EDP EDP-C2 User manual

1

EDP-C2

ELECTRONIC CONTROLLER

CONTRÔLEUR ÉLECTRONIQUE

EDP CONCEPTION

EDPCONCEPTION.COM

2

Table of Contents

Introduction page 3

Installation page 4

Controller Properties page 5

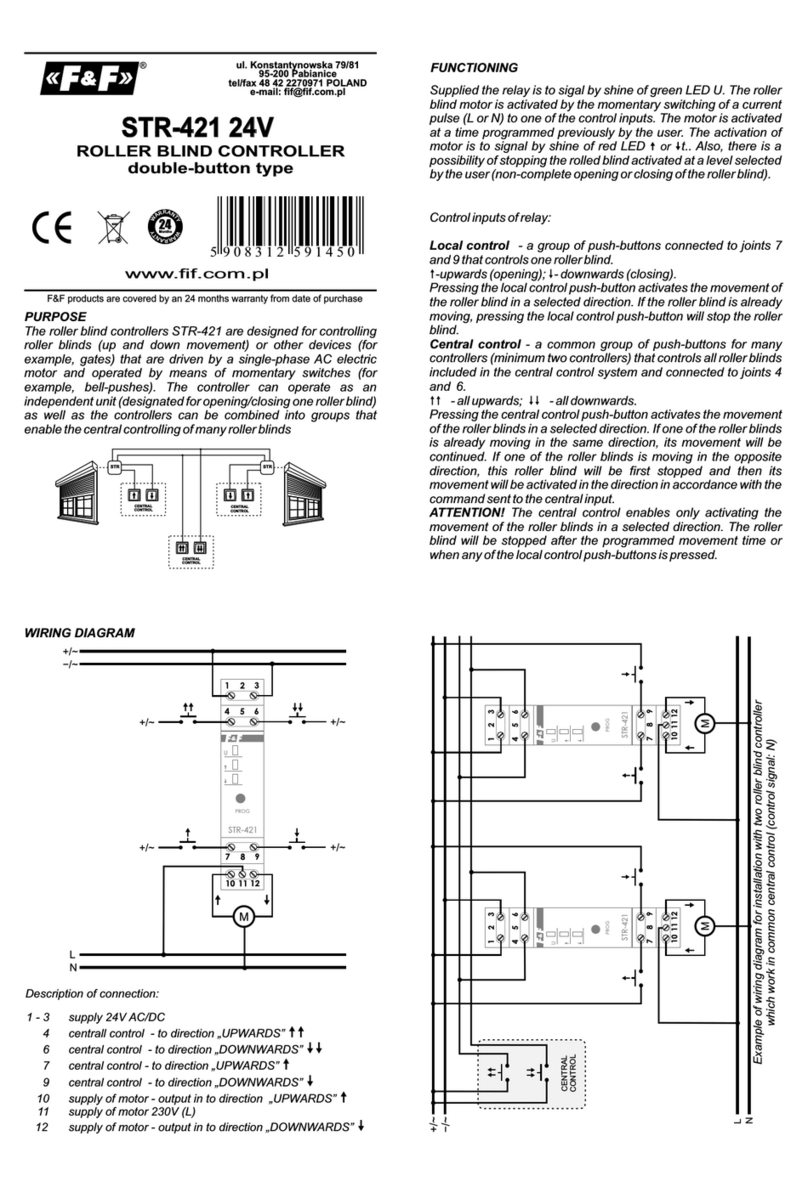

System Hook-up Diagram page 7

Programming page 8

Fuse Replacement page 10

Generator connection page 11

Conductor Size and Fuse Notification page 12

Pulley Size page 13

Number of Belts to Use page 14

Alarm Display page 14

Message page 15

Trouble Shooting page 16

Signalling Indicators Description page 17

Warranty page 17

Security Warning page 18

Value Notification Table page 20

3

Introduction

EDP-C2 consists of a complete electronic concept which allows a greater control of the working

parameters resulting in increasing the lifespan of the generator and the electromagnet.

The controller is easy to install. It only needs a few connections and it is pre programmed and

ready to use.

The controller adapts to most generators (within a range of 180 volts DC to 300 volts DC of

range with a maximum of 5 amps) on field.

The amperage of the electromagnet does not affect the controller.

The system tolerates + - 10% of generator RPM without affecting the efficiency, which is very

useful for the systems that use hydraulic driven generators.

The controller`s display shows the voltage and the amperage applied to the electromagnet.

The controller also shows the modulation and the voltage applied to the field signal.

The information displayed by the controller will allow us to guide you in the adjustments at a

distance, to increase the efficiency or to help fix your lifting equipment.

4

INSTALLATION

For new installation see page 13

For existing installations no pulley calculations are required

Important notice: The installation must be carried out by qualified personnel, voltages can reach

300VDC. Installation must be of professional quality.

