Ecosoft FU1013CABDVUP User manual

Manual for Ecosoft Pink

softeners

2

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

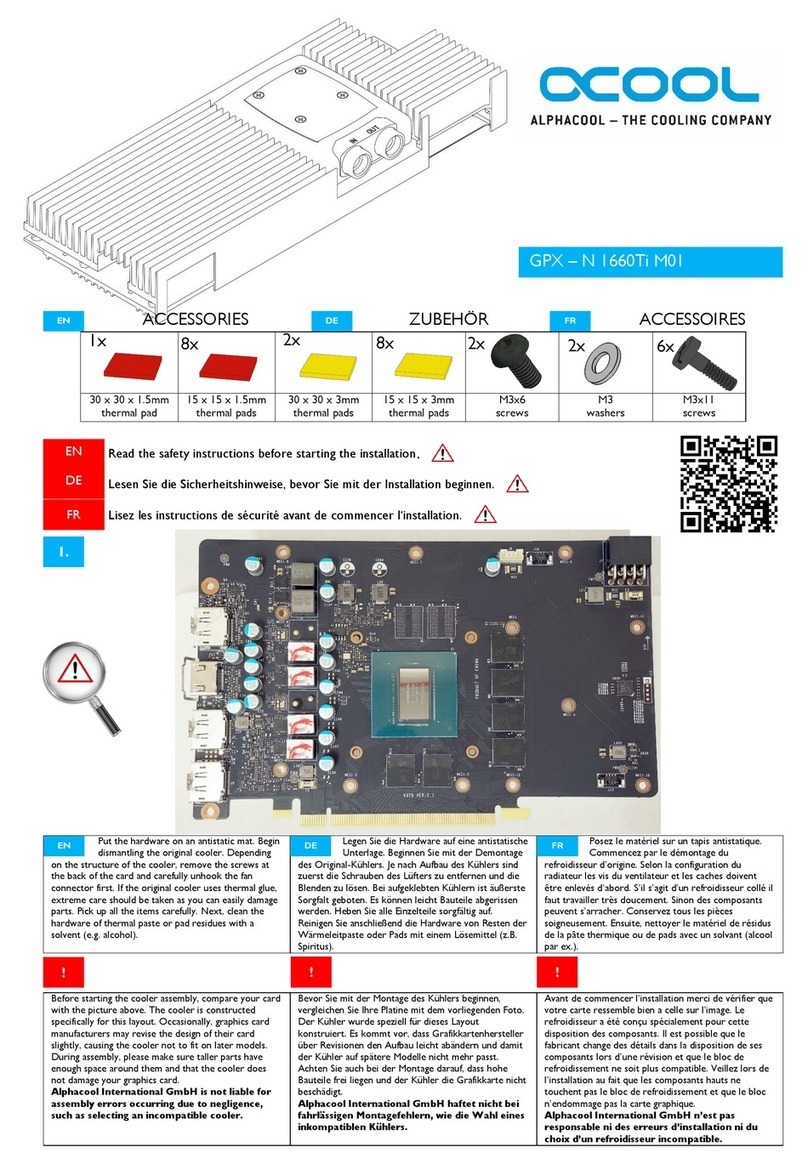

ECOSOFTPINK SOFTENER RANGE

Compact water soener

Part # Descripon Quanty of

media, L

FU1013CABDVUP Ecosoft Pink 10 compact water

softener 10

FU1016CABDVUP Ecosoft Pink 15 compact water

softener 15

FU1024CABDVUP Ecosoft Pink 20 compact water

softener 20

2 3

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

CONTENTS

1. Introduction 4

1.1 General provisions 4

1.2 Manufacturer 4

1.3 Safety rules 4

2. Technical data 6

2.1 6

2.2 7

Cabinet dimensions

Pink series

8

9

3. Delivery set

4. Preparation of the installation site

5. Procedure for installing an FU Cabinet system 9

5.1 Optional equipment 10

12

14

15

16

18

6. Quick Set Up Guide

7. Installation diagram

8. Service

9. Troubleshooting

10. Guarantee

11. Serial information 20

4

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

1. INTRODUCTION

1.1 General provisions

1.3 Safety rules

1.2 Manufacturer

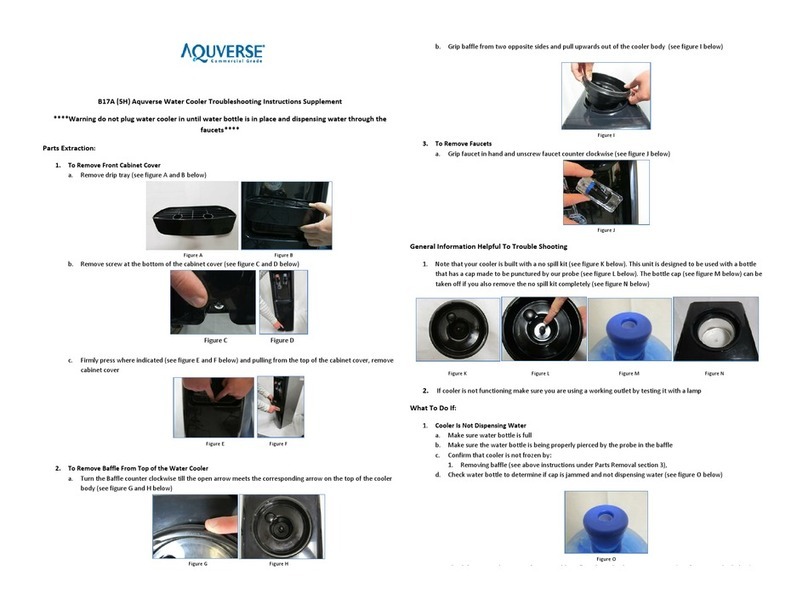

Filter installaon should be carried out by a specialist with appropriate qualicaons and

experience. Children aged 8 years and older, as well as people with limited physical, sensory and

mental abilies, with the lack of necessary knowledge and experience to use this device, they

can use soener only under supervision and in compliance with the specied data security rules

equipment and understand the hazards involved. Cleaning and user maintenance shall not be made

by children without supervision. Do not allow children to play with the device!

If the soener is not used for a long me used: If you do not plan soon somemes use the

equipment (for example, during holidays) put it in bypass mode and turn it o it from the water

supply network. For this it is necessary move the three taps to the opposite posion (according to

the installaon secon of this manual soener); or carry out the necessary procedures for using the

Mulblock block (depending on what you are the one using it).

