EcoInnovation React Pump User manual

August 2020 Version 2.1

React Pump

System Design and Installation Manual

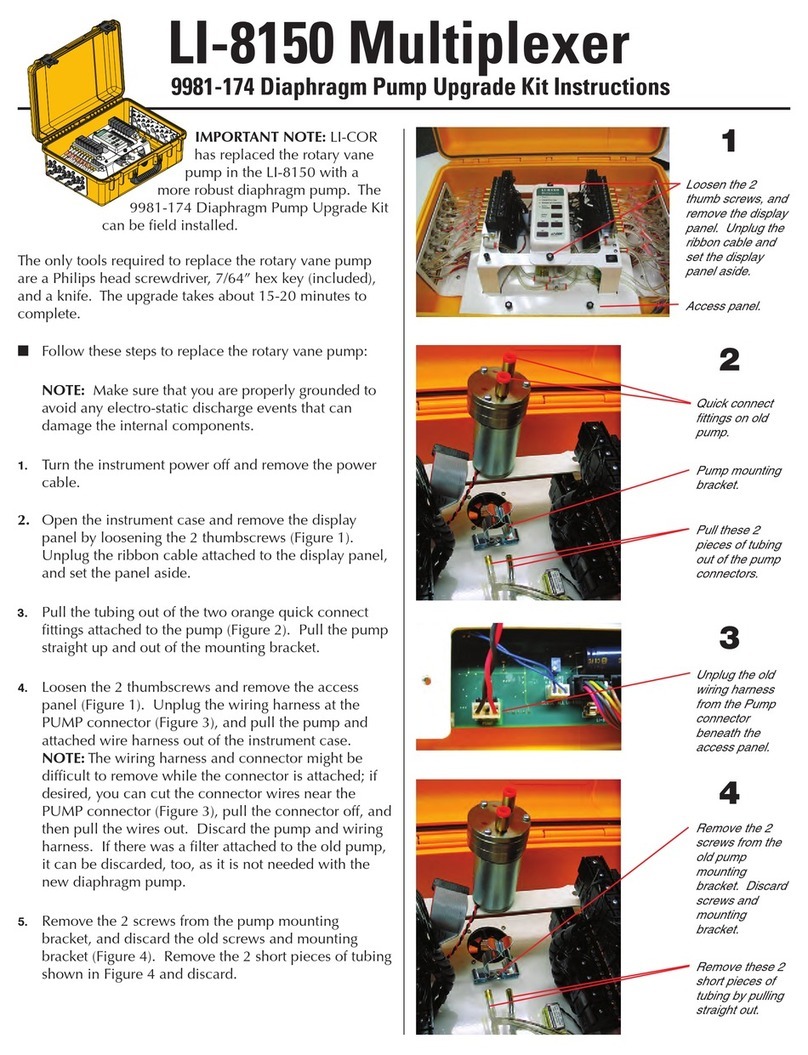

1080W of PV on movable frames (540W per frame)

React pump pontoon mounted

Please read this manual carefully before beginning the installation.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 2

4 panel React pump ground mounted adjacent to a farm pond

2 panel React pump ground mounted above a shallow farm well

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 3

8 panel East/West twin React pump install

Note valve riser pipes for priming of each suction line

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 4

Please read this manual carefully

before beginning the installation.

Note solar PV examples are often

based on 270W panels. Today

280W or larger panels may be

more common/cost effective.

Please note that the intended

application of this solar pump is

for high country stock water

pumping from Spring to Autumn.

Operation in winter (or when

freezing temperatures may occur)

is only permitted if protection

from freezing is implemented.

Damage caused by freezing

temperatures is not covered by

warranty.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 5

React pump with fairing removed

Fairing in place (Rebranded React pump –previously SHP-TX or SHP-Triplex)

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 6

Typical East/West Truss mounted array remote from the React pump location

React pump shed mounted (with fairing removed)

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 7

CONTENTS

1. Scope of Application and Safety............................................................................... 13

1.1. Scope.......................................................................................................................... 13

The client must determine:...........................................................................................131.1.1.

Items that are provided with all pump sales (NZ & International):..............................131.1.2.

1.2. Pump serial numbers................................................................................................... 15

1.3. Safety ......................................................................................................................... 16

Rotational Machinery Safety.........................................................................................161.3.1.

Pressurised Water Safety..............................................................................................171.3.2.

Fire Safety .....................................................................................................................171.3.3.

Electrical Safety: ELV Wiring rules specific to NZ and Australia....................................181.3.4.

