Ecom ECP2050 User manual

ECP2050

ECOM spol. s r.o., Trebonicka 239, 252 19 Chrastany u Prahy, Czech Republic

IČO: 411 92 192, DIČ: CZ411 92 192

User´s Guide

ECP2050

PREPARATIVE HPLC PUMP

ECP2050

2 / 64

Document properties

File:

Manual-ECP2050-en-03.doc

Number of pages:

64

File size:

6448 kB

Last save:

8/5/2021 8:48:00 AM Kateřina Kněžourková

Ver.

Date

Author

Approved by

Description

00

26.06.2019

Kateřina Kněžourková

Jaroslav Formánek

First issue.

00

05.11.2019

Dominika Pavlová

Jaroslav Formánek

Address change in the footage of the first

page, the in chapters 13 and 15.

01

08.04.2020

Dominika Pavlová

Jaroslav Formánek

Declaration of Conformity update in chapter

15.

02

11.12.2020

Kateřina Kněžourková

Jakub Hodaň

Change of port value in chapter 6.4.1.

03

05.08.2021

Kateřina Kněžourková

Jakub Hodaň

Update in chapter 6.4.3.

Related documents

Manual-Ethernet_devices

ECP2050

3 / 64

CONTENT:

1. GENERAL INFORMATION....................................................................................................6

1.1. Product Function................................................................................................................................6

1.2. Product Version..................................................................................................................................6

1.3. Accessories ........................................................................................................................................6

2. GENERAL OPERATING INSTRUCTIONS ................................................................................8

2.1. Safety Symbols on the Unit...............................................................................................................8

3. DESCRIPTION...................................................................................................................9

4. INSTALLATION AND FIRST START.....................................................................................11

4.1. Inlet Tubing Connection ..................................................................................................................11

4.2. Outlet Capillary Connection ............................................................................................................11

4.3. Injector Holder and Column Holder Mounting...............................................................................12

4.4. Injection Valve Mounting .................................................................................................................12

4.5. Piston Backwash..............................................................................................................................13

4.5.1. Simple Manual Use ....................................................................................................................14

4.5.2. Automatic Backwash..................................................................................................................14

4.6. Assemblage of Waste System ........................................................................................................15

4.7. Connection on Unit Rear Panel.......................................................................................................16

4.8. Start of Unit.......................................................................................................................................17

4.9. Basic Control by Keyboard .............................................................................................................18

4.10. Pump Initiation................................................................................................................................18

4.11. Description of Symbol on the Screen ..........................................................................................19

4.12. Door Installation .............................................................................................................................20

5. CONTROL FROM PC........................................................................................................ 20

6. WORKING WITH MENU ....................................................................................................21

6.1. Parameters........................................................................................................................................21

6.1.1. Flow Rate ...................................................................................................................................21

6.1.2. Pressure Limits...........................................................................................................................21

6.1.3. Concentration.............................................................................................................................22

6.1.4. Solvents Volume ........................................................................................................................22

6.2. Preferences.......................................................................................................................................22

6.2.1. General.......................................................................................................................................22

6.2.2. Purge..........................................................................................................................................23

6.2.3. Gradient......................................................................................................................................23

6.2.4. Compensation ............................................................................................................................24

6.2.5. Solvents......................................................................................................................................25

6.2.6. Log. Level...................................................................................................................................25

6.2.7. Leakage......................................................................................................................................25

ECP2050

4 / 64

6.3. Control...............................................................................................................................................25

6.3.1. Start Compensation Learning.....................................................................................................26

6.3.2. Gradient Program.......................................................................................................................27

6.3.3. Init/Stop/Reinit Program .............................................................................................................32

6.3.4. Program Setup ...........................................................................................................................32

6.3.5. Open/Close Gradient Valves......................................................................................................39

6.4. IO Config............................................................................................................................................39

6.4.1. Ethernet......................................................................................................................................39

6.4.2. Remote Keylock .........................................................................................................................40

6.4.3. Interface......................................................................................................................................41

6.5. Info.....................................................................................................................................................43

6.5.1. Device.........................................................................................................................................43

6.5.2. Boards........................................................................................................................................43

6.5.3. Ethernet......................................................................................................................................44

6.5.4. User Text....................................................................................................................................44

