Econo CWM Series User manual

www.econo.nl

Manual heatpump model Econo - CWM

- 2 -

Index

1.

Product introduction ....................................................................3

.1.1

Features .................................................................................................3

.1.2

Definition of specification.....................................................................4

2.

Technical data................................................................................4

.2.1

Specification parameter .........................................................................4

.2.2

The figure of working principle ............................................................6

.2.3

Figure dimension...................................................................................7

3.

Installation Instruction.................................................................6

.3.1

Installation .............................................................................................6

.3.2

Water system installation chart............................................................ 11

.3.3

Electrical diagram................................................................................12

.3.4

System test...........................................................................................14

4.

Parameter settings ..................................................................... 15

5.

Maintenance ............................................................................... 26

6. Malfunction protection and code………………………………29

- 3 -

1

Product introduction

.1.1

Features

Convenient operation

Microelectronics control, all temperature settings are set by manufacturer. System tests water

temperature and adjust water temperature automatically, all user needs to do is just to press

ON/OFF button. System finishes the other operation automatically.

Excellent performance

Adopt world famous components, and the best match of system design. Scroll compressor

with high EER and low noise. High efficient heat exchanger insures the utmost using of system

capacity. Professional air conditioner water pump insures smooth quiet operation.

Models adopting two compressors system may operate with one compressor on condition of

partial load, energy saving design.

Easy to install

The system is designed with full consideration of insuring installation as easy as possible.

Refrigerant circle is a sealed complete system finished by manufacturer. No needs for users to

connect copper pipes or refrigerant charging. Hydraulic circle of system can be connected to

hydraulic terminals by two tubes.

Operating protection

System is designed with over voltage, under voltage, over load protection to insure safe

operation. The microelectronics controller can start or switch off the machine by judging the water

temperature. If the water temperature is lower than designed water temperature, the machine will

be switch off to avoid freezing. The microelectronics controller can also supervise the status of

components. Malfunction occurred would be transmitted to the controller and displayed through

malfunction code.

Flexible applicability

Compact design. System can run at conditions high ambient temperature or low ambient

temperature with high EER.

Convenient for maintenance.

- 4 -

Suppose system is stopped by malfunction, special malfunction code will be displayed. The

cause may be found out easily.

.1.2

Definition of specification

The specification of heat pump are defined according to following rules:

C W M-15 X B

Heati ng power

Heat Source code

Company code

Desi gn code

Product t ype

Product desi gn code

Picture 1

2

Technical data

.2.1

Specification parameter

Table 1

Heat pump model CWM- 15XB

kW 15.0

Rated heating capacity kcal/h 12897

Heating power Input kW 3.2

Heating running

Current A 6.55

Sanitation

heated

water

condition

COP kW/kW 4.68

kW 11.5

Rated cooling capacity kcal/h 9872

Rated water flow

(air-condition)T/h 1.98

Equipment performance

Cooled

water

condition(a

ir-conditio

n)

Cooling power Input kW 2.5

- 5 -

Heat pump model CWM- 15XB

Cooling running

Current A 4.4

E.E.R kW/kW 4.6

kW 13Rated heating capacity

(air-condition)kcal/h 11178

Rated water flow T/h 2.23

Heating power Input kW 3.5

Heating running

current A 7.0

Heated

water

condition(a

ir-conditio

n)

COP kW/kW 3.3

kW 9.7Average cooling

capacity kcal/h 8342

Rated water flow T/h 1.7

kW 12Average heating

capacity kcal/h 10320

Average power Input kW 2.6

Average running

Current A 4.4

Alliance

for cool

and heat

conditions

Synthesis COP kW/kW 8.3

Max. Running Current A 12

Power source V/Ph/H

z 380/3N/50Hz

Compressor type Scroll

Charged refrigerant R417A 3

Connection pipe RC 32

Noise level dB(A) 60

W mm 680

D mm 1020

Dimension

H mm 770

Net weight kg 180

Enclosure Class IPX4

Date,S/N: See circuit

diagram

Note:

::

:1. Sanitation heated water condition: Rated environment temp.18/23Deg.C,heating water

temp.15/55Deg.C.

