Edgetech RH CAL User manual

RH CAL

Relative Humidity Calibrator

OPERATORS MANUAL

399 River Road ●Hudson, MA USA 01749

Tel. [508] 263-5900 ●[800] 276-3729 ●Fax [508] 486-9348

E-mail h2o@edgetechinstruments.com ●www.edgetechinstruments .com

Rev. A March 2011

2

TABLE OF CONTENTS Page

1.0 Quick Startup Card (Removable)

2.0 List of Illustrations 4

3.0 Introduction 5

3.1 General Description 5

3.2 System Overview 5

3.3 Operating Controls 6

4.0 Warranty Information 8

5.0 Edgetech Instruments Inc.’s Commitment to Quality 9

6.0 N.I.S.T. Traceability –What does It Mean? 10

7.0 Glossary 11

8.0 Installation 12

8.1 Unpacking 12

8.2 Wiring Connections 12

8.3 Water Fill 13

8.4 Air Connection (Optional) 13

9.0 Basic Block Diagram Theory of Operation 14

9.1 Basic Block Diagram Description 15

10.0 Panel Description 16

11.0 Information Display Functions 18

11.1 Information Displayed 18

12.0 Operating the RH Calibrator 20

3

12.1 System Status 20

12.2 Keypad Operation 21

12.3 Programming the RH-CAL 22

12.4 Calibrating RH Sensors 25

12.5 RS-232 Serial Port Setup 26

13.0 The Chilled Mirror Dew Point Sensor 30

13.1 Theory of Operation 30

13.2 Automatic Balance Cycle 31

13.3 Care and Maintenance of the Sensor 32

14.0 Maintenance 33

14.1 Routine Maintenance 33

14.1.1 Mirror Cleaning Schedule 33

14.1.2 Cleaning the Mirror 33

14.1.3 Dryer Tube Maintenance 34

14.1.4 Filling the Saturator 35

14.1.5 Removing the Front Panel 35

14.2 Replacing the Fuse 36

14.3 Modifying the Analog Output 36

15.0 Specifications 38

4

2.0 LIST OF ILLUSTRATIONS Page

3-1 RH Calibrator Panel 5

8-1 Removing Shipping Plug 12

8-2 Filling the Saturator 13

9-1 Basic Block Diagram 14

10-1 Panel Description 16

11-1 The Information Display 18

12-1 Keypad 21

12-2 Changing the RH Setpoint 22

12-3 Changing the AT Setpoint 22

12-4 Selecting Dew or Frost 24

12-5 Locking In the Changes 25

13-1 Chilled Mirror Block Diagram 30

14-1 Cleaning the Mirror 33

14-2 Replacing the Dryer Material 34

14-3 Fuse Location 36

14-4 Analog Mode Switch 36

14-5 DIP Switch Configuration 37

5

3.0 INTRODUCTION

3.1 GENERAL DESCRIPTION

The RH CALIBRATOR is a microprocessor based, programmable humidity control

and measurement instrument with many microprocessor controlled features built-in.

Using the NIST Traceable Optical Chilled Mirror primary measurement technique,

the RH CALIBRATOR was developed for precise calibration of RH Sensors and

Transmitters, as well as laboratory and research applications.

3.2 SYSTEM OVERVIEW

The RH CALIBRATOR has a Test Chamber, a menu driven LCD graphics display,

Automatic Balance Cycle (ABC), a selectable analog output, and an RS-232C serial

port.

