Eelectron TM11A01KNX User manual

Pagina 1 di 30

Inwall Room Thermostat

TM11A01KNX

TM11A11KNX

Product Handbook

Product: Inwall Room Thermostat

Order Code: TM11A01KNX – TM11A11KNX

Application Program ETS: EEL_RTH1_10 Room Thermostat

Pagina

2 di 30

Index

Page

1

General Introduction.................................................................................................................3

2.

Technical data ..............................................................................................................................4

2.1

Wiring Diagram ............................................................................................................................5

2.2

Operating and display elements.........................................................................................5

2.3

Dimension drawing....................................................................................................................5

2.4

Mounting and wiring hints.....................................................................................................6

3.

Product and functional overview .......................................................................................7

4.

Parameters ...................................................................................................................................10

4.1

Parameter window “ General Configuration”............................................................10

4.2

Parameter Window “Temperature Regulation Configuration” ........................12

4.3

Parameter Window “Setpoint Configuration”...........................................................16

4.4

Parameter Window “Input Configuration” ..................................................................19

4.5

Parameter Window “Relay Configuration” .................................................................22

5

Communication Objects .......................................................................................................25

6

Application Notes.....................................................................................................................29

Pagina

3 di 30

1 General Introduction

Eelectron is an Italian company with a focus on designing and manufacturing electronic devices

dedicated to building and home evolution and closely related software tools.

As of year 2005, Eelectron applies to KNX association, fulfilling his requirements with the main

goal of giving a contribution to the diffusion of the world’s only open Standard for home and

building automation.

Eelectron philosophy of comprehensive aesthetic design and engagement in developing

highly innovative devices, matched with KNX Interoperability and compliance with international

requirements, has engendered Eelectron’s distinct reputation.

Eelectron experience is devoted to end users, with a constant training activity, assistance on

products and a continuous development that deserves particular attention to upcoming needs

and applications, to energy saving and to solutions directed to make Users life easier and simpler.

Pagina

4 di 30

2. Technical data

Power Supply Via bus EIB/KNX

•

21..30 V DC available from the bus

Inputs Number

Input Signal Voltage

Input Signal Current (close contact)

•

1 (potential free)

•

Un = 24V

•

In = 1ma

Outputs relays Number

Output switching currents

•

1

•

48 VAC, 1A (AC1)

Control Elements 1 programming push button (back side)

1 push button to increase temperature

setpoint

1 push button to decrease temperature

setpoint

1 push button to increase fan coil speed

1 push button to decrease fan coil speed

Display Elements 1 LED red (back) for ETS programming

1 LCD display B/W, size 43,5X43,5 mm

Physical

specifications and

Dimensions

Housing

Colours

Dimensions

Weight

Installation

•

plastic

•

Light Grey Varnished

(TM11A01KNX),

Dark Grey (TM11A11KNX)

•

(WxHxD): 110 x 78 x 39,8mm

•

ca.65g

•

flash mounting in 2-3 modules or

wall round box Ø60mm, 40mm

deep

Electrical Safety Pollution degree

Protection class

Safety class

Overvoltage category

•

2 (according to EN 60664-1)

•

IP20 (according to EN 60529)

•

III (according to EN 61140)

•

III (according to EN 60664-1)

CE Mark and

Certifications

CE

EIB/KNX

•

In accodance with EMC and Low

Voltage guidelines

•

According to EN 50090-1-2

Inwall Room Thermostat

The Inwall Room Thermostat TM11A01KNX/TM11A11KNX is an

EIB/KNX wall mounting device designed for HVAC applications in

Home and Building installations (i.e. offices, hospitals, hotels,

private houses, etc..).

The device is equipped with one binary input (potential free

contact) that can be used, for instance, to control the HVAC units

whether a window has been opened (or closed) or for a general

purpose usage and one binary output relay to control fan coils or

for any different purposes.

The LCD on the front side displays information about temperature,

setpoint, fan coil speeds and operative status.

The control elements available on the front are four push buttons

for setpoint and fan coil speed modification.

La configurazione dell’apparecchio, indirizzo fisico, parametri e

oggetti di comunicazione, avviene mediante il software ETS

(Engineering Tool Software).

Order Code :

TM11A01KNX – Varnished Light Grey

TM11A11KNX – Dark Grey

Pagina

5 di 30

2.1 Wiring Diagram

BUS KNX

TP UART

max 60Vac/dc 1A

Out

In

5

6

7

8

2.2 Operating and display elements

2.3 Dimension drawing

5

6

7

8

9

10

KNX

(11)

12

13

15

16

14

1

2

3

4

5

6

7

8

KNX

9

10

(11)

Pagina

6 di 30

2.4 Mounting and wiring hints

The device may be used for permanent indoor installations in dry locations within wall

boxes.