The controller is isolated from the battery he have an isolator inside,follow the connection diagram.

1- Fix the main casing to a solid surface.

2- Before drilling holes in main casing, unscrew the four corner bottom plate screws so to

protect the controller unit.

3- Make wires pass through the bottom of the casing in a way to prevent water break

through.

4- Refer to the Installation Diagram (P7) and hook-up exactly as illustrated. Re-verify hook-

up.

5- Do not close the generator`s connection box for there is a possibility that F1 and F2 or F1

and F4 need to be reversed. If you have to respect color wire.

6- Turn the ignition key to power up the controller without activating the generator. Note:

the controller must stay activated during the start up procedure to insure a good start

up; that is why it is connected to ignition.

7- The controller can display the actual isolation of electromagnetic system .

This message is for information unly push right arrow. Now you can select the next

Isolation value with up and down arrow. If the isolation go under the selected value

An alarm appear unly for inform you the evolution of system isolation . The system still

working.

8- It is now time to program the system according to your system requirements; the default

settings are for an electromagnet of 230VDC. Refer to page 9.

9- Start the engine!

10- Adjust throttle to a maximum to maintain a good hydraulic pressure.

11- Activate the command button or the upper arrow to engage magnetism.

12- Observe the activity on the display, volts, amps, modulation field volts.

13- This step should be made with a cold magnet to have a best amp in autoajustement .

Push on command switch or on up arrow to load and still the control switch on and wait

NEW SET UP message appears and release switch .

The controller will automatically adjust the magnetisation in respect to the volt parameter

He can change many parameter identified by (*).

The same parameter can be change manually after.

To improve efficiency fill out the Value Notification Table at the end of the manual (p20) and

call a technician (many parameters are to be taken into consideration).

For more information you may call us at 1-866-535-6686

5

Controller Properties

The EDP-C2 is activated with 24v manual command instead of traditional 230v

therefore making it safer for the operator. He have is own control voltage.

If the electromagnet wires disconnect the controller will automatically lower the

voltage close to 0 VDC within less than 0.5 seconds to help protection of both

operator and equipment.

The controller will activate the field current only when needed to prevent

premature wear of the generator.

The controller offers the possibility of augmenting electromagnetic efficiency by

having two power levels.

1. One called ``High Tension’’ which can generate up to 30% more voltage

than the standard electromagnet voltage during a predetermined time (3-

10 seconds) permitting to pick up more material at a time.

2. The other called ``Transport Tension’’ which is about 15% less voltage

than the standard electromagnet voltage. This tension is used to carry

objects that have already been lifted thus keeping the electromagnet

cooler.

The demagnetisation is done by polarity inversion. A first dopping voltage is

applied and followed by a second cleaning Voltage.

This two voltage are controlled parameter for each .

The controller may provide two droping modes and two Loading modes (see next

page).

6

Working with the Controller

Manual Drop with one button mode

1- Press briefly on the command button for less than 0.5 seconds and the controller will

activate the electromagnet.

2- Each time that you briefly apply the command button, the controller will reactivate the High

Tension for a time determined by the parameter ``T-High Tension’’.

3- To drop the metal, hold the command button again for more than 0.5 seconds.

4-

Manual Drop with two button mode

Press on the second button it will be connected to (TB IN) . It was be programmed for droping

(NO or NC) with code 72. (NO) is more safe. This parameter will deactivates the single button mode.

Auto Drop one button mode

Hold the command button for more than 0.5 seconds; as soon as the button is released the

metal will drop.

Sorting

Press on the command button for more than 0.5 seconds then drop momentarily for more than

0.5 seconds. This coordination will made a quick release and grasp of the materials.

You can repeat this step with a longer release and as often as you want without overheating the

controller.

7

8

Programming

Hold the right arrow for a second. With the help of the arrows

enter code 42 for the main parameters and code 72 for auxiliary

input and output.

Press on the right arrow.

Use the right arrow to scroll through the parameters.

When you see the parameter you would like to adjust use

the top and bottom arrows to change the value.

Press on the right arrow; this will enter your changes.

To exit the programming mode, press on the right arrow as

many times as it takes to come back to the main menu.

9

Parameter description

And

Default values on far right(..)

