Edison TX-928-H User manual

TX-928-H

The manual is subject to change without notice Version:V1-2

Operating Manual

Product Introduction 2

Product Features 2

Technical Datas 3

LCD Display and Functions 4

Dimensions 5

General Setting

Advanced Setting

Wiring Diagrams

Installation Diagrams

Trouble Shooting

Product Features

2

TX-928-H series are available for boiler,

manifold and underfloor heating system

with 7-day, 6-period time program

control. Models are with NTC sensor to

detect ambient and floor temperature

and do the control by compared with the

setting one. Manual, time program and

temporary mode can be switched any time by pressing the relevant

keys. De-frost protection function will be active when ambient

temperature below 5℃, prevent water pipe from freezing and

burning.

1、7-day, 6-period time program

2、Touch screen LCD with blue backlight

3、De-frost protection≤5℃

4、Key-lock function

5、Memory function (can not memorized on/ off condition)

6、Advanced setting

7、Double sensors to control and limit the temp.

8、Ingress Protection:IP20

9、Flame retardant PC

Product Introduction

CONTENTS

1

10

10

6-7

8-9

11

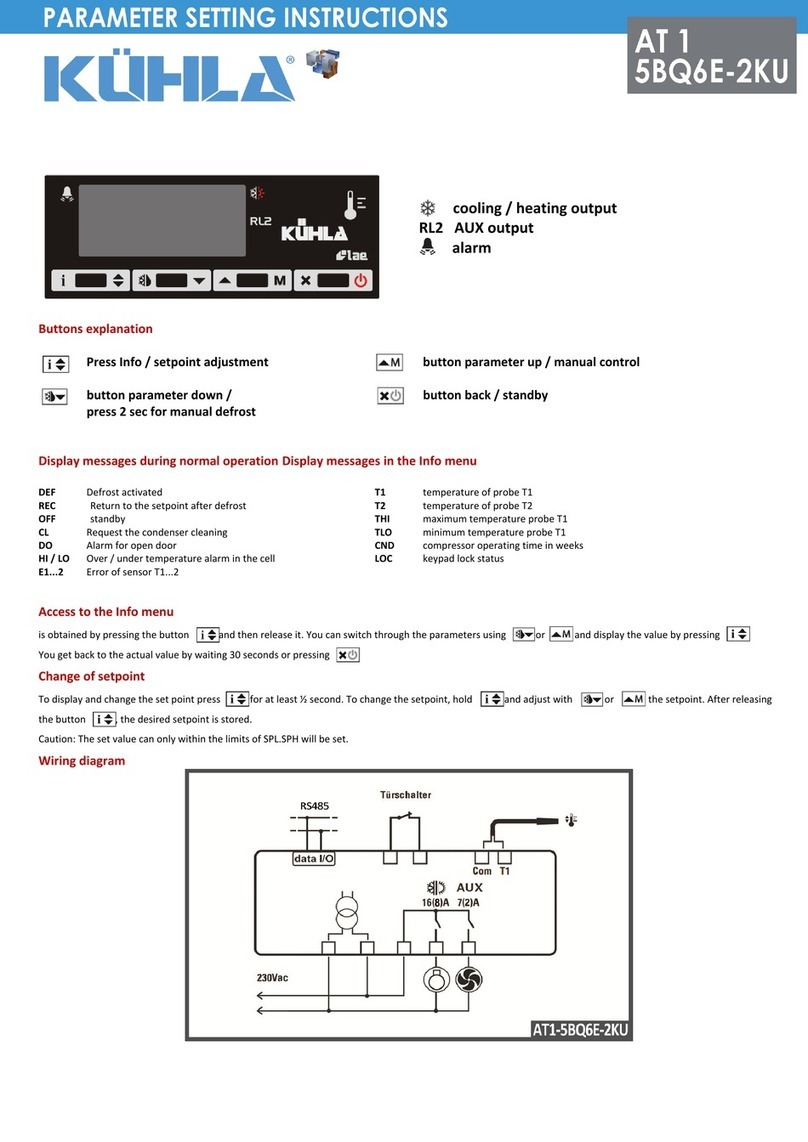

LCD display

LCD display and FunctionsTechnical Datas

43

Consumption:<2W

Power supply: ~240VAC 50/60Hz

Output switch: Active contact (NO) and passive contact (NO)

