevent liquid from spilling on the

internal electrical heat pump components, which could cause personal injury due to electrocution

and/or poor equipment operation.

300

300

500

600

50 - 300

300

300

600

50 - 300

500

Installer manual ecoGEO

39

EN

Do not install components that might cover the inlet or outlet of the safety valves; this could lead to a

risk of some of its components breaking and cause injuries and/or material damage.

3.2. Brine circuit

The ecoGEO heat pumps can be used with horizontal or vertical (A) geothermal brine systems or by using groundwater (B).

Aerothermal brine can also be used by replacing the geothermal collector with one or more ecoGEO AU12 aerothermal units (C).

Finally, hybrid collection can be obtained by combining a geothermal collector with one or more ecoGEO AU12 aerothermal units

(D).

Geothermal brine systems

Brine systems with more than one circuit must be connected in parallel, so the flow rate through each one is similar.

Groundwater brine systems

Groundwater brine systems must use a midway exchanger to prevent the heat pump evaporator from corrosion, freezing or getting

dirty.

Hybrid brine systems

In hybrid brine installations, the aerothermal collector and the geothermal collector must be connected in series so the antifreeze

mixture circulates first through the aerothermal collector and then through the geothermal collector.

On the other hand, open / close 3-way valves must be installed between the outlet and return of each collector so the collector can

be bypassed when it is not in use.

Figure 1.8. Brine circuit connection options.

Integrated components

The following brine circuit components are included within the heat pump.

Variable speed and high efficiency outlet pump (energy class A).

Expansion vessel with a capacity of 8 litres, with pre-adjusted pressure of 0.75 bar (pressure gauge).

DO17

DO17

DO16

AO3

DO6

DO6

DO16

AO3DO16

C)

D)

A)

B)

3

4

3

4

3

4

3

4

3

4

3

4

Installer manual ecoGEO

40

EN

Safety valve loaded at 3 bar (pressure gauge).

Drain valve.

Installation instructions

Follow the instructions below to wire the brine circuit.

Install the necessary components to carry out the filling/discharge of the return pipe.

Install a particulate filter in the return pipe with a mesh size no greater than 1 mm. It is recommended to install shut off valves

immediately before and after the filter to make it easier to clean or replace.

Check that the volume of the expansion vessel integrated in the heat pump is capable of absorbing any overpressures from

the circuit. If this volume is not enough, install a supplementary external expansion vessel.

If necessary, adjust the pressure of the expansion vessel integrated in the heat pump to guarantee that the circuit remains

pressurised at all points.

3.3. Heating / Cooling circuit

The ecoGEO heat pumps can be connected to various types of heating / cooling systems, both directly and by separating buffer

storage tanks. On the other hand, these enable control over several devices that are external to the heating / cooling system directly

from the heat pump's electrical panel.

Heating / cooling system

The ecoGEO heat pumps are designed to be used with heating systems with nominal outlet temperatures of up to 55ºC; such as

underfloor heating systems, low temperature radiators or convectors. They are not recommended for use in heating systems that

require higher temperatures.

The ecoGEO heat pumps can be used with cooling systems with nominal outlet temperatures of up to 7ºC, such as convectors and

underfloor cooling systems.

Special care should be taken in the design and control in installations with underfloor cooling, to prevent problems of condensation

on floors.

The models that are not equipped with integrated passive cold allow control of external passive cooling equipment.

Direct installation

In simple heating / cooling systems, ecoGEO heat pumps can be installed directly into the distribution system, in systems with

underfloor heating, low temperature radiators and convectors.

Figure 1.9. Wiring scheme directly to the heating / cooling system.

DI12

DI11

T

T

DI10

DI9

T

T

DI8

DI7

T

T

DI6

DI5

T

T

FBus2

1

2

1

2

1

2

DO5

DG1

DO14

AO4

AI13

SG3

DO15

AO5

AI14

SG4

DO6

AO3

AI12

SG2

TT T

M

M

M

Installer manual ecoGEO

41

EN

Installation using buffer storage tanks

If required by the application, the heat pump can also be connected to the heating / cooling system using a buffer separator tank. To

do so, it is equipped with two temperature probes that are used to control a buffer storage tank for heating and a buffer storage tank

for cooling. In installations where there is only one buffer storage tank for heating and cooling, both probes have to be installed in

the storage tank. Install the temperature probes at the points where heating / cooling production begins. Heating / cooling production

is stopped by the return temperature probe installed inside the heat pump.

