Edge BH 69 Owner's manual

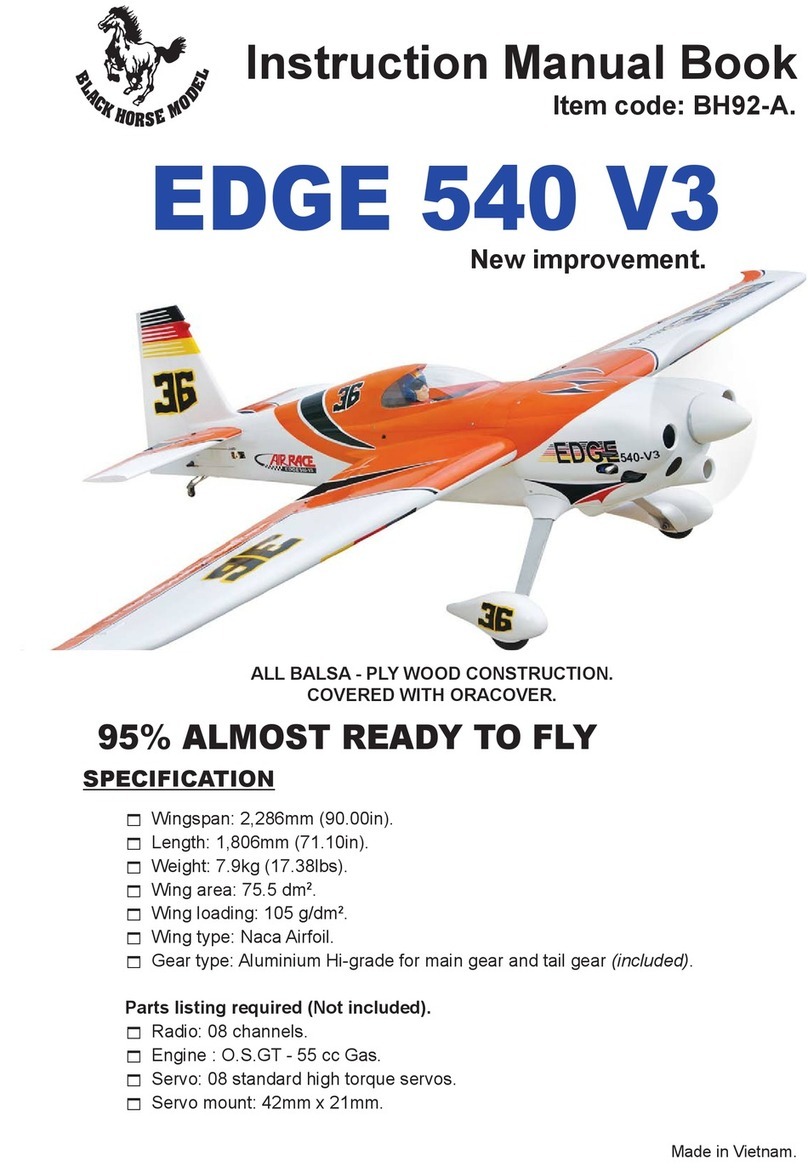

SPECIFICATION

Wingspan : 1,580 mm 62.20 in.

Length : 1,400 mm 55.12 in.

Weight : 3.6 kg 7.26 Lbs.

Radio : 06 channels.

Servo : 06 servos.

Engine : 61-75 2 stroke.

91 4 stroke.

Instruction Manual book

MadeinVietnam.

2

EDGE - Item code: BH69 . Instruction Manual

This instruction manual is designed to help you build a great flying aeroplane. Please read this

manual thoroughly before starting assembly of your EDGE. Use the parts listing below to identify

all parts.

WARNING.

Please be aware that this aeroplane is not a toy and if assembled or used incorrectly it is

capable of causing injury to people or property. WHEN YOU FLY THIS AEROPLANE YOU

ASSUME ALL RISK & RESPONSIBILITY.

IfyouareinexperiencedwithbasicR/CflightwestronglyrecommendyoucontactyourR/Csupplier

and join your local R/C Model Flying Club. R/C Model Flying Clubs offer a variety of training

proceduresdesignedtohelpthenew pilotonhiswaytosuccessfulR/C flight.Theywillalso beable

to advise on any insurance and safety regulations that may apply.

TOOLS & SUPPLIES NEEDED.

Thick cyanoacrylate glue.

30 minute epoxy.

5 minute epoxy.

Hand or electric drill.

Assorted drill bits.

Modellingknife.

Straight edge ruler.

2mm ball driver.

Phillips head screwdriver.

