Edgetech 2000 Series User manual

MODEL 2000 SERIES

DEWPRIME

DEW POINT

HYGROMETER

OPERATOR'S MANUAL

v

i

i

Model

2000

Serie

s

DewPrime

Dew

Poin

t

Hygrometers

Page

THEORY OF OPERATION.

.

.

.

...

.

..

..

.....

.

....

.

..

....

.

.....

..

.

....

.

.

.

.

.

.

.

...

....

..

.

.

..

..

..

...

..

..

......

..

.

.

.

.

.

...

..

.

...

.

.

..

..

..

.

.......

.

......

4-1

4.1

SYSTEM OPERATION.......

.

.

..........

.

..

.

.

.

..................

.

....

.

...

..

......

.

..

..

...

.

...

.

.......

..

...

.

....................

.

.......

4-1

4.1.1 Main

Control

Loop..

..

.

..

..................

.

..................

..

..

.

.........

.

...

.

.

.

..

.

.

.

...........

.

.

.

..

.

.....

...

....

.

..

.

.

...

...

4-1

4.1

.

2

Temperature

..

..

.

.

.

.....

.

..

.....

.....

..

.......

....

.

.

.

.

.

...

..

............

..

..

.......

...

...

...

..........

.

.

.

...

.

..

..

....

.

....

.

....

..

.

..

.

.

..

4-1

4

.

1

.

3

Automatic Balance Control.....

..

..

.

.

..

.

.....

.

..

..

..

...

....

..

.

......

..

.

....

..

...

.....

..

.

........

.

..

.

..

.

.......

...

.

....

..

.

...

4-

1

4.1.4

Microprocessor

Control............................................................................................

.

..

........

4-1

4.2 CIR.CUIT

DESCRIPTIONS...................

.

.

...

.

..............

.

..

.

.

.

............................

.

........

.

..................

..

....

4-1

42.1

Thermoelectric

Dew

Point Temperature Control

Circuits....

.

.

............

.

.

.

..

.

......

.

...

.

..

.

..

.......

.

.

..

. 4-1

4.2

.

2

Sensor

PRT Resistance-t<rVoltage

Converter

....

.

.

.

..

..

..

....

.......

..

.

.

...

.......

......

.....

.

....

.

...

....

.

..

.

..

4-3

4.2.3

Automatic Balance Control Circuits.................

.

..

.

...

....................

..

...........

...

.............

......

..

..

4-3

42

.

4

Alarm Setand

Protection

Circuits........................

.

.

..........

.

......

.

....................

...

..

.

........

..

.

...

..

4-3

4.2.5 Display

Circuitry...

.

....

..

.

.............

.

..

..

.

...

.....

.........

.

.

.

.

.

.

.

..................

.

.

.

...

.

.................

..

......

......

.

..

...

4-4

4.2.6

Track

or Hold

Circuitry

....

....

.

........

....

......

.

..

.

.

....

...

..........

.

.....

...

...

.....

......

.

..

..

..

..

..

.

......

....

.

.

.

....... 4-4

MAIN1'ENANCE

AND C

RATION............................................

.

................

.

....

.

...........................

5-I

5.1

ROlJTINE MArn'IENAN"CE

.

.

.

...........

...

...

...

..

.........

...

.

.

......

..

.........

......

......

.

...

......

......

...

........

.

.

..

..

..

..

.

5-l

5

.

2

OR

CLEANmG

SClffiDUI..E.........

..

...

.

......

.

.

...

.

....

.......

..

..

..

........

..

.........

.

.

.

..

.......

.......

..

....

.....

..

5-1

5.3

OR

CLEANmG....

.

.

........

..

.........

..

....

..

..

....

..

...

.....

......

..

.

..

..........

..

..

..

.

...

....

..

.....

..

..

..

........

..

..

..

..

...

5-1

5

.

4

CALffiRATION

OF

PRT

..

..

..

..

..............

........

.

..........

....

..

...

..

.

...

.

.

..

.

..

.....

..........

.

..

..

...................

.

..

.

....

.

5-l

5

.

5

CALIBRATION OF

THEPRT

AMPLmER..........

.

..

...

..

...

..............

....

.

..

.............

.

....

.............

......

..

..

5-2

5

.

6

OPERATlN'GADJUS'J'IIdENTS

........

....

.

......

....

.

.

.

.

..

.......

..

.....

.

.

..

......

......

...............

.

..

.....

...........

......

..

.

5-2

5

.

6

.

1

Balance

for S2

Sensor.....

.

....

...............

.....

............

.

....

..

.....

.

.

.

..........

.....

..

...

..

..

.

.

..

..

....

...

.....

.

..

....

5-2

5

.

6

.

2

Balance

for Sl

Sensor....................

.

..

.

.................

.

.......................................

..

.......

.

...

..

..........

5-3

5

.

6

.

3

Thickness..

..

..........................................

.

................................

..

...

..

....................

.

.........

.

..

.

....

.

5-3

5

.

6.4

Gain

.

....

.

.

...

.

....

.

.

.

..

.....

....

.........

....

.

............

.

...

....

....

.....

.

.......

..

.

..

...

..

...

....

..

...........

..

....

.

...........

.

.

.

..

...

..

5-3

5

.

6.5

Compensation..

.

.

.

....

..

.

..

.

......

.

..

....

....

.

.....

...

...

.

...

...

.

.

.....

.

.

..

.....

.

..

......

.

.

..

..

..

.

.....

..

.

.

.

..

.

..

.

..

.

..........

...

.

.

..

..

54

5

.

7

'WET1'ED

PAR.TS.

.

.

.

.

...........

.

....

.

.............

..................

..

..............

.

.

.

...

.

..............

..

...

..

......

.

..

...............

.

...

5-4

5

.

8

SUGGESTED SPARE

PAR.TS

..

...............

..

..

............

.

....

..

.

..

..........

..

........

.

....

..

...

..

.

..

..................

.

..

....

5-4

TR.OUBLESHOOTIN'G

AND

RE

P

AIR...

.

..

........

.

...

..

.

...

.

.

.

........

.

...

.....

..