6.5.5. Pump..........................................................................................................................................44

6.5.6. Parts ...........................................................................................................................................44

6.6. Diagnostics .......................................................................................................................................44

6.6.1. Errors..........................................................................................................................................44

6.6.2. Warnings ....................................................................................................................................45

6.6.3. Power .........................................................................................................................................45

6.6.4. Cooling .......................................................................................................................................45

6.6.5. Interface......................................................................................................................................45

6.6.6. Leakage State ............................................................................................................................45

6.6.7. Pump..........................................................................................................................................46

6.6.8. Solvents......................................................................................................................................46

6.6.9. Pulsation.....................................................................................................................................46

6.6.10. Gradient State ..........................................................................................................................47

6.7. Service...............................................................................................................................................47

6.7.1. Parts Replacement.....................................................................................................................48

6.7.2. Calibrations.................................................................................................................................52

6.7.3. Factory Settings .........................................................................................................................55

6.7.4. Special........................................................................................................................................56

7. WORKING MODES ..........................................................................................................56

8. RS232..........................................................................................................................56

9. REPLACEMENT OF LINE FUSE..........................................................................................57

10. TROUBLESHOOTING......................................................................................................57

11. MAINTENANCE .............................................................................................................60

11.1. Periods.............................................................................................................................................60

11.2. Cleaning and Decontamination.....................................................................................................60

ECP2050

5 / 64

11.3. Cleaning Check Valves ..................................................................................................................60

11.4. Storage and Transport...................................................................................................................60

12. SPARE PARTS..............................................................................................................61

13. WARRANTY AND POST-WARRANTY REPAIRS..................................................................62

14. TECHNICAL PARAMETERS .............................................................................................63

15. APPENDIX 1–DECLARATION OF COMFORMITY ...............................................................64

ECP2050

6 / 64

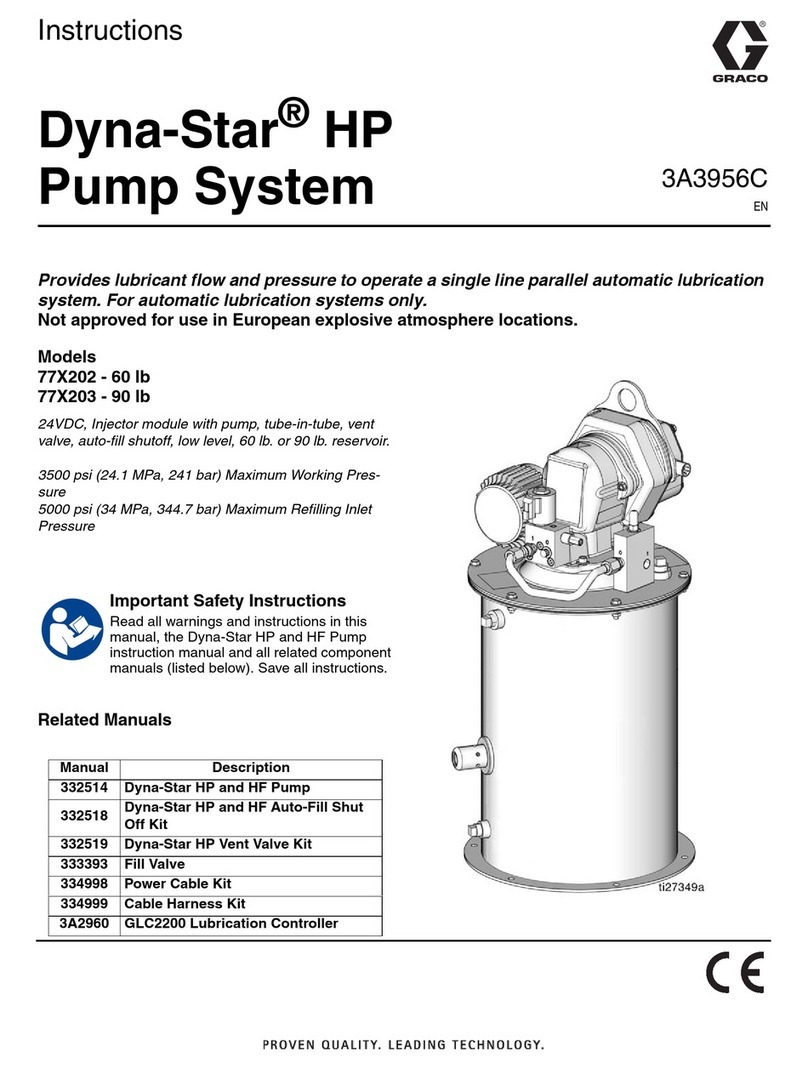

1. GENERAL INFORMATION

This unit is designed for use in laboratories in systems of liquid chromatography as

preparative HPLC pump.