Cooled water condition (air-condition): Rated environment temp.18/29Deg.C,cooling water

temp.12/7Deg.C.

Heated water condition (air-condition): Rated environment temp.15Deg.C,cooling water

temp.40/45Deg.C. The same to water flow in the summer.

Alliance for cool and heat conditions: Heating water temp.15/55Deg.C. cooling water

temp.12/7Deg.C.

2.Manufacturer tests the noise level showed above in lab. The noise level of installed unit could

- 6 -

be different with above data due to the surrounding condition.

3. Manufacturer keeps the right to change technical data due to technical improvement.。

.2.2

The figure of working principle

Gr ound souce wat er out l et

Gr ound sour ce wat er i nl et

A/ C wat er i nl et

A/ C wat er out l et

Heat i ng wat er out l et

Heat i ng wat er i nl et

Picture 2

compressor Four-way valve tube in tube heat exchanger

pressure drop switch Pump Filter

⑦liquid tank ⑧Thermal Expansion Valve ⑨gas-liquid segregator

Table 2

- 7 -

.2.3

Figure dimension

A/C water inlet

A/C water outlet

Ground source

water outlet

Ground source

water inlet

heat water outlet

heat water inlet

Picture 3 CWM-15XB

3

Installation Instruction

.3.1

Installation

The installation must be done by qualified professionals. Make sure the

The installation must be done by qualified professionals. Make sure the The installation must be done by qualified professionals. Make sure the

The installation must be done by qualified professionals. Make sure the

installation match

installation matchinstallation match

installation matching

inging

ing the following conditions.

the following conditions. the following conditions.

the following conditions.