If the installaon has not been used for a long me, we recommend soener regeneraon in manual

mode, in accordance with Secon 4.2. given instrucons Protecon against extreme temperatures:

Do not install the soener where it is joining it (including drainage pipes and overow hose) can be

exposed to temperature below 5ºC or above 40ºC.

Electrical safety - we ask you use an adapter or baery (opon) supplied with equipment Before

using the device, check compability of the technical characteriscs of the power supply unit with

characteriscs of the local power supply network.

A 50Hz 230V input voltage must be used to connect the water soener

Danger to life due to electric shock.

Work with electrical equipment is allowed only to authorized service centers or qualied electricians

who have been instructed

Electric shock!

ECOSOFT SPC LTD

Pokrovska 1st

08200, Irpin city, Kyiv region,

Ukraine

ECOSOFT 22

Industrieweg 8

3190, Boortmeerbeek

Belgie

!

4 5

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

1. INTRODUCTION

When carrying out service work with the control valve of the soener, turn o the power supply

from the outlet

The power cord cannot be replaced. If the power cord is damaged, the appliance should not be

used. If the power cord is damaged, please ask consultaon with a qualied electrician. In the event

of a power outage during regeneraon, ensure the draining of wastewater into the drain. So BE

SURE to connect to a soener overow hose and drainpipes and connect them to suitable for this

drainage / sewage system to avoid spillage of water in the room.

Warning: Do not use aggressive detergents. Wipe contaminated surfaces dry with a damp cloth.

Maintenance: When carrying out installaon and technical works maintenance and repair of the

soener isolate it. To make the soener last longer maintained good work results, necessary

regularly carry out service work service. In more detail you can nd out about it by contacng the

nearest one partner service organizaon of the Ecoso company

Before starng work with water soening systems, it is necessary to eliminate the pressure in the

water supply

Opening threaded connecons or taps can cause injury!