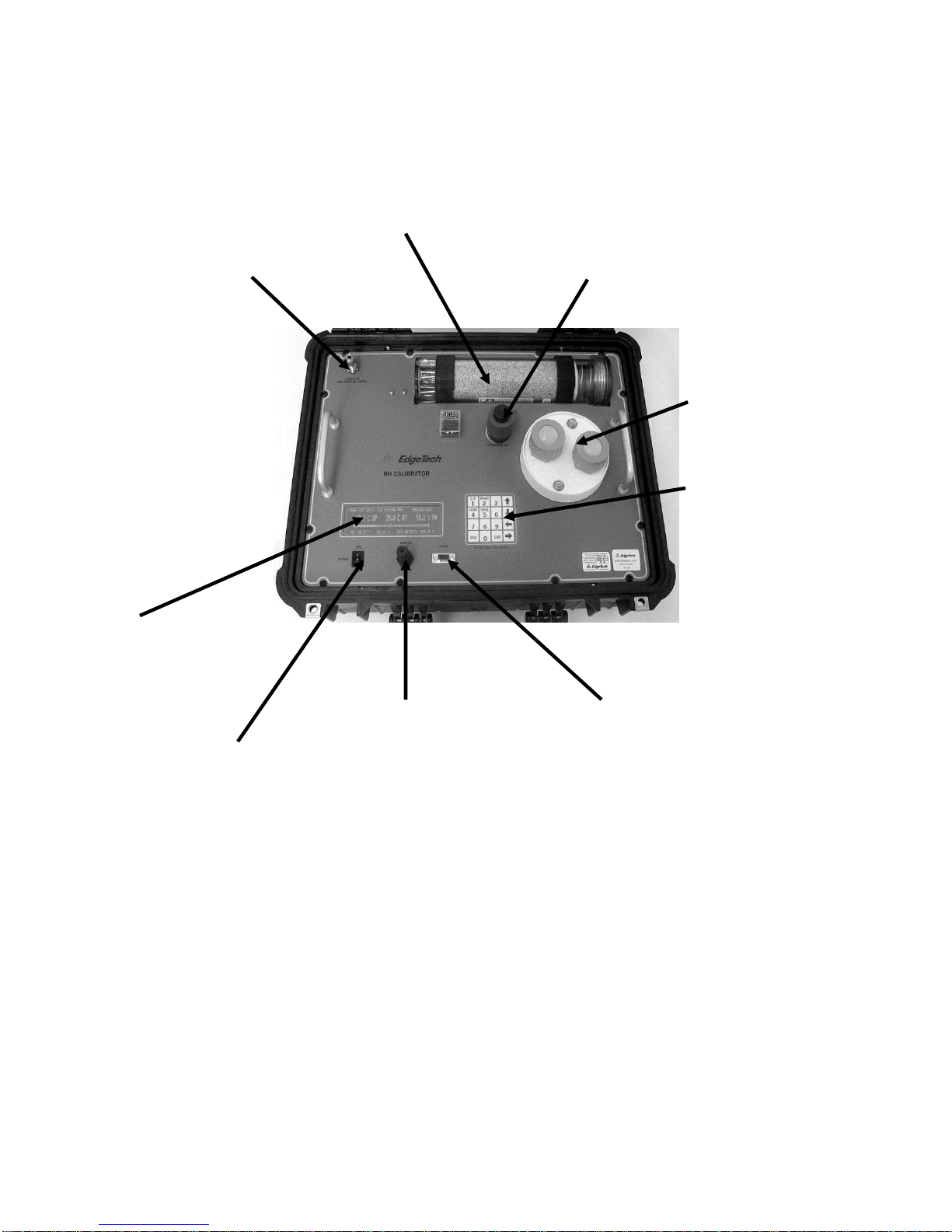

Figure 3-1 RH Calibrator Panel

6

An Air Temperature Probe and a Type D2 Chilled Mirror Sensor are located in the

Test Chamber. The relative humidity and temperature of the chamber are

programmable from the Scrolling Menu.

The 40 x 8 character backlit LCD displays Dew Point (C or F), Chamber

Temperature (C or F), and Percent Relative Humidity simultaneously.

The Automatic Balance Cycle (ABC) can be set to balance the sensor optics at

preset times and intervals or can be initiated manually at any time.

An analog output is available on the Panel as either 0 to 5VDC or 4 to 20 ma, and it

can be set to follow any parameter with individually programmable high and low

points. The output can be set to Track the selected parameter value during the ABC

cycle or Hold the last value prior to the ABC cycle.

The half duplex configured RS-232C serial port can be used to remotely control the

calibrator operation, and to output data to a data recording device.

3.3 OPERATING CONTROLS

The RH CALIBRATOR operates entirely under microprocessor control. State-of-the-

art software provides the opportunity to include a flexible, informational, and user

friendly interface. The setup and operation of the control unit can be programmed via

the front panel keypad or the RS-232 serial port.