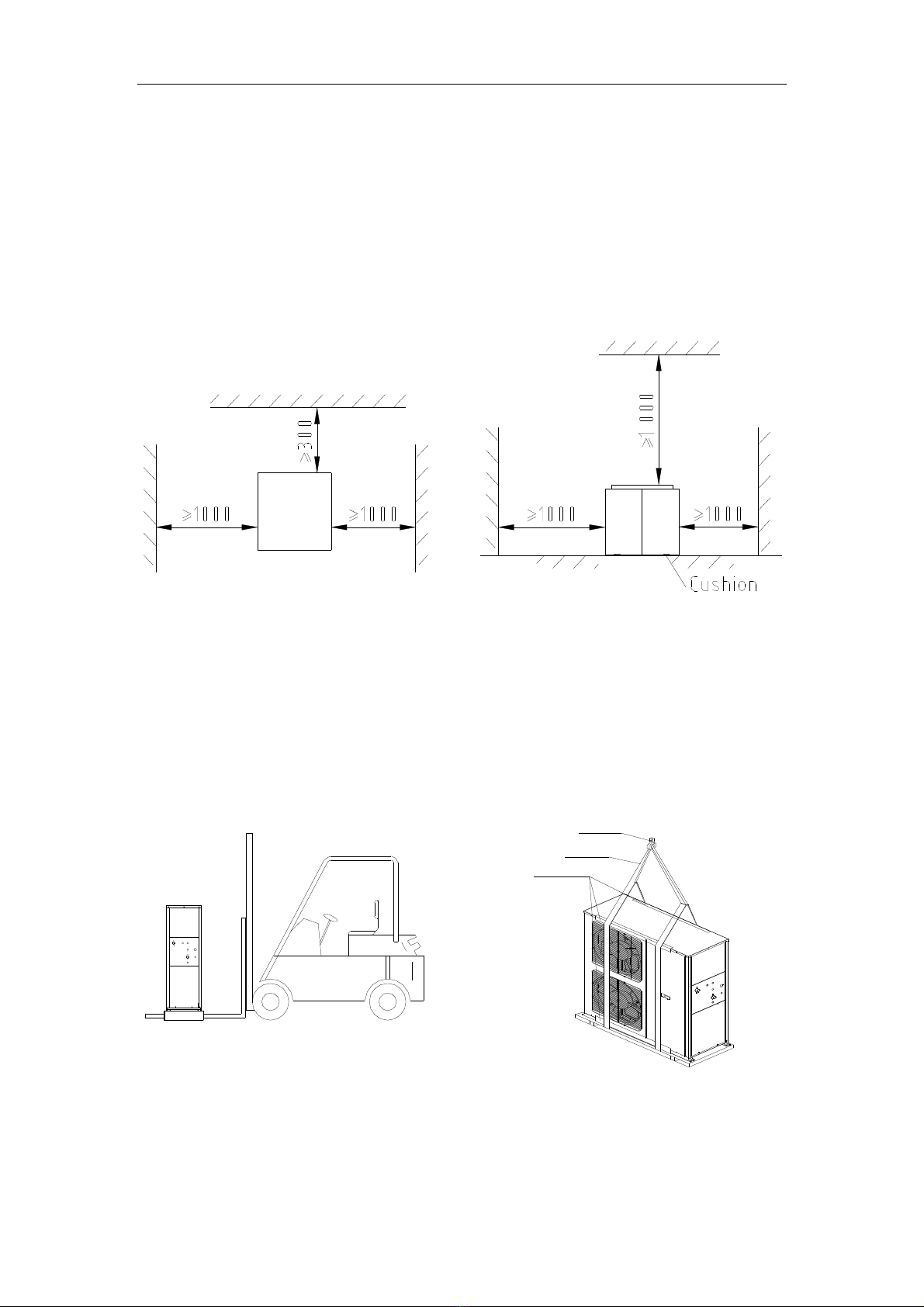

The selection of installation location

The installation location must match the following conditions:

Make sure the installation environment is open surrounding and good ventilation.

The machine may be installed above the ground, keeping enough space between the bottom

plate and ground. In order to assure draining water effectively. And the bracket must has enough

carrying capacity;

Hydraulic circle charged with clean water, no dust or oil. Soft water is recommended;

Make sure that the unit operating noise will not impact the living of neighbor.

The unit must be installed firmly, and the bottom of unit must be horizontal (the gradient must

be less 5 degree)

Keep enough space between the machine and wall. It is convenient for unit's repairment and

- 8 -

maintenances; and also you shouldn't lay the pipelines and top-ray tubes on the unit. The

suggested installation location as below. (Unit: mm)

Unit should have adequate drainage measures in the vicinity, so that the system stops running or

maintenance of the water drainage system.