Unauthorized modicaon or changes to the system design may adversely aect the safety of

people and the operaon of the system

Touching live parts can lead to electric shock

Pipelines of water soening systems are under pressure.

!

!

6

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

2. TECHNICAL DATA

2.1 Cabinet dimensions

Control valve port sizes (port height**, mm) Dimensions*, mm

Model Water

Inlet

Water

Outlet

Drain

Outlet

Brine

Inlet

E

(distance

between

Inlet /

Outlet)

W D H H1

FU1013CABDVUP 1″ M

(540)

1″ M

(540)

¾″ M

(640)

⅜″ CF

(640) 78 270 430 469 387

FU1016CABDVUP 1″ M

(970)

1″ M

(970)

¾″ M

(1070)

⅜″ CF

(1070) 78 270 430 539 457

FU1024CABDVUP 1″ M

(970)

1″ M

(970)

¾″ M

(1070)

⅜″ CF

(1070) 78 270 430 741 659

6 7

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

2. TECHNICAL DATA

2.2 Pink series

TECHNICAL SPECIFICATION:

Parameter FU1013CABDVUP FU1016CABDVUP FU1024CABDVUP

Operating flow rate, m3/h 1.21.5 1.8

Quantity of media, L 10 15 20

235

Usage of salt per regeneration1, kg 1.0 1.5 2.0

Usage of water per regeneration

(= discharge per regeneration), m30.08 0.1 0.12

Duration of regeneration, minutes 80–110

Pressure drop in service mode, bar 0.5

Inlet pressure, bar 2–6

Electrical requirements 230 V, 50 Hz

Power consumption, W 30

Inlet/outlet pipe connections 3/4’’

Dry weight, kg 18.8 22.2 32.5

Overall dimensions,

(Width × Depth × Height), cm 270 х 430 х 469 270 х 430 х 539 270 х 430 х 741

Volume capacity, m3

@250 mg/L CaCO3 influent harness

INFLUENT WATER LIMITATIONS:

Hardness 750 mg/L CaCO3

Iron 0.2 mg/L

Manganese 0.05 mg/L

Chemical Oxygen Demand 5 mg/L O2

Sediment prelter rating 100 μm

Temperature of water 2 +4…+30 °C

8

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

3. DELIVERY SET

Ecoso fabric soener comes in

Kits with the following parts and blocks:

a) Soener body assembly

(includes pressure tank with media inside,

Clack DV control valve)

b) Cоnnecon kit c) Plug connector for connecon

to power grids (EU)

d) Equipment passport

Compact

water soener

89

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

4. PREPARATION OF THE INSTALLATION SITE

•Installation area must meet all relevant building code. Water and power supply, and

ambient conditions must meet Specification requirements of this manual.

•Observe all local plumbing and electrical code when connecting system to utilities.

•Install check valve when connecting the filter to water mains. Install second check valve after the

system to prevent back flow.

•Particles such as sand, scale or rust can damage the control valve. Install a point-of-entry

sediment filter.

•Equip the system with sampling taps and pressure gauges as shown on drawings. It will help in

case any maintenance or troubleshooting is necessary.

•Install a vacuum relief valve as shown if there is a booster pump downstream of Ecosoft filter.

The FRP tanks may implode if subjected to negative pressure.

•If your system does not include bypass valve assembly, run a bypass pipeline along the entire

system. This may be necessary for diagnostics and maintenance.

5. PROCEDURE FOR INSTALLING AN FU CABINET SYSTEM

If your cabinet was delivered pre-loaded with media, place the cabinet in the installaon spot, ll

salt compartment with salt pellets, and then only carry out steps 5 – 8 of the procedure, skipping

steps 1 – 4. If the resin was shipped in bag, then carry out all of the following steps.

1. Disconnect the exible tube from brine inlet of the control valve. Unmount the valve by screwing

it counterclockwise.