Installation Safety Checklist..........................................................................................181.3.5.

1.4. CE and FCC Declaration................................................................................................ 20

1.5. Standards and certification.......................................................................................... 20

1.6. Consents and environmental impact............................................................................ 21

Frame building consent.................................................................................................211.6.1.

Electrical wiring COC (code of compliance) ..................................................................211.6.2.

Water abstraction resource consent ............................................................................211.6.3.

Water usage with minimum impact on the environment ............................................211.6.4.

React pump’s Noise Levels............................................................................................211.6.5.

2. Product Overview.................................................................................................... 22

2.1. Product up close.......................................................................................................... 22

Image cutaway of React pump......................................................................................222.1.1.

React pump exploded view and parts list (14mm stroke with 20mm diameter ceramic2.1.2.

plungers) 23

Pump parts list ..............................................................................................................232.1.3.

Image of React pump with body fairing........................................................................24

2.1.4.

Image of React pump (with body fairing removed & land mounted)...........................252.1.5.

Wiring detail..................................................................................................................262.1.6.

Rodent guard (customers required to cut & fit as shown) ...........................................262.1.7.

Smart Drive motor ........................................................................................................272.1.8.

React pump (Pontoon)..................................................................................................272.1.9.

2.2. React pump performance............................................................................................ 28

Summer flow volumes (litres per day)..........................................................................282.2.1.

Estimated flow per day over the calendar year............................................................282.2.2.

Maximum flow rate possible at each head...................................................................292.2.3.

Peak pump efficiency....................................................................................................292.2.4.

Solar PV utilisation efficiency........................................................................................292.2.5.

Maximum input power of React pump at various heads .............................................302.2.6.

Pumping Height of the PowerSpout React pump.........................................................302.2.7.

Seasonal Variation ........................................................................................................30

2.2.8.

Recommended PV array size ........................................................................................302.2.9.

2.3. Step by step design overview....................................................................................... 31

PowerSpout React pump site data requirements.........................................................312.3.1.

Measuring head ............................................................................................................312.3.2.

Measuring flow in your water resource........................................................................312.3.3.

Choosing the correct number of React pumps for your site ........................................322.3.4.

Matching the React pump supply to demand changes ................................................332.3.5.

Incrementally increasing the system size cost to meet your needs.............................332.3.6.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 8

2.4. Multiple React pump install examples ......................................................................... 34

Higher flow parallel installation....................................................................................342.4.1.

High head series installations .......................................................................................342.4.2.

High flow twin React pump to lower farm, high head series React pump to upper farm2.4.3.

35

2.5. Effects of having not enough water for the React pump ............................................... 36

2.6. Pumping too much water and conserving your water resource..................................... 36

Setting the off-pressure................................................................................................362.6.1.

Resetting the off-pressure ............................................................................................362.6.2.

If you fail to set the off-pressure ..................................................................................372.6.3.

2.7. Supply water to top or bottom of storage tank ............................................................ 37

Overflow pipe................................................................................................................382.7.1.

Conserving your resource .............................................................................................392.7.2.

2.8. Dealing with dirty water.............................................................................................. 40

Our advice for moderately clean water resources: ......................................................402.8.1.

Our advice for rather dirty water resources:................................................................402.8.2.

3. Solar array design and installation ........................................................................... 41

3.1. Understanding PV size and orientation ........................................................................ 41

Single array facing midday sun .....................................................................................413.1.1.

Array split into two halves facing East and West..........................................................423.1.2.

Sites with shading in the morning and/or evening.......................................................423.1.3.

Smaller PV array orientation.........................................................................................433.1.4.

Larger PV array for maximising pumped volume in winter or poor weather conditions.3.1.5.

43

1620W PV - facing morning, midday and evening sun (160-300m head) in the shade3.1.6.

free zone 43

3.2. Wiring the PV to the React pump................................................................................. 44

ELV Wire protection......................................................................................................443.2.1.

Over current wire protection........................................................................................453.2.2.

"Maximum Series Fuse" rating and the possible need for string fuses........................453.2.3.

Selecting suitable fuses where needed.........................................................................473.2.4.

Lightning protection......................................................................................................493.2.5.

Earth Connection ..........................................................................................................493.2.6.

Wiring schematic for 540W PV array............................................................................493.2.7.

Wiring schematic for 1080W PV array..........................................................................503.2.8.

Wiring schematic for 1620W PV array..........................................................................503.2.9.

Solar array general wiring practice ...............................................................................513.2.10.