Picture 4

②

②②

②

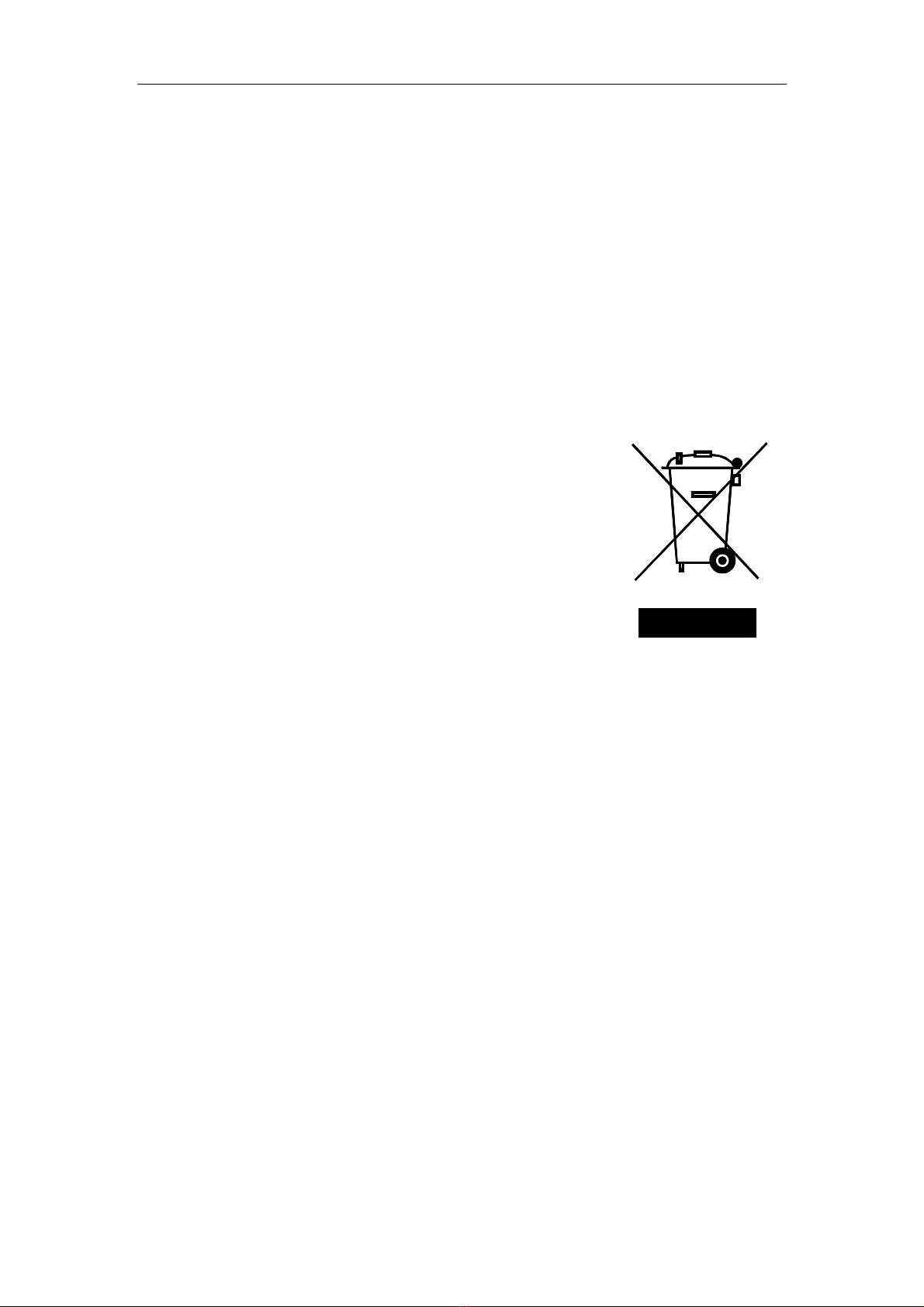

Attention of moving machine

Fork lift stacker or crane is suggested to move the machine;

The surrounding ambient temperature of unit during transportation must be among –25 to 55

Picture 5

While suspending the machine, crane cable must be tie to machine tightly, keeping the machine

horizontal.

disassemble the ground bolt in the pallet after the machine is well located, and take the pallet

pr oe c t i ng c h i p bo ar d

c r a n e c ab l e

c r a n e hoo k

- 9 -

aside。

Fixation

Rubber gasket is recommended to reduce vibration and noise while rivet the bottom plate.

④Water pipe connection

Heated water pipe must be packed with thermal isolation material to avoid thermal capacity loss

or dew dropping.

Inlet connection pipe must be equipped with a water filter.

The connection water pipes must be well matched (refer to specification parameters sheet).

PVC or PP-R pipe is recommended to use as water pipe.

Hot water pipe must be equipped with water pump 、Soft tie-in、a water filter、One way valve、

Flow meter、exhaust valve、Drain valve、Shutoff valve and so on。

Cooling pipe must be equipped with Soft tie-in、a water filter、One way valve、Flow meter、

Drain valve、Shutoff valve ,And then connected to underground inlet/outlet water pipe.

Drain cock should be installed at the highest point of hydraulic circle. After the hydraulic circle

is connected completely, exhaust air inside hydraulic circle.

Drain valve should be installed at the lowest point of water pipe.

Please note:

The appliance shall be installed in accordance with national wiring regulations.

Please make sure the following working conditions. the voltage can not be more or less than

10% of rated voltage and the frequency can not be more or less than 1% of rated frequency. The

height above sea level should be less than 1,000 meters.

Working water temperature available from 8~50, maximum water pressure 10 bar.

Wires must be connected according to the instruction of electrical connection diagram.

Also an all-pole air-break switch is needed and the pole clearance should be more than 3mm.

The ground wire must be well connected. Ground wire can’t be connected to coal gas pipe,

water pipe or telephone wire.

Drain electricity protection switch is needed for the system. No drain electricity protection

- 10 -

switch may cause electrical shock.