2. Put a plug or cap on the top end of the riser pipe to prevent geng any media inside the pipe.

Pour the media in the tank using the funnel. When loading the tank, keep riser pipe vercal. If the

pipe lts, restore it to straight vercal direcon. When nished, rinse the thread of tank opening

with water to remove any beads of media stuck in the groove.

3. Mate the top distributor with the top end of riser pipe, then screw control valve in the tank

opening. Connect the free end of brine tube back to the brine inlet of the control valve.

4. Place the cabinet in the installaon spot. Open top lid and ll the salt compartment with soener

salt pellets at least half full.

5. Connect drain pipe to the male threaded drain outlet of the control valve. Run the drain pipe to

oor drain or gravity drain pipe socket. Secure the drain pipe end above the receiving xture with

at least 1″ air gap.

10

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

5. PROCEDURE FOR INSTALLING AN FU CABINET SYSTEM

5.1 Oponal equipment

6. Mount the pipe thread elbow adapters to the control valve’s In and Out ports and ghten the

coupling nuts. Do not put any mechanical load on ngs or use them to support pipes.

Connect the system to water supply and downstream pipework without turning on the water

supply. Do not confuse In and Out ports. They are embossed with direcon arrows.

7. Remove the front panel by pulling the locking tabs on the le and right side. Run the power cord

through the cord guide in the control valve’s backplate and connect it to 12 VAC socket on the circuit

board. Plug the power supply in the mains to power up the system.

8. Start manual regeneraon of the system. Scroll regeneraon to backwash if it isn’t the 1st step of

the sequence. When the control valve starts the backwash, turn on mains water supply slightly at

rst. Air will be displaced from the system via drain line while the pressure tank is being lled with

water. When the tank is full, water will start owing down the drain line. At this point, fully open

mains water supply.

Let the system complete regeneraon, then perform one more manual regeneraon.

Soening systems can be

addionally equipped with a Clack

or Mulblock bypass valve.

The Clack bypass valve is aached

directly to the inlet and puried

water pipes and has 4 operang

modes, listed below:

NORMAL OPERTION

DIAGNOSTIC MODE

BYPASS OPERTION

SHUT OFF MODE

“TREATED”

WATER EXIST

SUPPLY

WATER EXIST

SUPPLY

WATER EXIST

NO WATER

EXIST

SUPPLY WATER

ENTERS

SUPPLY WATER

ENTERS

SUPPLY WATER

ENTERS

SUPPLY WATER IS SHUT

OFF FROM THE HOUSE

AND THE VALVE

10 11

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

5. PROCEDURE FOR INSTALLING AN FU CABINET OR FK CABINET SYSTEM

The mulblock performs a bypass funcon, is equipped with a sampler and has 2 modes

of operaon:

Open posion — Supply via

soener/limescale protecon

system: handwheel in UPPER

posion (stop)

Bypass posion — Supply via

soener/limescale protecon

system: handwheel in LOWER

posion (stop)

Place the ng of the overow hose (1) at

least 20 mm below the height of the safety

overow of the domesc water soening

system. Fix vercally with the bracket

(H). Connect the ush water hose with a

downward slope to the ng (2) and insert to

a depth of approx. 90 mm.

Connect the overow hose from the brine

tank to the ng (1) and x with a hose

clamp.

The ush water hose and the overow hose

mustn`t be connected and mustn`t have

narrowing in the cross secon.

12

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

6 QUICK SET UP GUIDE

After installing and powering up an Ecosoft FU or FK system,set display language, water hardness,

current me, and regeneraon opons in the Installer menu of control valve.

Use ▲and ▼ buons to change seng; NEXT buon to save and go to next step; CLOCK to save and

exit menu; REGEN to move back one step.

To proceed, hold NEXT and ▲ buons simultaneously

for 3 seconds.

STEP 2I. Hardness: Set the amount of hardness as

calcium carbonate per PPM, using ▼ or ▲.

Press NEXT to go to Step 4I.

Press REGEN to exit Installer Display Settings

STEP 3I. Service Water Hardness (PPM): If a mixing

valve is installed in the valve, service hardness needs

to be set. Setting range is always less than the setting

in Step 2I. This screen will only appear if Step 4S is set

to rES. Press NEXT to go to Step 4I. Press REGEN to

return to previous step.