1.1. Product Function

The pump is double-acting with two pumping blocks which are connected in parallel. Both

pumping heads are equipped with inlet and outlet valve. Smooth flow of mobile phase is ensured

by suitable shape of driving cams, achieving steady run of ceramic pistons pumping in back

pressure and also by precise control of motor rotation. The pump works independently as

isocratic. Together with unit Gradient box without degasser ECB2007, ECB2007PC, supplied

separately, works also as a gradient pump. If the box is disconnected, the unit informs about its

disconnection. When entering menu items designated for gradient mode (e.g.

Menu/Parameters/Concentration) and pump is isocratic mode, unit informs too.

1.2. Product Version

ECP2050 Preparative HPLC pump Cat. No.: ACC0000X

1.3. Accessories

BASIC ACCESSORIES

P/N

Qty.

Picture

Description

EKAB-011

1

Mains cable 10A-250V 2 m

00343122

1

Tube fuse T –3,15A/250V, CSA

(main unit fuse; for combined power socket with main switch and main

fuse)

23987000

1

Tube fuse T - 6,3A/250V, CSA

(internal fuse for professional service; mustn’t be used as main fuse

!!!)

EKAB-040

1

LAN cable 1 m

(to connector ETHERNET)

00051478

1

Terminal block 8 pins green

(for connector IO INTERFACE)

18331000

1

Screwdriver Torx T20

(for mounting injector holder, mounting heads during seals

replacement)

E1132890

1

Open End Wrench 1/4-5/16"

(for metal through bolts on capillaries, for mounting valve holders)

PN000080

1

Waste tubing bypass 3/32"

(from by-pass valve to waste system)

ECP2050

7 / 64

P/N

Qty.

Picture

Description

ACA99012

1

Injector holder Series 2000

ACC99400

1

Capillary injector-column 1mm with fittings

(OD=1/16“ ; ID=1mm ; l=300mm ; volume=236µL ; thread 10-32 UNF)

ACC99300

1

Outlet capillary to injector 1mm with fittings

(OD=1/16“ ; ID=1mm ; l=300mm ; volume=236µL ; thread 10-32 UNF)

ACC16001

1

FEP tubing 1/8“ 1000 mm with filter 20um with lid

(FEP tubing, ID=1/16“, volume=1986 µL only tubing, PEEK screw 1/8“

, KEL-F ferrule 1/8“, thread ¼“-28 UNF, PP lid on tray GL45 with PA

plug with tubing holes, PE filter, PEEK screw 1/8“ , KEL-F ferrule 1/8“)

ACA99700

1

Piston back washing set

ACA99000

1

Waste set ECP2010

00016000

1

Door 2000

(To be installed after complete installation of the unit! Never

manipulate with the unit, if the door is mounted!)

DOC00001

1

-

User’s guide

DOC00002

1

-

Production protocol

Spare parts and selectable accessories see 12.

ECP2050

8 / 64

2. GENERAL OPERATING INSTRUCTIONS

Caution: If the unit is used in a manner not specified by the manufacturer, the

protection provided by the unit may be impaired!

Caution: The unit may not be used, if it is leaking.

Caution: Do not place unit or any other equipment so that disconnecting power cord

is difficult.

Caution: Never manipulate with the unit, if the door is mounted. There is a danger of

its damage.

Caution: Never dismount unit cover. There is nothing needing customer service or

maintenance.

Caution: The pump is filled with isopropanol after production or service.

Caution: When using buffers or other crystalizing agents in mobile phases, piston

back washing must be done.

Caution: The pump and box must be calibrated together, see Production protocol.