React pump wiring to main DC disconnect switch......................................................533.2.11.

Wiring of DC switch to React pump..............................................................................533.2.12.

Check polarity ...............................................................................................................533.2.13.

Final wiring to React pump (1080W example)..............................................................543.2.14.

Regulations about cable ties, and UV protection of PV wiring.....................................543.2.15.

How to feed your electrical wire inside a long LDPE pipe. ...........................................543.2.16.

How to wire and fit the Slocable MC4 connectors .......................................................563.2.17.

To fit MC4 connectors with correct tools (barrel crimping tool):.................................563.2.18.

To fit MC4s with available farm tools: ..........................................................................573.2.19.

3.3. Operating your React pump from auxiliary (not solar) power sources........................... 58

Systems with a 230/115 VAC supply.............................................................................583.3.1.

Using the React pump solar array for other purposes..................................................583.3.2.

4. Intake...................................................................................................................... 60

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 9

4.1. Suction or gravity feed (pump priming issues)? ............................................................ 60

4.2. Site installation options............................................................................................... 61

Gravity feed (very little fall –small creek or stream)....................................................614.2.1.

Gravity feed with silt settling tank (where more fall allows)........................................614.2.2.

Small pontoon (pond, dam, stream or small lake with changing surface level)...........634.2.3.

Small pontoon (large water surface with little change in surface level) ......................634.2.4.

Small pontoon on rivers subject to moderate flooding................................................644.2.5.

Larger pontoon with solar PV and React pump (large water surface with changing4.2.6.

surface level).................................................................................................................................64

Suction lift up to 3m will self-prime..............................................................................664.2.7.

Suction lines with 3-6m lift will need to have a manually assisted prime while turning4.2.8.

on the React pump........................................................................................................................66

Submersible pump & settling tank for dirty water supplies from 3-50m below the4.2.9.

React pump...................................................................................................................................67

Submersible pump with clean water from 3-50m below the React pump ..................674.2.10.

Choosing a submersible bore pump .............................................................................684.2.11.

Key parts to a good suction intake design: ...................................................................694.2.12.

Filter sock advice...........................................................................................................694.2.13.

React pump pipe fittings supplied ................................................................................704.2.14.

5. Practical examples of installations ........................................................................... 72

5.1. Pontoon pump system ................................................................................................ 72

How to make a simple pontoon (1 x React pump’s).....................................................735.1.1.

How to make a simple plastic pallet pontoon (1-2 React pumps)................................745.1.2.

How to make a large pontoon for 1 x React pump and 540W or 1080W array ...........755.1.3.

Making the pontoon .....................................................................................................765.1.4.

5.2. How to make a ground mounted 1080W array............................................................. 77

Dig holes and position the 4 corner posts as shown ....................................................785.2.1.

Position trussed frame..................................................................................................785.2.2.

Aluminium rail mounting ..............................................................................................795.2.3.

Completed East/West array..........................................................................................795.2.4.

Arrays for East, Midday and West orientation with 6 panels.......................................795.2.5.

5.3. How to land mount the React pump ............................................................................ 80

Mounting React pump base to support pegs..............................................................815.3.1.

Where ground foundations are not possible................................................................835.3.2.

6. Pipe size selection.................................................................................................... 84

6.1. Selecting suitable delivery pipes (from React pump to tank)......................................... 84

The difference between internal and outer diameter..................................................846.1.1.

Quick guide to finding the best pipe with a single React pump ...................................856.1.2.

Pipes commonly available from Rural Direct in NZ.......................................................856.1.3.

The IPLEX pipe range of LDPE/MDPE/HDPE pipes........................................................866.1.4.

6.2. Example of the full calculation to predict pressure loss at a higher accuracy ................. 86

Head loss in m per 100m length of new smooth bore plastic pipe ..............................876.2.1.

Onsite flow test (25 NB)................................................................................................886.2.2.

6.3. The Suction (intake) Pipe............................................................................................. 89

7. Commissioning the system ...................................................................................... 90

7.1. Installation plumbing of the React pump ..................................................................... 90

7.2. React pump Components ............................................................................................ 91

React pump Protection .................................................................................................917.2.1.

7.3. Commissioning procedures.......................................................................................... 91

Checks with cover off - before start-up ........................................................................917.3.1.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 10

Commissioning the React pump ...................................................................................917.3.2.

Trouble shooting commissioning problems..................................................................927.3.3.

7.4. Commissioning checks................................................................................................. 92

Operating checks...........................................................................................................927.4.1.