.

.....

..

.

..

.

......

..

.......

.

....

.

.

.

..

..

..

.

.

.

.

.....

..

.

.

.

6-1

6.1

LOCA'IW'G

TROlJBLE......

.

....

..

.......

.

............................

...

..........

.

.

.

.....

..

..........

..

..............................

6-1

6.2

TEST

POrnTS

.

...

.

.............

.

.........

..

.......

..

.

.......

..............

.

.....

..

.........

.

.

..

.

.

.............

..

..........

.

..................

6-1

APPENDIX-BASIC

HUMIDITY

DEF1NITION

S

.

....

.

.

.

....

..

.

......

...

.

.....

.

....

.

...

.

.

.

....

..

......

.

..

...

..

.

..

..

.....

..

......

.

A-1

CUSTOMERSERVICE ANDRMA FORM

v

i

i

WARRANTY

STATEMENT

Model2000

Serie

s

DewPrime

Dew Point

Hygrometers

viii

List of

illustrations

Figure Page

1-1 EdgeTech Model 2000 Series.

DewPrime

Dew Point

Hygrometers.........

.

......

.

.....................

.

.

.

.

........

1-2

1-2 Rear Panel, EdgeTech Model 2000 Series

DewPrime

Dew

Point

Hygrometers..........

.

.

.

..

............... 1-2

2-1 Suggested sampling

system

...••.•...•..•..•

••

......•.

.

.

.

.•.••.•..••••.....•..•.••...••.•................

.

.

.

.•••......

.

.

.

.•••....•...•.....

2-4

2-2 Typical sample line material

response

characteristics...

.

.

.

..................................

.

.......................

.

.....

2-5

2-3

Flow corrections

for

variousflow

pressures...........................................................................

.

........

2-7

2-4

Flow corrections

for

various

gases.......

.

.

.

...............................

.

..

.

........................................................

2-7

3-1 Front panel, EdgeTech Model 2000 Series

DewPrime

Dew

Point

Hygrometers........................

...

.

3-2

4-1 Block diagram of

EdgeTech

Model 2000

DewPrime

Dew Point

Hygrometers..............................

4-2

List of

Tables

Table

3-1 Identification of keys on front panel

keypad................................................................................... 3-1

3-2 Identification of

:front

panel

indicator

s........................

....

.......

....

............

.

........

.

................................

3-4

3-3 ImLP

menu

.

......

.

..

...

..........

..

........

..

....................

.

.

.

........

..

..............

.

..

.

.........

.........

...

.............................

3-6

3-4 Programmable

limits.....

.

.....

.......

..

.

..

.......

..

............

.

..

........

....

.

..

..

..

....

....

............................

...

..

.......

....

....

3-9

3-5 Default programmable

parameters

......

.

............................................................................................

3-9

6-1 Troubleshooting chart:preliminary

checks......................................................................................

6-2

6-2 Fault

isolation...................................................................................................................................

6-3

Model2000

Serie

s

DewPrime

Dew Point

Hygrometers

Page

2.13

2.14

2.15

2.16

RECO

1v.t1tr1END

ED

HARDWARE

.

.

..

..

..

...

.

...

.

...

.

.

..

.

..

....

.

..

..

.

..

...

..

.....

.

.......

.

.

.

..

..

.

...

..

...

..

.

.

..

.

.

.

.

..

.

.

....

.

..

.

...

..

2-5

2.13.1

Pumps

.

·-

·

···············

·

·

·

·

·

·

·

·········

·

·

·

·

·

········

··············

·

·

·

················

·

·

·

··············

·

·

·

·

·

·

·

·····

·

·

·

·············

·

·

·

·

·

·

·····

2-5

2

.

13

2

Filters

..

............

.

.

.

.......

.....

.

.........

.

..

..

....

.

.

.

.............

..

..

..

......

.

.......

..

.......

..

................

.

.

.

.................

.

.

.

..

2-5

2

.

13

.

3

Flow

Gauge

s

.

...

...

...

...

..

..

.

.

.

.

.

.

.

.

....

.

...

....

.

..

.

..

.....

..

....

......

.

..

......

.

.

.

.

.....

..

...............

.

.

.

..

...

..

.........

...

...

.

..

.

.

2-6

2.13

.

4

SampleTubing

and

Recommended Fittings..

.....

.

....

..

.

..

...

......

..

.

.......

..

.

....

..

...........

.

.......

.

..

.

.

....

2-6

PRESSURE

l\1EAS S...........

.

.................

.

.

..

........

.

..

..

...

..

..............

.

..

..

.

...

.............

......

.

....... 2-6

CLEANmG 11iE

S LmG

SYSTEM...............

..

.........

...

..

.

....

.

...............

.

.

.

.

...

.....

.

....

.

..

..............

2-6

SArv.tPI..E

FLOW

RA

'I'E....

.

..

.

.

.

.

.....

.

..

.

..

........

.

.

.

.

.

.........

.

.

.

...

.

.....

.

.

.

......

.

..

.

.

...

.

.

...........

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

.

.

..

.

.

.

.

...

.

..

........

2-6

OPERATIN'G

IN'S1'R.UCI10N

S

.

...............

....

.

.

.

.

.

............

.......

.

..

............

...

.

..

......

.

......

.

..

...

............

.

.

.

.

.

.

.

.

.

.........

.

3-1

3.1

3.2

3

.3

3.4

3.5

3.6

KE'YP.AD

IDENTIFICATION

..........

......

...............

...

.

..

..............

..

.............

.

.

.

.

..

..

..

.

...

.

........

····

·

·

·

·

········

3-1

KEYPAD

LOCKO'UT

SEClJRITY·

·

·

·

·

·

·

·

·

·······-·······

·

·

·

·

·

·

·

·

·

·

···

·

·

·

··

·

·

·

·

·

·

·

··

··

·

·

·

··

·

·

·

···························

··

··

·

·

·

·

·

·

·

··-

·

3-1

F'R.ONT

PANEL

KE'YPAD

OPERATION...

..

.

..

.

..

.....

.

.

.

.

...

..........

..

..

..

..

.

...

.