Language

Select language-------------------------------------------------------------- (English)

High Tension

Tension in electromagnet

at time of high tension-------------------------- 220VDC to 300VDC (240VDC)

T-High Tension

Time in which High Tension will be active------------------------ 5 to 15 s (6s)

Transport Tension

Tension in electromagnet

at time of Transport tension------------------- 180VDC to 240VDC (220VDC)

Time out delay

Maximum charge time ------------------------- 0 to 10 minute 0=infinity

(5 minute)

Generator amperage (Electromagnet +10%)

Alarm amperage---------------------- 15 to 200 amps (100 amps) *

Field Voltage

Field tension--------------------------------------------------- 120v to 300v (250v)

Droping amps

Amps of first droping --------------------------------------- 0 to 20 amps (0) *

Ratio 1’ droping

Power of first droping sequence --------------- 1 to 10/10 (5)

* This parameter will chage with autoajustement

INPUT/OUTPUT (CODE 72)

TB SW- MODE -TWIN + BOOST First short puls made load all other short pulse

restart hight volt time and a long pulse made a droping cycle.

-TWIN - BOOST First short puls made load and a long pulse made a

droping cycle.

-PULS First short puls made load and a next pulse made a

droping cycle.

.

DEFAULT IS TWIN + BOOST

10

TB IN MODE -NIL set one button mude.

-DROPING NC drop when open.

-DROPING NO drop when close.

(NO) is more safe than (NF).

. DEFAULT IS NIL

TB OUT MODE -HYDRAULIC VALVE output go on at load mode

With a minimum time between 0 to 255 seconds.

-MESSAGE ON DISPLAY output flash if an message

apears on display

With an interval between 0 to 255 seconds.

. -TIME OUT. output flash if time out is reached

with an interval between 0 to 255 seconds.

-LOAD UNLOAD output go on /off with load an unload.

- TWIN like load unload plus flash if an message appears

on display

With an interval between 0 to 255 seconds

message est affiché avec un intervalle de 0 a 255 secondes.

VALEUR D’ORIGINE EST DOUBLE

.

TEMPS TB VO -VALVE HYDRAULIQUE sortie active a la magnétisation

avec un délais minimum de 0 a 255 secondes.

VALEUR D’ORIGINE 30 SECONDES

To put parameters back to default values

Press one second on the right arrow.

With the help of the arrows enter 0 and then press once on the right arrow.

Fuse Replacement

NOTE B : 1

FUSE NO.1 MDL 2AMP

FUSE NO.2 MDL 5AMP FOR A 36 VOLT SYSTEME

FUSE NO.3 CERAMIC MDA 5AMP 250V

FUSE NO.4 CERAMIC MDA 5AMP 250V

11

12

Conductor Size and Fuse Notification

The power conductors must be of proper size to resist the

load. Use following table for conductor size:

AMP

AWG

IEC

0-20

12

4mm

20-30

10

6mm

30-45

8

10mm

45-75

6

16mm

76-125

4

25mm

Important Notice

The two power fuses D type are critical and must be well

calibrated in regard to the generator used.

13

Pulley Size for maximum power

The RPM must be 15% faster than the spec on generator

To reach 250 volt at the output .

New Installations

1800 rpm generators 180 vdc field

Power pulley diameter/2100RPM X (Max motor RPM)

Equal generator pulley . D/2100 X RPM

2500 rpm generators 230 vdc field

Power pulley diameter/2900 RPM X (Max motor RPM)

Equal generator pulley . D/2900 X RPM

3450 rpm generator 180 or 230 vdc field

Power pulley diameter/4000 rpm X (Max motor RPM)

Equal generator pulley . D/4000 X RPM

Existing Installation

Note: Choose the easiest pulley to change.

Power pulley calculations

RPM written on generator name plate + 15% / Used RPM X diameter of the power pulley

Calculation of generator pulley

Used RPM / RPM written on generator name plate + 15% X diameter of generator pulley

Note: The direction of the rotation has no importance.

Note: Use C type Belts (.625 inch)

14

Generator Power in KW

Number of Belts

10-15 KW

2

15-33 KW

3

33-35 KW

4

Memory Alarm Display

Up to 20 alarms are memorized. Pressing and holding the

bottom arrow for 1 second will allow you to visualize all

memorized alarms. Use the bottom arrow to visualize the

oldest alarms and the upper arrow to visualize the most

recent alarms.

When you are done close the menu by pressing on the right

arrow and the bottom arrow to leave without erasing the

alarms. Pressing on only the right arrow will erase all

alarms.

15

MESSAGE

The digital indicator will display controller abnormalities as help indicators.

However verify abnormality indications for proper cause.

List of possible abnormalities:

"1.>WIRE DISCONNEC" - Check magnet connection

"1.> OR FUSE BLOW " - Check the tow power fuse

- After this alarm the power off is requested.

"2.> OVER AMP " - check megnet isolation .

- After this alarm the power off is requested.

"3.> BROKEN CT " - The current transformer is bad or diconnected .

"4>RPM LOW " - The speed is to low check strap or mecanic problem .

"4>BRUSHES " - The brushes is too short or is jamed in holder .

"4.SHORT-CIRCUIT " - The wire can have been circuit .

"5. ROTATEE F+ F-" - The direction of rotation is bad .

