PART 2 SERVICE

DANGER: Be sure the manual Main Shut-Off Valve combination valve and Burner Power Switch are turned OFF before

removing any parts for service.

-6-

11.

12.

13.

14.

15.

= BTU/Hr

= 180,000 BTU/Hr = 180 MBH

control to OFF or thermostat below room temperature for

at least 60 seconds. If burner still fails to light, turn it off

and repeat from step 4. Then, if necessary, refer to the

trouble chart to isolate the problem.

WARNING: Repeated unsuccessful attempts to

light will result in accumulated gases in combustion

chamber. To prevent these gases from reaching an

explosive level, periodically purge the combustion

chamber as described in step 4 above.

8. To make a preliminary setting of the burner input,

determine the manifold gas pressure required from Table

3 and adjust the combination valve main gas pressure

regulator accordingly. See Section XI.

9. To determine the firing rate for NATURAL gas:

Accurately time test dial for the number of seconds for

one revolution and use the following formula. All other gas

utilization equipment must be off.

3600 x test dial size x BTU value

No. of seconds for one rev. test dial

Then divide by 1,000 for MBH value.

Example: 3600 x 1 x 100

20

For PROPANE gas, consult your supplier for method of

determining firing rate.

10. Readjust the primary air shutter to provide a quiet, soft

blue flame with well defined orange and yellow tips for

NATURAL gas or with well defined yellow tips for

PROPANE gas.

Check the operation of the burner; start and stop it

several times with the thermostat or operating control.

With the burner running, check the operation of all limit

and associated controls.

PERFORM THE FOLLOWING FINAL ADJUSTMENTS

for combustion and flue gas temperature. Take the flue

gas samples and temperature immediately ahead of the

draft control.

A. The flue gas temperature should be above 325¡ but

not exceeding 550¡F. Excessive flue gas

temperatures will result in low efficiencies. Low

flue gas temperature may causes excessive

condensation. Reset gas input if necessary to

adjust stack temperature.

B. Make the final setting of the primary air shutter by

checking the flue gases with an ORSAT or similar

combustion testing instrument. The carbon

monoxide content should conform to local codes

or, in their absence, to the level specified in the

United States or Canadian Standard reference on

the front cover of this manual; the carbon dioxide

content should be approxiamately 9.5% for

NATURAL and 12.1% for PROPANE, or within the

limits prescribed by the local codes.

Check the draft control to make sure there is no spillage

of flue products into the room.

FILL OUT THE INSTALLATION ADJUSTMENT DATA

TAG and affix to the burner or gas utilization

equipment.

NOTE: For subsequent normal starting and shut-off

procedure, refer to CONSUMER INSTRUCTIONS or to

the instruction plate mounted on the burner.

outlet pressure of 3.5" W.C. must be installed in the pilot gas

line and the pilot adjustment screw set full open.