.

.

..

.

..

..

.

..

..

.

.......

.

.

.

..

.

.

.

...

..

..

...

.

..

3-3

F'R.ONT

PANEL rnDICATORS......

.

..

..

.....

.

.

.

.

.

.

........

.

.......

..

..

.

.

.

...

.......

.

....

.

.

.

..

.

..

.

.

.

...............

.

...

.

..

.

.

.

.

.....

.

..

3-4

FUNCTIONS OF

FRONT PANEL

INDICATOR

S

..

...

.

..

.

...............

.

.

.

.....................................

.

...

.

...

3-5

RS-232 SERIAL

PORT....

.

.

.

..

.

...

.

......

.

.

..

.

.

.

.

...

..

....

.

....

.

.

.

....

.

.

.

.

.

..

......

.

.......

.

.

.

.

.

.

..

...............

.

..

.

.

.

...............

.

.

.

...

..

.

3-5

3

.

6.1

Computer Connection

.

...

.

.

...

.

.

.

....

.

.....

.

..

.

..

.

...

....

..

.

.

.........

.

..

....

.

..

..

.

..

....

.

..

.

.

.

...

..

.

.

..

.

..

.

..

..

.

....

.

....

.

..

.

.

..

...

3-5

3

.

6.2 PC

Setu

p

...

..

.

.

.

.

..

.

.

.

.

..

.

..

.

..

..

.

.

.

.

.

.

.

.

..

..

....

.

..

.....

.

...

...

..

.....

.

....

.

.

..

......

..

.

....

..

..

..

.

.

.

..

.

..

.

..

.

..

.

.

.

..

.

....

.

.

.

..

.

...

.

.

.

.

.

..

..

..

.

3-5

3.7

RS-232 COMMANDS

ANDPARAMETER

SETIIN

G

...........

.

.

.

.

..

.

.............

.

.........

.

.

.

..........

.

......

.

..

.

3-6

3.7

.

1

3.7.2

3

.

7

.

3

3.7.4

3.7

.

5

3.7.6

3.7.7

3

.

7.8

3

.

7.9

Time

..

.

..

..

.

.

.

.

...............

.

..

.

...........

.

..

.

................

.

..

...

.

.

.

...

.........

.

.

..

.

.

....

..

..

.

.........

.

.

.

.

.

.

.............

.

.

.

.

..

.

......

.

Date

..

.

..

.....

.

..

................

.

..

..

.

.....

.

.

.

.

.

..

..

....

...

.

.

..

........

...

.....

.

......

.

..

.....

.

..

.

...

.

......

.

..

.

....

.

.

.

.

.

.

...

.

.

.

.

.

.

....

.

..

...

.

Unit

s

..

.......

..

..

.

..

.

.

.

....

..

.

.

.

..

..

.

..

....

.

.

.

....

...

..

...

.

.

.....

..

.

...

.

.

.

.

.

....

......

.

.

.

.......

..

..

.

.

..

....

.

.

.

..

..

.

..

..

.

.

.

..

.

.

.

.

.

...

.

.

.

.

.

.

..

..

..

ABC

Start

Time..................

.

.

.

.

............................................

..

..................

.

.

.

...........................

.

ABC

Interval

..............

..

..........

.

.....

.

..

.

............

.

.................

.

.

.

.

..

..

.

........

.

.

.

........................

.

..

.

...

.

..

.

Alarm

I

and

Alarm

2

.

.

..

.......

...

..

..

....

.

.

..

..

...

.

....

.

.

.

.

...

..........

.

.

.

.

.

...

.

..

...

.

.

.

........

.

...

.

.

.

.

..

....

...

...........

.

.

.

...

.

Analog

Output

...

..

..

..

.

..

..

.

.

.

.

..

.......

.

.

.

...

...

.

...

....

.......

...

...

..

..

.

....

.........

.

..

.

..

.

..

.

..

..

..

.

..

.

....

.

.

..

..

..

..

.

.

..

...

.

Baud

Rate

.

..

..........

.

...

.

..

..

........

.

.

.

.

..

.....

..

..........

.

......

.

.......................................

.

.

.

................

.

.

.

....

.

RS-

232

Output

Interval

........

..

.

.......

..

...........

.

........................

.

..

.

..........................................

.

3-6

3-6

3-6

3-7

3-7

3-7

3-7

3-7

3-8

3

.

7.1

0

Poll for Dew Point.

.

..

.

......

.

.

.

.....

..

..

.....

.

.

.

.

.

.....

.

.....................

.

.

.

.

.

.

.............

.

.........

..

...

...

.......

.

.

.

.

......

.

3

.

7

.

11 Startan ABC

Cycle

...

..

..

......

.

.

....

.

.......

.

...

.....

..

.......

.

..

..

..

.

...

.

.

.

.

.....

.

.

....

...

.........

.

..........

.

........

.

.

....

..

3

.

7

.

Model2000

Serie

s

DewPrime

Dew Point

Hygrometers

12

Number

ofPoints

t

o

Average

.................

.

..

......

...

..

....

.

.

.

...

........

.....

.

.

.

.....

........

................

.

..

..

..

.

.

..

3.7.13

Max

Heat

...........

.

....

...

................

.

.

.

.

..

...

......

.

.

...

........

.

..............

..

..

..

.

.......

.

..........

.

.........

.

..

.

....

.

.

.

..

.

3

.

7.14

Max

Cool.

.

...........

..

.....

.........

.

...

.

.

.

.

......

...............

..

.....................

.

......

.

.

.

........

.

...............

.

.

.

.

.

....

.

..

.

3-8

3-8

3-8

3-8

3-8

3.8

3

.

9

3.

7

.

15 Alarm1

and Alarm

2

Latches...

....

....

.

......

..............

.

..

.......

....

.

.

....

.........

.

..

....

..

.

..

.

..........

..

..

.

.......

3-8

3.7

.

16 Status

Report.

..

.

..

..

..

..

..

....

.......

.

..

.

.......

.

......

.........

.

..

....

..

.

.

........

.

...

.....

.

..

.

.

...

..

...

.

..

.

..

........

.

...

.

..

..

.

.

...

..

3-8

PROGRAMMABLE

INPUT

PARAMETER LIMITS...

.

.

.

.........

..

.

.

.

...

........................................

.

.

....

3-9

DEFAULT PROGRAMMABLE

P

TER

S

...

..

....

.

.

...............

...

.

..........

.

.

..

.....

.

..................

.

..

..

3-9

vi

Contents

Model2000

Serie

s

DewPrime

Dew

Point Hygrometers

Page

INTRODUCI'IO

N

..

.

..

..

.

.

.

.

.

...

.

..

.

........

............

.

..

.

.

.

.

........

.

.

.

....

.

....

...

........

......

....

.

.

.

.

.

.

.

..

.

........

.

..

.

.

.

.

.

.

.

...

.

.

.

.

.......

....

....

..

.

1-1

1

.

1

GENERAL

..

...

.

.

..

..

..

.

...

.

...

..

.

......

.

...

.

..

.

..

..

...

.

.

..

.

.

......

...

.

..

...

..

..

.....

...

.

..

...

.....

.

...

.

.......

.

..

.

.

.

.

.

......

.

.

.

.......

.......

..

..

.

..

1-1

1

.

2

DESCRJPTION

..

...

.

.

.

..

...

.

..

.

.

.

.

..

.

..

.

..

.

...

.

.

...

..

.

...........

....

.

.

..

.

.

.....

..

...

.

.

.

..

.....

.

...

.

.

.

....

.

.

..

.

.

.

.

...

...

.

.

.

..

...

.

....

....

..

..

.

.

.

.

1-1

1.3

Al.ITOMA.TIC

BAI..ANCE

CON"fR.OL..............

.

........

...........

.

......

..

.

...

..

..

.....

.

...

.

....

.

.....

.

..

..

....

.

.

.

..

.

...

.

1-3

1

.

4

PROGRAl\.WABll.,ITY".

.

.

.

.

..............

.

................

.....

.

.

....

..

..

.

......

.....

...

...

.

..

.

.

..

.

.

........

.

.............

..............

1-3

1.5

OPTION

S

...

.

.

..

.

...

.

...............

.

.

.

.

.

....

.

.

......

.

.................

...

.

.

.

.

...............................

..

....

...........................

.

..

1-4

1.5.1 Remote Mounting

.

....

..

.

..

.

....

..

........

...

......

...................

.......

..

...

..

.

....

...

.....................

.

..

...

.

..

........ 1-4

1.5.2 Panel/Rack

Mounting

.

..

..

.

.

...

..

.

..

..

....

.

..

.

......

..

.

...

.

.....

..

....

.

..

.....

..

....

..

.

............

.

..

.........

........

.

..

...

.

..

1-4

1

.

5.3

Sample

System

.

Module

.

.

.

.......

.

..

..

.....

.

..

.

.

.......

.

..

.....

.

.

..

...

.

......

..

.

..

..

.

.........

............

.

.

.

..

.

.........

..

.

.

...

1-4

1.5.4 MirrorMicroscope..

.

...

.

..

.

...............................

.

..

..

.........

.

........

.

.....

.

.........

.

...............

.

..

..

.

.

.

.......

1-4

1.5.5 Explosion-Proof

Housing.......................

.

.

....

.

..............................

..

.....

.

..............

.

.........

.

...... 1-4

1.5.6 Isolated4-20 ma..............

..

.

..

....................

..

...

..

..

...

..........

.

.................

..

...

......................

..

.....

1-5

1

.

5

.

7

ln.-Line

Filter.....

.

.

.

.

.........

.

...

....

...

........

...

..

..

.........

.

.

.

..

............

.

...

..

.....

.........

.

.

.

.

.............

.....

....

.

..

.

..

1-5

1

.

6

SPECIFICATIONS

..

.

.......

............

.....

..

..

.

..................

.

.....

..

.

.

..

.....

.....

.

....

..

.

...

..

...

..

.

.....

.

.

.

.......

.

..

.....

.

.

.

.....

1-5

IN'STALLATION

PROCEDURES.

..

..........

.

................

.

.

.

..

.

....

.

.................

..

..

..

.

.

...

......

..

............

.

.

.

.

..

..

.

....

.

.

.

..

.

2-1

2.1

lJNPACKIN'G......

.

.............

...

.

..

......

.

...................

...

.

.

.........

...

...............

.......

..

.

.....................

.

......

.

...

.

.

.

2-1

2

.

2

MOUNI'rn'G.......................

.

.

.......

.....................

....

.

.

.

....

.

..............

..

.....

.

.......

..

...

.

.

.....

..

................

.

.

.

.......

2-1

2.2.1

General

.

.

.

.

..

.

.

...........

.

...

.

.

..

.

.

.

..

..

.

.

...

..

..

....

..

..

........

..

.

..

....

.....

.

....

.....

.

..........

....................

.

.........

..

.

...

..

2.2

.

2

Desk-Top Operation

.

...........

......

...

.

....

.

.

.

...

..

.........

.

.

...

.....

.

..

..

.

......

..

..

.

.....

.....

.

.

.

.........

..

...

....

.

....

..

.

.

.

...

2-1

2-1

2.2

.

3

Panel/RackMounting

.....

..

...

.

......

..

.

.

.

.....

.

.

.

..

...

..

..

..

.......

...

..

..

.

.

....

..

....

.

...

.....

.

..

..

..

.

....

.

.

.

.

.

.

.

...

.

.........

...

..

2-1

2.2.4

Rem.ote Senso

r

Mounting.......

.

..

...........

....

.

.......

..

.

.........

.

....

..

.

.............

..

.

.

...................

.

.

.

.......

2-1

2

.

3

COOLANT

CONNECTIONS....

..

.......................

..

..

.

........................

.

.....

.

..................

..

........

.

..........

2-1

2

.

4

1El\1PERA11JRE

L S.........

.

.

..

.

....................

..

.......

..

.................

....

............

.

.

.

...

......

.

..

.

.

.

.

..

....

.

...

....

2-2

2.5

WIR.IN"G

CONNECTIONS

.

.

..

...

......

............

...

........

..

.

....

...

................

....

..

.

......

..

......

.

................

..

...

..

...

2-2

2

.

6

Al--miENT

1El\1PERA

TI.JRE

PROBE.......

.

.....................

.

....

.

.

..

.........

...

.

...

....

....

.

...............

........

....

...

2-2

2

.

7

PLtJh.miN'G

CONNECTIONS

.

......

..

...........

.............

.

..

..

......

..

...

....

..

.

..

..

..

.

........

..

..

.............

.........

..

....

2-2

2

.

8

SAI\1PLIN'G

CONFIGtJRATIONS

.

.

......

.

...................

..

..

...........

..

.

.

...

.

.....

...

..

.

....

.

.

.

..

......

........

...

.

....

..

.

..

2-3

2.9

PREHEATING SENSOR AND SAMPLE

LINES..

.

.

.

...................................

.

..

..

.............

.

...

.

..

..

......

2-3

2.10

SELECTION OF COI\iPONENTS AT LOW DEW

POINTS......

.

.

..

.

.

.........

..

.

.

.

.

........

......

.

..

.

.......

.

.

.

...

2-4

2

.

11

MA.1'ERIAL

MOISTIJRE

PROPER11ES..

.

.

....

..........

.......

..

..

...........

.

.

..

.

...

.

....

.....

..

........

.

....

.

.....

.

..

....

.

..

2-5

2

.

12

SELECTION OF

SAMPLIN

G

PUMPS

.

......

..

.

...

.

........

..

.

.

..

.

...

...

.....

..

.

.....

.

...

.

.

.

..

..

................

..........

..

.

..

2-5

v

Model

2000 Series DewPrime

Dew

Poin

t

Hygrometers

EdgeTech's Commitment to

Quality

To Our

Customers:

Thank

you for purchasing one of our products. At EdgeTech, it is our policy to provide cost-effective

products and support services that meet or exceed your requirements, to deliver them on time, and

to

continuously look for ways to improve both. We all take pride

in

the products we

manufacture.

We want you to be entirely satisfied with your instrument. The information in this manual will get you

started. It tells you what you need to get your equipment up and running, and introduces its

many

features.

We always enjoy hearing from the people who use our products. Your experience with our products

is

an

invaluable source of information that we can use to continuously improve what we manufacture. We

encourage you to contact or visit us to discuss any issues whatsoever that relate to our products or your

application.

The Employees

ofEdgeTech

EdgeTech

19 Brigham Street, Unit

8

Marlborough, MA

01752

Phone:

508

-

263

-

5900

Toll

Free

:

800-276-3729

Fax

:

508-486-9348

E-Mail:

h2o@edgetec

h

.com

www.edgetech

.

com

iii

Introduction

T

.....

.!!!!..

Edge

Tech

Model 2000 Series DewPrime

Dew Point Hygrometers

Introduction

1.1 GENERAL

he

EdgeTech

Model 2000 Series

DewPrime

Dew Point Hygrometer (Figure 1-1) is a

micro-

processor based, programmable dew point

instrument

with many built-in features. It has a

measurement range

of -50

to+100°C.

Two sensor types are available for

a

depression of either 45 or

60°C.

The DewPrime Series is presented in two major

con-

figurations.

The

first

,

the Model

2001,

is a dew

point

only measurement instrument. The second, the

Model

2002, is a dew point, relative humidity, and

ambient

temperature measurement

instrument.

This instrument has been designed to include the

most

desirable

I/0

options in the standard

configuration

.

By

"

buildin

g

in" these options, the cost is reduced

signifi-

cantly when compared to "added in"

options.

Using a primary measurement technique,

including

provisions for self-checking and automatic

balancing

,

the Model 2000 Series verifies its own performance on

a

timed sequential basis, and is ideally suited for

process

control and

continuousunattended

operation.

Devel·

oped primarily for industrial process use, the

Model

2000 Series is also useful for

laboratory,

scientific,

and

research

applications,

and can be equipped with a

mirror

microscope when used as a

calibration standar

d

.

It

is

designed to meet reliability

requirements

of

high

temperature, high dew point process drying and

curing,

and the Model 2000 Series is finding broad

applications

in areas where energy

conservation

is a major

consider-

ation.

1.2

DESCRIPTION

The Model 2000 Series consists of a Control Unit

and

either a single or dual stage dew point Sensor and

a

built-in cooling jacket (S2 Sensor only). The

Model

2000 Series is equipped with a timed,

electronic,

automatic

selfs·tandardization

circuit

;

a Track or

Hold

output

;

mode indicators; and an Alarm

Set.A platinum

resistance

thermometer

(PRT)

continuously measures

the mirror

temperature,

directly

displayed

in °C or °F

on

the front of the 4-digit Digital Panel Meter, with a

resolution of 0.1°C. Standard outputs of 0 to 5 VDC

and

4·20 ma are available directly on the rear panel

connec-

tor (Figure

1-2).

The Model 2000·S2 is also equipped with

(I)

a

mirror

overtemperature protection circuit, which shuts down

the

thermoelectric cooler at a mirror temperature

over

100°C; and (2) an additional

overtemperature circuit,

which also shuts down the cooler if base

temperatures

exceed

100°C.

The Sensor

incorporates

an inert Rhodium

(nickel

electroplate-based

surface) mirror that has a hard, bright

surface to provide superior abrasion

resistance

,

and

an

inherent

antiwetting

characteristic

to enhance dew

and

frost formation. The Rhodium mirror was developed as

a

result of on-going material evaluation studies

coupled

with applied research in the physics of dew and

frost

formation on a mirrored

surface.

Extensive field tests

in

harsh industrial applications show that the

Rhodium

mirror provides significant advantages over

conventional

mirrors, especially gold-surfaced

mirrors.

The S2 Sensor has a depression capability of

60°C

(108°F) at an ambient temperature of 25°C and the

S

1

Sensor has a

depression

of 45°C

(81

°F)

.

Depression

decreases approximately 1o for every 3° drop in

ambient

temperature and increases approximately 1° for every

3

°

rise in ambient temperature from 25°C.

Depression

capability is sufficient at any temperature to permit

dew

point

measurement corresponding

to less than 1%

RH.

The S2 Sensor

has

a built-in cooling jacket that

should

be used when the dew point to be measured exceeds

the

cooling depression of the Sensor

itself.When

the

jacket

is used, Sensor cooling is based on the temperature

of

the coolant, which can be water, ethylene glycol,

etc.

Response is 1.7°C

(3°F)/second

at dew points above 0°C

(32°F).Below

0°C, less water is available for

condensa-

tion, and the response is governed by both the frost

point

and the sample flow

rate

.

The Sensor is usually mounted on the

instrument's rear

panel; however, it can be mounted remotely up to

75

meters (250 feet) from the instrument by using

the

optional Remote

Mounting

Cable

Kit.

The Model 2000 Series is equipped with

convenience

features such as: (1) a Sensor spin-off cover that

permits

1-1

Model

2000Series DewPrime

Dew Point

Hygrometers

...

EdgeTech

-------------

Introduction-------------

-

----·

--

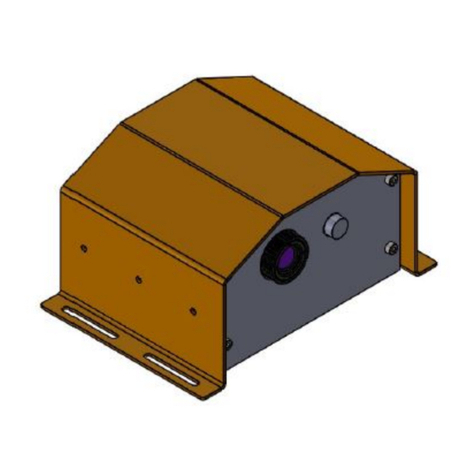

Figure 1-1. EdgeTech

Model2000

Series DewPrime Dew Point

Hygrometers.

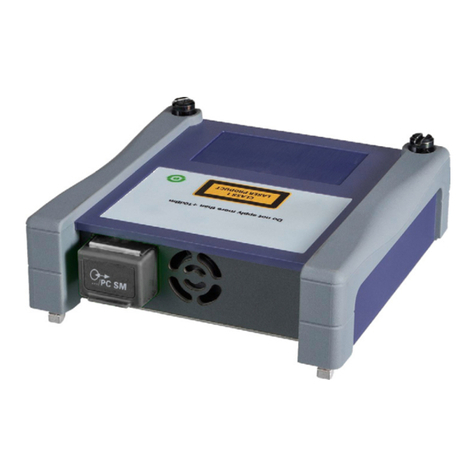

Figure 1-2. Rear Panel, EdgeTech Model 2000 Series

DewPrime

Dew Point

Hygrometers.

1-2

Model2000 Series DewPrime

Dew

Point Hygrometers

Introduction

------------

easy

access

to the mirror for cleaning without

discon-

necting sample lines and connections (S2); (2) the

logic

level front panel

Automatic

Balance Control

(ABC)

LED

is "ON"

steady

when the instrument is

standardiz-

ing, and

"

ON"

fla

s

hing when the

standardization

cycle

is

completed

and the instrument is

depressing

(cooling)

to the dew point; (3) Alarm set points

that

are

program-

mable over the entire Sensor range; and

(

4)

a

"CON-

TAMJNATED"

LED

and

logic level olllput that

signals

when and

if

the Sensor miJror needs cleaning.

1.3 AUTOMATIC BALANCE CONTROL

(ABq

-ABC

Cycle.

Thi

s

cycle can be

programmed

to start

at

any specified time and repeated at

programmed

inter-

val

s

.

Thi

s

feature allows the user to program the

ABC

cycle to occur at off-hours such as late at night or

early

morning when the

restandardization

will

cause

the

least

interruption of the sampling

process.

--8erial

Port

.

The

serial

port is RS-232C compatJ.'ble

and can be used to remotely

program

setup

paxameters,

initiate an ABC cycle, or output data to a

terminal,

printer, or

computer.

-The

Setup

Parameters

include time plus date,

units

The

Model2000

Series

incorporates

an

all-electronic,

(°F

or

0

C),

ABC

start

time

,

ABC

interval, alarm limits,

timed,

Automatic

Balance Control (ABC) circuit

To

correct for

changing

"dry mirror' reflectance as

a

fimction of

contamination,

the mirror is heated

periodi-

cally to a

temperature

in excess of the

dew

point,

and

the

optical bridge output isbalanced electronically

for

the present

reflectance

.

Thisheating is accomplished

by

reversal of the voltage across the th.mnoelectric

cooler

inside the

Sensor.

The ABC cycle in the

Model2000

Series can be

pro-

grammed to start at a specific time

and

at any

interval

thereafter

.

The cycle can also be initiated manually by

a

pushbutton

on the front panel or via the serialport

This

feature

increases

the time interval between sensor

and

sample-line

cleanings

without adversely

affecting

overall

performance.

Sensitivity

to

particularly

troublesome

impurities,

such

a

s

salts and other soluble contaminants,is

negligible

with

EdgeTech hygrometers

because the

compensation

circuit and the low thermal mass of the Sensor

design

permit use of a heavy condensate layer on the

mirror

surface

without need for a coalescence precool cycle

or

other

gimmickry

to offset the servo instability, drift,

and

loss of

accuracy

often

enco1.mtered

in other

chilled

mirror

hygrometer

s

.

1.4

PROGRAMM.ABn.JTY

The Model 2000 Series' fimctions can be

programmed

via the front panel keypad or the RS-232

serial

port.

analog outputs, baud rate, automatic

data

output

interval,

and digital averaging interval

(0-16).

-The

Data Output Function

sends

the

date,

time,

dew

point, and a1mn status to any

serial

device

such

as

a

computer,

printer, or

dat

a

logger

equipped

with an

RS-

232C input. The

data

can be sent either on

command from

the external device or

automatically

at

programmed

intervals.

-The

Control Function allows the userto start

an

ABC

cycle, initiate xoaximmncool/heat, and send

the

status such as alarm condition, ABC cycle, or

maximmn

heat/cool.

