Econ 79652 User manual

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 1

ECON Limit Switch Box

Fig. 79652

Scan for manual

Installation & Operation Manual for Limit Switch Box: Fig. 79652

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 2

Contents Page

1. INTRODUCTION 3

2. SWITCH BOX SPECIFICATION 3

3. SWITCH TYPE SELECTION 3

4. SWITCH BOX MARKING 3

5. STANDARD FEATURES 4

6. INITIAL INSPECTION 5

7. STORAGE 5

8. INSTALLATION 5

8.1 Mounting of the Limit Switch Box 5

8.2 Setting of switch/sensor cams 6

8.3 Cam types 6

8.4 Wiring of the Limit Switch Box 6

8.4.1 Mechanical switch - 2 SPDT (Standard) 7

8.4.2 Proximity switch - P&F NBB2-V3-Z4L 7

8.4.3 Proximity switch - P&F NBB2-V3-E2 8

8.4.4 Mechanical switch - 2 SPDT with CPT, Current Position Transmitter (Optional) 8

8.5 Setting of the Current Position Transmitter unit –CPT (Optional) 9

8.5.1 Calibration of the potentiometer 9

8.5.2 Calibration of the zero span 9

9. MAINTENANCE 10

10. TROUBLE SHOOTING 10

11. TOOLS 11

12. GENERAL INSTALLATION AND MAINTENANCE TIPS 11

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 3

1INTRODUCTION

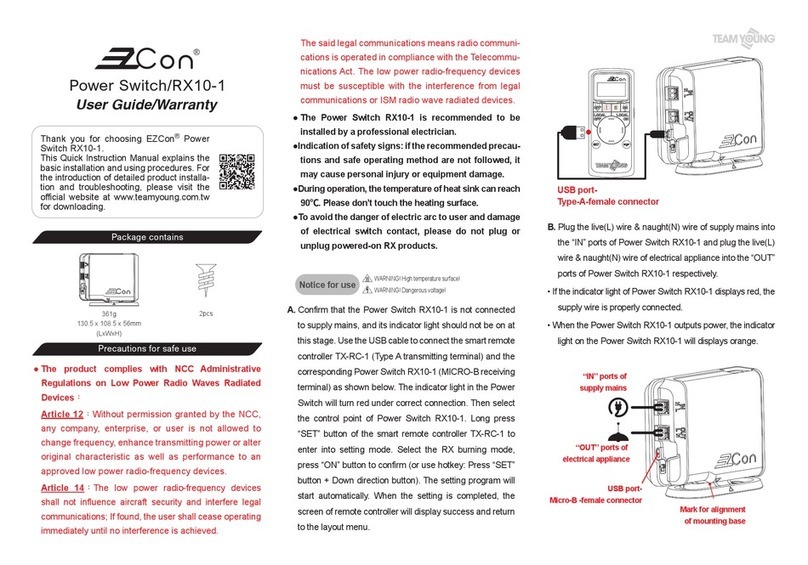

The ECON Fig. 79652 limit switch box is designed to provide accurate and reliable valve position information of

actuated valves and hand operated valves.

The Fig. 79652 limit switch box consists of an aluminium body a polycarbonate visual position indicator, quick-set

cam assemblies, terminal strip, switch assemblies and an easy mounting bracket. Quick-set cams enable rapid

manual switch adjustments. Tools are not required.