7.5. Record the facts!......................................................................................................... 92

Problem table check list................................................................................................927.5.1.

Documentation as per AS/NZS 5033.............................................................................947.5.2.

Labelling for disconnection devices as per AS/NZS 5033..............................................947.5.3.

Advised periodic maintenance NZS 5033 (these are advised only)..............................957.5.4.

7.6. Feedback .................................................................................................................... 95

8. Operation and maintenance .................................................................................... 96

8.1. Starting and stopping .................................................................................................. 96

8.2. Priming....................................................................................................................... 96

Manually Priming the React pump ...............................................................................968.2.1.

Changing a foot valve:...................................................................................................97

8.2.1.

8.3. Particular points to monitor ........................................................................................ 97

Oil..................................................................................................................................978.3.1.

Operating conditions ....................................................................................................978.3.2.

Rapid pump deceleration..............................................................................................978.3.3.

Pump stopping for a few second and then starting again............................................978.3.4.

Advice on freezing.........................................................................................................988.3.5.

8.4. Regular checks ............................................................................................................ 98

8.5. Spare parts.................................................................................................................. 99

8.6. Lubricating the React pump......................................................................................... 99

8.7. Changing the bearings ............................................................................................... 100

8.8. Service agreement/plan NZ only (10 year life with annual premium) .......................... 100

9. Warranty and disclaimer........................................................................................ 101

9.1. What we require from the customer.......................................................................... 101

9.2. How to make a claim................................................................................................. 101

9.3. Claim form................................................................................................................ 102

10. Exclusion and liability......................................................................................... 103

11. Contacts............................................................................................................. 103

12. Product Specifications and Performance............................................................. 104

React pump Electrical Input Specifications.................................................................10412.1.1.

React pump Specifications..........................................................................................10512.1.2.

13. Installation details log ........................................................................................ 106

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 11

EcoInnovation endeavours to reduce their footprint in many different ways, e.g. to save on

paper and airfreight, this manual is only supplied electronically to customers. We encourage

users to minimise printing where appropriate and to provide feedback via our website or via

email (see contact details inside front cover).

If English is not your language, click here for instructions on how to translate this PDF to

your desired language.

Notice of Copyright

PowerSpout Installation Manual

Copyright © 2019 All rights reserved

Notice of Trademark

PowerSpout –is a USA registered Trademark

React pump, React pump , PHP, TRG, PLT, LH & LH-mini - are non-registered Trademark

product names of EcoInnovation

Notice of Company Registration

EcoInnovation –is a NZ Registered Limited Company

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, ECOINNOVATION LIMITED:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY

OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUAL OR

OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

Revisions history

1.0 New release February 2019 content by ML, edited by HP & EL.

1.1 Minor typing corrections and additions 7/3/2019 by ML

1.2 Minor typing corrections 27/3/2019 by ML

1.3 Clearer advice on string protection when >2 PV strings installed by HP & ML

1.4 Corrections to section 1.1.2, to align with web site options by ML 29/9/19

1.5 Image update minor by ML 30/10/19

1.6 Clearer clarification that oil level is to be normally at top of sight glass and never

allowed to operate lower than centre of sight glass.

1.7 Correction, no 25mm suction hose supplied as standard, optional extra item only.

1.8 Better advice on oil selection - refer to revised section 8.6

1.9 Additional install images. Anti-clockwise rotation for best lubrication see section

1.3.1.

2.0 Clearer advice on the intended application of the product and when frost/freezing

protection is needed by ML 30/6/2020

2.1 Rebranded to React pump, new name and logo. General corrections and updates

to text by ML 20/8/20

Ensure you are reading the latest version.

The most recent release of all our products documentation can be located in our INDEX

here.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 12

PowerSpout Contact details

Web: www.powerspout.com

If you cannot find the answers to your questions about our products, renewable

energy systems, or your site's potential in this document or on our website at

www.powerspout.com, please submit a question via email to any of the dealers listed

on our website. We will answer this as quickly as possible.

PowerSpout is a product proudly designed and manufactured by:

EcoInnovation Ltd

671 Kent Road

New Plymouth R.D.1

New Zealand 4371

Web: www.ecoinnovation.co.nz or www.powerspout.com

If you need to contact EcoInnovation by phone then email first via our web site and

check the local time in NZ if calling from overseas. Business hours are 9:00am to

5:00pm weekdays only. EcoInnovation is closed for up to 3-4 weeks over the

Christmas break from 24th December.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 13

1. Scope of Application and Safety

This document is part of the product. It refers to the PowerSpout React pump (formerly

called the SHP-TX Solar Hydraulic Pump Triplex) and the associated PV array, wiring and

pipe connections.