All

commands are listed on a Help menu

that

can be

printed

or displayed on a

terminal.

-Aualog

Outputs.

Two

outputs

,

0-5

VDC and

4-20

ma, are available

simultaneously

at the rear

terminal

connectors.

They can be scaled

electronically

to corre-

spond to any

dewpointnmge.For

instance,

0

V/4

ma

can be set to -40°C

and

5 V

/2

0ma can be set to

+

1

0°C.

Any combination of

dew

points within the

measuring

range can be used This feature allows the user

to

customize the rangefor a particular

strip

chart

recorder

or to

expand

the

scale

for greater

precision.

Scaling

can

be programmed easily via the front panel keypad or

the

remote

serial

port

-Alar

m

Relays. Two programmable Form C relays

are

provided to control valves,

anmmciators,

etc.Each

alarm

relay can be set independently for high or low,

latching

or unlatching,

and

at any dew

point

1-3

Model2000

Serie

s

DewPrime

Dew

Point

Hygrometers

-------------Introduction-------------

1.5

OPTIONS/ACCESSORIES

1.5.1 Remote

Mounting

When it isdesired

t

o

mo\Dlt

the

Sensor

in a

location

different

from

the location of the

Model2000 Series

Control Unit, use the Remote Mounting kit.

The

Remote

Mounting kit allows for distances

between

Sensor and Control Unit to be as much as 250 feet

(75

meters). Instructions for installing the Remote

Mount-

ing kit are included with the

kit.

If

a

Remote MountiDg

kit is ordered with theModel 2000 Series

Control

Unit, the Control Unit and Remote MountiDg kit and

Sensor are checked out and calibrated at the

factory

as

a system. However,

i

f

a

Remote Mounting kit

is

ordered separately for field instaJJation, then

field

calibration of the PRT

Resistance-to-Voltage

con-

verter will be

necessary

to

compensate

for the

slight

resistance changes

introduced

by the change in

cable

length.

1.5.2

Panel

and

Rack

Mounting

The Panel and Rack Mounting option allows

the

Model 2000 Series to be

converted

from a bench-

mounted model to one

tbat

can be mounted in either

a

panel or rack. When mounting in a

panel,a template

included with

the

kitprovides for ease in locating

the

cutout and mounting

hole

s

.

Once

installed in

a

panel,

the hole cutouts are covered by the front panel of

the

kit.

1-5.3

Sample

System

Module

The Sample System consists of a Neptune Dynapump

Model No.2, a Brooks 0-5SCFH flowmeter,

eight

feet

of tubing, and

allhardware

and fittings

necessary

for attaching to a Model

S

1

or S2 Sensor.

1.5.4

Mirror

Microscope

(S2

Sensor)

A Mirror Microscope option is offered for

applica-

tions requiringa view of the

actual

dew layer

esta

lished on the Sensor mirror

surface

.

Thi

s

is

particu-

larly useful when

attempting

to obtain an

NIST

certified calibration when it must be determined

i

f

the

system is controlling on the

actual

frost point

at

temperatures below 0°C, or on supercooled

dew.

Since the

relationship between

dew

point and

frost

point for temperatures

below

0°C is

11

known,

it

is

easy to

convert

from one to the

othe

r

<mce

i

t

is

verified

that control has been

established

on

dew

or

frost

below

0°C.

This

can be

determined

by visually

observing

the mirror

surface

using

this Minor

Micro-

scope

option.

To

incorporate

this option, it is only necessary

to

remove the S2

Sensor

housing provided with

the

standar

d

instrument

and replace

it

withthe

one

provided

in the Mirror :Microscope kit. Use the

same

screws

that

were

removed

from the original

Sensor

housing to

retain

the new

microscope

Sensor

housing,

since these

screws

are especially strongand

will

ensure that the pressure integrity of the

Sensor

is

maintained.

IwARNING!

The

microscope

provided

for this

op-

tion has been pressure-tested to

1800

psi, six

times

the

allowable

workiDg

pressure

of the Seasor, to

eDSDI'e

its

integrity.

However

,

with the

micro-

scope

installed,

it

is

recommended

that

maximum

SeDSOr

internal

pres-

sure not exceed 25 psi, since a gas

under

pressure

could cause the JDi.

c:roscope to become dislodged

aad

bec:ome

a

projectile

that

mightiDjlll"e

someone

observinl

the dew layer

at

the

time

of

dislodgement.

1.5.5 Explosion-Proof Housing

(S2

Sensor

only

)

The

Explosion-Proof

Housing is comprised of

compo-

nents designed for Class

1

,

Division 1, Groups C

&

D

hazardous enviomments

vmere

high

accuracy

,

long-

term

reliability,

and NIST traceable dew points

are

required.

Power

is

supplied

to the chilled

mirror

Sensor

through a

remote

cable from the

controller,

enabling the

Sensor

to be mounted at a distance of

up

to 250 feet. The

housing

assembly is not agency-In

in-

1-4

-

!

a

Series

DewPibe

DeW

PoiDI

Bonnnelels

1.5.6 Isolated 4-20 ma

Output

The4-20

maoption

i

s

available for

applications

requiring .

complete isolation between the

Model200

0

Series

and

the 4-20 rna output. As with the standard 4-20

rna

output, the range matches the 0-5 V output set on

the

Model2000

Series. Maximum loop resistance is

1000

ohms.

1.5.7

In-Line

Filter

An in-line filter can beadded to the

sampling

system in

orderto

provide

additional

protection tothe chilled

mirror

and associated

optics.The

filter assembly is a

combina-

tion particulate and

coalescin

g

filter rated for 250

psi.

The filter head assembly is anodized

aluminum.

Filter

efficiency is rated at 99.99% for particulate and

droplet

sizes ofO.l micron and

greater.

1.7

SPECIFICATIONS

The following

specifications

refer to the

Model2000

Series.Thosespecifications

that apply to the

Model2002

only

are

highlighted

by

an

(*).