Figure 1.10.Wiring scheme using two buffer storage tanks.

Figure 1.11.Wiring scheme using a single buffer storage tank.

Outlet units

These can manage as many as four different outlet temperatures. This is done by managing one direct outlet unit and three combined

outlet units. The combined outlet units have to use modulating 3-way valves with an analogue signal of 0-10Vdc. Each outlet unit has

independent terminals for heating and cooling demands. These signals are supplied with 24Vac or 24Vdc voltage.

T

T

DO10

AI16

AI15

DO13

DO13

DO12

DI12

DI11

T

T

DI10

DI9

T

T

DI8

DI7

T

T

DI6

DI5

T

T

FBus2

1

2

1

2

1

2

DO5

DG1

DO14

AO4

AI13

SG3

DO15

AO5

AI14

SG4

DO6

AO3

AI12

SG2

TT T

M

M

M

T

T

DO10

AI16

AI15

DI12

DI11

T

T

DI10

DI9

T

T

DI8

DI7

T

T

DI6

DI5

T

T

FBus2

1

2

1

2

1

2

DO5

DG1

DO14

AO4

AI13

SG3

DO15

AO5

AI14

SG4

DO6

AO3

AI12

SG2

TT T

M

M

M

Installer manual ecoGEO

42

EN

Auxiliary equipment integrated in the heating buffer storage tank

This is used to control an auxiliary unit integrated in the heating buffer storage tank. It can be used for normal heat production or as

emergency equipment.

Auxiliary boiler

This is used to control start-up / stop of an auxiliary boiler and regulate final temperature downstream from the boiler by a 0-10 Vdc

modulating 3-way valve. The heat pump can use the boiler to assist in normal heat production or as emergency equipment.

NOTE

The hydraulic installation must ensure that while the boiler is operation, the temperature through the

heat pump never exceeds 65ºC, since this could cause serious damage to the refrigerant circuit.

Integrated components

The following heating / cooling circuit components are included within the heat pump.

Variable speed and high efficiency pump (energy class A).

Expansion vessel with a capacity of 12 litres, with pre-adjusted pressure of 1.3 bar.

Safety valve loaded at 3 bar (pressure gauge).

Drain valve.

Installation instructions

Follow the instructions below to connect the heating / cooling circuit.

Install a particulate filter in the return pipe with a mesh size no greater than 1 mm. It is recommended to install shut off valves

immediately before and after the filter to make it easier to clean or replace.

Check that the volume of the expansion vessel integrated in the heat pump is capable of absorbing any overpressures from

the circuit. If this volume is not enough, install a supplementary external expansion vessel.

If necessary, adjust the pressure of the expansion vessel integrated in the heat pump to guarantee that the circuit remains

pressurised at all points.

If there is an auxiliary system integrated in the heating storage tank, install a safety valve to protect it from any overpressures.

3.4. DHW circuit

ecoGEO Compact Models

The ecoGEO Compact heat pumps are provided with an integrated inter storage tank with a capacity of 165 litres, so it does not

require the installation of an external DHW storage tank.

ecoGEO Basic Models

The ecoGEO Basic heat pumps are designed to be used with external storage systems with a midway heat exchanger that can be

either internal or external.

DHW Recirculation

This is used to control a DHW recirculation pump. The storage tanks included in the ecoGEO Compact models are provided with a

separate inlet for DHW recirculation. If an external storage tank without a separate inlet for DHW recirculation is used, it is

recommended to connect recirculation to the cold water inlet pipe.

Auxiliary equipment integrated in the DHW storage tank

This is used to control a support system integrated in the DHW storage tank. This can be used as support to reach higher temperatures

during normal production, to carry out legionella protection programs or as emergency equipment.