The operation handle of power switch is suggested to be black or gray, and it can be fixed at

OFF status. The installation location of power switch is suggested among 0.6 to 1.7 m. electrical

short circuit protection is needed.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

dispose

Do not dispose this product as unsorted municipal waste. Collection of such waste separately for

special treatment is necessary.

Meaning of crossed-out wheeled dustbin: Do not dispose of

electrical appliances as unsorted municipal waste, use separate

collection facilities.

Contact you local government for information regarding the

collection systems available.

If electrical appliances are disposed of in landfills or dumps,

hazardous substances can leak into the groundwater and get into the

food chain, damaging your health and well-being.

When replacing old appliances with new ones ,the retailer is legally obligated to take back your

old appliance for disposal at least free of charge.

It is prohibited to dispose of this appliance in domestic household waste. for disposal there are

several possibilities:

a) The municipality has established collection systems, where electronic waste can be disposed of

at least free of charge to the user.

b) When buying a new product , the retailer will take back the old product at least free of charge.

c) The manufacturer will take back the old appliance for disposal at least free of charge to the

user.

d) As old products contain valuable resources, they can be sold to scrap metal dealers.

Wild disposal of waste in forests and landscapes endangers your health when hazardous

substances leak into the ground-water and find their way into the food chain.

- 11 -

Warning

.3.2

Water system installation chart

⑥

⑥

②

①

③

⑤④

⑥

⑥

⑩

④

⑧

Out l et heat ed water

I nl et wat er

⑥

⑥

⑥

⑥

⑤

⑤

10

Indoor

terminal

Cooling Tower

12

12 45

5

⑥⑥

Storage

water

tank

Expansion Tank

15

13

14

15

13

13

Picture 6

Table 3

1 Ground Source Heat Pump

Water Heater 2 Soft tie-in 3 Pressure drop switch 4 One way valve

5 Pump 6 Shutoff valve 7 Water supply valve 8 Water valve

9 Back valve 10 Y type filter 11 Water tanks 12 Thermometer

13 Flow Control Valve 14Safety valve 15 Pressure switch

Hydraulic circle is recommended while installing Water Source Heat Pump Water Heater .

Warning

Any abnormal accident, such as burning smell, switch off the machine immediately. Contact

!

Warning

It is forbidden to clean the hydraulic circle by water pump inside system.

!

Warning

Make sure the machine has been power connected over 12 hours before starting the system. Otherwise,

machine could be damaged.

!

- 12 -

The installation of hydraulic circle can be finished according to above chart.

NOTES:

::

:

A、

、、

、Please do exhaust the air in water system before running the machine, if you completely finished

the circulating water system piping.

B、

、、

、The water flow switch must be installed at the straight pipeline section of the same level, from

the elbow, valves and other pieces of partial resistance to more than 5 times the diameter.

C、

、、

、The pipe must be insulated closely in order to improve cooling (heating) effect and energy

conservation.

D、

、、

、The take-over of this unit must be installed with drainpipe to make it convents to drain water

inside the unit and prevent it from freezing.

.3.2 Electrical diagram.

- 13 -

TRON2

TRAN1

C

XT

T

S

R(L)

DI P swi tch

Wat er

sour ce

pump

KM2

U1 V1 W1

Heat

wat er

pump

Ai r swi t ch

COMP

R S T N

N

W1

CCH1

11

V1U1

KM1KM3

A/ C

wat er

pump

KM4

R(L)

10

①

①①

①unit wiring

Model Power Voltage (V) Power wire(

mm

2

)

Allowed max

current (A)

Allowed leakage

current

CWM-15XB 380V/3N/50HZ 342-418V ≥4.0

12A 3mA

②

②②

②

attentions of wire connecting

All wires must be well connected.

- 14 -

All wire should avoid touching refrigerant tube. If it is not avoidable, vibration protection and

isolation must be well done.

All wire no touch to compressor or any other kinetic components.

When the heated water flow switch and ground water flow switch is unused, the 10 and 11

terminal on the bank terminal should be short-joined,or the unit can't start.

When the high water level switch、in water level switch and low water level switch is unused, the

12、13、14 and 15 terminals on the bank terminal should be short-joined,or the unit can't start.