1.1. Scope

The product is designed to pump fresh water with the use of solar power (or other approved

power sources) in the following conditions:

The application of the React pump is to lift water on hill country farms for stock water

needs. If you plan to use (or store) this pump in conditions below freezing then extra

protection in needed to protect the React pump from damage due to freezing

temperatures.

Do not install unprotected in situations where the pipeline may freeze. Protection from

freezing temperatures is outlined later in this document. Frost will damage the pressure

sensor first, which is designed to fail safe and prevent operation of the pump.

Water that will not corrode aluminium parts. Seawater is not permitted.

Dirty pond water is acceptable within reason. River water that includes pumice or other

sharp abrasive material must be adequately filtered.

Terrain that can be walked over safely for pipe laying etc. (i.e. no large vertical drops).

The client confirms that the site is unlikely to: slip, have rock falls, flood, earthquake etc.

Where such conditions exist the client has taken appropriate measures (i.e. insurance

cover). Product warranty does no cover such events.

The client has read the manuals, viewed online videos and understood installation

examples before starting on this project.

We advise engaging an experienced/qualified installer who has good mechanical,

electrical, plumbing, reading and comprehension skills if you do not possess these skills

yourself.

The React pump must be sited above any flooding level unless pontoon mounted. React

pump submersion will result in serious equipment damage which is typically 50% of the

new cost to have repaired.

The React pump, solar PV array and power cable must be adequately protected from

large animal damage.

The client must determine:1.1.1.

Vertical lift from the React pump centre line to header/storage tank.

Size of header tank to meet their needs.

Length of pipe to the header tank.

Inside diameter of pipe to the header tank (already installed or available to purchase) to

allow for the extra friction pumping head to be determined.

Suction lift (vertical distance) from the lowest level of the water resource surface to the

React pump centre line (if a floating React pump on a pontoon is not being employed).

The suction pipe length. This must be less than 5m long, or the suction pipe size will

need to be increased from the 25mm ID to 30mm ID. Long suction lines should be

avoided where possible.

Maximum daily water requirement in summer, or the driest season.

Items that are provided with all pump sales (NZ & International):1.1.2.

React pump with pressure limit control

Thick rubber vermin guard

Inlet and outlet fittings (final pipe outlet fitting rated up to 16 Bar, > 16 bar threaded

connector to pipe fitting not supplied)

Non-return valve for supply pipe to storage tank

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 14

Foot valve, pipe clamp, stainless mesh filter cage to go inside filter bag & 2x filter bags

7 x pairs of Slocable brand MC4 matching connectors

1 x pair of twin Slocable parallel connectors (for up to 4 panels –2 strings)

1 x 30 amp DC switch with MC4 Slocable connectors

Stainless steel & ACP fairing with securing strap

Optional extras are:

High Head Upgrade - High Power PMA & stainless steel inlet and outlet fittings for heads

>16 Bar (> 16 bar threaded connector to pipe ting not supplied)

25mm ID clear suction hose

Slocable connector and fuse upgrade kit (for up to 6 panels –3 strings)

We can also supply as needed:

Fixing kit (50mm SS Tek Screws x4)

Float switch

Additional MC4 connectors

15 amp MC4 inline fuse (often needed if > 2 x PV arrays are installed)

Spare foot valve

KWhr meter

Flow meter

Seal service kit and valve set (x6)

Plunger ceramic liner set (x3)

Wet side seal kit

Oil side seal kit

Complete React pump seal/valve service kit

System design service

For New Zealand Customers we can also supply:

PV array sized to suit

1080W PV array and one MC4 2-1 branch connector set

1620WPV array and one MC4 3-1 branch connector set

Red solar PV wire

Black solar PV wire

PV panel aluminium racking

Installation service (within 2 hours drive of New Plymouth ask us for a quote)

Note: Some items above may be provided by a local dealer/supplier/installer in your country

or you can source them yourself. Many will be available on our website at the time of

purchase for an additional charge.

Note1Nominally based of 270W pairs. Panels in the range 250-325W are also acceptable

refer to 12.1.1.

Note2PV panel ratings tend to increase by 5W/per year for the same size. The best price

panel today (2019) is likely to be 280W. Last year it was 270W. This manual and

examples herein mainly refer to 270W panel examples.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 15

1.2. Pump serial numbers

All React pumps have identification plates and serial numbers. We use the same plate as on

our hydro turbines.

