CARBURETOR PREPARATION

1. Compare throttle arm of your new carburetor with the old one to be

sure that all required linkages will hook up. Install proper throttle

and transmission linkage for your particular application. Throttle

stud is removable and must be installed in the proper location.

Chrysler vehicles

with automatic

transmission will

require Throttle

Lever Kit #1481.

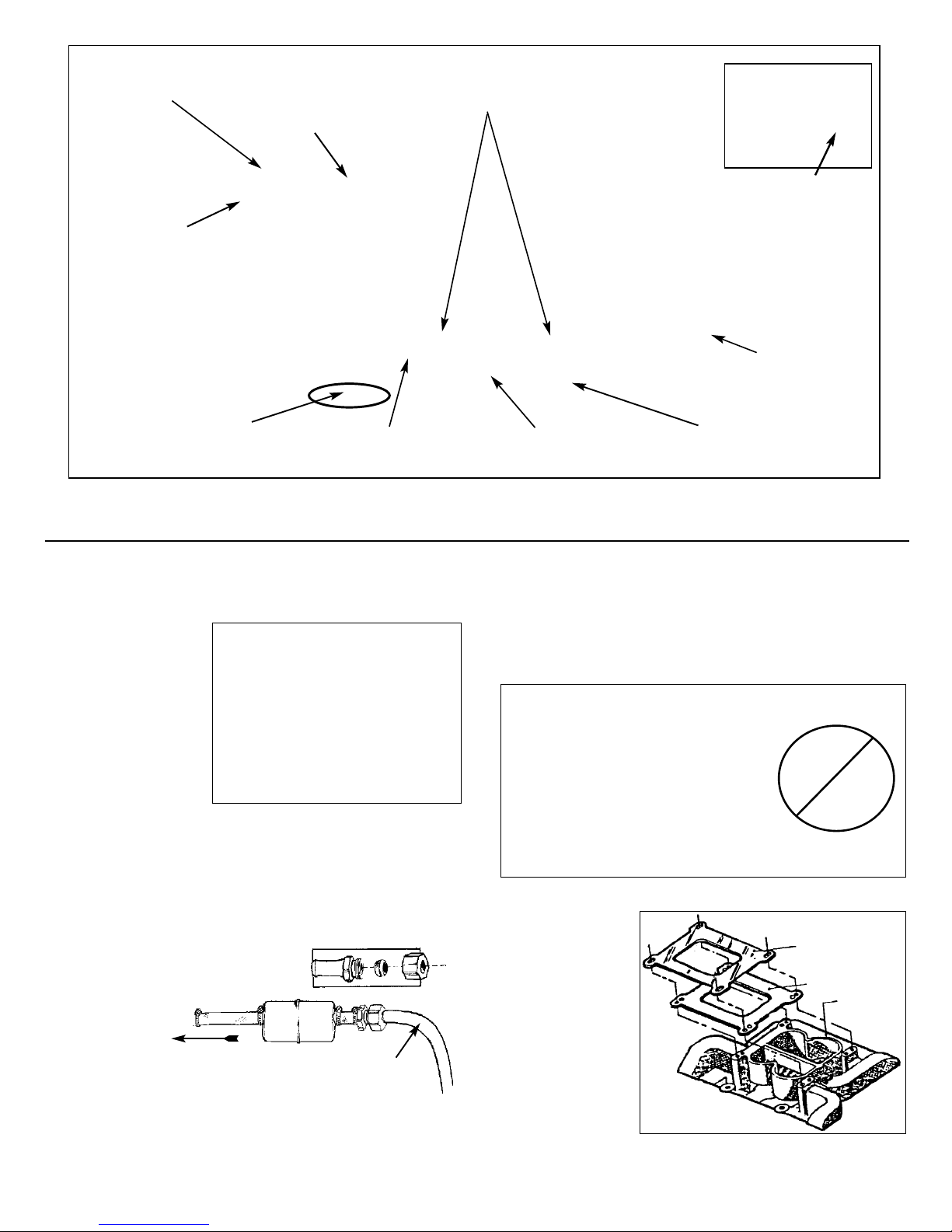

Ford vehicles with

automatic

transmission and

cable linkage will

require Throttle

Lever Kit #1483

(See Fig. 6)

and

Throttle Cable Plate

Kit #1490 (for 289-302), #1491 (for 351-W), #1493 (for 351-C &

351-M/400), or #1495 (for 429/460).

2. Check and prepare carburetor for proper vacuum fitting installation

(EGR, power brakes, PCV, distributor, transmission, etc.) using

supplied vacuum caps, “T”, and hose when applicable. If vacuum

port at rear of carb is not used, plug with the 1/4" pipe plug

supplied (Except marine models, port is not drilled).

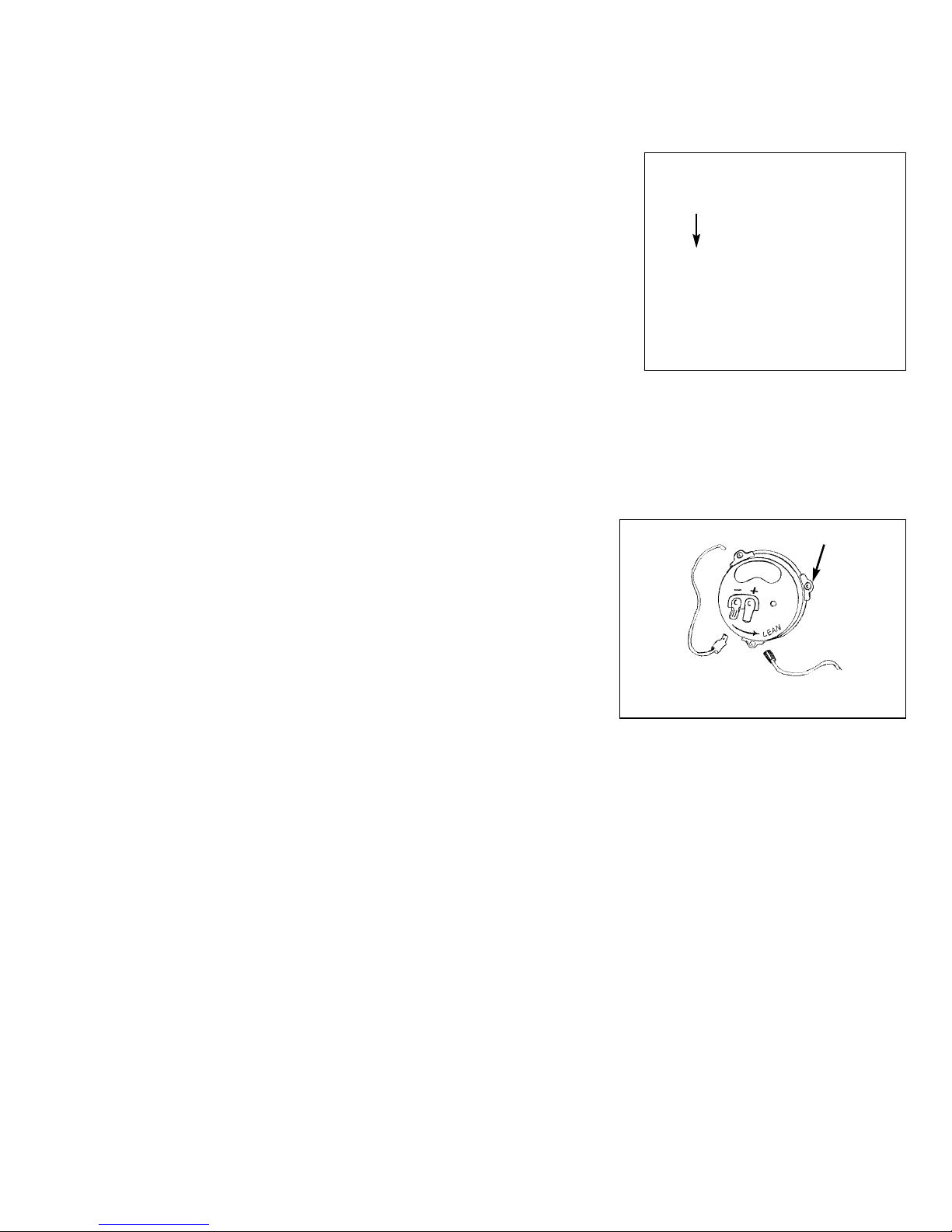

3. On electric

choke models

(See Fig. 7)

,

remove one

choke housing

retaining screw

and install

eyelet end of

choke ground

wire (black) to

choke housing

and reinstall

screw. Connect

clip end of choke ground wire to negative (–) spade terminal on

choke housing.

CARBURETOR INSTALLATION

1. Remove rag from intake manifold and install new studs, mounting

gasket and adapters (where applicable).

NOTE: Do not use any cement, glue or RTV sealant on gasket.

2. Carefully place new carburetor on gasket.

3. Replace all mounting nuts and washers. EnduraShine™ finish

carburetors should use the supplied 5/16” flat washers under any

other washers used. Hand tighten with a short box end wrench,

alternating between diagonally opposed nuts.

CAUTION: Overtightening may break carb base and void

warranty.

©2005 Edelbrock Corporation

Brochure #63-0061, Rev. 12/05 - RS/mcPage 3 of 4

Catalog #s 1403, 1404, 1405, 1406, 1407, 1409, 1410,

1411, 1412, 1413 - Performer Series Carburetors

6. Do not use more than 6.5 psi fuel pressure. Excessive fuel

pressure may cause flooding. If your fuel pressure is too high,

install an adjustable pressure regulator such as Edelbrock #8190.

7. It may be necessary to re-route the fuel line to prevent interference

with the air cleaner. Test fit your air cleaner on your new carburetor

before you begin installation. Look for areas of interference such as

the choke housing, fuel inlet fitting and fuel line.

PERFORMER SERIES CARBURETOR INSPECTION

1. Check for possible damage to carburetor.

2. Make sure all throttle linkages operate freely.

3. Ensure that all fuel inlet and vacuum ports are free from packing

material.

CARBURETOR REMOVAL

1. Prior to removal make sure that the engine is cool.

2. Disconnect negative battery cable from battery.

3. Remove air cleaner. Be sure to carefully disconnect any hoses from

the air cleaner and note their location for re-installation. You may

want to mark them with masking tape for easy reference.

4. Disconnect throttle linkage, kickdown linkage (certain automatic

transmission applications only), cruise control (if equipped) and any

return springs if present.

NOTE: Check carefully for the precise location of all these linkages

and return springs. You may want to mark them with masking tape

for easy reference.

5. Disconnect all wires, tubes and hoses from carburetor and note

their location.

NOTE: There should be a maximum of one wire to the

electric choke and one to the idle compensator solenoid. Any other

electrical wiring attached to your carburetor indicates a computer

controlled engine, and Edelbrock carburetor will not function

correctly on computer controlled applications.

6. Disconnect the heater tube from the choke housing (if so equipped).

Edelbrock carburetors do not use the hot air style choke, so this

tube may be left disconnected with no problems. If you want to

cover this opening on a stock intake manifold, you may be able to

use the appropriate Edelbrock choke adapter plate: #8901 for

small-block Chevrolets; #8961 for big-block Chevrolets; #8951 for

Oldsmobile V8s; #8971 for 351-M/400 Fords; #8981 for 351-W

Fords.

7. Carefully remove fuel line from carburetor. TAKE EXTREME CARE

NOT TO SPILL ANY EXCESS FUEL. Place a rag underneath the fuel

line to absorb any spillage that may occur. Certain models require

two wrenches to remove the fuel line; one to hold the fitting on the

carburetor and the second to turn the fitting on the fuel line. Use a

tubing wrench to avoid rounding the tube fitting nut.

8. Remove mounting nuts or bolts and washers. Be sure to put them

where they won't fall into the intake manifold upon carburetor

removal.

9. Remove carburetor, being careful not to spill any dirt into the intake

manifold. Immediately place a clean rag into the manifold to keep

foreign objects out.

10. Remove old mounting gasket and thoroughly clean mounting

surface. Compare old carb gasket to gasket included with new

carburetor. If there is a difference in bolt pattern or bore spacing,

an adapter will be required (see “Before Removing Old Carburetor”,

steps #4 & #5).

Ford Throttle

Lever #1483

bolts on carb

throttle arm

Fig. 6

Figure 7– Choke Wire Installation

Retaining Screws (3)Black wire (–); to ground

(carb body)

Red wire (+); To ignition key activated 12V source;

NOT coil or alternator!