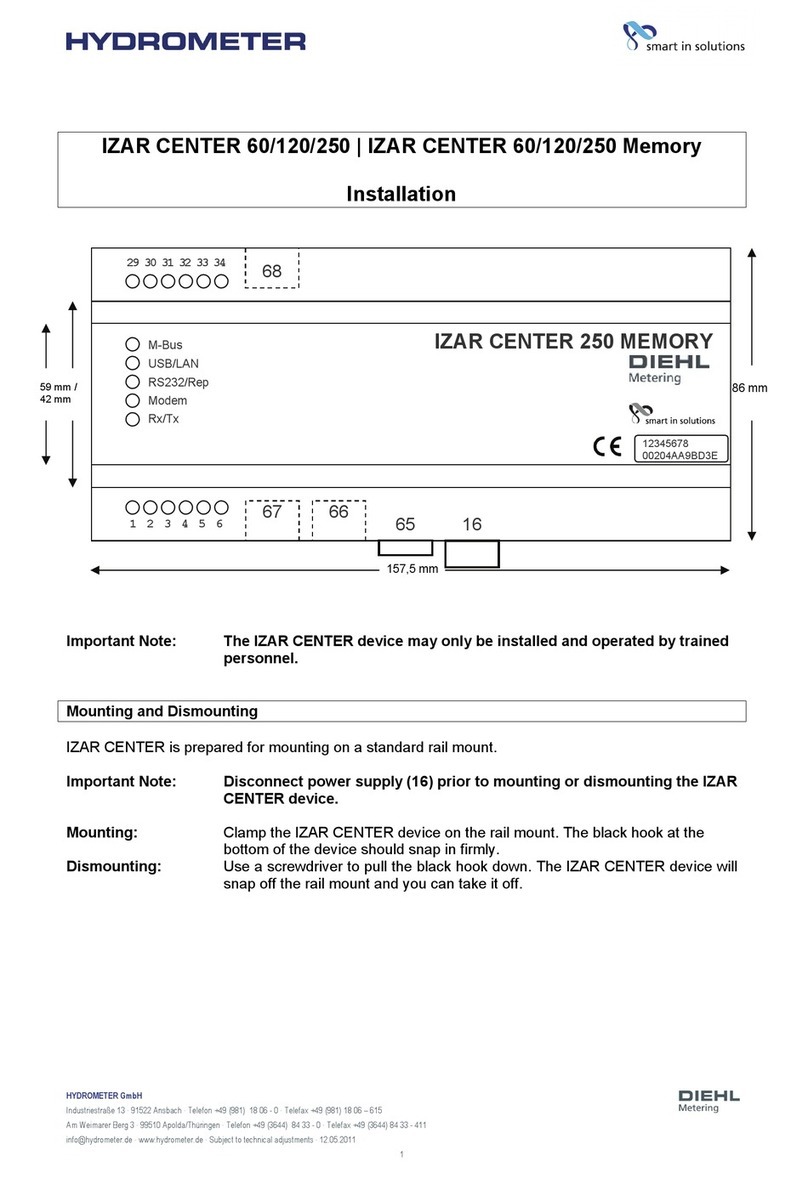

2SWITCH BOX SPECIFICATION

Model: Fig. 79652

Enclosure rating: Weather-proof IP67, NEMA 4, 4X and 6. (optional IP68, NEMA 6P)

Enclosure: High grade anodized Aluminium alloy

Ambient temperature range: -20°C (-4°F) up to +80°C (176°F)

Conduit entries: 2x M20x1,5 or 2x NPT1/2” (optional PG13,5)

Travel angle: 90° +/-10%

Visual position indicator: Open: Yellow; Close: Red. Language: English (Open / Closed)

Switch types: See chapter 3 for standard switch types

Terminal strip 8 point; 0,08-2,5mm2(optional : 9 to 14 points)

External coating: Dry powder polyester

Potentiometer (optional): 1kΩ (optional : 0~5kΩ , 0~10kΩ)

Current output signal unit (optional): 4~20mA, 20~4mA

3SWITCH TYPE SELECTION

ECON code

Position feedback devices

Switch/Sensor specification

EC79652000AMS

Micro Switch, 2-SPDT

Starion, SZM-V16-5FA-61

EC79652004AMS

Micro Switch, 4-SPDT

Starion, SZM-V16-5FA-61

EC7965200APS22

Proximity Sensor, 2-wire (minimum off-state current)

Pepperl & Fuchs, NBB2-V3-Z4L

EC79652000APS3

Proximity Sensor, 3-wire

Pepperl & Fuchs, NBB2-V3-E2

EC79652000CPT

4-20mA position transmitter (CPT) and

Micro Switch, 2-SPDT

Starion, SZM-V16-5FA-61

Other switches or sensors can be fitted upon request. Please contact your local distributer.