Installer manual ecoGEO

43

EN

Figure 1.12.Wiring scheme of the DHW circuit.

Installation instructions

Follow the instructions below to wire the DHW circuit.

In the ecoGEO B models, install a particulate filter in the return pipe to the heat pump with a mesh size no greater than 1

mm. It is recommended to install shut off valves immediately before and after the filter to make it easier to clean or replace.

Install a check valve at the tap water inlet to prevent the possible return of hot water from the mains.

If necessary, install a safety unit (expansion vessel + safety valve) at the tap water inlet to prevent overpressure in the DHW

storage tank.

If there is a risk of scalding, a thermostatic mixing valve should be installed at the DHW outlet.

If the maximum system pressure can exceed 5 bar, it is recommended to install a pressure reducing valve in the mains inlet

to prevent overpressure in the storage tank.

If there is an auxiliary system integrated in the DHW storage tank, install a safety valve in the production circuit return to

protect it from any overpressures.

3.5. Pool circuit

The ecoGEO heat pumps can be used to send hot water directly to the pool production storage tank through an open / close 3-way

valve. It can be connected two different ways for this purpose, depending on the application. In both cases, the POOL mode must be

activated via a voltage-free signal from a thermostat.

Connection to the heating circuit (A)

In models that are not equipped with the HTR system, pool production should be connected to the heating circuit via an open / close

3-way valve. This type of connection allows non-simultaneous production for the pool on the one hand and heating or cooling on the

other hand.

Connection to the HTR system (B)

In addition to the option mentioned above, in ecoGEO Basic models with an HTR system, pool production can be connected to the

DHW circuit. This allows two options: exclusive pool production with the primary condenser and simultaneous heating / cooling and

pool production through the HTR system.

T

DO11

AI10

DO4

T

DO4

T

P

P

Installer manual ecoGEO

44

EN

Figure 1.13.Pool production wiring schemes.

3.6. Drain

Condensation may occur one certain internal heat pump components during normal operation. On the other hand, antifreeze mixture

or water may spill from the heat pump's internal safety valves due to eventual circuit overpressure.

There is a drain connection at the rear of the heat pump to evacuate these liquids.

4. Filling and discharge circuits

DANGER!

During filling work on the hydraulic circuits, take special care to prevent liquid from spilling on the

internal electrical heat pump components, which could cause personal injury due to electrocution

and/or poor equipment operation.

4.1. Filling the production circuit (heating, cooling, DHW and pool)

The heat pump is equipped with internal filling / discharge valves for the production circuit. It is recommended to use these valves

to ensure that the internal circuits are completely bled. Take the following steps to fill the circuit.

1. Open all the valves of the production circuits.

2. Fill the circuit through the filling valve until the target pressure is reached. Make sure that the pressure does not exceed 3

bar (pressure gauge) under any circumstance.

3. Remove the air from the circuit using the traps installed for that purpose.

4. Check the circuit pressure and repeat the filling process if necessary.

The ecoGEO Compact models are equipped with a manual trap at the entry to the coil to bleed the DHW production circuit.

T

DO11

AI10

DO4

T

DI4

T

DO2

B)

P

DI4

T

DO2

A)

DI4

T

DO2

A)

Installer manual ecoGEO

45

EN

Figure 1.14.Bleeding the DHW production circuit in ecoGEO Compact models.

4.2. Filling the brine circuit

The brine system temperature can fall below 0°C, so a mixture of water/antifreeze must be used. It is recommended to use propylene

glycol as an antifreeze additive or ethylene glycol with a corrosion inhibitor. Please check local regulations before using any type of

antifreeze mixture.

When preparing the mixture, be careful to calculate the volume of antifreeze necessary to reach the desired degree of antifreeze

protection. It is recommended to use a mixture with a freezing point at least 10ºC below the nominal minimum temperature.

Brine circuit filling should be done with the filling unit installed in the return pipe and an external circulation pump, taking the

following steps.

