Installation Instructions

Maintenance Instructions

Operating Instructions

A notification from the PAV-WS pressure switch on the bottom of the vent assembly indicates a system pressure

reading due to a failure of the primary float valve, which renders the ECS Ejector Automatic Air Vent inoperable.

1. The ECS Ejector Automatic Air Vent must be inspected annually at minimum.

a. Check the pressure gauge on the bottom of the vent assembly for a system pressure reading.

2. If a system pressure reading is detected the primary vent valve may require service or replacement.

a. While isolation ball valve is in the open position check for air/water leaks.

b. Close isolation ball valve to perform maintenance on the ECS Ejector Automatic Air Vent.

c. While isolation ball valve is in the closed position, inspection the “Y” strainer blockage, clean as necessary.

d. If replacement is required, contact Engineered Corrosion Solutions for replacement parts and instructions.

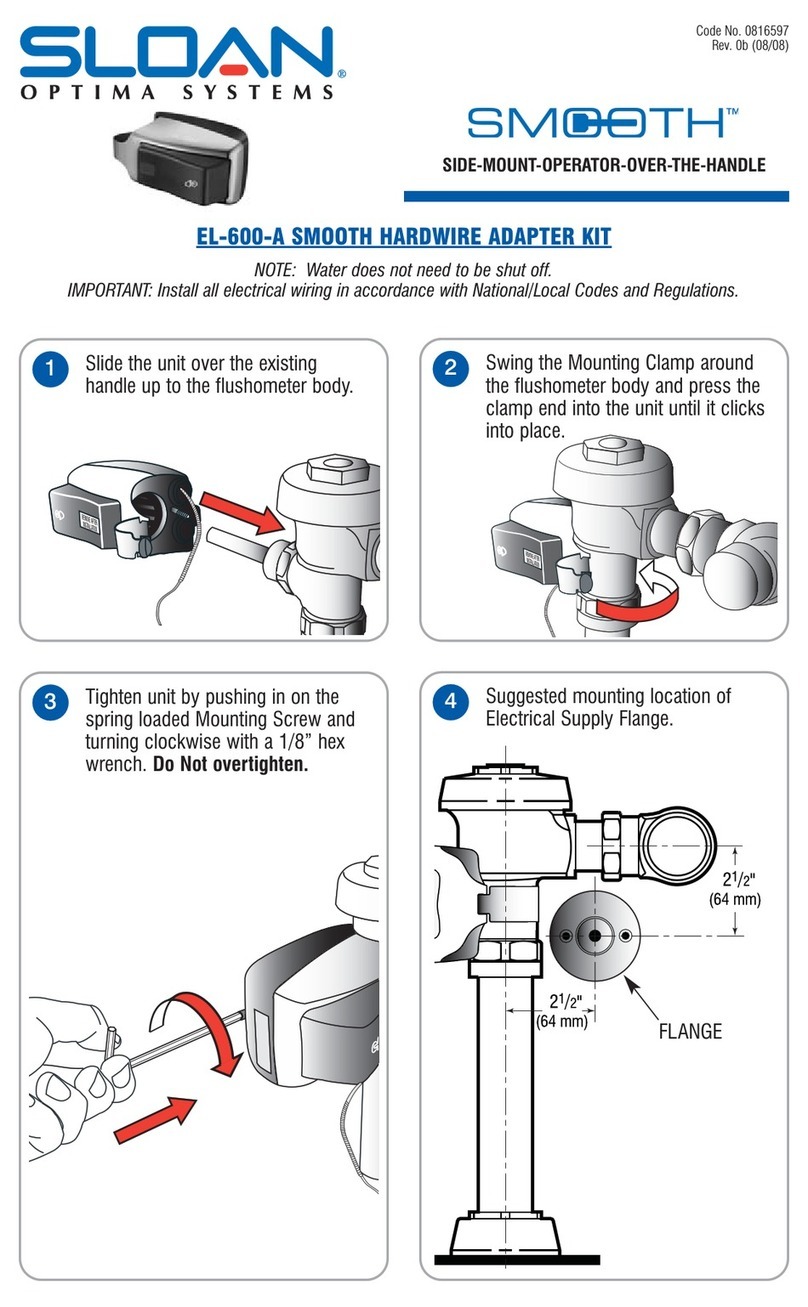

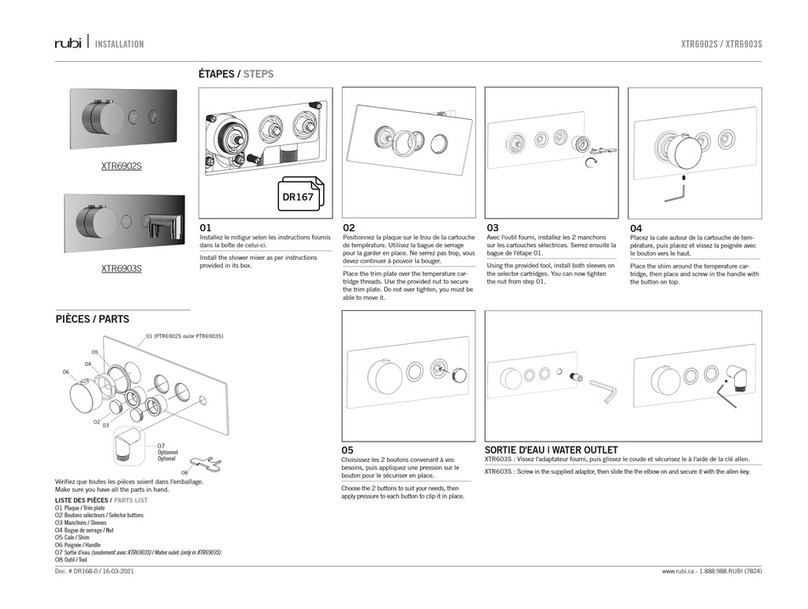

1. The ECS Ejector Automatic Air Vent is equipped with an isolation ball and a quick connect for easy installation

and servicing (see Figure 2).

2. Install the PAV-W/WS vent assembly at the location provided by the engineering design documents in a level

position at an accessible high point on the sprinkler system where trapped gas can be vented.

3. The contractor must install a ½” outlet (welded or mechanical) to connect the vent assembly to the sprinkler

system.

NOTE: Piping to the vent assembly cannot be installed in a configuration that would trap water and prevent

drainage to the sprinkler system. A water trap impedes the ability of the vent to remove gas from the fire

sprinkler system.