2.1. Safety Symbols on the Unit

Caution, electrical device! Disconnect power cord before servicing.

Electrical device! Disconnect power cord before servicing. Read the

operation guide before replacing fuse!

ECP2050

9 / 64

3. DESCRIPTION

FRONT VIEW

No.

Description

1

Front switch.

2

Keyboard.

3a

Connection for input tubing (pump inlet) –working block with pumping and washing

head (behind the pumping head).

3b

Connection for output capillary (pump outlet).

4

Washing/degassing (bypass) valve –compensating block with pumping and washing

head.

5

Leakage sensor.

6

Drain channel with cone for connecting waste system.

7

Door hinges.

8

Slots for tubing and capillaries.

9

Display.

10

Status LED:

PUMP (green) for indication of pump motor status (PUMP and PURGE).

RMT (yellow) for indication of unit remote control status. If it is on, the unit

communicates through ETHERNET or RS232 interface.

ERR (red) for indication of unit error status. If it is on, there is an error indicated, if it

blinks, there is a fatal error indicated and unit status has changed.

ECP2050

10 / 64

KEYBOARD BUTTONS AND THEIR FUNCTION

Symbol

Description

MENU

Entering unit menu, fast menu leaving.

PUMP

Pump start/stop and other functions when working with gradient program

(see 6.3.2).

FLOW

Direct setting of pump flowrate.

PURGE

Entering purge mode.

ENTER

Confirms selected MENU item, confirms newly set parameter value,

evokes QUICK DIAGNOSTICS screen.

ESC

Returns one step back without saving changes.

“B“, “ D“, “

A“, “C“

Direction keys.

Using arrows up/down increases/decreases value of set parameter.

A, B, C, D –direct choice of mobile phase valve.

D –starts gradient program.

MENU

Entering unit menu, fast menu leaving.

REAR VIEW

No.

Description

1

Combined power socket with main switch and main fuse.

2

Connector for adding box.

3

Connector for external start.

4

Connector IO Interface.

5

Connector Ethernet/LAN.

6

Connector USB.

7

Connector RS232.

ECP2050

11 / 64

4. INSTALLATION AND FIRST START

Place the unit in a suitable location that satisfies the following conditions:

•Horizontal place.

•Keep at least 10 cm space behind the rear of the unit.

•Keep away from equipment generating strong magnetic field.

•Equipment is intended for use in regular laboratory environment only - see Technical

parameters –operating environment conditions.

4.1. Inlet Tubing Connection

For connecting pump in isocratic mode, use inlet tubing with lid, filter, screw and ferrule

(ACC16001) from supplied accessories. For gradient mode connection is supplied inlet tubing

(ABD21000), which is among accessories of the box.

At first unscrew the white cap on pump inlet.

Caution: The pump is filled with isopropanol after construction or service.

Isocratic connection of pump

inlet

Connect inlet tubing with filter.

Snap the tubing to the socket for

tubing and capillaries.

Set of inlet tubing with a lid and

filter (picture on the right).

Gradient connection of pump

inlet

Connect inlet tubing. Connect the

other end to the box.

Tubing is fixed into the upper

socket for tubing and capillaries.

Note: The upper and side sockets in the unit front panel are determined for gripping

tubing and capillaries. FEP tubing with outer diameter 1/8“ are fixed by snapping

into the slot. Capillaries and tubing with outer diameter 1/16“ are fixed using a

short FEP tubing with outer diameter 1/8“ and inner diameter 1/16“, threaded on

the capillary. Such a threaded tubing cannot be snapped in the slot, it should be

pushed in from the side.

4.2. Outlet Capillary Connection

To connect the pump to injector, use outlet capillary (ACC99300). For connecting pump to

column, use outlet capillary (ACC99400).

ECP2050

12 / 64

Connect outlet capillary.

Tighten capillary nut with side

wrench 1/4"

Connect the other end of capillary

to injector valve.

4.3. Injector Holder and Column Holder Mounting

Use Torx screwdriver TX20 to

unscrew two screws in front part of

the right panel of the unit.

Use the unscrewed screws to

mount the injector holder,

according to the picture.

4.4. Injection Valve Mounting

Injection valve is not a part of pump accessories, neither a part of the entire system

accessories and shall be ordered separately.