220 grit sandpaper.

90° square or builder’s triangle.

Wire cutters.

Masking tape & T-pins.

Thread-lock.

Paper towels.

Some more parts.

HARDWAREPACK

COWLING.

Landinggear.....

Toavoid scratching yournew airplane,donot

unwrap the pieces until they are needed for

assembly. Cover your workbench with an old

towel or brown paper, both to protect the air-

craftand toprotect thetable.Keepacoupleof

jars or bowls handy to hold the small parts af-

ter you open the bag.

Pleasetrialfitalltheparts. Makesureyouhave

the correct parts and that they fit and are

alignedproperly beforegluing!Thiswillassure

proper assembly. EDGE ARF is hand made

from natural materials, every plane is unique

andminor adjustmentsmayhave tobe made.

However, you should find the fit superior and

assembly simple.

The painted and plastic parts used in this kit

are fuel proof. However, they are not tolerant

of many harsh chemicals including the follow-

ing:paintthinner,C/Aglueaccelerator,C/Aglue

debonderandacetone. Donotletthesechemi-

cals come in contact with the colors on the

covering and the plastic parts.

PARTS LISTING.

FUSELAGE ASSEMBLY

(1) Fuselage.

WING ASSEMBLY

(1) Right wing half with pre-installed

aileron.

(1) Left wing half with pre-installed

aileron.

Tail section assembly

(1) Vertical stabilizer with pre-

installedrudder.

(1) Horizontal stabilizer with pre-

installedelevator halves.

SUGGESTION.

NOTE.

3

EDGE - Item code: BH69 . Instruction Manual

+ This is not a toy

+ Be sure that no other flyers are using your

radio frequency.

+ Do not smoke near fuel

+ Store fuel in a cool, dry place, away from

children and pets.

+ Wear safety glasses.

+Theglowplug clipmustbesecurely attached

to the glow plug.

+ Do not flip the propeller with your fingers.

+ Keep loose clothing and wires away from

thepropeller.

+ Do not start the engine if people are near.

Donot standinlinewiththesideof thepropel-

ler.

+ Make engine adjustments from behind the

propeller only. Do not reach around the spin-

ningpropeller.

SAFETY PRECAUTION.

REPLACEMENT LARGE PARTS

B. Wing panel.

C. Fuselage.

A.Cowling.

D . Horizontal stabilizer.

F. Aluminium wing dihedral

brace.

E.Vertical stabilizer.

G.Decal sheet.

REPLACEMENT SMALL PARTS

1) Install the rubber grommets and brass

eyelets onto the aileron servos.

1.INSTALLING THE AILERON SERVOS.

I. AILERON.

Aileron

Top side.

Aileron Bottom side

C/Aglue

Bottom side

A.

B.

B.

C.

G.

D. E.

F.

4

EDGE - Item code: BH69 . Instruction Manual

C/Aglue

C/Aglue

3) Using the thread as a guide and using

masking tape, tape the servo lead to the end

of the thread: carefully pull the thread out.

When you have pulled the servo lead out, re-

move the masking tape and the servo lead

from the thread.

Remove

covering

2.Usinga modelingknife,remove thecov-

ering servo tray.

4. Drill 1,5mm pilot holes through the block

of wood for each of the four mounting screws

provided with the servo. Install servo into ai-

leron servo tray as same as picture below.

Aileron

Bottom side

C/Aglue

C/Aglue

Electric wire

Thread

5

EDGE - Item code: BH69 . Instruction Manual

3 x 40mm.

Nilon control clasp.M3lock nut.

INSTALLINGTHEAILERON CONTROLHORN.

Removecovering

6

EDGE - Item code: BH69 . Instruction Manual

Repeat the procedure for the other wing

half.

Installing the aileron linkages as pictures

below.

INSTALLING THE AILERON

LINKAGES.

M3 M3 lock nut

C/Aglue

C/Aglue

70mm

7

EDGE - Item code: BH69 . Instruction Manual

Repeat the procedure for the other wing

half.

INSTALLING THE ENGINE MOUNT.

See pictures below:

INSTALLING THE STOPPER ASSEMBLY

FUEL TANK.

4x30mm

4x30mm

1. The stopper has been pre-assembled at

the factory.

2.Using amodeling knife,cut onelength of

siliconfuelline (thelength ofsilicon fuellineis

calculated by how the weighted clunk should

restabout 8mmaway fromtherearofthetank

andmove freelyinside thetank). Connectone

end of the line to the weighted clunk and the

otherend tothenylonpickuptubein thestop-

per.

3.Carefully bendthesecond nylontube up

ata 45degreeangle (usingacigarettelighter).