STEP 4I. Set Day Override to 1 – 28 days or OFF using

▲ or ▼. Press NEXT to go to Step 5I. Press REGEN to

return to previous step.

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023

12 13

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

6 QUICK SET UP GUIDE

STEP 5. Choose whether to Turn off display backlight

5 minutes after last keypad input event (only

accessible in CE valves). Pressing NEXT will exit the

menu.

STEP 6. Enter current time setting by pressing CLOCK.

STEP 7. Set current time, hours then minutes.

NORMAL MODE

NORMAL MODE

14

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

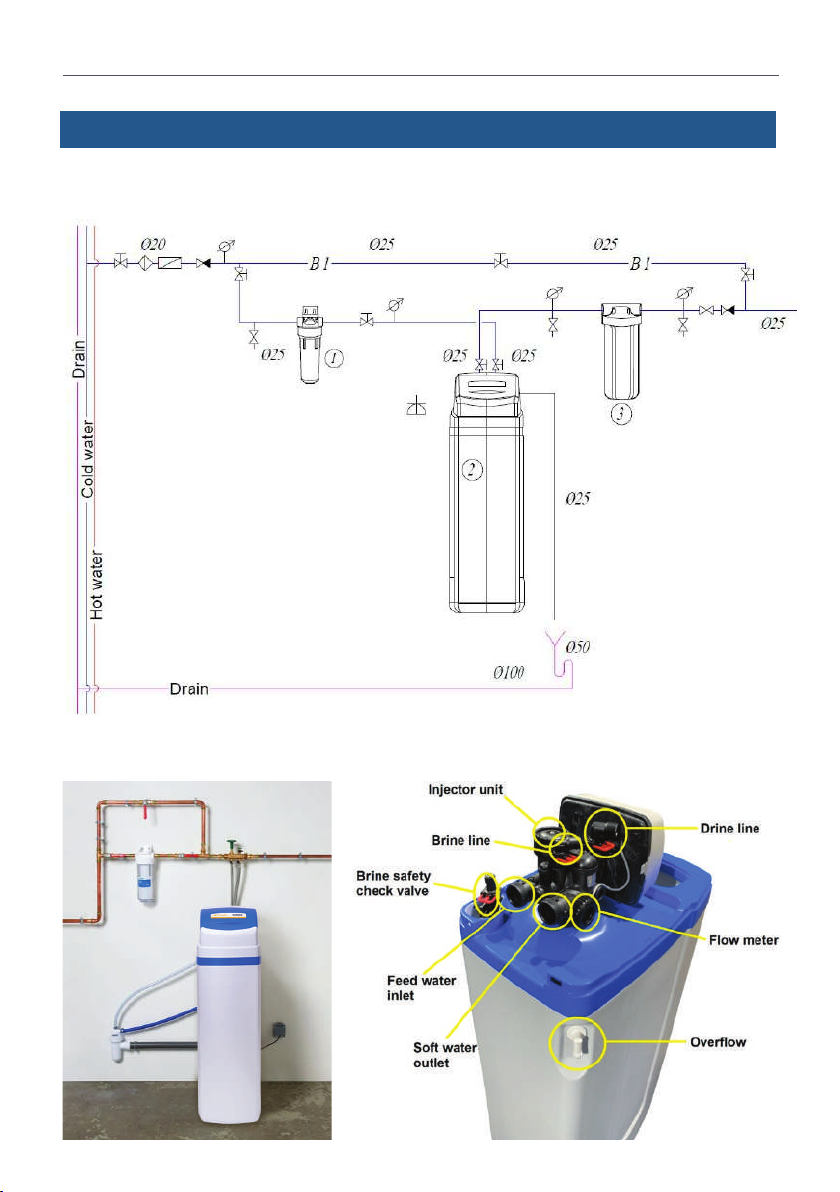

7. FK, FU INSTALLATION DIAGRAM

Compact water soener

14 15

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

8. SERVICE

8.1 Maintenance work

8.2 User responsibility

8.3 Service and spare parts

8.4 Disposal

To ensure proper operaon soener, the user should regularly carry out the following checks:

Check the presence of salt and if necessary, add.