For example:

You might see Serial number: 00235 as the serial number. This means you have number

235 made. Write the serial number in your records, as from this number we can locate when

it was made, when it was sold, to whom, software version etc.

If you ever need to query an installation or order spares for a product, take a picture of the

identification plate and forward it with your query.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 16

1.3. Safety

The following safety warning signs are used throughout this manual.

Caution

Risk of electric shock. On this Solar ELV (extra low voltage) pump system

electric shock is very unlikely if these instructions are followed. All voltages

are ELV if the solar panels are correctly connected together. Incorrect

connection of >3 solar PV panels is LV (over 120VDC) and can result in

electrocution (and/or damage to the React pump speed controller).

Caution

Cautions identify conditions or practices that could result in damage to

equipment, fire, or personal injury, other than by electric shock.

EcoInnovation will not be liable if you connect this equipment incorrectly and in doing harm

yourself, harm others, cause a grass/bush fire or damage other equipment in your system.

This section addresses safety concerns as required by international standards and accepted

best practices.

If you are not technically competent, experienced and qualified you should not install this

equipment until after you have read this manual and watched all relevant videos provided.

Our INDEX provides links to the most recent version of all these documents/videos.

Equipment can be installed or operated in such a manner that hazardous

conditions can occur; compliance with this manual does not by itself assure a

100% safe installation. If the equipment is properly selected and correctly

installed and operated according to this manual, then any such hazards will be

minimized.

Rotational Machinery Safety1.3.1.

The PowerSpout React pump is rotating equipment and is provided with a

stainless steel protective enclosure. There are rotational hazards present if the

protective enclosure is removed. The React pump must be turned off at the DC

switch(s) prior to removing the protective enclosure. It is also possible to turn off

the React pump (if the PV array is distant) using the "ignition switch" which is located inside

the protective enclosure (on the end of the microprocessor enclosure). This can be also

wired to an external switch if required.

Note: a React pump can start rotating without warning if the DC switch is on and the

microprocessor switch is on.

Once the React pump has been commissioned, the protective enclosure needs to be

fastened in place with the latching tie-down provided.

The installer should ensure that the React pump is mounted such that

inquisitive children are not exposed to a rotational machine hazard.

Note: Direction of rotation is best anti-clockwise when looking on the electric motor end, this

direction provides slightly better lubrication on the plunger guide surfaces when run anti-

clockwise. For a full explanation view this video.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 17

Pressurised Water Safety1.3.2.

In some countries, legislation covering pressurised pipes applies for pipe

pressures over 10 bar (100m head). The PowerSpout React pump often

operates at more than 10 bar. It is capable of pumping to 30+ bar (300m head).

Check with your local authority if you have any legal requirement that may

concern this installation in your country.

Generally there is little risk at less than 10 bar pressure. The biggest risk is insecurely

fastened pipe joiners that blow off, with the free end of the pipe hitting people. Securing the

pipe at regular intervals, particularly near the joins, and checking all joiners are tight and that

the pipe's pressure rating exceeds the pumping pressure will eliminate such risks.

Fire Safety1.3.3.

Solar pumping is often done in very dry parts of the world. In tinder-dry conditions the risk of

fire can be extreme. These manual instructions comply

with AUS/NZS 5033:2012 and AS/NZS 4509.1:2009, as

such if installed as per this document the installation

meets the requirements in NZ and Australia for ELV

systems. Not all countries have the same rules and in

many countries the rules are not clearly defined. Check

with your local electrician and fire department if you are

unsure of the rules in your country. Also call your

insurance company to check that your cover meets your

needs in this regard.

Warning: if you do not comply with standards/codes and

laws in your own country then your fire insurance may not be valid and if your inadequate

installation of this React pump were to cause a fire you could be personally liable for any

damaged caused.

The electronics in the React pump are contained in a metal enclosure to reduce the

fire risk.

The smart drive motor (stator and rotor) are made from fire resistant UL listed plastic

and are the same parts used in Whirlpool washing machines.

The pump outer casing is a metal skin. This product does contain a small amount of

combustible plastic material.

Where the risk of a grass or forest fire is real in your area, the following

measures shall be taken:

Mount the React pump on a concrete base at least 1m square.

Ensure the React pump is shaded if exposed to high summer temperatures. The

BLDC motor and pump do need cooling airflow. Provide shade but do not enclose it.