This tube will be the vent tube to the muffler.

Drillahole4mm

diameter

Silicon tube not included

8

EDGE - Item code: BH69 . Instruction Manual

5. Test fit the stopper assembly into the

tank. It may be necessary to remove some of

the flashing around the tank opening using

amodeling knife. Ifflashing is present, make

sure none of it falls into the tank.

8. Feed three lines through the fuel tank

compartment and through the pre-drilled hole

in the firewall. Pull the lines out from behind

the engine, while guiding the fuel tank into

place. Push the fuel tank as far forward as

possible,the frontofthetankshould justabout

touch the back of the firewall.

6. When satisfied with the alignment of the

stopper assembly tighten the 3mm x 20mm

machine screw until the rubber stopper ex-

pandsand sealsthetank opening.Do notover

tighten the assembly as this could cause the

tank to split.

7. Using a modeling knife, cut 3 lengths of

fuel line 150mm long. Connect 2 lines to the 2

vent tubes and 1 line to the fuel pickup tube in

the stopper.

Blow through one of the lines to ensure

the fuel lines have not become kinked inside

the fuel tank compartment. Air should flow

througheasily.

9. To secure the fuel tank in place, apply a

bead of silicon sealer to the forward area of

thetank, whereit exitsthefuselage behindthe

enginemountingbox andtotherearofthetank

at the forward bulkhead.

Do not secure the tank into place perma-

nently until after balancing the airplane.

You may need to remove the tank to mount

the battery in the fuel tank compartment.

When the stopper assembly is installed

in the tank, the top of the vent tube should

rest just below the top surface of the tank.

It should not touch the top of the tank.

4. Carefullybend thethirdnylon tubedown

ata 45degreeangle (usingacigarettelighter).

This tubewill bevent tubeto thefuelingvalve.

9

EDGE - Item code: BH69 . Instruction Manual

Locate the long piece of wire used for the

throttlepushrod. Oneendofthewire hasbeen

pre-bend in to a “Z” bend at the factory. This

“Z” bend should be inserted into the throttle

armofthe enginewhentheengine isfittedonto

theengine mount.Fittheengineto theengine

mount using the screws provided.

Markpoint

4 x 30mm

Pushrod wire.

Fueltank

115mm

INSTALLING THE ENGINE.

Drill a hole 4mm

diameter

10

EDGE - Item code: BH69 . Instruction Manual

Left side

Secure

1. Slide the fiberglass cowl over the en-

gineand lineup thebackedgeofthe cowlwith

the marks you made on the fuselage.

COWLING.

2. While keeping the back edge of the

cowl flush with the marks, align the front of

thecowlwiththecrankshaftoftheengine. The

front of the cowl should be positioned so the

crankshaft is in nearly the middle of the cowl

opening. Hold the cowl firmly in place using

pieces of masking tape.

3. Slide the cowl back over the engine

andsecure itin placeusing fourwood screws.

See picture below.

4. Installthemufflerandmufflerextension

onto the engine and make the cutout in the

cowl for muffler clearance. Connect the fuel

and pressure lines to the carburetor, muffler

andfuel fillervalve.

Trim and cut

Botom side

Right side

Left side

11

EDGE - Item code: BH69 . Instruction Manual

Top side

Right side

Botom side

Machine screw.

Right side

Right side

Trim and cut

Front view

3 x 12mm

Installthe spinnerbackplate,propellerand

spinner cone. The spinner cone is held in

place using two 3mm x 12mm wood screws.

3 x 12mm

INSTALLING THE SPINNER.

Secure

12

EDGE - Item code: BH69 . Instruction Manual

Throttle servo

Secure

SERVO INSTALLATION.

ELEVATOR INSTALLATION.

2. Mount the servo to the tray using the

mountingscrews providedwithyourradiosys-

tem.

1. Install the rubber grommets and brass

colletsintothe elevatorservo.Testfit theservo

into the servo tray.

Servo arm.

Throttle pushrod

Throttle servo

Install one adjustable metal connector

through the third hole out from the center of

one servo arm, enlarge the hole in the servo

arm using a 2mm drill bit to accommodate the

servo connector. Remove the excess mate-

rial from the arm.

INSTALLING THE THROTTLE PUSHROD.

After installing the adjustable metal con-

nector apply a small drop of thin C/A to

the bottom nut. This will prevent the con-

nector from loosening during flight.

Secure

Connector.

Cut

13

EDGE - Item code: BH69 . Instruction Manual

Horizontal stabilize installation .

See picture below.

C/Aglue.

C/Aglue.