Swap F+ and F- to fix the problem .

"6.>FIELD + 30% " - Normaly this message apears if RPM is to low and the voltage is

good. In this case the field volt will to hi.

"7.> TIME OUT " - The time out parameter is reached.

The controller will drop vol to 50 vdc to prevent overheat

Of magnet.

"8.> HIGHT VOLT" - Check if the magnet is connected .

- After this alarm the power off is requested.

"9. ROTATE CT" - Swap the connection of the CT.

"10. OVERHEAT" - The inside temp uf controller is to hi.

The controller will drop the output power and you can

Still working. If the temp continious to go up ,the

Controller waits an droping and cancel load mode

And waits low temp.

Press on the right arrow to reset abnormality display to zero.

16

Trouble Shooting

Problems frequently encountered

Proper Voltage is not reached or Causes

bad magnetisation or demagnetisation -Slipping Belts

-Low RPM

-Bad Connection(s)

-Generator is

too small

-Faulty Brushes

-Insufficient Voltage

-Electronic circuit Fuses.

The voltage is good but there is a lack

of amperage or the electromagnet does -A bad connection

not lift enough material. -and/or the resistance of

the electromagnet

Tth output voltage is unstable. -Check if field volt is less than

125v Then the RPM is to low.

The demagnetisation is not constant -verify the brushes

-insufficient RPM

17

1-Manual Command

2-IGBT Positive

3-IGBT Negative

4-PWM Active

5-Cycle

6-Enter(IN)

7-V OUT>0 VOLTS

8-OUT

V=Positive armature voltage

v=Negative armature voltage

A=Positive Amperage

a=Negative Amperage

F=Field voltage Positive

f=Field voltage negative

Signalling Lamps and Description

18

EDP CONCEPTION PRODUCT WARRANTY

EDP Conception warrants that the EDP product you have purchased shall be free of any

defects in parts and workmanship if used under normal operating conditions for a

period of one (1) year from the date of purchase. This warranty shall run only to the

original purchaser when purchased from an authorised EDP Dealer.

Defective products that qualify for coverage under this warranty will be repaired or

replaced, at EDP’s discretion with a like or comparable unit, without charge.

To receive warranty service, return the complete product to an authorised EDP Dealer

service center. The EDP Dealer from whom you purchased your unit may also be

authorised for warranty service and should be the first point of contact when service is

required.

TRANSPORTATION COSTS ARE NOT INCLUDED IN THIS LIMITED WARRANTY.

Any repair or service performed by any person or entity other than an authorised EDP

Service Center is not covered by this limited warranty. This limited warranty becomes

void if the product has been damaged by alteration, misuse, accident, or neglect; or the

product has been repaired or serviced by persons not authorised by EDP Conception.

EDP CONCEPTION ASSUMES NO LIABILITY FOR PROPERTY DAMAGE RESULTING FROM

NEITHER FAILURE OF THIS PRODUCT NOR ANY LOSS OF INCOME, SATISFACTION, OR

DAMAGE ARISING FROM THE LOSS OF USE OF SAME DUE TO DEFECTS OR AVAILABILITY

OF SAME DURING SERVICE.

This warranty applies only to EDP Conception products purchased and serviced within

Canada and the United States of America.

19

Service instructions:

Call your EDP authorised dealer to receive a Request for Service (RS) number before

shipping. Be sure to check your entire system before shipping your unit. Units received

that are in good working condition, will be returned with a service fee to cover

inspection and return shipment.

EFFECTIVE DATE: SEPTEMBER 1, 2008

EDP CONCEPTION INC.

2883, TRUDEL BLVD EAST

ST‐BONIFACE (QUEBEC) CANADA G0X 2L0

Phone: 819‐535‐6686 fax: 819‐535‐6247

info@edpconception.com

www.edpconception.com

20

Important Notice

Security Warning

The controller is only a portion of the electro mechanic lifting system and

electromagnet therefore precautions must be taken around the system by the

user to ensure the safety of all users and workers. In this type of system a bad

wire, bad fuse, generator malfunction, or other may cause the load to suddenly

drop and cause serious injuries and even death.

Note A:1

Important notice

A tension of 0 to 24 volts DC may be found at the exit of the

controller when the generator is turning even if the manual

command is not activated. This tension is due to the magnetic

activity coming from the generator.

Table of contents

Other EDP Controllers manuals

Popular Controllers manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MOVIPRO X4101 Addendum to the operating instructions

ABB

ABB Relion 670 series Product guide

Emotiva

Emotiva UMC-1 Operation manual

Rockwell Automation

Rockwell Automation Allen-Bradley 45MLA user manual

Zytronic

Zytronic ZXY200 Integration manual

Huawei

Huawei SmartACU2000D Series quick guide