Check water hardness: hardness of drinking water and the hardness of mixed water should be

checked no less than 2 mes a year, if necessary, it should be adjusted the hardness of the mixed

water (see the “Installaon” secon).

Check for ghtness, carry out: visual inspecon: check for possible leakage of all connecons and

pipelines. Check the cleanliness of the salt and saline soluon storage capacity 1 me in 2 months,

if necessary, clean and rinse clean water

The indicated terms of the recommended inspecons are available are minimal and must be

adjusted, depending on operang condions.

Any technical equipment requires regular maintenance.

Constantly monitor the quality and level of soened pressure water If the water quality has

changed, change it too parameter sengs are set. If necessary, consult a specialist.

Regular checks by the operator are required as a guarantee normal funconing of the device.

Emollient water should be regularly inspected compliance with the condions of its operaon.

Frequency of checks performed by the user:

Aer use: add salt for regeneraon.

2 mes a year: check the pressure

2 mes a year: check water quality

Once a year: clean the salt tank

Parts that wear out must also be replaced in the specied maintenance period so that to guarantee

awless operaon of the installaon and perform warranty condions. Soener maintenance it is

recommended to carry out once a year.

Replacement of wearing parts can be performed only qualied personnel (specialists of the

organizaon water supply or service).

We recommend concluding a service contract service with our service department.

Cleaning: do not use alcohol for cleaning or alcohol-based detergents to avoid damage surfaces of

plasc parts.

Aer the end of the service life of the installaon contact Ecoso Service to arrange soener

replacement. Disposal of soener and of all electrical parts is carried out only in specialized

recycling centers.

16

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

9. TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

1. Decreased

service ow

capacity.

Decreased supply water pressure. Increase supply water pressure.

Clogged lter bed. See paragraph 3.

Obstructed/clogged drain line. Clean the drain line.

Clogged control valve. Inspect and clean the control valve.

NHWBP/MAV failure (if used). Inspect and repair the motorized valve.

2. Decreased quality

of treated water.

Faulty chemical analysis of water. Perform one more test using freshly

prepared reagents.

Supply water chemistry has changed. Make new check analysis and if changed

contact your dealer.

Bypass valve is set to bypass. Turn bypass valve to operating position.

Riser pipe or seals are damaged. Take apart the lter, inspect and replace or

lubricate pipe and seals if necessary.

Clogged lter bed. See paragraph 3.

Filter media loss. See paragraph 4.

Improper lter regeneration. See paragraph 6.

Leakage of raw water inside the control

valve.

Take apart the control valve, inspect and

replace or lubricate the seals if needed.

3. Clogged lter bed. Insucient backwash ow rate. Check backwash ow rate. If supply pres-

sure is within the limits and the ow rate is

insucient, inspect and clean the drain line

ow control or replace it if needed.

Insucient backwash stage. Increase the duration of backwash stage.

Clogged top distributor. Clean the top distributor.

Excessive backwash ow rate. Measure backwash ow rate. If supply

pressure is normal and the ow rate is

exceeding, consider changing the drain

line ow control.

4. Filter media

entrainment.

Filter media is entrained and discharged

during backwash.

Replace the top distributor if needed.

Filter media is entrained and discharged

during service.

Replace the bottom distributor if needed.

5. System will not

regenerate.

No electric power. Check power supply.

No/insucient salt in brine tank. Chech the amount of salt in brine tank and

add salt if needed.

Brine is not sucked in during regen., or not

all brine is drawn.

See paragraph 6.

Control valve is out of order or settings

were changed.

Check the control valve and its settings

(see the manual for the control valve).

Brine tank is not relled or is relled with

not enough water.

See paragraph 7.

16 17

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

9. TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

6. Brine will not draw

during regeneration

or not all brine will

draw.

Low supply water pressure. Check supply water pressure.

Clogged injector or brine tube. Clean brine injector and/or brine tube.

Clogged basket or salt crystals on ball in

air check valve.

Clean air check valve basket and/or ball.

High pressure drop on the lter (control

valve, distributors or lter media are

clogged).

See paragraphs 1 and 4.

Air is injected due to brine line not being

airtight.

Check airtightness of the drain line.

Control valve settings changed. Increase brine stage duration.

7. Brine tank is not

relled or relled

with less water than

needed.

Low supply water pressure. Check supply water pressure.

Clogged injector or brine tube. Clean brine injector and/or brine tube.

Stuck ball in the air check valve. Clean the air check valve.

Control valve settings changed. Check the duration of brine tank rell and

correct if necessary.

8. Excess use of salt

per renegeration.

Control valve settings changed. Decrease the amount of salt per

regeneration in the control valve settings.

Brine tank lled with excess water. See paragraph 9.

9. Brine tank is

relled with excess

water.

High main water pressure. Check water pressure. Install pressure

regulator if needed.

Control valve settings changed. Check the duration of brine tank rell and

correct if necessary.

18

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

10. GUARANTEE

WARRANTY OBLIGATIONS

WARRANTY OBLIGATIONS

The warranty period of the water puricaon system is 12 months and is counted from the day of sale of the

system through the retail network (unless otherwise stated in the product warranty card).

The manufacturer guarantees that this water puricaon system does not contain manufacturing defects

and that such defects will not be detected during the warranty period specied in the warranty card, from

the moment of sale from the manufacturer’s warehouse or retail network, in the event that the puricaon

system is installed and operates in accordance with the technical requirements and operang condions.

Before using the water puricaon system, be sure to read the instrucons for connecng and operang the

water puricaon system and the terms of the warranty obligaons.

Carefully check the appearance of the water puricaon system and its completeness. Submit all claims

regarding appearance and completeness to the seller upon receipt of the product.

We reserve the right to make changes to the design, conguraon, or manufacturing technology, such

changes do not impose obligaons to replace or improve previously released products.

The warranty card is valid only if the model, date of sale, and clear stamps of the seller are correctly specied.

Consumer claims, in accordance with current legislaon, can be submied during the warranty period

of operaon, provided that the defects of the water puricaon system did not arise as a result of:

- non-observance of the condions of operaon and storage of systems specied in the instrucons

for connecon and operaon of the system;

- caused by transport damage, incorrect installaon, careless use or misuse, connecon to a power supply

voltage that does not correspond to that specied in the operang instrucons, failure to follow the aached

connecon and operang instrucons.

- operaon with unremedied defects, or with defects that arose as a result of maintenance or repair by

persons or organizaons that are not representaves of an authorized service center;

- causes independent of the manufacturer, such as: power supply voltage drops, natural phenomena,

and natural disasters, re, ingress of foreign objects (liquids) or other substances into the product;

- external and internal contaminaon, scratches, cracks, bruises, abrasions, and other mechanical damage

that occurred during operaon;

- changing the design or unauthorized opening of system nodes, when changing the serial number

of the product or the date of manufacture;

- unmely replacement of elements, the terms of which are indicated in the instrucons for connecon

and operaon, as well as when using replaceable elements of other manufacturers.

18 19

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibit This manual is the intellectual property of Ecosoft. Copying and reprinting is prohibited. © 2023 ecosoft.com

10. GUARANTEE

WARRANTY OBLIGATIONS

Warranty obligaons do not extend to:

- replaceable elements (cartridges, reverse osmosis membrane, carbon posilter, mineralized, and other

replaceable elements that can be equipped with the system) and sealing rings;

- components that need to be replaced as a result of their wear and tear;

- types of work, such as adjustment, cleaning, replacement of consumables, and other care of water

puricaon systems, spulated by the instrucons for connecng and operang the product.

The manufacturer shall not be liable for any damage or any other damage, including lost prots, arising

incidentally or as a result of the use or inability to use this product. The material liability of the Manufacturer

under this Warranty cannot exceed the cost of the water treatment system.

In the case of an independent connecon of the system, the manufacturer is not responsible and does not

accept claims that may be caused by incorrect connecon and incorrect operaon of the system as a whole.

The list of authorized service centers is indicated on the website hps://ecoso.ua/contacts/

All claims regarding the quality of water, taste, smell and other properes of water puried with the help of

water puricaon systems are accepted only in the presence of a conrming protocol of analysis performed

by a research accredited laboratory in accordance with the ISO 17025 standard.