LCD Graphics Display: Displays three parameters simultaneously, time, date,

operational status, sensor mirror condition, and alerts the user to fault conditions.

When activated from the Scrolling Menu, the AT SETPOINT (chamber

temperature) and the RH SETPOINT (relative humidity), are displayed. The

display of Dew Point may also be selected with the Keyboard.

Keypad: A membrane type keypad allows the user to enter setup and instrument

control information. A Scrolling Menu guides the user through the setup

procedure. The Setup Parameters include RH SETPOINT, AT SETPOINT, time,

date, analog output parameter and scale, ABC start and interval, and serial port

settings.

SERVOLOCK ™: The SERVOLOCK feature continuously displays the servo

control loop status. This is especially useful when the sample dew point is

varying widely or quickly. When SERVOLOCK is displayed, the system is locked

on to and tracking the dew point.

ABC Cycle: The Automatic Balance Cycle checks for proper operation of the

system and re-balances the sensor to compensate for changes in reflectivity of

the mirror due to aging, optics drift, or minor contamination due to impurities in

the sample gas. The on board real time clock permits the user to program the

7

ABC cycle to start at any specified time of day and repeat at regular-

programmed intervals. The user can therefore program the ABC cycle to occur at

off-hours such as late at night or early morning when the re-balance will cause

the least interruption of the sampling process. The cycle can also be initiated

manually at any time by a pushbutton on the front panel or via the serial port.

The analog output can be programmed to either TRACK or HOLD the information

during an ABC cycle.

Serial Port: The RS-232C serial port can be used to remotely program setup

parameters, initiate an ABC cycle, or output data to a local or remote terminal,

printer, or computer. The data output function outputs, in ASCII format, the date,

time, three parameters, and system status to any RS232C equipped serial

device. The data can be sent on command from the external device or

automatically at programmed intervals. HELP and STATUS menus can also be

displayed to guide the user.

Analog Output: The analog output, either 0-5 VDC or 4-20 ma, is available at

the Panel terminal connector. The output can be set to track any parameter, and

may be independently scaled via the Scrolling Menu.

8

4.0 WARRANTY STATEMENT

All equipment manufactured by Edgetech Instruments Inc. is warranted against

defective components and workmanship for repair at their plant in

Massachusetts, free of charge, for a period of twelve months. Malfunction due

to improper use is not covered in this warranty and Edgetech Instruments Inc.

disclaims any liability for consequential damage resulting from defects in the

performance of the equipment. No product is warranted as being fit for a

particular purpose and there is no warranty of merchantability. This warranty

applies only if (i) the items are used solely under the operating conditions and

in the manner recommended in the instruction manual, specifications, or other

literature; (ii) the items have not been misused or abused in any manner or

repairs attempted thereon; (iii) written notice of the failure within the warranty

period is forwarded to Edgetech Instruments Inc. and the directions received for

properly identifying items returned under warranty are followed; and (iv) the

return notice authorizes Edgetech Instruments Inc. to examine and

disassemble returned products to the extent Edgetech Instruments Inc. deems

necessary to ascertain the cause for failure. The warranties expressed herein

are exclusive. There are no other warranties, either expressed or implied,

beyond those set forth herein, and Edgetech Instruments Inc. does not assume

any other obligation or liability in connection with the sale or use of said

products.

Equipment not manufactured by Edgetech Instruments Inc. is supported only to

the extent of the original manufacturer’s warranties

9

5.0 EDGETECH INSTRUMENTS INC.’S COMMITMENT

TO QUALITY

Thank you for purchasing one of our products. At Edgetech Instruments Inc.,

it is our policy to provide cost-effective products and support services that

meet or exceed you requirements, to deliver them on time, and to

continuously look for ways to improve both. We all take great pride in the

products we manufacture.

We want you to be entirely satisfied with your instrument. The information

contained in this manual will get you started. It tells you what you need to

get your equipment up and running, and introduces its many features.

We always enjoy hearing from the people who use our products. Your

experience with our products is an invaluable source of information that we

can use to continuously improve what we manufacture. We encourage you

to contact or visit us to discuss any issues whatsoever that relate to our

products or your application.

The Employees of Edgetech Instruments Inc.

10

6.0 N.I.S.T. TRACEABILITY –WHAT DOES IT MEAN?

The RH-CAL, or Relative Humidity Calibrator, is certified by Edgetech Instruments Inc.

to be traceable to N.I.S.T., the National Institute of Standards and Technology (formerly

known as the National Bureau of Standards, or NBS), in Gaithersburg, Maryland, U.S.A.

You have received a Certificate of Calibration with this instrument. What does N.I.S.T.

Traceability mean in terms of the RH-CAL?

The calibration chamber in the RH-CAL can be set by the user to any desired relative

humidity (RH). The instrument measures and controls the chamber RH by measuring

both the air temperature (AT) and the dew point temperature (DP) in the chamber.

Since there is a mathematical relationship between dew point temperature, air

temperature, and relative humidity, a built-in microprocessor can therefore compute the

chamber RH.

Dew Point is a fundamental measurement of humidity. It is not affected by temperature.

In addition, the chilled mirror dew point sensor in your RH-CAL provides a primary

rather then a secondary measurement of dew point temperature.

Both the AT and the DP are measured with Platinum Resistance Thermometers (PRTs).

These devices are coils of nearly pure platinum, where the rate of change of resistance

with temperature is precisely known. Resistance is accurately measured and is

automatically converted to temperature information in the RH-CAL.

TRACEABILITY:

1. The precise platinum thermometers are N.I.S.T. traceable by the traceable

resistance standards maintained by the PRT manufacturers.

2. A multi-point dew point calibration is performed on every RH-CAL chilled

mirror dew point sensor, using Edgetech Instruments Inc.’s traceable secondary

dew point standard. This instrument, a precise chilled mirror hygrometer, is

periodically sent directly to N.I.S.T. for certification against their dew point

transfer standard, a Two-Pressure Generator.

11

7.0 GLOSSARY

ABC: Automatic Balance Control –a method of maintaining accuracy in the

presence of contamination and minimizing maintenance requirements.

Analog Out A voltage or current that tracks changes in a parameter.

AT Air Temperature –the temperature inside the test chamber.

Depression The magnitude of available mirror cooling in the chilled mirror sensor.

Desiccant A chemical material which removes moisture from the air sample and

thereby produces very dry air.

DP Dew Point Temperature –the temperature that moisture in the

air just begins to condense on a cooled surface.

Hold Analog output which holds the last humidity reading just before the ABC

cycle.

Hysteresis The tendency of a sensor to give one set of readings when going up, and

a different set of reading when going down.

Mirror A small metallic reflective surface within the dew point sensor.

RH Percent Relative Humidity –the ratio between the actual moisture

content in the chamber and the maximum moisture content if the chamber

air was saturated, at a given air temperature.

RS-232 An accepted industry standard for a serial digital interface.

Saturator A device which brings the air sample to 100% RH.

Serial Port See RS-232.

ServolockTM A method of indicating that the system is locked on and tracking the dew

point.

Slew Rate The rate of temperature change of the mirror assembly in the chilled mirror

dew point sensor.

Track Analog output which follows (tracks) the mirror temperature during the

ABC cycle.

12

8.0 INSTALLATION

8.1 UNPACKING

Remove the RH CALIBRATOR from its shipping carton and remove any shipping

ties, clamps, and packing material. Save the Certificate of Calibration shipped

with this manual. Locate and save the Cleaner Kit included in the shipping

carton.

IMPORTANT:

1. Locate the RH-CAL on a flat horizontal surface. Leave a minimum of 6 inches

(15 cm) on both sides for proper air flow.

2. Before first use, unscrew the Saturator Cap and remove the Shipping Plug

(Red Top/Clear Tube) from the small stainless steel Saturator Air Outlet Tube.

Put the Shipping Plug away in a safe place –you may need it later.

Figure 8-1. Remove Shipping Plug NOTE: Whenever the RH CALIBRATOR

is moved, the saturator Shipping Plug

should be installed to prevent water

leakage.

8.2 WIRING CONNECTIONS

Connect the RH CALIBRATOR to a

grounded, instrument quality power

source of between 100 to 240 VAC, 50-60

Hz. There are no jumper or switch setting

modifications over this range; only the fuse must be changed if changing from a

nominal 115 VAC to 230 VAC.

Note: The correct fuse is installed at the Factory, depending upon the normally

supplied voltage at the shipping location.

Fuse Location: The AC power line fuse is located behind the left side of the

carrying handle, on a printed circuit board mounted inside the carrying case.

Fuse Values:

For U.S. use (and others): For power line voltage between 100 to 150 VAC, the

fuse type is 3A, 3AG, 250VAC, Slo-Blo. For power line voltage between 150 to

240 VAC, the fuse type is 1.5A, 3AG, 250 VAC, Slo-Blo.

For European use: Use Type T fuses. For nominal 230 VAC, the required fuse

value is 1.6A.

13

8.3 WATER FILL

Figure 8-2. Filling the Saturator

Note: Only distilled or deionized

water should be used. The

minerals in tap water may

gradually contaminate the

instrument and cause inaccurate

readings.

With power ON, remove the cap

from the clear water reservoir. Using

the supplied syringe, draw water into

the syringe until full. Place the

flexible hose at the end of the

syringe into the opened Saturator fill tube such that the tip extends below the

clear portion of the fill tube, and depress the plunger. Do not fill above the panel

surface. In case of overfill, draw the excess water into the syringe and bring the

water level below the clear portion of the fill tube. Total capacity of the Saturator

is approximately 40 ml (2 –3 full syringes). Replace the reservoir cap firmly.

8.4 AIR CONNECTION

(Optional)

A ¼ inch compression fitting is mounted on the panel. In normal portable

operation, it is not necessary to connect anything to this port, since room air is

automatically drawn into the calibrator, through the fitting, by the vacuum pump.

If you prefer to use your own source of instrument quality dry air, a ¼ inch line

may be connected. In this mode, the requirement for periodic maintenance of

the desiccant dryer material is eliminated.

Note: Air line pressure must NOT exceed 5 psig.

14

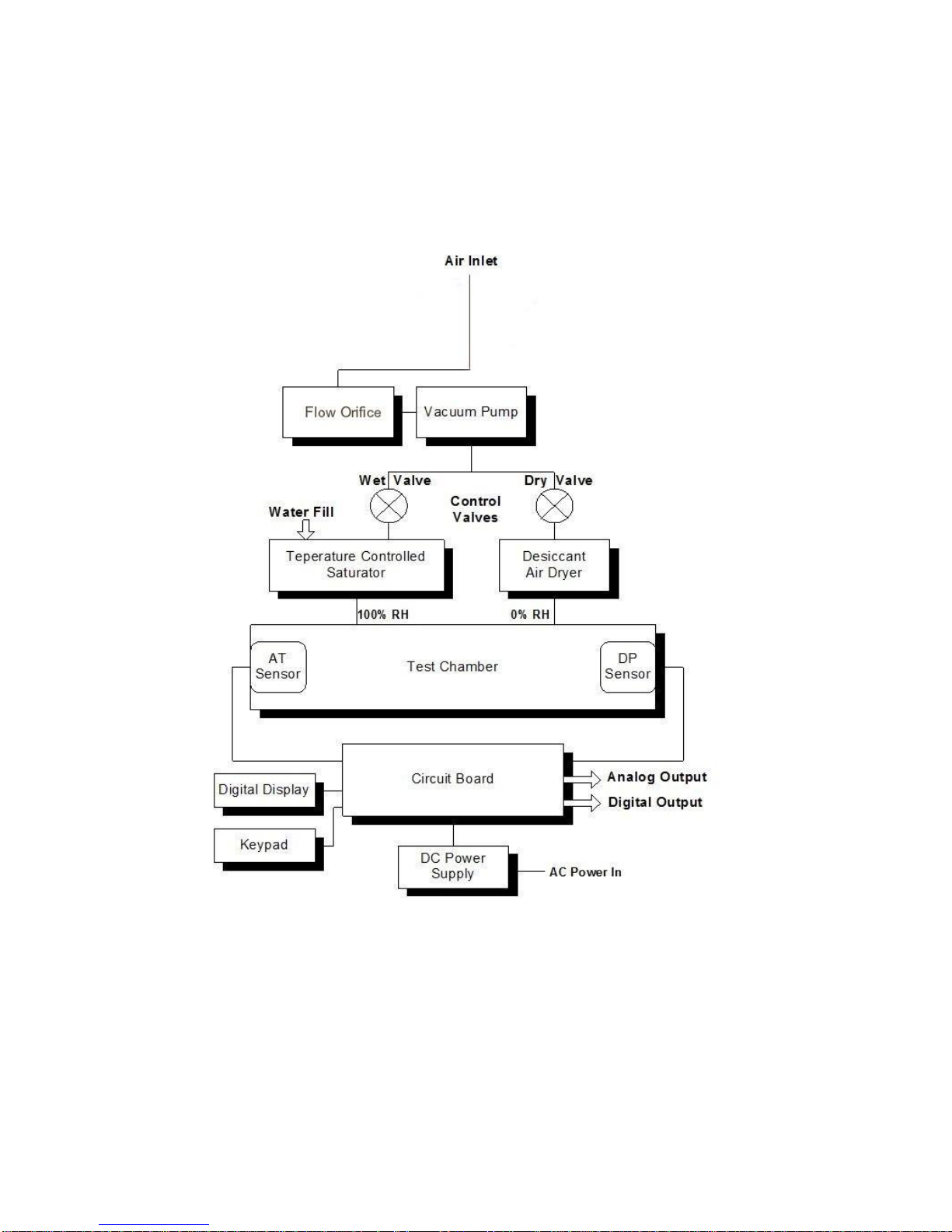

9.0 BASIC BLOCK DIAGRAM THEORY OF OPERATION

Figure 9-1. Basic Block Diagram

15

9.1 BASIC BLOCK DIAGRAM DESCRIPTION

See the Basic Block Diagram, Figure 9-1.

Room air enters the instrument, via the fitting on the panel. (Note: See the Installation

chapter regarding use of an instrument air line.)

A built-in Vacuum Pump is used to draw in the air sample, and to provide a positive

pressure in the Test Chamber.

The air flow is than divided and sent to a pair of finely matched volumetric Control

Valves. The RH CAL independently modulates the “Dry” and “Wet” valves from full-

open to full-closed, or any points between. The “Wet” valve feeds the heated

Saturator, which has a water fill mounted on the panel. The “Dry” valve feeds the Air

Dryer. When a desired RH setting is programmed into the instrument by the user, the

Control Valves automatically control the proper mixing of the wet and dry air in the

Test Chamber.

A Dew Point (DP) sensor is mounted within the Test Chamber. Control circuits on the

Circuit Board control the sensor mirror temperature, which tracks the Dew Point up

and down as it changes. An Air Temperature (AT) sensor is also installed in the Test

Chamber. Mounted in each of these sensors is a precise platinum thermometer to

provide AT and DP information. When the desired RH is selected by the user, a

microprocessor on the Circuit Board converts this information to Percent Relative

Humidity (RH). The proportion of wet and dry air in the chamber is automatically mixed

to keep it at the programmed RH at all times. In addition, the chamber Air

Temperature(AT) will also be controlled at any point programmed by the user.

An LCD Digital Display is mounted on the panel. It provides all pertinent information to

the operator, and allows programming of all parameters, including real time data. The

Keypad is used to enter desired programming information to the RH CAL.

The Analog Output (selectable 0 to 5 Vdc or 4 to 20 mA) is provided at a connector on

the panel. The Digital Output (RS-232C Serial Port) is also mounted on the panel.

A Power Supply module converts the AC power line voltage to DC to power the

electronic circuits.

16

10.0 PANEL DESCRIPTION

2. AIR DRYER

1. AIR INLET 3. WATER FILL TUBE

4. TEST

CHAMBER

5. KEYPAD

9.

INFORMATION

DISPLAY

7. ANALOG OUTPUT 6. DIGITAL OUTPUT

8. ON/OFF SWITCH

Figure 10-1 RH-CAL Panel Description

1. Air Inlet (Sample In) –Brings in room air for use in the system. An

Instrument Air line may also be connected. (1/4 inch compression

fitting)

2. Air Dryer –Removes moisture from incoming air.

3. Water Fill Tube –Supplies water to the temperature controlled Saturator.

17

4. Test Chamber –Contains controlled RH and Temperature environment for

calibrating sensors.