Requirements for installation

•

The device must not be connected to 230V cables.

•

The prevailing safety rules must be heeded.

•

The device must be mounted and commissioned by an authorised installer.

•

The applicable safety and accident prevention regulations must be observed.

•

The device must not be opened. Any faulty devices should be returned to manufacturer.

•

For planning and construction of electric installations, the relevant guidelines, regulations

and standards of the respective country are to be considered.

Requirements for commissioning

•

Connect each single KNX/EIB bus core inside the bus connection terminal block

observing bus polarity .

•

Slip the bus connection block into the guide slot placed on the front side of this device

and press the block down to the stop.

•

In order to commission the device, a PC with ETS2 version V1.3 or higher is required as

well as an interface to the bus, e.g. via an RS232 interface or via a USB interface.

•

The device configuration (KNX physical address assignment) is done by pressing the

programming push button located on the front of the housing.

Supplied state

•

The device is supplied with the physical address 15.15.255.

•

It is therefore necessary to load parameters and group addresses during

commissioning. However the complete application program can be reloaded if required.

•

The bus connection terminal block is included in the package.

•

The instruction sheet is included in the package.

Manutenance

•

The device is maintenance free.

•

In case of damage during transportation or storage, no repairs my be carried out by

external staff.

•

When the device is opened the right to claim under guarantee expires.

Pagina

7 di 30

3. Product and functional overview

The Inwall Room Thermostat TM11A01KNX/TM11A11KNX is an EIB/KNX wall mounting

device designed for HVAC applications in Home and Building installations (i.e. offices,

hospitals, hotels, private houses, etc..).

The device is equipped with one binary input (potential free contact) that can be used, for

instance, to control the HVAC units whether a window has been opened (or closed) or for

any other general purpose usage and one binary output relay to control fan coils or for any

different purposes.

The temperature control is managed with an On/Off, Proportional, Integrative or PI

algorithm and can be configured to control the following applications:

Heating and Cooling with two tubes common to both fluids (Warm and Cold).

Four circuits for heating and cooling

1, 2 or 3 fancoil speed in ON/OFF regulation

Proportioned motorized valves regulation (continuous control).

In addition to the temperature regulation described, the thermostat allows the following

operating modes:

User inside the room (Comfort mode). The regulation follows the set point that is

fixed from the control/supervision center or modified by the client.

User outside the room (Standby mode). The regulation follows the set point fixed

from the control/supervision center for this mode.

Night Application (Economy Mode). The regulation follows the set point fixed from

the control/supervision center for this mode.

Antifreeze (frost protection).

The user, using dedicated push buttons placed in front of the thermostat, can modify the

temperature setpoint and fancoil speeds.

In case user changes the fancoil speed via a front push button the thermostat pass from

automatic to manual functioning. The automatic functioning mode is restored when the

functioning scheme changes (Comfort, Standby or Economy).

In the thermostat the following parameters can be configured:

Room Temperature Set Point (from 5,0 to 45.0°C or °F correspondent value). The

set point is normally fixed from the control/supervision centre. The client can vary

the set point trough dedicated buttons. The variation can be executed in between

limits fixed from the control/supervision centre (minimum and maximum).

Fan Coil Speed (OFF,1, 2, 3). The fan coil speed is normally managed automatically

from the thermostat. If the clients modify the speed set, the thermostat is forced in

manual mode. The fan coil will get off when the temperature is reached.

Comfort temperature set point (one for cooling and one for heating). This parameter

is set from the control/supervision centre and used when the client is in the room.

Stand by Temperature Set Point (one for cooling and one for heating). This

parameter is set from the control/supervision centre and used when the client is not

in the room.

Economy Set Point (one for cooling and one for heating). This parameter is set from

the control/supervision centre and used when the room is not assigned or by night

to generate an energy saving.

System Type: Two Tubes ON/OFF (only heating, only cooling or both), Four Tubes

ON/OFF (heating and cooling with independent lines), Two Tubes with proportional

command, Four Tubes with proportional command. The parameter is fixed while

installing or testing the system, using ETS SW.

Valves Type: ON/OFF Valves, or Motorized. The parameter is fixed while installing

or testing the system, using ETS SW.

Pagina

8 di 30

Commutation Range between Heating and Cooling. Heating or Cooling action can

be forced from the control/supervision centre and at each season change.

On the display the following information are visualized (see Fig. 1):

Setpoint. The value is displayed in the LCD with XX.X°C format (or in the

correspondent °F value to be selected while installing the system). Using the Set

point variation buttons, the temperature is varied in a range fixed with ETS. Pushing

continuously a button, the value will initially vary of 0,1°C and will proportionally

accelerate the variation speed.