Cases not covered by this Warranty are regulated by the Legislaon.

20

MANUAL FOR ECOSOFT COMPACT WATER SOFTENERS

ecosoft.com

11. SERIAL INFORMATION

INSTALLATION

INSTALLER

_______________________________________________________________________________

date of installaon

_______________________________________________________________________________

address and phone

_______________________________________________________________________________

accepted (customer`s name and signature)

_____________________________________________

organizaon

_____________________________________________

address and phone

_____________________________________________

works accomplished (name and signature)

_______________________________

date of sells

_______________________________

dealer company

_______________________________

saller name

Only the original Warranty Registraon Card with signature and stamp of the dealer is valid.

This manual suits for next models

2

Table of contents

Other Ecosoft Water Dispenser manuals

Popular Water Dispenser manuals by other brands

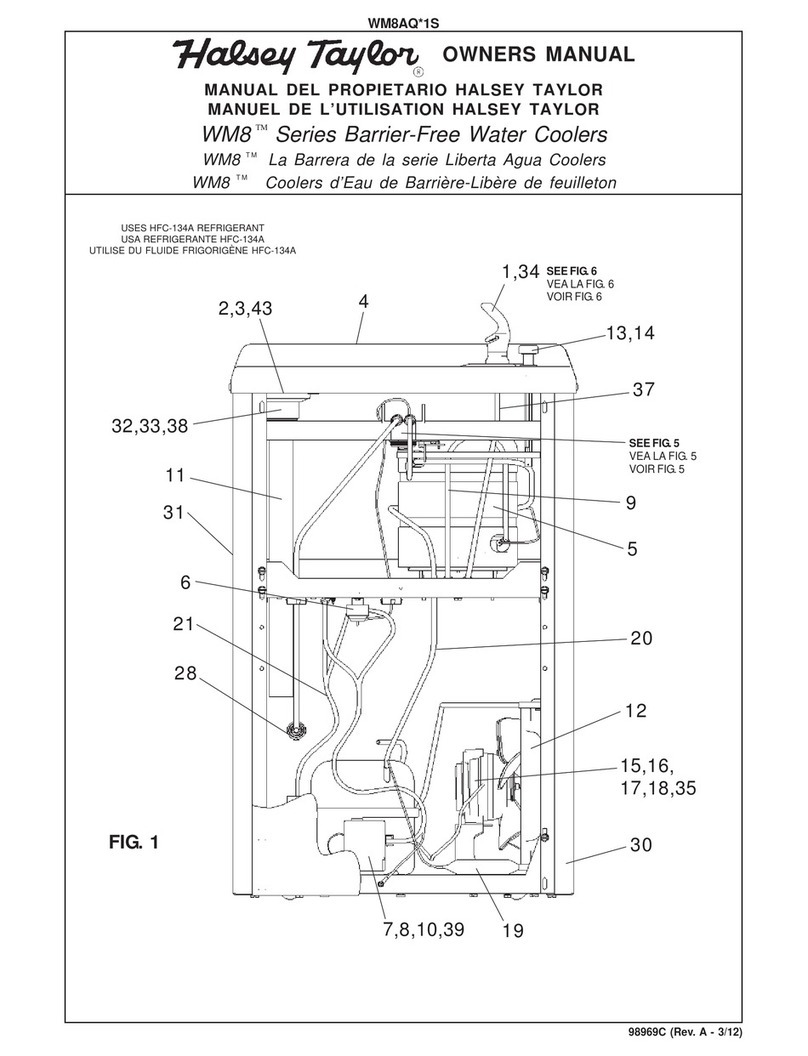

Halsey Taylor

Halsey Taylor WM8 Series owner's manual

Aqua Essentials

Aqua Essentials Borg & Overstrom B2 user guide

Hatco

Hatco ATMOSPHERIC AWD-12 Series Replacement parts list

Scotsman

Scotsman HID312 instructions

Kenmore

Kenmore ULTRASOFT 250 625.38826 owner's manual

Excalibur Water Systems

Excalibur Water Systems EWS SD2MQC120 Installation and user guide