Max. Current

On/ Off differential temp.: 1~5℃

Transport and storage temp. : -20~60℃

Relative humidity: 10%~90% (No condensation)

Setting temp.: 5~35℃/0.5℃ per step

Accuracy: 1℃

Temp. limitation: 30~60℃(external sensor)

Wiring port: 2.5 mm²

Working temp.: 0~50℃

1. Manual control mode

LCD displays “ ”, the controller is under manual setting. In the

“ON” state, press “ ” to swich the manual control mode or time

program control mode.

2. Time control mode

LCD displays“ ”, adjust temperature of periods automatically

against time program setting. In the “ON” state, press “ ” to

switch the time program control mode or manual control mode.

3. Temporary control mode

LCD displays “ ” and “ ”, current period is manual control

mode, but next period resume to the time program control mode.

In the time program control mode, press “ ” or “ ” to enter into

temporary control mode.

Day Display

Manual Control

Time Control

Clock/

Setting Temperature/

OFF

Time Program

Heating

Menu

Reduce

Increase

Setting

Temperature Value

Power

Ambient

Temperature

20A

20 Amp Max

85

at least

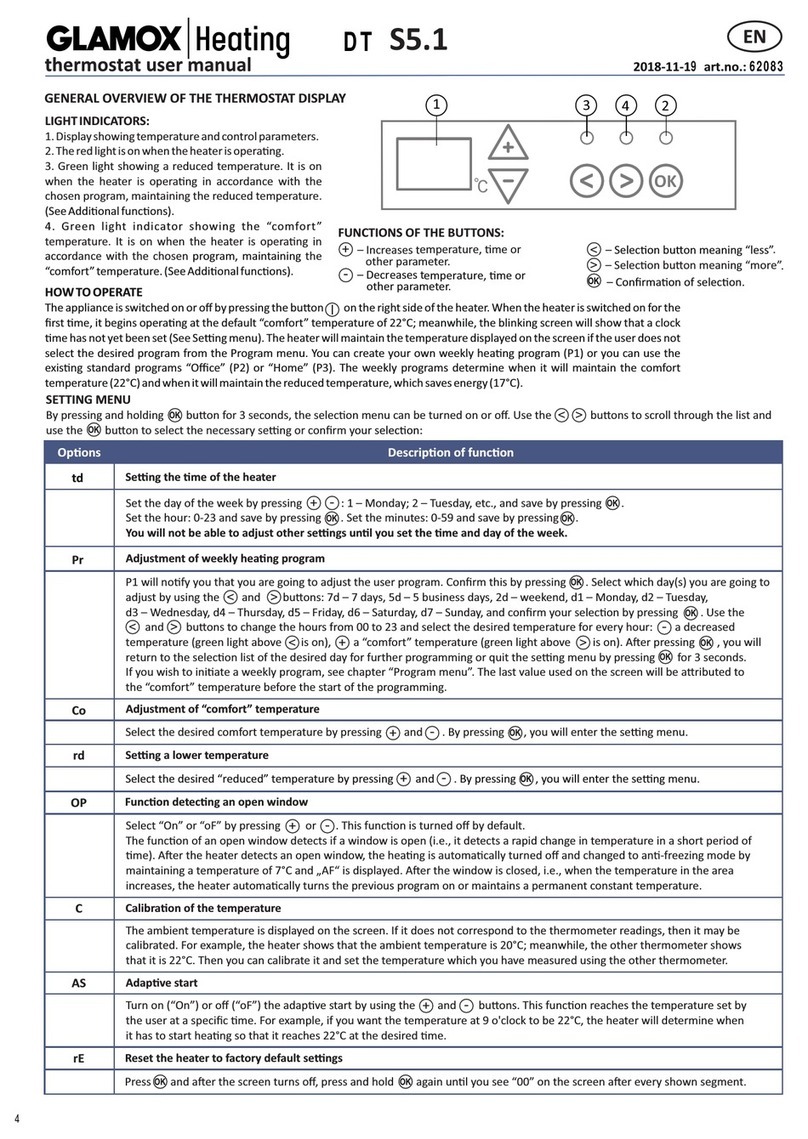

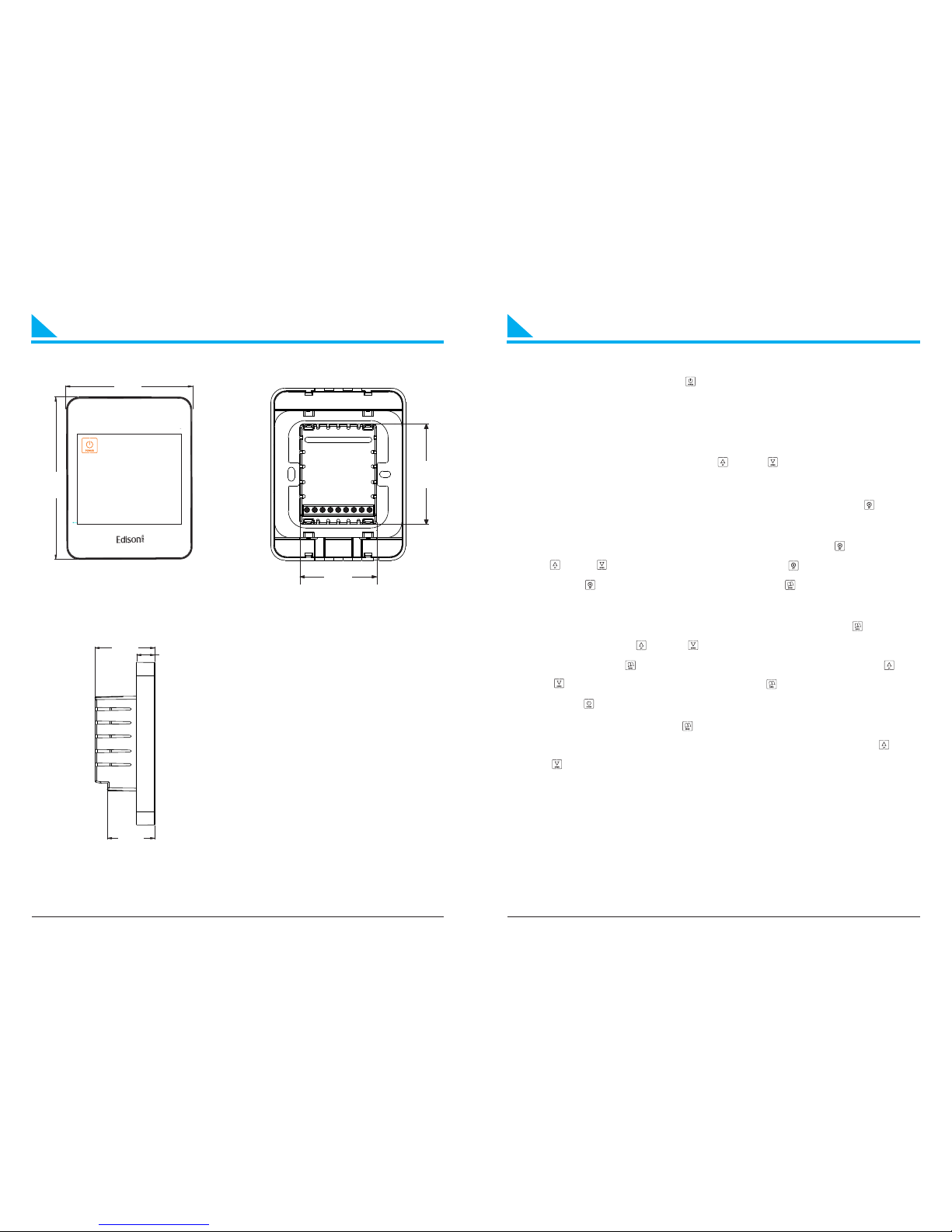

General SettingDimensions

64.1

49.2

32.2

40.6 12.4

86

110

① ②

③

5

Front View

①

②

③

Unit:mm

Back View

Left View

1. Power on / off: Presss “ ” to turn on or turn off the controller.

When power is off, it displays “OFF” and current time

alternatly; when power is on, it displays setting temp. and

current time alternatly.

2. Adjust setting temp.: Press “ ” or “ ”to adjust temp. during

manul control and temporary control mode.

3. Key-lock function: In the “ON” state, keep pressing “ ” for 3s

until the coin “LOC” displays, to lock or unlock the controller.

4. Time and week setting: In the “ON” state, press “ ”, then press

“ ” or “ ” to amend the minute; press “ ” to amend the hour;

press “ ” to set the day of week, press “ ” to save and exit the

setting.

5. Time program: In the “ON” state, keep pressing “ ” to start

setting, press “ ” or “ ” to adjust the current time(15mins/

step). Press “ ” again to check related temp., press “ ” or

“ ”to adjust setting temp.. Press “ ” to adjust next period.

Press “ ” to save and exit the setting.

6. Control mode: Press “ ” to switch manual or time program

control mode. In time control mode, keep pressing “ ” or

“ ”to enter into temporary control mode.

6

General Setting

Periods

22℃

Coins Default Time Default Temperature

WeekdaysHoliday

LOC

Wake up, Period 1 Leave(am), Period 2

Return(am), Period 3 Leave(pm), Period 4

Return(pm), Period 5 Sleep, Period 6

Key-LOC

Advanced Setting

Normally set by technicians during the first installation. Press

“ ” first, then press “ ” for 3s to enter into setting in the “ON”

state.

Tips: (Amend the datas via advanced setting, press “ ” to save and

exit the setting.)

01. Adj Temperature compensation, press “ ” or “ ” to adjust

during range -9~9℃. Press “ ” to enter into next setting.

02. Sen Sensor slection, press “ ” or “ ” to choose the sensor.

“IN”-internal sensor, “OU”-external sensor, “AL”-double

sensors. Press “ ” to enter into next setting.

03. Lit Limitation temperature of external sensor, press “ ” or

“ ” to change the exact limited temperature of external

sensor during 30~60℃, press “ ” to enter into next

setting.

04. Dif Switch deviation ( bandwidth), press “ ” or “ ” t o adjust

the differential temp. during range 1-5℃, press “ ” to

enter into next setting.

Main output from “OFF” to “ON”: Action temp.=setting temp.-

differential temp.

Ma i n ou t p u t f r o m “ O N ” t o “ O F F ” : A c t i o n t e m p . = s e t t in g

temp.+differential temp.

05. Prg 5+2/6+1/7 or off, press “ ” or “ ” to switch workdays,

5/6/7 workdays, or turn off the time program. Press “ ”

to enter into next setting .

Tips: workdays divided into 6 periods, and holidays divided into 2

periods only .

78

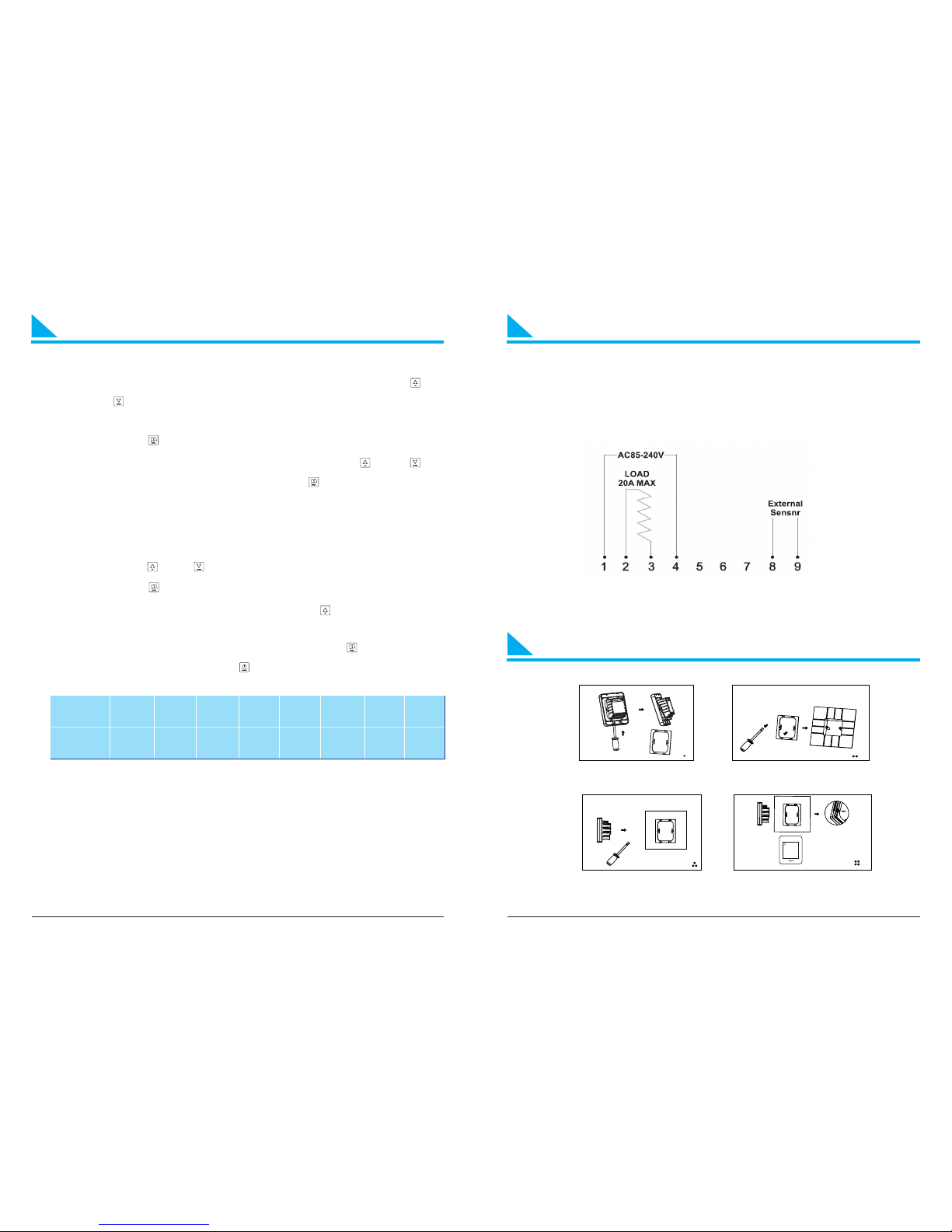

Wiring DiagramsAdvanced Setting

06. Rle Setting of passive linkage and main output, press “ ” or

“ ” to change the condition of linkage; “00” means

correspond with main loop output, “01” means opposite.

Press “ ” to enter into next setting.

07. Dly Dry contact function output delay: Press “ ” or “ ” to

amend from 0-5minutes, press “ ” to enter into next

setting.

When the output from “ON” to “OFF”, dry contact will be “OFF”

at the same time.

08. Hit Press “ ” or “ ” to adjust the max.temp. from 35~60℃.

Press “ ” to enter into next setting.

09. Fac Recover factory setting, press “ ”, then the coin

“-” appears on the screen, hold on until it changes to “- -”,

finishes recover factory setting. Press “ ” to enter into

next setting; or press “ ” to save and exit of setting .

Setting 01 02 03 04 05 06 07 08

Default 0 IN 35 1 5 00 00 35

The highest elevation for the controller working under full load

situation is 2500m; or if higher than 2500m, the rated power of

external loads should be≤80% rated power of the thermostat.

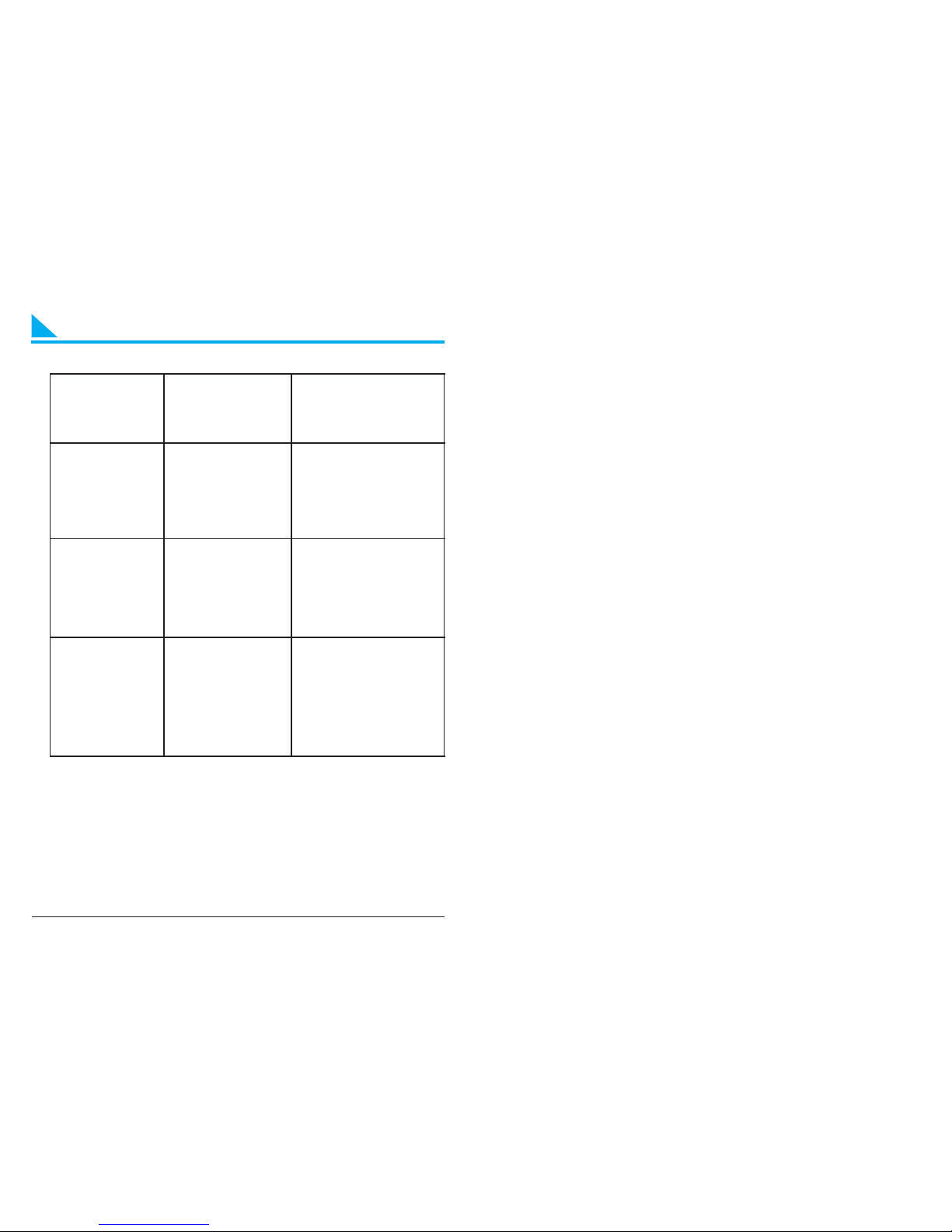

Installation Diagrams

910

Wiring diagrams

1. Insert the screwdriver into the gap to detach

the back cover and iron plate of the thermostat 2. Fix the iron plate with screw and install it on

the junction box in the wall

3.To correctly connect the wires as the wiring diagram 4.Insert the thermostat and fix it on the iron plate

Fault

phenomenon

Reasons Methods

No display Power line input

errors or without

Input

Check the power line

connection and the

power supply

Display Er1 Internal sensor

errors

C h e c k t h e p i n o f

i n t e r n a l s e n s o r i f

there is a short cirsuit

Display Er2 External sensor

errors

C h e c k t h e p i n o f

ex t e r n a l s e n s o r i f

t h e r e i s a s h o r t

c i r s u i t . C h o o s e

internal sensor via

advanced setting

11

Trouble Shooting

Zhuhai IDC Software Technolog y C o ., L t d http://www.idcz h.net

Table of contents

Popular Thermostat manuals by other brands

Remotec

Remotec ZTS-110 Z-Thermostat user manual

Elan

Elan EL-TSTAT-8810 Safety & installation instructions

CALOR

CALOR DG3000WHB-7B Installation and operation instructions

tecnoswitch

tecnoswitch CR035WB manual

Pro1 Technologies

Pro1 Technologies T855iSH installation manual

meitav-tec

meitav-tec ETN-24-PD-1S owner's manual