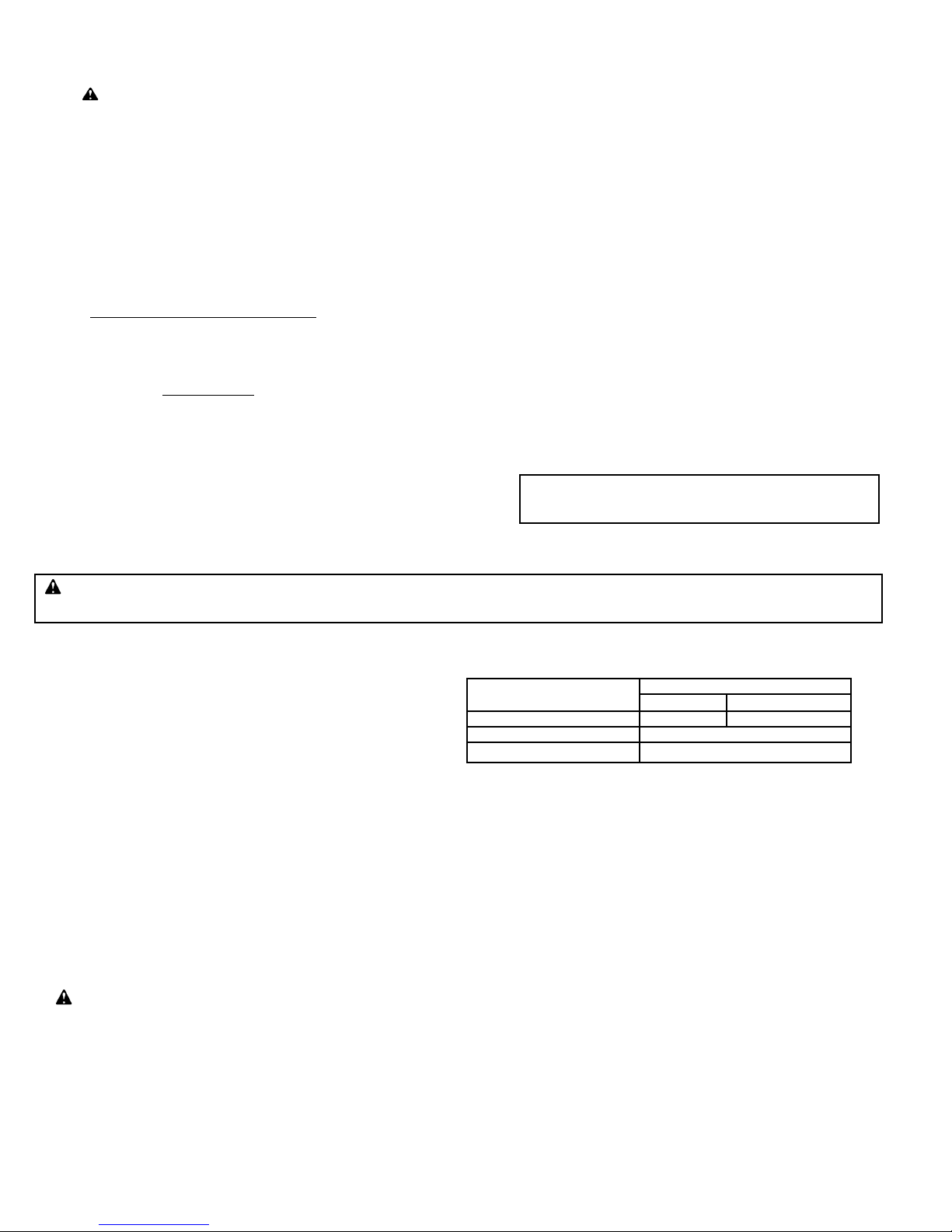

Nominal BTU /Cu. ft. Value

NAT-1000 PROPANE-2500

Orifice Diameter .032 .025

Pilot Flame Gas Pressure

3.0"-4.0" W.C.

Approx. Capacity 2400 BTU/Hr.

TABLE 4 Pilot Specifications

X BLOWER ASSEMBLY

Cleaning of the blower wheel is usually the only service

required. Need for cleaning is indicated if the inlet screen or

blower wheel shows an accumulation of dust and lint, or if the

character of the flame indicates a deficiency of air. Motor

cooling air vents if present, should also be cleaned at this time.

■ If the motor must be replaced: Disconnect motor leads,

remove inlet ring and screen, blower wheel and the three

motor mount retainer clips. Pull motor out of keyhole brackets.

Remount in reverse order noting that brass flanges of rubber

motor mounts are located against motor. The wheel should be

located 1/4 inch inside the edge of the inlet side of the blower

housing.

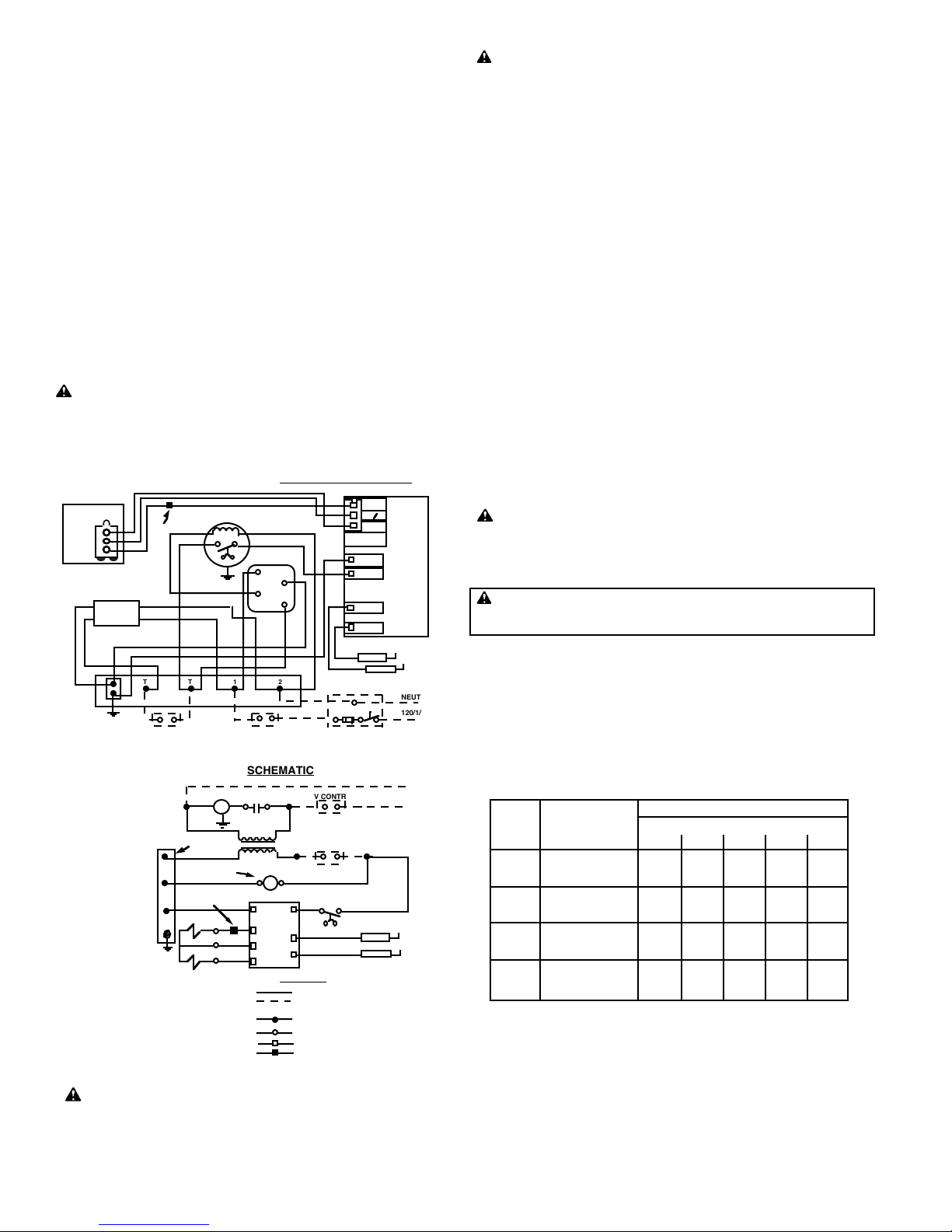

XI COMBINATION GAS VALVE

The 24 volt combination valve serves four functions: 1) Main

Manual Gas Shut-Off, 2) Manifold gas pressure regulation, 3)

Automatic electric pilot gas valve, and 4) Automatic electric

redundant main gas valve. A pilot adjustment screw and filter

are also included.

■ The pilot adjustment screw is located on the combination

valve. Remove plug for access and turn clockwise to

reduce flow.

■ The main gas pressure regulator, which has an outlet

pressure setting range of 2.0 " to 4.0 " W.C. is factory set for a

IX DRAWER ASSEMBLY

When the pilot flame gas pressure is in the proper range (see

Table 4), lint, dust, or corrosion is the most common cause of

pilot problems.

■ The retention plate and pilot are part of the drawer

assembly which can be removed as a unit. Remove the four

back plate screws; then, disconnect the pipe union, pilot tube

and control wires and pull out the drawer assembly.

■ When servicing, clean the retention plate ports and pilot

assembly including the pilot spud and electrode porcelain on

sensor rod and/or spark electrode. Examine the sensor rod. If

there is any serious corrosion or loss of metal at the tip replace

the sensor rod.

■ Make sure that the pilot mica peepsight is not damaged or

missing as air leakage through the peepsight hole could mimic

some of the conditions described below. See Figure 7.

■ Check that the pilot orifice diameter is correct.