1. Prepare the appropriate proportions of antifreeze mixture in external tank A.

2. Connect the external recirculation pump outlet to valve D.

3. Connect a transparent hose from valve E to antifreeze mixture tank A.

4. Close valve C and open filling valves D and E.

5. Start the external recirculation pump and keep it running until the return is completely free of air and the antifreeze mixture

is mixed perfectly.

6. Open valve C and keep the external pump connected to remove the air between valves D and E.

7. Close valve E and pressurise the circuit to target pressure. Make sure that the pressure does not exceed 3 bar (pressure gauge)

under any circumstance.

8. Close valve D.

After completing the brine circuit filling process, it is recommended to check the concentration of antifreeze mixture again using a

refractometer.

Manual trap

Installer manual ecoGEO

46

EN

Figure 1.15.Filling the brine circuit.

4.3. Discharging the circuits

The heat pump is equipped with internal drain valves that ensure complete discharge of the various internal circuits.

3

4

A

B

C

E

D

3

4

A

B

C

E

D

Installer manual ecoGEO

47

EN

5. Electrical system

DANGER!

Before performing any operation on the electrical panel, disconnect the power supply.

5.1. General instructions

The locations of the main electrical panel components are shown below.

Figure 1.16.Location of the components in the electrical panel.

Several installation devices are controlled from the heat pump electrical panel. Some are internal and other are installed externally.

The internal components are connected to the electrical panel in the factory. Depending on the installation that the heat pump is

going to be connected to, in addition to the power supply, it may be necessary to connect various temperature probes (analogue

inputs AIxx), control signals from thermostats or other external equipment (digital inputs DIxx) on/off switching of pumps and/or

valves (digital outputs DOxx) or regulation of pumps and/or valves (analogue outputs AOxx).

The figure below shows a sample installation with the options for connecting external components to the heat pump.

DIxx

Digital inputs

AIxx

Analogue inputs

Distributor

230/400 Vac

Heat pump power

supply

Controller pCO OEM+

Fbus2

ModBus

communication port

Compressor driver

Inverter

Internal auxiliary

heater power supply

AOxx

Analogue outputs

DOxx Block II

Digital outputs to

relay

DOxx Block I

Digital outputs to

relay

Transformer 24 Vac

Electrical power filter

Controller fuse

Main switch

Controller expansion

module

Compressor contactor

Installer manual ecoGEO

48

EN

Figure 1.17.General electrical connections scheme of the heat pump (ecoGEO Basic models).

DO5

T

DG1

DO14

AO4

SG3

DO15

AO5

SG4

DO6

AO3

SG2

T

T

DI4

T

DO10

DO11

AI10

AI16

AI15

DO4

DO13

DO13

T

DO17

DO17

DO16

AO3

DO6

DO6

DO16

AO3DO16

TAI11

DO12

DO1 DO1

DI12

DI11

T

T

DI10

DI9

T

T

DI8

DI7

T

T

DI6

DI5

T

T

FBus2

DO2

P

AI13 AI14AI12 TT T

M

M

M

3

4

3

4

3

4

3

4

Installer manual ecoGEO

49

EN

Analogue inputs (AIxx)

These terminals are used to connect external temperature probes. Only passive NTC temperature probes can be connected, so cable

connection polarity is not important.

If necessary, use extension cables with a maximum length of 50 m and a minimum diameter of 0.75 mm2. For greater lengths (up to

120 m) it is recommended to use cable with a section of 1.5 mm2.

NOTE

Use original temperature probes only; other types of components could cause poor heat pump

operation and/or cause heat pump component breakdowns.

Figure 1.18.Example of temperature probe connections.

Digital control inputs (DIxx)

Digital signals from thermostats or other external devices can be connected to these terminals to control heat pump production

functions.

NOTE

Take special care with the working voltage of each digital input; improper handling could cause poor

heat pump operation and/or heat pump component breakdowns. Some digital inputs require voltage-

free signals, while others require 24Vac / 24Vdc signals.

Figure 1.19.Example of voltage-free digital input connections.

NOTE

Do not power external components connected to the digital inputs from the 24 Vac power supply of the

heat pump; this could cause poor heat pump operation and/or heat pump component breakdowns.

Com

Sgn

AIxx

NTC

Com

Sgn

DIxx

Installer manual ecoGEO

50

EN

Figure 1.20.Example of digital input connections with 24Vac / 24Vdc voltage.

Analogue outputs (AOxx)

These terminals send analogue 0-10Vdc regulation signals to modulate the control of outlet units with mixture, aerothermal brine

units with variable speed fan, external auxiliary boilers, etc. On the other hand, these connectors have a 24Vac power supply terminal

to supply the modulating valve motor.

Figure 1.21.Example of 0-10Vdc modulating regulation signal connections.

Digital outputs to relay (DOxx)

These terminals provide 230Vac activation signals for various external components, such as outlet units, open / close 3-way valves,

external auxiliary equipment, etc. The connectors used for valve control allow connection of any type of 2 or 3-point control valve,

as long as it has a single-phase 230Vac power supply.

NOTE

Pay special attention to the maximum consumption allowed by each connector. Use an intermediate

relay for the connection, if necessary.

Figure 1.22.Example of digital outputs to relay for A) circulator pumps and B) open / close 3-way valves.

GND

24Vac

Vout

AOxx

M

PE

N

L

DOxx

PE

N

Lin

Loff

Lon

DOxx

A)

B)

Com

Sgn

DIxx

24Vac

Com

Sgn

DIxx

24Vdc

Installer manual ecoGEO

51

EN

ModBus RS485 (FBus2) Communication Port

Internal terminals with thT bus communication data can be connected to this terminal.

5.2. Heat pump power supply

Depending on the model, the heat pump may require single phase 1/N/PE 230 V / 50 Hz power or three phase 3/N/PE 400 V / 50 Hz

power.

The heat pumps should be powered by an external automatic breaker that shuts down all the circuits. Shown below are the

recommended cable diameters for each heat pump model and the recommended range of external electric thermal-magnetic

protection. Maximum heat pump electrical consumption can vary widely depending on working conditions; for more information,

please refer to the Technical Service Manual.

Model

Electric

power supply

Cable

section

Maximum

current

ecoGEO B/C 3-12 kW

Single phase

4 mm2

16 to 25 A

ecoGEO B/C 5-22 kW

Single phase

10 mm2

25 to 40 A

ecoGEO B/C T 5-22 kW

Three phase

2.5 mm2

16 A

Table 1.2. Dimensioning of the power cord and the external switch.

To carry out the electrical installation, insert the power cable through the rear cover of the heat pump and pass it to the bottom right

part of the heat pump. Continue by connecting the cables to the power terminal block of the heat pump, as described below.

Figure 1.23.Power supply connection scheme in A) single phase and B) three phase models.

5.3. Internal auxiliary equipment power supply

The ecoGEO heat pumps are equipped with an internal auxiliary heater comprised by three 2 kW components each (6 kW in all) that

requires an independent power supply. This heater can be connected to either a single phase or three phase power supply, depending

on the thermal power required.

If the power supply is single phase 1/N/PE 230 V / 50 Hz, each of the elements can be connected independently to obtain 2 kW, 4 kW

or 6 kW, respectively.

A)

B)

L3

L2

L1

N

Power Supply

PE

L1

N

Power Supply

PE

Other manuals for ecogeo basic

4

This manual suits for next models

1

Table of contents

Other ECOFOREST Heat Pump manuals

ECOFOREST

ECOFOREST ecogeo hp User manual

ECOFOREST

ECOFOREST ecoGEO AU12 User manual

ECOFOREST

ECOFOREST ecoSMART PSM Gen1 User manual

ECOFOREST

ECOFOREST ecogeo basic User manual

ECOFOREST

ECOFOREST ecoAIR EVI User manual

ECOFOREST

ECOFOREST ecogeo basic User manual

ECOFOREST

ECOFOREST ecogeo basic User manual

ECOFOREST

ECOFOREST ecoGEO B1 3-12 kW User manual

ECOFOREST

ECOFOREST ecogeo basic Operating manual

ECOFOREST

ECOFOREST ecoGEO C User manual