.3.3

System test

○

○○

○

1Checking items before test run of system

1)、Seal test to make sure system is well sealed.

2)、Power source checking to make sure required voltage and current are available.

3)、Pressure inside hydraulic circle reaches to operating pressure(1-3)kgf/cm

2

。

4)、Make sure hydraulic system inside is clean and no jam.

5)、make sure hydraulic circle is fully filled with water and no air inside.

6)、Check to make sure all valves are switched on, well thermal isolated.

7)、Make sure all electrical wires are connected correctly according to wiring instruction, and wiring

screws are driven properly.

8)、Exhaust the air inside hydraulic circle by manual drain cock in hydraulic tube and drain cock on the

water pump.

9)、Check if there is visual damage caused during transportation.

10)、make sure all wiring correct.

②

②②

②

Commissioning

1)、Make sure all above checking items are passed.

- 15 -

2)、Open controller cover, then connect the power source wires. If the power source is three phases,

check the phase order immediately. Red lamp on controller board will light while phase order is correct.

Check if water pump works smoothly. If there is scream from water pump, it means there is air inside

the water circle. In this case, stop the machine and exhaust air inside water circle. Then start machine

again. The compressor will start to run 3 minutes after the system is switched on. Check if compressor

run at right direction.

3)、Check if there is unusual noise from system by listening. If there is, switch off the machine and

check system. If no unusual noise, let system running.

4)、If all checking items passed, keep system running.

5)、At heating mode , if water tanks temperature≤45, compressor starts to work. The compressor stop

working until the water tanks temperature increase to 50.

6)、Check the temperature difference between return water temperature and outlet water temperature of

outdoor unit. Normally, the temperature difference should be less than 6. If the temperature difference

is over 6, check if water flow match designed standard.

7)、All hydraulic circle filters must be cleaned after finishing test run.

③

③③

③Normal operation:

::

:

Heating running process: Start the unit---pump running--- Detection of flow

switch---Compressor running (When disconnected from the low water level, the solenoid valve will

open to compensate water)

Water level control: in cycle mode,when disconnected from the low water level, the unit Stop

running,the compressor is permitted running the circle when the switch of low water level is pull in,

when the low water level switch is disconnected, then the power begins to compensate Water. At

the same time stop provide water for the pump.. When tank temperature is lower 3, the tanks begin

to detect the temperature, if the tank temperature is higher than the setting temperature, the

compensate water valve would work for water-filled, If the tank temperature is 3lower than the

setting temperature, it would stop compensate water and power off, At the high-water absorption time,

it stops water supply. When the high-level is broken up but the mid-water level is running it won’t

- 16 -

supply water, on order to avoid frequent moving of compensating valve.

In Direct thermal mode, when the mid-water level is disconnected, the host will Open the water

valve, heat pump thermostat begins to work. If the thermostat switches pull in, the host would press

and the fan would work and the circulating water pump would shut down. The same for the

high-water absorption mode, thermostat stops working. At high water absorption time, when water

temperature is 5lower than the setting temperature, it will enter the heating circulation and pumps

circulation, compressors and fans will run, the compensating water valve will shut down, and the

thermostat won’t work; when the low water level is disconnected, the pumps won’t supply water and

electric heating begins. At the low-water level absorption time, when the water temperature is lower

than the setting temperature limitation, it will take the priority for circle heating.

When the supply water valve is turned on, if the high-water level is disconnected and the tank

water temperature is lower than -3(initial setting)then the tank would not compensate water. If the

tank water temperature is higher than setting value then it would compensate water and the

high-water level would last pull-in water 2 minutes before shut down the compensating water

valve( when there is a temperature control the supply of water).

If power up for the first time, it is necessary to circulate pumps after lower-water level absorbs,

then the compressor would run.

When the unit is running, the circulating water pump opens. When the unit stops, the circulating

pump will stop operation 30 seconds later.

Backwater Solenoid valve runs according to water temperature detection. When the return water

temperature is higher than the setting temperature, the solenoid valve will stop return water. When

the return water temperature is lower than setting temperature, then the valve will open to keep the

water supply pipe preserving hot water for a long time.