4. When electronic supervision is used, the PAV-WS must be utilized instead of the PAV-W. When connected to the

building alarm system, connect the PAV-WS to an addressable monitor module with an end-of-line resistor

(provided by others) in accordance with applicable national and/or local codes (i.e. NFPA-70 & NFPA 72). (see

Figure 1)

5. Inspection of the vent assembly should be performed after installation and hydrostatic testing of the fire sprinkler

system. Inspection should be performed periodically thereafter in accordance with the applicable national codes,

NFPA codes and standards, and/or the authority having jurisdiction.

NOTE: Patented redundant float design eliminates piping the PAV-W/WS to a drain.

1. Once the fire sprinkler system has been hydrostatically tested, open the isolation ball valve on the PAV-W/WS.

Trapped gas should be expected to immediately vent from the device if the system has been re-filled with water.

2. The isolation ball valve must remain in the open position to allow for venting of any additional trapped gas

remaining in the system that may migrate to the vent location.

3. Plumbing the PAV-W/WS to drain is not required. Occasionally during venting operations a small amount of water

may leak past the primary gas vent valve and collect in the intermediate plumbing. This is considered normal and

not a failure of the valve.

4. Water traps that would restrict operation of the ECS Ejector Automatic Air Vent can be cleared by closing the

isolation ball valve and removing the “Y” strainer plug. Once the water trap has been removed, replace the “Y”

strainer plug and reopen the isolation ball valve.

April 2020 - Rev 42

ECS EJECTOR

AUTOMATIC AIR VENT

PAV-W

Engineered Corrosion Solutions •11336 Lackland Road St. Louis, MO 63146 •Phone: 314.432.1377 •www.ecscorrosion.com