Actual Temperature. In the LCD is displayed the real or actual temperature, in

XX.X°C Format (or in the correspondent °F value to be selected while installing the

system).

Fan Coil Speed Visualisation. The value, from speed 1 to speed 3, is indicated by a

specific icon on the display. This indication is visualised if the system is configured

for fancoil usage.

Some icons concerning actual operative status.

Fig. 1: Display and icons

The thermostat transmits to the KNX/EIB bus the following information:

Real Setpoint Value (also cyclically sent with time period setting)

Real Temperature (also cyclically sent with time period setting)

Objects for actuator command (Fan coil and Valves)

Power failure (and restore) alarm, if enabled.

This device provides also an alarm function by sending an “Alarm” object (1bit) to alarm, for

instance, a centralized visualization software that a power failure has been occurred and

then recovered next (this object is sent as the power supply is recovered).

The physical address, group address and parameters are assigned and programmed with

the ETS tool software. In order to commission the device, a PC with ETS2 version V1.3 or

higher is required as well as an interface to the bus, e.g. via an RS232 interface or via a

USB interface.

The device TM11A01KNX/TM11A11KNX must be configured and loaded with the

following application program: EEL_RTH1_10 Room Thermostat

Climatizzazione

Riscaldamento

Funzionamento Notturno (Economy)

Funzionamento Automatico

Funzione cliente in camera o stand-by

Velocità fan-coil

Spento

Antigelo

Pagina

9 di 30

With this application program the followng functions can be parametrized and configured:

Application Program: EEL_RTH1_10 Room Thermostat

Max number of group addresses: 35

Max number of group address associations: 32

General Configuration

•

Cyclical sending of actual temperature (environment)

•

Cyclical sending of actual setpont temperature

•

Power failure and recovery alarm enable

Temperature

Regulation

Configuration

•

Type of temperature regulation (ON/OFF, P, I, PI)

•

Type of HVAC plant (2/4 tubes ON/OFF, 2/4 tubes

Proportional)

•

Fan Coil type (1,2,3 speeds or proportional regulation)

•

Temperature sensor adjastment (calibration)

•

Temperature coefficient regulation (hysteresis)

Setpoint Configuration

•

Setpoint settings for Comfort, Stand-by, Economy modes

in Summer/Winter conditions (Cooling/Heating)

•

Setpoint antifreeze winter (frost protection)

•

User’s setpont temperature range regulation setting

Input Configuration

•

“Window Switch” or “General Purpose” functions setting

•

Window switch mode (normally opened or closed)

•

If “General Purpose” switching states ON or OFF can be

set depending on input pulse adge evalutation (rising or

falling edge).

•

Cyclical sending option at adjustable intervals

Configurazione

Relay di uscita

•

“General Purpose” or “Velocity V1 Fan Coil”

•

Normally open or closed contact setting

•

Timed OFF switching (e.g.: “Door lock timing release”)).

Note: The default settings for the options are underlined (e.g. Options: no/yes)

Pagina

10 di 30

4. Parameters

4.1 Parameter window “ General Configuration”

Fig. 2: Parameter window “General Configuration”

•

Temperature Send Cycle

Options: Off

1 Min

10 Min

30 Min

1 Hour

Option “Off”: cyclical sending disabled

Option “1Min”..”1Hour”: enable actual temperature value via object “Actual

Temperature” to be sent cyclically every “1Min”…”1 Hour”.

•

Setpoint Actual Send Cylce

Options: Off

1 Min

10 Min

30 Min

1 Hour

Option “Off”: cyclical actual setpoint sending not enabled.

Pagina

11 di 30

Option “1Min”..”1 Hour”: enable actual setpoint cyclical sending every 1Min”…”1

Hour” with the communication object “Actual SetPoint”.

The actual setpoint value is the base setpont setting ± last user’s variation via front

push buttons.

•

Send Alarm

Options: OFF

ON

Option “OFF”: the device does not send the object “Alarm”

Option “ON”: the device sends the object “Alarm” in case of power failure after the

power supply has been recovered.

Note: this feature is useful to visualization software for instance to re-synchronize

some information in the HBES installation.

Pagina

12 di 30

4.2 Parameter Window “Temperature Regulation Configuration”

Parameters concerning the regulation algorithm and the type of HVAC plant

system and the fancoil type are configured here.

This parameter window also provides the temperature adjustment for the

temperature sensor calibration (± 1,5°C) and the hysteresis regulation range for

the two step setpoint control (ON/OFF).

Fig. 3: Parameters Window “Temperature Regulation Configuration”.

Temperature Regulation

This parameter is useful to set the regulation algorithm required.

Options: Regulation ON/OFF

Proportional Band

Integral Band

Proportional/Integral Band

Option “Regulation ON/OFF”: with the switching ON/OFF control the control

value is determined internally according to a two-step algorithm with an

adjustable hysteresis set with the next parameter “Temperature Coefficient

Regulation”.