In pontoon applications (see pontoon section) no additional fire protection is needed).

Assessing the fire risk is the owner/installers responsibility:

The precautions required are the same as for petrol/diesel water pumps, which

have a high fire potential due to their liquid fuel and high exhaust temperatures.

The risk is small but the consequences can be very high, so please take the time

to ensure that your installation is fire safe.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 18

Electrical Safety: ELV Wiring rules specific to NZ and Australia1.3.4.

Two definitions exist in NZ for ELV ("extra low voltage"):

Any voltage normally not exceeding 50 volts AC or 120 volts ripple-free DC

Any voltage not exceeding 50 volts AC or 120 volts ripple-free DC

AS/NZS5033 also defines “ripple free DC” as:

1.4.62 Ripple-free D.C.

For sinusoidal ripple voltage, a ripple content not exceeding 10% r.m.s.

NOTE: The maximum peak value does not exceed 140 V for a nominal 120 V ripple-

free d.c. system

All extra low voltage wiring should be performed by a 'competent' person, defined by

NZS4509.1 as:

"a person who has acquired through training, qualifications, experience or a

combination of these, knowledge and skill enabling that person to correctly perform

the task required"

Note –even with a reduced shock hazard there is danger of fire from

incorrectly installed ELV wiring systems. Note the word “should”is

advised (best practice) and not a legal requirement in NZ. ELV work in NZ

is classified as “non prescribed electrical work”. So you cannot break the

law as the law does not apply to this work, nevertheless you can be liable

for the consequences of improper installation practice. Do a quality job and seek paid

assistance if/as required.

This document and supporting videos are sufficient training and knowledge to enable a

capable owner/installer to perform the tasks required. If you feel you are not capable and do

not have the time to fully read and view our installation material (to become capable and

competent) then engage the services of an Electrician or Renewable Energy

Installer/Technician.

Wiring is simple. You will need to attach MC4 connectors from the Solar PV DC switch box

to the pump as the wire length/size will vary from site to site. All that is required is for the

installer to plug together the waterproof connectors (in the correct sequence) and secure the

wiring as per our supporting videos. If using three or more strings of solar panels you should

determine whether there is also a need for string fuses in the design. (See 3.2.3)

Installation Safety Checklist1.3.5.

The installation shall be carried out by installers, owners or contracted persons with relevant

experience and good practical skills relating to general water reticulation systems and ELV

electrical systems.

To meet good working practices and safety requirements for this installation, the installer

must:

GENERAL

Check for any transit damage to the product prior to installing it. If damaged it must

not be installed.

Connect equipment to a high standard to relevant good practices and standards.

Read and comply with this installation manual and supporting videos.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 19

PIPES

Ensure both the suction pipe and the tank supply pipe are of the correct size.

Undersized pipes will reduce React pump performance and can result in pressure

blowouts and failure of the React pump to operate. There is a section later in this

document to assist with pipe sizing.

Do not confuse pipe ID with pipe OD when purchasing pipe.

Use standard LDPE, MDPE or HDPE pipes. The pipes must withstand the maximum

total pressure to which they are subjected. A safety margin is already included in the

pipe rating, this safety margin allows the pressure stop switch to operate without

rupturing the pipe. If you skimp on the pipe cost by installing 12 bar pipe when you

have 160m of head, the lower section of the pipe will likely rupture on a hot day once

the tanks is full - you have been warned.

In hot dry climates where the pipe lays on the ground the pressure rating must

be reduced to allow for the maximum temperatures. Burying the pipe protect

the pipe from physical damage, heat (pressure derating) and cold (damage due

to freezing). If necessary bury the pipe to protect it against heat, stock damage, rock

falls, tree falls, slips, avalanches, freezing etc.

PLUMBING WORK

Tighten all water connections with appropriate sealing tapes or compounds to ensure

connections do not leak.

Provide a suitable disconnection point fitted with a non-return valve close to the

React pump so that it can be easily removed for servicing.

The React pump includes a digital pressure sensor that monitors the pressure and

will turn off the pump when a set pressure is reached. The pump will stop if is detects

a pressure above 300m, this can be easily adjusted downwards or reset (a reset

returns default to 300m).

INSTALLING YOUR REACT PUMP

Make sure that you install the React Pump such that it will not be exposed to freezing

temperatures which may damage it. If the React Pump is only to be used from Spring

to Autumn to provide stock water for hill top gazing, then no extra freezing protection

may be needed, provided the React pump is removed to a dry/warm store for the

winter. Carefully read section 8.3.5 before you decide how best to install your React

pump.