The injection valve holder is constructed for mounting two different types of valves and with

hole for outlet capillary from pump to injection valve –Rheodyne and Vici type. The difference is in

spacing of holes for mounting the valve, see picture below.

Spacing 25.4 mm is designed for injection valve

Rheodyne.

Spacing 27.5 mm is designed for injection valve

Vici.

Spacing 12.5 mm is designed for outlet capillary

from pump to injection valve.

All diameters are in millimeters (mm).

Injection valve Rheodyne is

mounted to the holder with two

screws using allen/imbus key.

Usually it is among the injection

valve accessories.

ECP2050

13 / 64

Handle of injection valve is

mounted with two imbus worms,

using imbus key 2 mm.

The cable is connected to

connector START on unit rear

panel.

Injection valve Vici is mounted to

the holder with two screws

M4 x 6 mm instead of original

M4 x 10 mm, using imbus key

3 mm. Screws and imbus key are

among the injection valve

accessories if it is ordered in

Ecom spol. s r.o.

Handle of injection valve is

mounted by snapping into the

valve body.

Put the cable through the window

and connect to connector START

or IO Interface connector on unit

rear panel. Make configuration

(see. 6.4.3).

4.5. Piston Backwash

Caution: If you are using puffers or other crystallizing agents in mobile phases, you

must use piston backwashing.

Each pumping block (left and right) has two heads –pumping and washing. Pumping heads

are farther from the unit. Washing heads have in upper and lower part slot with LUER cone, for

connection of piston backwash. Both heads are equipped with a seal (piston padding) and during

work with buffer solutions may buffer crystals adhering to the piston may damage the seal and

pump can start leaking.

ECP2050

14 / 64

SET PISTON BACKWASH

1. Inlet part; 1a. Luer cone for connecting to washing head; 1b. Flowrate regulator; 1c. Lid GL45 with plug;

1d. Luer cone for connecting syringe; 2. Connection of washing heads; 3. Outlet into waste system;

4. Syringe 50ml

4.5.1. Simple Manual Use

Connect both Washing heads in series using tubing and LUER adapters. Fill syringe with

HPLC water (or mobile phase dissolving buffers) and wash the heads. Washing heads are now

filled with liquid, rinsing the pistons from rear side. Now once in a while during work with the pump

push through the pump some liquid to the washing system (approx. 1x per hour 5 ml).

4.5.2. Automatic Backwash

Connect both Washing heads in series using tubing and LUER adapters. Insert tubing with

flow regulator into reservoir with HPLC water (or mobile phase dissolving buffers). Loosen the flow

regulator and suck liquid into the system using plastic syringe connected to the other end of the

system (left picture). Disconnect the syringe and place the tubing end into waste reservoir. Now the

liquid is flowing through the system by gravity (right picture). Set the flow regulator so that at the

end of the tubing escapes approx. 5-7 drops per minute.

ECP2050

15 / 64

4.6. Assemblage of Waste System

he pump is equipped with waste channel, leading the liquid off the pumping block. In its

proximity is leakage sensor. The function of the sensor is closely described in chapter 6.2.7, in

chapter 6.4.3.4 is described the setting of IO INTERFACE Digital Out Switch –LEAKAGE

signalizing the leakage of pump to another unit. In chapter 6.6.5 is displayed the status of IO

INTERFACE and in chapter 6.6.6 is shown the leakage sensor status.

WASTE SET ECP2050

1. Silicone tubing 2 m with connector Y and I; 2. Connector Y with two pieces of silicone tubing;

3. Connectors L into the drain channel.

The pump is usually a part of a system, together with other units. Connection of waste

system can be adjusted according to given system.

One possible system is pump with box. Among box accessories is T connector, one end

should be pushed into the box drain channel (see picture below). Second end should be connected

with longer tubing of part 2 (see picture above) and third end may be used i.e. for waste tubing

from injection valve.

ECP2050

16 / 64

Shorter tubing of part 2 (picture above) should

be connected between the pump and the backstop

on holder of injection valve. This tubing serves as

waste tubing from washing head, put through window

in valve holder. The opening of part 2 should be

connected with connector L, forming a 90° angel with

desktop, and is connected with one of two tubing,

connected to connector Y of part 1. This tubing

should be cut from 1 m silicon tubing part 1,

according to your needs. Second connector L is

pushed into the drain channel of pump, horizontally,

and is connected with second tubing of connector Y

of part 1. Third tubing of part 1 should be placed into

waste reservoir. Connector Y of part 1 is placed

under level of the working surface.