Dew/Frost Point

Range

-40 to +100°C (-40 to

2l2°F)-Sl,

Ds1

Sensor

-50 to +100°C (-50 to

212°F)-

S2, Ds2

Sensor

-75

to+100°C

(-103 to

212°F)-

S3

Sensor

Accuracy

Dew

Point/Frost

::1::0.2°C

(±0.36°F)

Ambient

Temperature*

::1::0.2°C

(::1::0.36°F)

Relative Humidity*

:::1::0.5%

RH,

nominal

Dew/Frost Point

Temperature Sensor

3-wire Platinum Resistance

Thennometer

(PRT), 100 ohms at 0°C,

nominal

Depression

45°C

(81°f),

nominal-

S1, Ds1

Sensor

65°C (

ll7°F), nominal-

S2, Ds2

Sensor

95°C

(171°f), nominal-

S3

Sensor

Relative

Humidity Range

5 to 100%,

no

minal-S1, Ds1

Sensor

1 to 100%,

nominal-52

,

Ds2

Sensor

<I%

to 100%,

nominal-53,

Sensor

Ambient Temperature Range*

-50°C to 130°C (-58°F to

266°f)

Auxiliary Coolant

Water (or

other)-2liters/minute

(0.5

gallon/

minute) at 100 psig maximum, to

augment

depression capability of Sensor

when

necessary

S1

Sensor-

Coolant port

standard

S2

Sensor-

Coolant port

standard

S3

Sensor-

Coolant port

standard

Sensor Material

Rhodium orNickel Chromium

mirror,glass,

epoxy,isofoam insulation, anodized aluminum

sensor

body.

Remote

Sensors

Up to 75 meters (250

feet)

Depression

Slew

Rate

1.7°C

(3°F)/second

max., above

0°C

Repeatability

±0.01

oc

(0.2°F)

Hysteresis

None

Sample Flow

Rate

0.25-2.5

liters/minute

(0.5-5.0

SCfH)

Sample

Pressure

0-21

kglcm:t

(0-300

psia

)-

S1, S2,

S3

0-63 kg/cm2 (0-900

psia)-

SIP,

S2P

Operating

Temperature

0 to +50°C (+32

to+122°f)-

Control Unit

-50 to +70°C (-58 to

+158°f)

Sl

Sensor

-50

to+

I

oooc

(-58 to +2

I

2°F) 52

Sensor

-75 to +75°C (-103 to

+167°F)-

S3

Sensor

1-5

Model2000

Serie

s

DewPrime

Dew

Point

Hygrometers

-------------

Introduction------------

Operating

Temperature

o to

+sooc

(+32 to

+l22°F)-

Control

Unit

-50 to +70°C (-58 to

+158op)-

SI Sensor

-50 to

+l00°C

(-58

to+212°F)-

S2 Sensor

Display

4-digit LED

alphanumeric

data

display

0.6 in. high

digits

O.l

0

C/O.I°Fresolution,

(-)

xxx.x

CIF

Keypad

16 keys, to

provide programming

for

Model

2000 Series

functions:

0

CfO

F

toggle

View/change

time,

date, digital

averaging,

baud

rate

Manual Auto

BalanceControl

initiate

Programmable

Auto

Balance

Control

for

start time, interval,

output Track/Hold

Maximum Heat

toggle

Maximum Cool

toggle

View/change high and

low

limits

for

analog

outputs

View/change

A.l.amJ.

parame

higbllow limits, high

and/or

low

alarms,

latched or

unlatched

relays

Reset front panel

Alarm

indic:alors

(la!ched

only)

Current

Imemal

or

Extema1

Power(Standard)

4 to 20 ma,scalable from -100 to

+

IOOOC

(-148 to

+212Gf'),

1000

ohms

maximum

loop resistance

Isolated (Optional)

4 to 20 ma, scalable from -100

to

+IOOOC

(

-148

to

+

21,2C'F),

1000 ohms

maximum

loopresistance

RS-232

300/1200/2400/4800/9600/19200

Baud

N8

I

25-pin

D-subminiarure

connector

(female)

Output of time and dew/frost point

during

operation.

Output

interval

is user

proglB

'

••mahle.

Progm nming of

all

keypad

functicms

plus

poll

dew/frost

point,

OUipUI

imervaJ.s,

plus

on-line Help menu.

Mirror Condition(

Conmminated

)

Rear panel TIL output and front panelLED

Two

Alarms

Outputs

Track

or

Hold

Outputs (analog, digital,

ala:rm.s)

can be

set

to Track or

Hold

while

in

Auto

Balance

or

Programming

mode

Allalog

Voltage

(Standard)

0 to +5 VDC,

scalable

from -100 to

+

1

00°C

(-148

to

+

2I20f),

I K minimum impedance

TwoFmm C,

SPDTalarm

relays rated

for

3

amps

at 24 VDC, 120

VAC

Alar

m

mode (high and low)

programmable

from

keypad

or

RS-232

Alarm set point

programmable

from -99.9

to

+99.

(

-148

to 212Gf) from

keypador

RS-232

port.

Alarms can be latched or

tmlatched.

Auto Balance

Control

Manual initiate of ABC at any

time.

Automatic

ABC

with start time and

interval

programmable

from keypad or RS-232

port

1-6

Model

2000 Series

DewPrime

Dew Point Hygrometers

Introduction

------------

Weight

Outputs programmable for Track or

Hold

during

ABC.

7.0 kg (15.5 pounds), desk-top

version

Rack mount

available

Power

Requirements

100/115/230

V

AC,

±

10%,

50-60

Hz,

75

"Watts

max:imlDil

Fuses

240 VAC

Operation-

lA,3

AG

,

250 VAC,

Slo-Blo

Dimensions

28.2 (W) X 13.0 (H) X 45.7 (D) em

(11.1

(W)x

5.1

(H)x

18 (D)

in.

),

desk-top withS2 Sensor motmted

Mounting

Desk-top (standard)

Panel/Rack

(optional)

NEMA 4 Enclosure

(optional)

120 VAC

Operation-

2A,

3

AG, 250 VAC,

Slo-Blo

1-7

Table of contents

Other Edgetech Measuring Instrument manuals