4SWITCH BOX MARKING

ECON-logo

Figure number (Fig.)

Switch type specification

Switch certification information

QR-code for I.O.M (Installation and Operation Manual)

Enclosure rating

EC79652000AMS & EC79652004AMS EC79652000CPT

EC7965200APS22 EC79652000APS3

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 4

5 STANDARD FEATURES

No.

Part Name

Q’ty

Description

1

Window / Indicator

1

Polycarbonate / ABS

2

Cover Captive Cover Bolt

4

Stainless steel

3

Cover

1

Aluminium Die casting

4

Name Plate

1

Sticker

5

Shaft

1

Stainless steel

6

Body

1

Aluminium Die casting

7

Terminal Strip

1

8 positions

8

Cams

2

PC

9

Switch

2

See switch type specification (chapter 3)

10

Grounding Lug

1

Stainless steel

4

2

3

1

5

6

7

8

9

10

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 5

6 INITIAL INSPECTION

Upon on the receipt of the switch box, the user should inspect the condition of the product and ensure that the

product specification stated on the name plate matches with the order sheet.

Remove the packing wrap or cardboard box carefully. Inspect the product for any physical damage that may

have occurred during shipment.

Check the product specification of the received product. If a wrong product has been supplied, please

immediately report this to the distributing company.

7 STORAGE

Limit switch boxes must be stored in a clean, cool and dry area. The unit should be stored with the cover installed

and the conduit openings sealed. Storage must be off the floor, covered with a sealed dust protector.

8 INSTALLATION

8.1 Mounting of the limit switch box

CAUTION: PREVENT INJURIES

Before installing the limit switch box on the actuator, air supply and

power supply of the pilot valve must be shut off.

ECON limit switch boxes are supplied with a mounting bracket according to the VDI/VDE 3845 (NAMUR) standard.

This standard bracket is selected for actuators with a VDI/VDE connection 30x80 mm and an actuator shaft height of

30mm. Brackets for other VDI/VDE dimensions are available upon request and are mentioned in the table below.

Available bracket sizes

ECON code

30x80mm, Height: 30 mm (standard)

EC7965X0BR80X30

30x80mm, Height: 20 mm

EC7965X0BR80X20

30x130mm, Height: 30 mm

EC7965X0BR130X30

Put the actuator in the fully open or closed position.

Mount the bracket on the switch box.

Put the switch box with bracket on the actuator and do not

tighten the bolts yet (4 pieces).

Check the actuator shaft and switch box shaft alignment

Check if the position of the open and closed switches/sensors

and also the visual position indicator corresponds with the valve position.

Tighten the bolts in order to secure the bracket to the actuator (4 pieces).

Check again if the position of the open and closed switches/sensors

and also the visual position indicator corresponds with the valve position.

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 6

8.2 Setting of switch/sensor cams

The colour of the cams corresponds with the visual position indicator. Cams can be easily set without using any tools.

ECON cams have a spline connection and can be set by lifting or pushing down the cams over the shaft . The cams

are spring loaded and therefore self-locking.

Note : Cams are pre-set by the factory for most standard applications. This setting however must always be

checked before commissioning.

Loosen the switch box cover bolts.

Remove the cover carefully.

Setting of the open-cam setting:

- Put the actuator in the fully open position.

- Lift the yellow (lower) cam and rotate it until the switch is activated.

- Release the cam and it will lock itself to the shaft.

Close cam setting

- Put the actuator in the fully closed position.

- Push the red (upper) cam down and rotate it until the switch is activated.

- Release the cam and it will lock itself to the shaft.

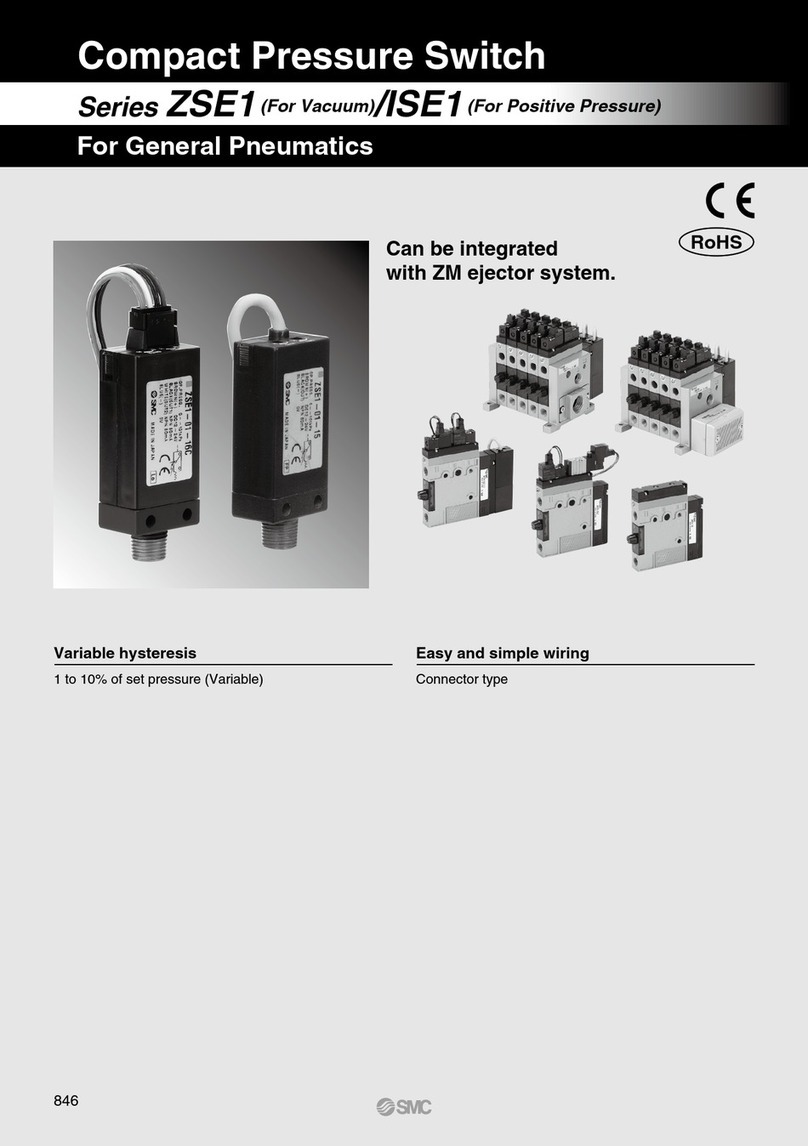

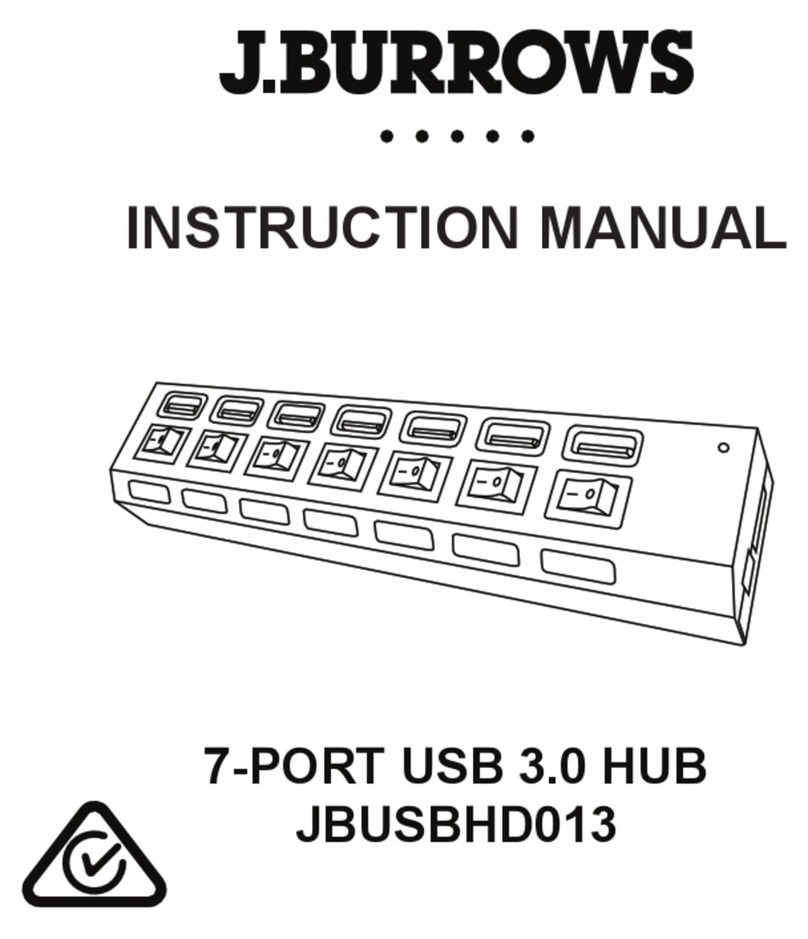

8.3 Cam types

8.4 Wiring of the limit switch box

DANGER:

HAZARDOUS VOLTAGE. Electrical power must not be connected until all

wiring and limit switch adjustments have been completed. Once the

power is supplied to the actuator, precautions must be taken if the cover

is not mounted.

Cams for mechanical switches

Cams with metal insert for

proximity sensors

Splined cam

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 7

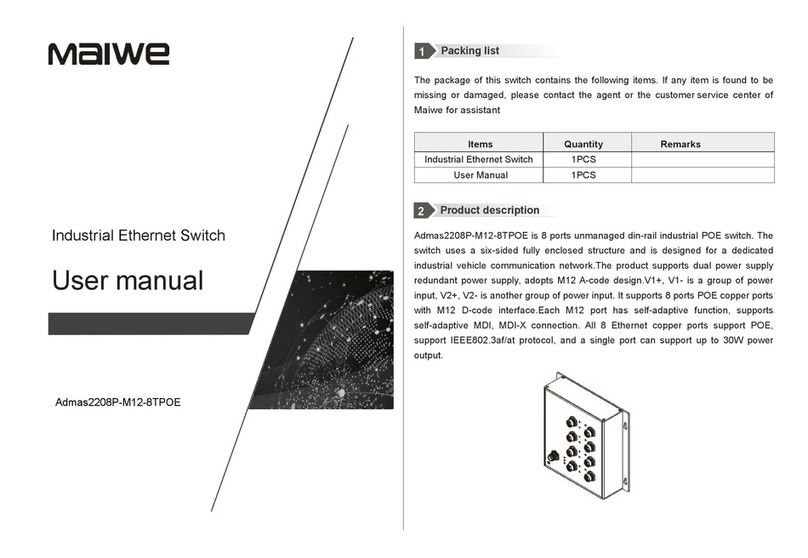

ECON limit switch boxes have prewired switches. All user connections must be made on the numbered terminal strip.

A wiring diagram, located inside the cover, indicates which terminal numbers correspond with switch contacts. Follow

the wiring diagram in order to make a correct connection to your system.

A solenoid valve may also be wired through the ECON limit switch box. Two auxiliary terminals (EXT) are included as

a standard.

ECON limit switch boxes have two cable entries and are being supplied with a blanking cap/plug. A cable gland must

be selected by the user or installer and must meet the applicable enclosure rating

8.4.1 Mechanical switch –2 SPDT (Standard)

8.4.2 Proximity switch - P&F NBB2-V3-Z4L

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 8

8.4.3 Proximity switch - P&F NBB2-V3-E2

8.4.4 Mechanical switch - 2 SPDT with CPT, Current Position Transmitter (Optional)

Note:

The limit switch box must be grounded at all times.

At least a 2 sq. mm wire is recommended for grounding.

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 9

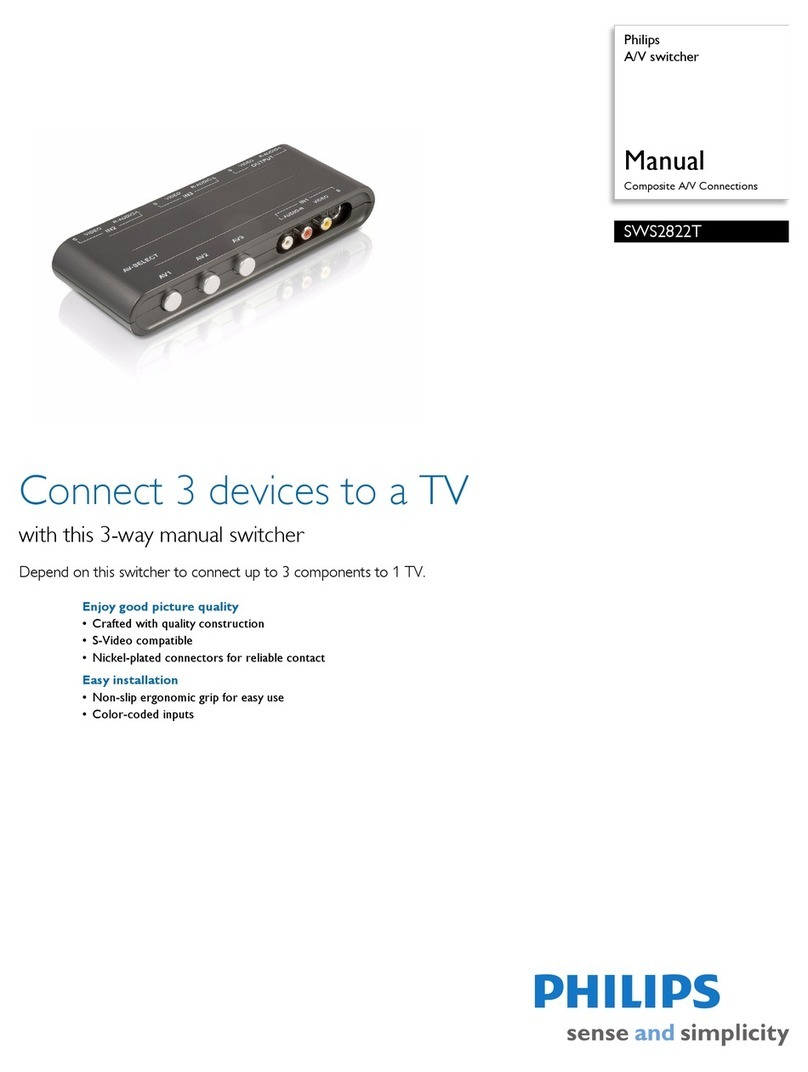

8.5 Setting of the Current Position Transmitter unit –CPT (Optional)

A potentiometer reads the current position of the actuator (valve) and transmits a resistance value to the

position transmitter PCB. The transmitter indicates the actuator (valve) position throughout the complete stroke and

converts resistance value it into a 4 to 20mA output signal.

Technical features

Power supply range: 12.5 to 37VDC (25V typical)

Current signal output: 4 to 20mA

Max. load resistance: Max. resistance (Ohm) = (Supply voltage –12.5) / 0.02

Potentiometer: 0 to 500Ω/ 10kΩ

Operation temperature: -20 to 60°C (-4°F to 140°F)

Dimension: 40 x 60 x 15mm

DC power supply

8.5.1 Calibration of the potentiometer

Operate the actuator into the closed position.

Connect an Ohm-meter to the P1 and P3 resistor. The value shall be approximately 1kΩ.

Loosen the potentiometer gear wheel from the shaft and connect the Ohm-meter to P1 and P3

and rotate the gear wheel gently until a value between 80 to 120Ωis achieved (100Ωpreferred!).

While maintaining the value, tighten and lock the gear wheel to shaft.

8.5.2 Calibration of the zero span

The zero span setting has been calibrated by manufacturer. However, if re-calibration is required, please

follow the hereunder mentioned instruction:

Operate the actuator to the middle position and thereafter to the fully closed position.

As soon as the actuator reaches the fully closed position, adjust the “zero” rotary switch on the

PCB until a value of 20mA is achieved.

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 10

9 MAINTENANCE

The ECON Fig. 79652 limit switch box is designed to provide accurate and reliable valve position signalling and

indicating of most automated valves.

WARNING:

Inspection and maintenance work must be performed by qualified and trained

personnel

When working in potentially explosive areas, the standard EN 60079-14

“Electrical Installations in Hazardous Areas” must be observed.

Work on an open limit switch box, which is under voltage, may only be

performed if there is no explosion risk.

Observe local and national regulations and legislation.

Flame proof enclosures may only be opened if there is no explosion risk.

CAUTION:

Shut-off all incoming power or air supply on the valve actuator before starting

maintenance work on the limit switch box.

Be sure that the working area is clean before disassembling the limit

switch box. Clean all parts and seals before re-assembling.

Use only genuine spare parts, which can be purchased from your local ECON

distributer.

Maintenance should be performed every six month or after every 100,000 operation cycles. In severe operation

conditions inspections must be performed more frequently. During maintenance the following parts of the limit switch

box must be inspected:

Check the alignment of the valve, actuator and limit switch box.

Check the wiring insulation and the terminal strip connections.

Check the adjustment of the cams.

Check the cams on wear and replace them if necessary.

Check if al screws are present and tightened.

Check if the cable connections are installed properly and not leaking.

Check internal devices for condensation.

Check the enclosure for damages, especially on the sealing surfaces.

Check the enclosure O-ring seals and also check if the O-ring is in the correct position.

Visually inspect the limit switch box during operation.

Inspect the type plate of the limit switch box and replace it if necessary.

10 TROUBLESHOOTING

The following instructions are offered for the most common difficulties that could be encountered during installation

and start-up.

Signal errors to main control room.

Check if the wiring of the limit switches/sensors is in accordance to the wiring diagram.

Check if the cams or switches/sensors are damaged or broken.

Check the connections on the terminal strip.

Re-set the limit switch box

Check the potentiometer gear for jamming (if present)

Check the zero and span calibration if a CPT has been installed.

Check the PCB for damages if a CPT has been installed.

Installation & Operation Manual Proven Quality since 1892

ECON Limit Switch Box Fig. 79652 www.eriks.com

Rev.0 11

11 TOOLS

For installation or maintenance the below tools may be necessary:

1 Set of metric Allen keys

1 Set of screw drivers

1 Set of metric spanners

1 Wire stripper with long nose

1 Needle nose plier

1 Multi-meter (AC, DC, Resistance)

12 GENERAL INSTALLATION AND MAINTENANCE TIPS

For any installation and maintenance work, the following should be observed:

Check the limit switch box visually. Ensure that no outside damages or changes are visible. The electric

connecting cables must be without damage and wired correctly.

Cable entries, cable glands, plugs etc. have to be checked for tightness.

Check whether Ex-connections are fastened correctly.

Take care of possible discolorations of the terminals and wires.

Check the flame path gaps of flameproof enclosures for dirt and corrosion. Since the

dimensions of all Ex gaps are strictly defined and inspected, no mechanical work shall be performed on

them.

Ensure that all enclosure seals are handled carefully and are being checked for damages. All cables and

cable entry seals have to be checked.

If defects are found during maintenance, repair measures must be taken immediately.

Sealing surfaces must not be coated.

Parts may only be exchanged by genuine parts.

Table of contents

Other Econ Switch manuals