Caution: Replace the connector Y of part 1 at least 10 cm below the desktop.

4.7. Connection on Unit Rear Panel

Plug the power supply cord into the instrument socket on unit rear

panel. The cord is among unit accessories.

Plug the interconnecting cable between pump and box into

connector ECB2000. Cable is among box accessories.

ECP2050

17 / 64

Plug injection valve cable into START connector. Plug it all the

way in until it snaps in.

In order to unplug the connector, press the safety pin (see arrow

on right picture) and pull out.

Insert terminal block into connector INTERFACE, it is among the

pump accessories. If there is no signal connected to the terminal

block, it is not necessary to connect it.

Plug LAN network cable into connector ETHERNET, it is among

the pump accessories. Press the connector in until the safety pin

snaps in. In order to unplug the connector, press the safety pin

(see arrow on the right picture) and pull out.

The other end of network cable shall be plugged into PC or

computer network element.

Connector USB serves for plugging USB cable for interconnection

with PC.

Cable is not among the unit accessories.

Plug serial line cable into connector RS232 for interconnection with

PC.

Cable is not among the unit accessories.

4.8. Start of Unit

Use a switch on the rear panel of the unit for connecting to mains voltage, then switch on the

unit using push button on the front panel. The push button glows red, if power source is off and

green, if power source is on. If power supply is disconnected, the unit remembers last status of this

push button and after power supply reconnection it restores the last status. This can be used for

automatic start in the system with a common switch of power source for whole system of liquid

chromatograph (for example using a multiple socket-outlet with a switch).

ECP2050

18 / 64

4.9. Basic Control by Keyboard

After unit start (mode START) display shows unit

type.

Then the unit turns to mode IDD, pump motor is in

idle status.

Main screen –isocratic pump mode.

Main screen –gradient pump mode.

Gradient mode is detected automatically by cable

interconnection with a box after unit start.

4.10. Pump Initiation

The unit is filled with isopropanol, it is necessary to rinse it out and fill the system with

mobile phase and degas the entire system.

Loosen purge/degassing valve by turning it by

90°.

Slip a plastic syringe on purge/degassing valve,

the syringe (50ml) is a part of pump accessories.

In gradient mode is necessary to check, whether appropriate valve (A, B, C or D) with mobile

phase is opened. By pressing key PURGE and then pressing key PUMP is started pump washing.

Suck in the mobile phase with the plastic syringe as long as bubbles come out from the pump. It is

possible to switch the valves during washing, by pressing keys with arrows, this allows the liquid to

penetrate to all necessary channels Press key PUMP again to stop the pump washing. Tighten the

purge/degas valve and take out plastic syringe.

For repeated gas purging/degassing it is possible

to put the waste tubing on purge valve.

If waste tubing is put on purge/degas valve, it is

not possible to close the unit door.

In chapter 6.2.2 it is possible to set parameters

foe washing.

Now the flow can be set by pressing key FLOW.

Use arrows left and right to move with cursor and

arrows up and down to change value. Press

ENTER key to confirm the value, press PUMP to

start the pump. Press PUMP again to stop

ECP2050

19 / 64

the pump.

For fast setting of one of the valves to 100%, it is

possible to use arrow with the letter of the

appropriate valve. this switching is functional in

gradient mode during modes IDD, PRG a PMP

(see 7).

Note: We recommend to run and stabilize the unit before starting analyzes or

after a longer shutdown of the device at 1 ml/min, pressure 15-20 MPa for

approximately 30 min.

Note: Run the gradient pump with a 25 % concentration setting for each valve

approximately 10 min.

4.11. Description of Symbol on the Screen

Value/Symbol

Meaning

10%20%30%40%

0 ml

Actual gradient concentration for A, B, C, D.

In isocratic mode is displayed remaining mobile phase volume.

12.0-15.0

Value of low –high pressure limit in actually set pressure units.

1.00ml/min

Actual flowrate value.

13.0MPa

Actual pressure value.

IDD

Abbreviation of actual pump mode.

Actual piston position is displayed after first finished pump rotation.

During flowrate higher than ~3 ml/min actual position cannot be displayed

and this dummy symbol is shown.

Pulsation compensation status:

OFF –turned off.

FIXED –according to predefined values.

LEARNING –learning in progress.

LEARNED –according to learned values.

LEARNED OFF –compensation is turned off.

LEARNED 0 –according to learned values (from FW 5.x).

LEARNED 0 –compensation is turned off or not learned (from FW 5.x).

LEARNED 1 –according to learned values (from FW 5.x).

LEARNED 1 –compensation is turned off or not learned (from FW 5.x).

/ / / /

Gradient valve status (A, B, C, D). Only in gradient mode. During very fast

valve switching (low percentage of component and higher flowrate) it may

not manage to display valve switching.

Mark X –all valves are closed.

ECP2050

20 / 64

Value/Symbol

Meaning

Indication of leakage, at the same time may be displayed an error or

warning (according to setting).

One IO INTERFACE inputs are used for pump control.

E(1)

An error has occurred „ERROR“ (number of errors). By using key ENTER

on main screen, it is possible to enter screen QUICK DIAGNOSTICS and

see a description of all errors and warnings.

W(1)

„WARNING“ (number of warnings). By using key ENTER on main screen, it

is possible to enter screen QUICK DIAGNOSTICS and see a description

of all errors and warnings.

4.12. Door Installation

In order to prevent damage of door hinges, the door is supplied apart. The door should be

slipped on the hinges in opened position, see pictures below.

Door mounting must be easy, no strength needed, otherwise the hinges may get damaged.

Caution: Never manipulate with the unit when the door is mounted.

5. CONTROL FROM PC

During unit control from PC communication proceeds through serial line RS232, USB or

through LAN. Communication protocol can be supplied upon request.

Unit may be controlled with SW Clarity or ECOMAC.

When using program Clarity for pump control, use last upgraded program version, including

drivers for this unit. Help regarding the control of this unit can be found in installation directory of

Clarity (C:\Clarity; C:\Clarity\Bin) in file: CswEcomECP2000.chm . Double-click on the file opens it

for reading.

Table of contents

Other Ecom Water Pump manuals

Popular Water Pump manuals by other brands

Becker

Becker T 4.10 operating instructions

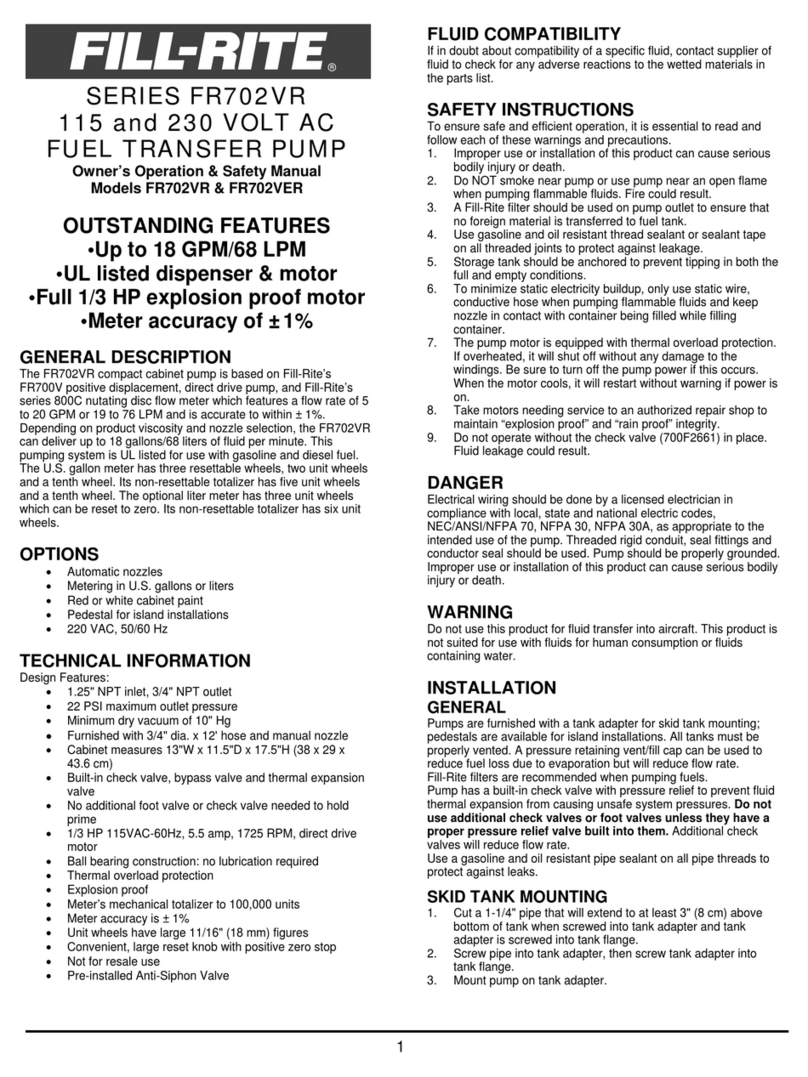

FILL-RITE

FILL-RITE FR702VR Series Owner's operation & safety manual

Pentair

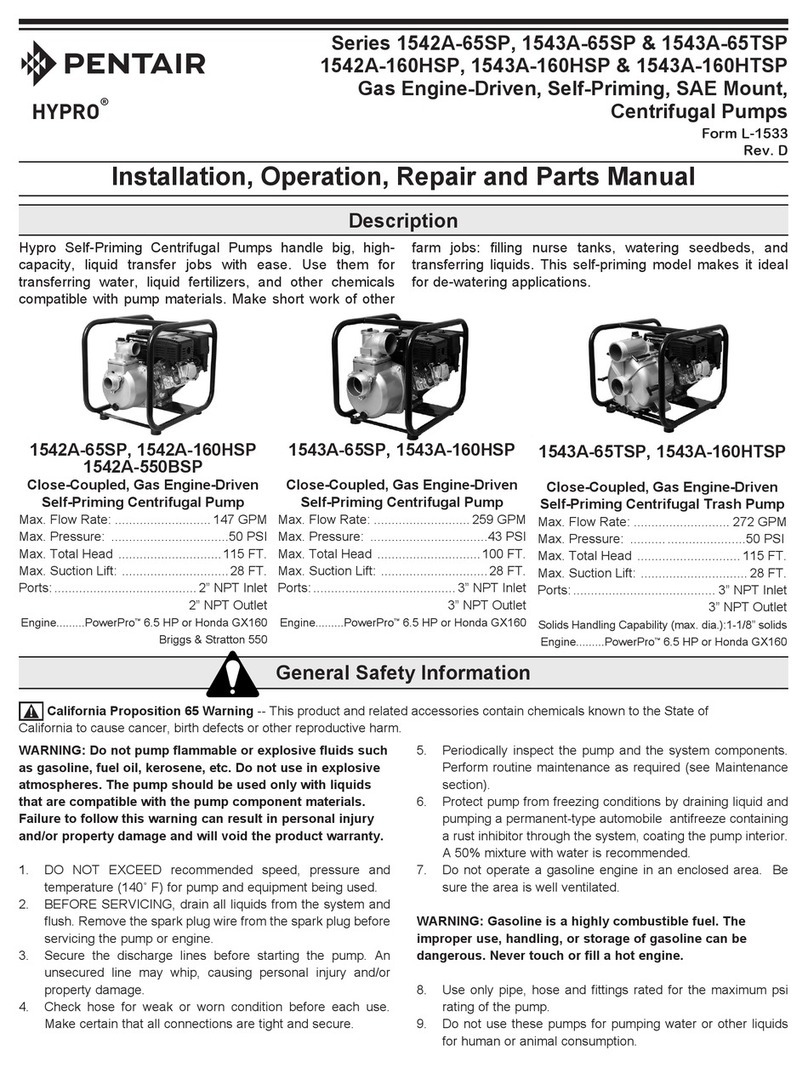

Pentair HYPRO 1542A-65SP Series Installation, operation, repair and parts manual

Meganex

Meganex MEG35211 instruction manual

VONROC

VONROC GP529AC Original instructions

Ideas at Work

Ideas at Work ROVAI Operation and maintenance manual