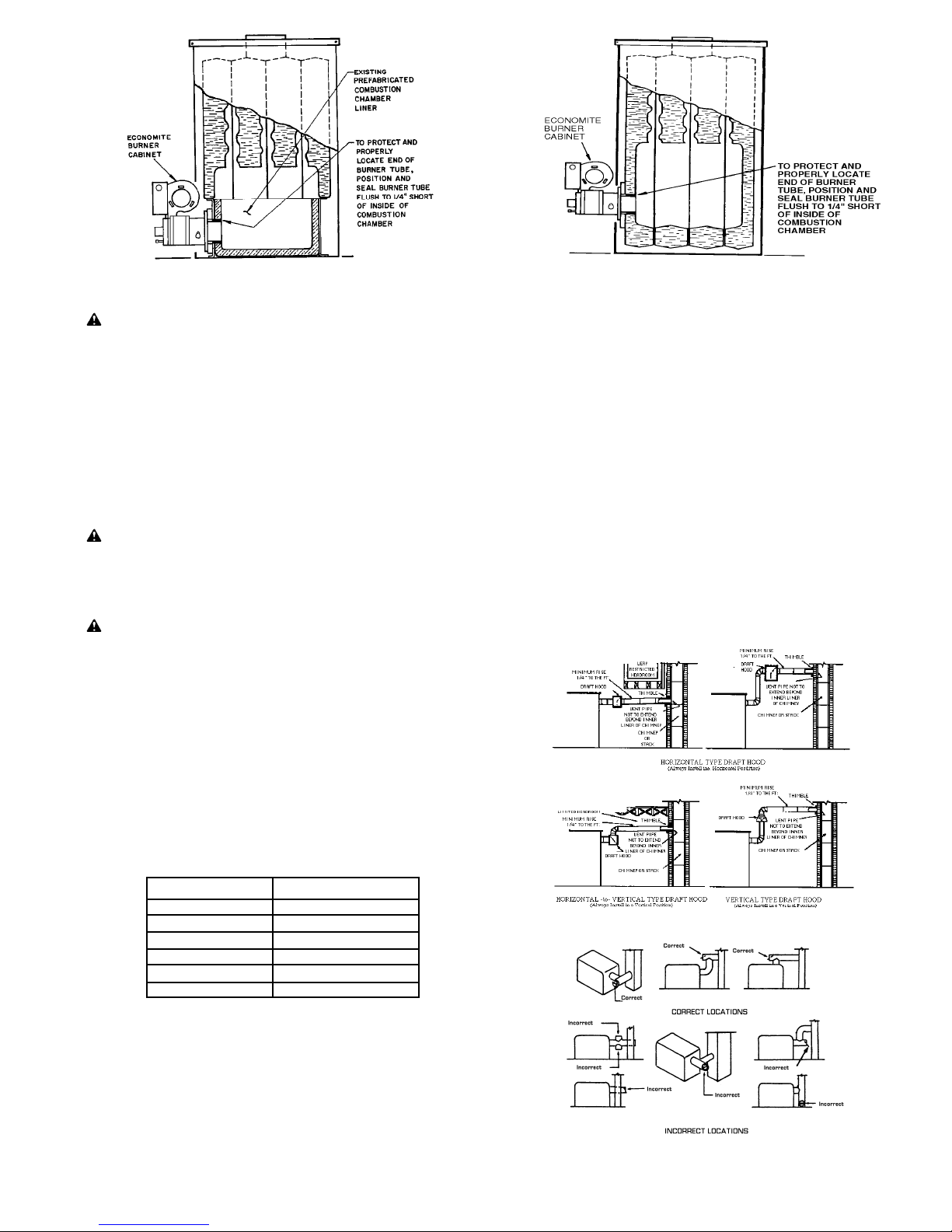

■ Make sure that the burner tube is properly positioned in the

combustion chamber entry. It must be set flush to 1/4" short of

the inside of the combustion chamber as shown in Figure 2 or

3. It must not protrude into the combustion chamber.

■ If cleaning does not eliminate the lighting problem, further

checks are required:

CAUTION: Do not indiscriminately increase pilot

orifice diameter. Pilot troubles are rarely cured in this

manner and new troubles may be introduced by causing

the pilot flame to float and lose contact with the sensor

rod.

■ If the standby gas pressure is over 14.0" W.C., or less than

4.0" W.C., refer to Section VI.

■ If the standby gas pressure is between 4.0" W.C. and 14.0"

W.C. and does not vary more than 1.0" W.C., use the pilot

adjustment screw in the combination valve (Section XI) to set

the pilot flame gas pressure at 4.0" W.C.

■ If the inlet pressure varies more than 1.0" W.C., a 1/8 inch

Maxitrol RV12 series(or equal) pressure regulator set for an