You can choose water moods of compulsory and time, when the water temperature is over 40,

press the "WATER SUPPLY" key, or it meets the time requirement and it will supply the water,

When it is supplying the water, pressing "WATER SUPPLY" key, or it meets the stop water supply

requirement, water supply will stop. When the water temperature is below 40, it won’t supply

water.

- 17 -

4

Panel operation

Settime

Time

△

△

▽

Chec Model

Temp.

Set

- 18 -

1) On/Off function

□ Press“on/off”button,the unit starting,the pilot lamp is lighting;

□ Then press“on/off”button,the unit stop,the pilot lamp put out。

□ “On/off” is all storied date。

2) Model conversion

□ Press“Model”button,choose the required model,“Refrigeration”or“Heating”

model. “Refrigeration and heat water” “Heating and heat water” “ heat water”

model.

□ “Refrigeration” displays snowflake symbol.

□ “Heating” displays sun symbol

□ When the unit is off, the “Refrigeration” and “Heating” mode display the A/C

temperature.“Heat water”mode display the temperature of tank, “Refrigeration”

and “Heat water”mode, and “Heating”and “Heat water”modes will be display

the A/C temperature and the temperature of tank by turns.

□ The unit is on, at the “Refrigeration”and “Heating” mode, the first two shows

- 19 -

air-conditioning return water temperature, the after two display air-conditioning

temperature setting.

□ “Refrigeration”and “Heat water” mode, “Heating”and “Heat water”mode, the

first two shows air-conditioning return water temperature and the tank

temperature by turns, the after two display air-conditioning temperature and the

tank temperature setting.

□ Water tank when water temperature symbols, air-conditioning temperature, no

water symbol

□ There is water symbols display the temperature of water tank, but display A/C

water temperature, there is not.

Refrigeration heating Refrigeration and heat water

Heating and heat water heat water

3)

Set time

on/off

i. Set 〖b7〗is for 0 which shows compares’ timing.

□ In the case of running,press“

Set time

”button,shutdown

Set time

;

□ In the case of shutdown,press“

Set time

”button,start

Set time

;

□ Press“

Set time

”button,then hour time flashing;

□ Press“time▽△”button,adjust hour of regular time

- 20 -

□ Then press“

Set time

”button,minute time flashing;

□ Press“Time▽△”,adjust minute of regular time.

□ Then press“

Set time

”button,

Set time

set

s finished.

□ Then press“

Set time

”button,canceled

Set time

.

ii. Set 〖b7〗is for 1 which shows circulation timing.

□ Press“Set time”button,then hour time flashing,begin set

Parameter Name Unit No.

Default

setting

MAX MIN

Refrigerating P1 12 30 〖b6〗

A/C Heat water

set temperature

P2 40 〖b7〗 25

Setting

temperature heat

water recovery

P3 55 〖b8〗 10

Combine timing/

Cycle timing

selection

P4 0

1: Cycle

timing(Cycle

every 24 hours

operation)

0: Combine

timing(Within 24

hours once a valid)

Set time

-open′time.

□ Press“Time▽△”button, adjust hour of regular time

□ Then press“

Set time

”button,minute time flashing

□ Press“time▽△”button,adjust minute of regular time

This manual suits for next models

1

Table of contents

Other Econo Heat Pump manuals

Popular Heat Pump manuals by other brands

Pentair

Pentair UltraTemp-E installation guide

Immergas

Immergas AUDAX PRO 4 V2 Instructions and warnings

Dimplex

Dimplex LI 8MSR Installation and operating instructions

Amana

Amana American Pride ACNF Series manual

EMI

EMI Volts/HZ/pH Installation & operation manual

salmson

salmson SIE Installation and starting instructions

Heat Controller

Heat Controller SMH 24 installation instructions

Alpha

Alpha E-Tec 33 Installation and commissioning instructions

Dimplex

Dimplex LI 11AS Installation and operating instructions

Enerflow

Enerflow Eskom ERHP-SU08 user manual

Rotex

Rotex RBLQ05CAV3 installation manual

Riello

Riello AARIA START Installation and technical service instructions