COMMISSIONING

Securely fix the pump base prior to operation, at least 300mm above ground level to

allow for pipe and wire connection that enter via the underside.

Ensure:

Rodents cannot get access inside the pump.

Grass and other vegetation are prevented from growing into the pump via the

cooling vents. Cover the ground with corrugated steel or concrete to prevent

plant growth if required. Plant growth can be a significant fire hazard.

Do not run the pump without first adding oil. Each pump has been tested at our

factory, this testing oil is drained out prior to freighting.

Fill the pump body with clean SAE15W/40 (see section 8.6) to the top of the oil

level indicator glass. Oil level should never be less than the middle of the level

glass. A little higher than the top of the level glass is OK.

Do not intentionally run the pump without the water supply connected for more than

10s. Water is needed to cool and lubricate the ceramic plungers.

Do not run the pump at a supply head above 160 or 300m (depend on option

purchased).

To turn on the pump you must ensure:

Solar panel switch is on.

If pump fails to rotate check sunlight is on panels and that the microprocessor

switch is on.

PowerSpout React Pump Installation

© 2019 EcoInnovation Ltd (NZ) V2.1 Page 20

Any float switch connected to the “float switch” connections is on.

Wiring has been done correctly.

MC4 plug connectors have been pushed fully home (this is a common error).

In a pump runaway situation (where the high pressure output pipe bursts) turn off the DC

switch to stop the React pump.

If you start the pump against a closed valve this will stall the pump. (You may also burst

your pipe or fitting.) It may also go into sleep mode as it thinks your water tank is full.

Turn off the solar power at the switch and wait 30s. Open the valve, turn the switch back

on and it will run fine.

Check for excessive noise. There should be little/modest noise from the pump. Get

familiar with what your React pump normally sounds like.

Check water is being pumped at the expected rate for the sunlight conditions.

Ensure that all protective fairing/enclosures are locked in position after commissioning.

Complete sensible signage requirements to help with pump maintenance and as

required for AS/NZ 5033 compliance.

Complete all documentation and take picture of your installation and the serial number

identification plate.

Make relevant notes in the manuals that will be of assistance to yourself and any future

service personnel.

If installing the React pump for a client then all of the above must be completed before

client handover.

Train the client/user of the pump in routine care and maintenance of the React pump and

general solar system.

SERVICING

Keep the React Pump packaging and red oil transport cap. If you ever need to return the

pump under warranty or for factory service you will need to: drain out oil, fit red oil

transport cap and repackage for freight in a similar manner to which it was received.

Hold is stock a complete spare parts kit, spare suction hose, spare foot valve, spare foot

valve filter sock, spare SAE 15W40 oil.

Check oil level and ensure level is always close to the top of the sight glass. If oil level is

allowed to fall below the bottom of the sight glass serious damage may result.

1.4. CE and FCC Declaration

Refer to PowerSpout Document INDEX for compliance declaration documentation.

The React pump pump contains electrical or electronic components.

The React pump will be tested for radiated emissions as soon as practically possible.

The fact that the BLDC driver and Smart Drive BLDC motor are mass-produced & globally

available means that it is likely that they already comply. We will provide an EMC lab test

report in due course. Once tested the certificate can be located in our INDEX.

1.5. Standards and certification

All PowerSpout pumps have been evaluated against the relevant sections of major

international standards in regard to rotational machine safety and the restriction on the use

of hazardous materials in the manufacture of the React pump.

The React pump has a metal casing and meets product safety, impact durability and freight

drop test requirements.

Refer to PowerSpout Document INDEX for more information.

Table of contents

Popular Water Pump manuals by other brands

Nordson

Nordson Tribomatic 635598 instruction sheet

Strend Pro

Strend Pro SPA 350 instruction manual

Oase

Oase Aquamax Dry 6000 operating instructions

Greencut

Greencut BAS130C instruction manual

Bell and Gossett

Bell and Gossett NRF-25 Installation, operation & service instructions

Jebao

Jebao DCP-2500 owner's manual

Textron

Textron Klauke EHP 3 Instruction and maintenance manual

K2 Pumps

K2 Pumps Contractor Series owner's manual

SFA

SFA SANIPUDDLE Operating & installation manual

Suez

Suez tonkaflo AS8000 series Installation, operation and maintanance manual

Novacom

Novacom POMPE 90 Series instructions

IPT

IPT ER 1134Y Operation and maintenance manual