5. Keypad –A pressure-sensitive keypad that allows the user to program setpoints

and to control functions.

6. Digital Output –RS-232C serial port for computer communication.

7. Analog Output –Can be programmed to provide information for Dew Point, Air

Temperature, or Percent Relative Humidity. User may select either 0 to 5 VDC

or 4 to 20 ma.

8. ON/OFF Switch –Turns Power ON or OFF.

9. Information Display –Reads out all system information, such as Set Points and

actual Test Chamber conditions.

ITEMS NOT SHOWN:

Air Outlet –on right rear of carrying case (1/4 inch compression fitting).

AC Power Input Socket and Fuse Holder –on left side of carrying case.

18

11.0 INFORMATION DISPLAY FUNCTIONS

Figure 11-1. The Information Display

11.1 INFORMATION DISPLAYED

The large LCD Display mounted on the Panel provides the user with all the information

necessary to properly operate the RH-CAL. It can be used as the primary interface with

the instrument, showing status of all parameters, and allowing calibration points to be

easily programmed.

NOTES:

1. The RS-232 Serial Port, along with a computer or terminal, may also

be remotely used for the same purpose.

2. All programming is in non-volatile memory, so that it is retained

when Power is off.

TOP ROW:

DATE The Current Date

TIME The Current Time

CONTROL LOOP STATUS Shows Chilled Mirror Control Loop

condition

CENTER ROW (MAIN DISPLAY):

DEW POINT The actual Chamber Dew Point

AIR TEMPERATURE The actual Chamber Temp.

RELATIVE HUMIDITY The actual %RH in the Chamber

19

Note: The above three parameters may be programmed to be

displayed in any desired sequence.

S_HEAT DISPLAY: Cycles on and off to show when

power is applied to Saturator

heater.

BAR GRAPH DISPLAY: The Bar Graph displays a picture of the

dew layer on the chilled mirror surface.

The right hand vertical bar indicates the

mirror itself, and the white bars show the

actual dew layer. The layer can be seen

to vary in thickness as the control loop

brings the mirror into control, and then

maintains a thin layer of dew as the

mirror temperature tracks the dew point

temperature.

BOTTOM ROW:

AIR TEMP. SETPOINT The programmable AT setting

RH SETPOINT The programmable RH setting

20

12.0 OPERATING THE RH CALIBRATOR

In order to operate this instrument, it is assumed that you have read the

INSTALLATION section of this manual, and preliminary tasks have been done.

These include:

1. The Shipping Plug has been removed from the Saturator Fill Tube.

2. The Saturator has been properly filled with water.

3. The instrument has been connected to the AC power source.

4. If desired, the Analog and/or Serial Digital (RS-232) Output has been wired.

If not, the INSTALLATION chapter should be reviewed before proceeding.

Turn the Power Switch to the ON position. The small adjacent indicator lamp will

light, and the Digital Display will: (1) light up; (2) briefly indicate RH

CALIBRATOR by EDGETECH INSTRUMENTS INC.; and (3) go into the normal

display mode. A hum will be heard, indicating that the fans and vacuum pump

are operating.

12.1 SYSTEM STATUS

The status of the RH-CAL control systems may be seen in the upper right corner

of the Display. When first turned on, it will read STARTUP. At other times, it

may read MAX HEAT, or ABC: HEAT, or ABC: STABLE, or SEEKING DP. After

several minutes, the Display will read SERVOLOCK. This indicates that the

system is tracking the Dew Point, and that the RH condition in the chamber is

stabilizing.

The chamber should only be used for calibration when the display reads

SERVOLOCK and the RH reading has stopped changing and reads the setpoint

value +/- the RH-CAL accuracy specification.

12.2 KEYPAD OPERATION

The RH CALIBRATOR Panel has six keys that support user set up and

operation. The label for each key, and its function, is described below.

Key Function

C/F Toggles the displayed parameters, internal parameters and RS-232 output

between degrees Fahrenheit and Centigrade. Output values are also converted

This manual suits for next models

1

Table of contents