HORIZONTALSTABILIZER

INSTALLATION. C/A glue.

C/Aglue.

C/Aglue.

1. Draw a center line onto the horizontal

stabilizer.Then putthe horizontalinto thefuse

large.

2 Using a modeling knife, cut away the

covering from the fuselage for the stabilizer

and remove it.

Center line.

14

EDGE - Item code: BH69 . Instruction Manual

3. Mark theshape ofthe verticalonthe left

and right sides onto the horizontal stabilizer

using a felt-tip pen

When cutting through the covering to re-

move it, cut with only enough pressure to

only cut through the covering it’s self. Cut-

ting into the balsa structure may weaken

it. This could lead to possible failure dur-

ing flight.

Removecovering.

5. When you are sure that everything is

aligned correctly, mix up a generous amount

of 30 minute epoxy. Apply a thin layer to the

topand bottomofthestabilizermountingarea

and to the stabilizer mounting platform sides

inthefuselage.Slidethestabilizerinplaceand

re-align. Double check all of your measure-

ments one more time before the epoxy cures.

Remove any excess epoxy using a paper

towel and rubbing alcohol and hold the stabi-

lizer in place with T-pins or masking tape.

Check to mark sure the wing and stabi-

lizer are paralell. If they are not, lightly sand

theopening inthefuselageforthe stabilizer

until the stabilizer is paralell to the wing.

Remove covering

Markline.

Botom side

4. Remove the stabilizer. Using the lines

youjustdrew asa guide,carefully removethe

coveringfrom betweenthem usingamodeling

knife.

15

EDGE - Item code: BH69 . Instruction Manual

6. Afterthe epoxy has fully cured, remove

the masking tape or T-pins used to hold the

stabilizer in place and carefully inspect the

glue joints. Use more epoxy to fill in any

gaps that were not filled previously and

clean up the excess using a paper towel and

rubbingalcohol.

Epoxyglue.

C/Aglue.

Elevator control horn install as same as the

way of aileron control horn. Please see pic-

tures below.

3mm x 40mm.

Nilon control clasp.

M3 lock nut.

ELEVATOR CONTROL HORN

PUSHROD INSTALLATION.

Bottom side

C/A glue

C/A glue

Top side

Remove

covering.

16

EDGE - Item code: BH69 . Instruction Manual

Elevatorpushrod installas sameas theway

of aileron pushrod.

ELEVATOR PUSHROD INSTALLATION.

Elevator

control horn.

Remove covering.

Elevator

pushrod

17

EDGE - Item code: BH69 . Instruction Manual

Elevator

control horn. Elevator

control horn.

Botom side

Secure

Cut

Cut

Bend and

cut after

Elevatorservo

Elevator pushrod

18

EDGE - Item code: BH69 . Instruction Manual

VERTICAL INSTALLATION.

Rudder servo install as same as method of

elevator servo. See picture below:

2. Markthe shapeofthe verticalon theleft

and right side on the rudder using a felt-tip

pen.

1. Put the rudder into the fuselage as

same as picture below.

Markpoint

3. Now, remove the rudder and using a

modeling knife, carefully cut just inside the

marked lines and remove the film of the rud-

der. Just as you did with the horizontal stabi-

lizer, make sure you only press hard enough

to cut the film, not the balsa rudder.

Hinge.

C/Aglue

C/Aglue

19

EDGE - Item code: BH69 . Instruction Manual

Also carefully remove the covering from

below the lines as you drew as same picture

below.

Removecovering

4) When you are sure that everything is a

aligned correctly, mix up a generous amount

of 30 minute epoxy. Apply a thin layer to the

slot in the mounting platform and to the verti-

cal stabilizer mounting area. Apply epoxy to

the lower rudder hinge. Set the stabilizer in

place and re-align. Double check all of your

measurements once more before the epoxy

cures. Remove any excess epoxy using a

paper towel and rubbing alcohol and hold the

stabilizerin placewithT-pins ormasking tape.

Allow the epoxy to fully cure before proceed-

ing.

Removecovering Epoxyglue

5. Using a modeling knife cut away the

covering from the end of fuselage for the rud-

derhinge.

C/Aglue

Epoxyglue

Epoxyglue

20

EDGE - Item code: BH69 . Instruction Manual

Rudder control horn install as same as the

way of aileron control horn. Please see pic-

tures below.

Remove

covering

Hingeslot

C/Aglue

C/Aglue

RUDDER CONTROL HORN INSTALLA-

TION.

3mm x 40mm.

Nilon control clasp.

M3 lock nut.

Other Edge Toy manuals

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions