Ecoplus 727184 Operating and maintenance manual

This manual suits for next models

2

Table of contents

Other Ecoplus Water Pump manuals

Popular Water Pump manuals by other brands

AL-KO

AL-KO JET 1300 INOX Translation of the original operating instructions

Aquasub engineering

Aquasub engineering AQUA GROUP AQUATEX AV Series Operation manual

SKF

SKF KFGL Assembly instructions

Blagdon

Blagdon minipond 700 user manual

Clarke

Clarke Hippo 2A Operating and maintenance instructions

Wilo

Wilo Medana CH1-LC Installation and operating instructions

VEVOR

VEVOR GYB-630B user manual

Homa

Homa TP 50 Original instruction manual

Homa

Homa KX...-R series Original instruction manual

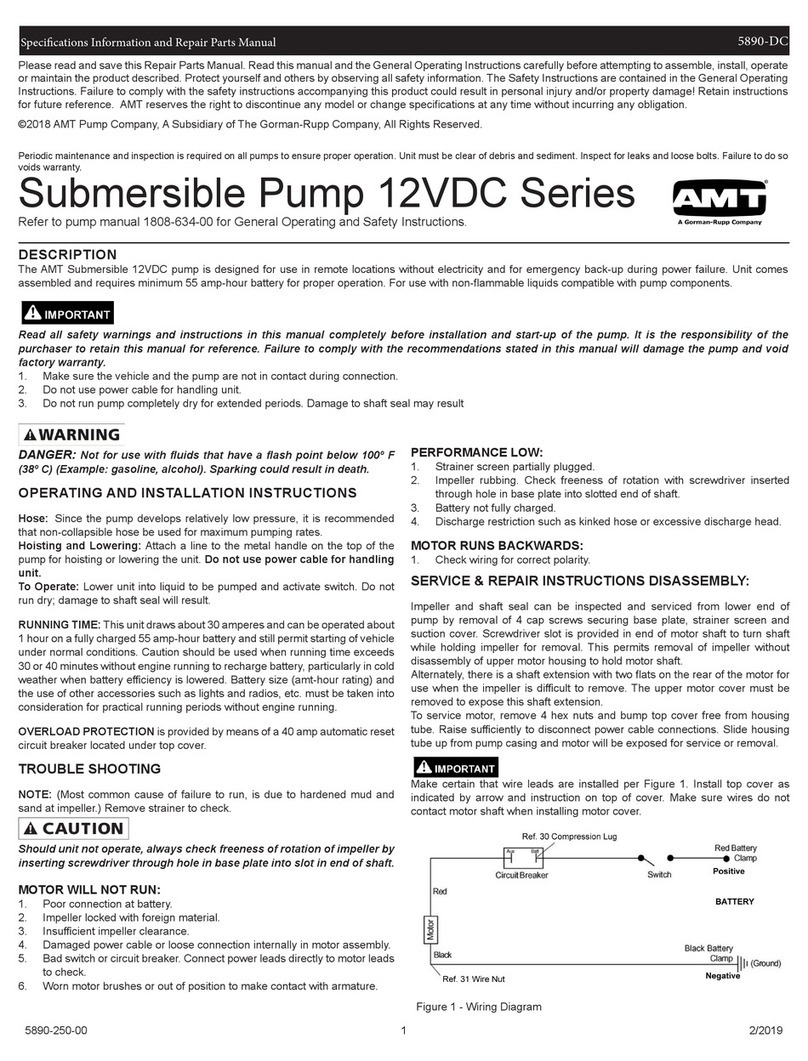

AMT

AMT Submersible Pump 12VDC Series Specifications information and repair parts manual

Homa

Homa C250 W Original instruction manual

Nutricia

Nutricia flocare Infinity Instructions for use

Sears

Sears Craftsman 390.304051 owner's manual

Mouvex

Mouvex SLS24 i Installation operation & maintenance

Samoa

Samoa PM35 Service guide

Watson Marlow Pumps

Watson Marlow Pumps 730 S Installation, operating and maintenance manual

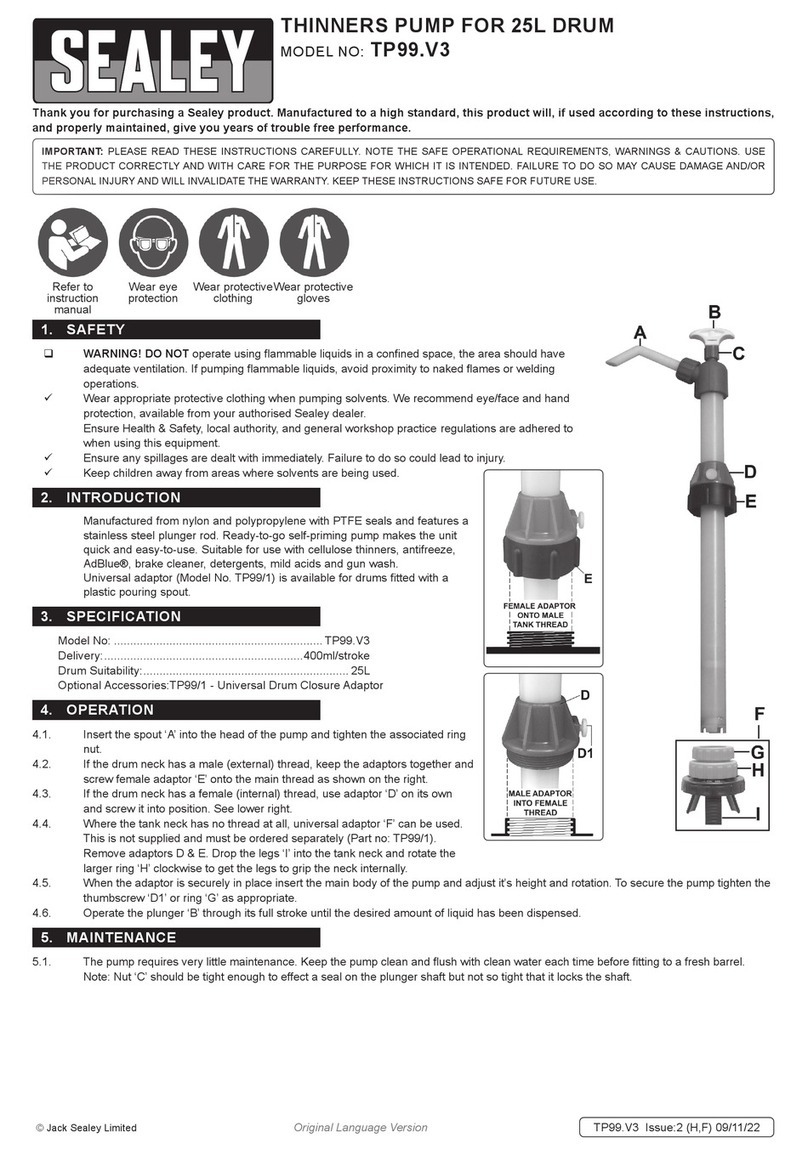

Sealey

Sealey TP99.V3 manual

KSB

KSB Rio-Eco N Series Installation & operating manual