The ON/OFF control is normally used in HVAC plants with small thermal inertia

installed in small environments.

Option “Proportional Band”: with proportional regulation the actuator (valve)

assumes positions proportional to deviation between the external measured

temperature and the current setpoint (error). The output control command

depends only to this deviation.

The proportional bandwidth is fixed and handled internally.

Pagina

13 di 30

The P control is normally used in:

i. plants where temperature doesn’t change frequently and rapidly.

ii. plants where a constant deviation between the temperature and the

setpoint is acceptable (within a certain limited range)

iii. plants with great volumes (accumulators) or with constant flow rate.

Option “Integral Band”: the integral action acts on the actuator with a speed

proportional to the deviation between the temperature and the setpoint. Here

doesn’t exist a direct relationship between the valve position and the deviation

(error) as in case of a pure proportional regulation. The integral rate and time are

fixed and handled by the thermostat internally.

A pure integral regulation can be used in case of HVAC plants with a fast

reaction, without or with a small thermal inertia and with slow load variations.

Option “Proportional/Integral Band”: the PI regulation provides both features of

a pure proportional and integral controls, i.e. a fast response due to the

proportional regulation at the start up and a quite “load independence” of the

integral action at the end. Normally the proportional control acts immediately as

the thermostat is activated in order to reduce the quite big deviation at first, than

the integral regulation acts as the temperature move towards near the setpoint

reducing completely the permanent deviation remained after the proportional

control.

The PI control allows reaching immediately the setpoint reducing the permanent

deviation left by the proportional action especially in wide environments and

rooms with a big thermal inertia.

Type Plant

This parameter allow the selection of HVAC plant type installed inside the

premises.

In case a 2 or 4 tubes ON/OFF is selected the thermostat sends a switching

ON/OFF command via 1 bit object to the valves when the temperature cross the

range of actual setpoint ± temperature coefficient regulation (hysteresis) ∆T in a

two steps algorithm. It’s therefore possible, for example, for electro thermal

control valves to be addressed via switch actuators. In case a 2 or 4 tubes circuit

proportional is used the control value is determined internally always according

to a two-step algorithm with an adjustable hysteresis and output via 1 byte

communication object. In this case the room thermostat sends only values 0

(=0%=valve closed) or 255 (=100%=valve fully opened).

The toggling between heating (winter) and cooling (summer) is not carried out

neither manually nor automatically but the two control are completely

independent.

Options: 2 Tubes Circuit ON/OFF

4Tubes Circuit ON/OFF

2Tubes Circuit Proportional

4 Tubes Circuit Proportional

Option “2 Tubes Circuit ON/OFF:” with this option the HVAC plan is composed

of 2 circuits with ON/OFF switching valves. The thermostat provides only 1 bit

Pagina

14 di 30

object (“Valve 0=Cold / 1 = Warm”) in order to open or close the valve

connected to an actuator.

Option “4 Tubes Circuit ON/OFF”: with this option the HVAC plan is composed

of 4 circuits with ON/OFF switching Cold and Warm valves. The thermostat

provides two 1 bit object, one dedicated to control the Warm valve and the other

to Cold valve via an external bus actuator.

Option “2 Tubes Circuit Proportional”: with this option the HVAC plan is

composed of 2 circuits with proportional Cold and Warm valves. The thermostat

provides here one 1 byte object (“Valve Proportional 0%=Cold / 100%=Warm”)

with only two values: 0% (cold) and 100% (warm).

Option “4 Tubes Circuit Proportional”: with this option the HVAC plan is

composed of 4 circuits with proportional Cold and Warm valves. The thermostat

provides here two 1 byte object (“Warm Valve Proportional” and “Cold Valve

Proportional”) with only two values: 0% (valve completely closed) and 100%

(valve completely opened).

Fancoil Type

Options: Single Speed V1

Double Speed V1-V2

Three Speed V1-V2-V3

Proportional Regulation

Option “Single Speed V1”: the fan coil has only 1 speed and is so controlled with

a 1 bit object (“Fancoil Speed V1”) via an external bus actuator.

Option “Double Speed V1-V2”: the fan coil has two speeds V1 and V2. With this

option the device provides two 1 bit objects to control the two speeds (“Fancoil

Speed V1” and “Fancoil Speed V2”) via an external bus actuator.

Option “Three Speeds V1-V2-V3 the fan coil has three speeds V1,V2, V3. With

this option the device provides three 1 bit objects to control the three speeds

(“Fancoil Speed V1”, “Fancoil Speed V2”, “Fancoil Speed V3”) via an external

bus actuator.

Option “Proportional Regulation”: the fan coil is controlled by proportional

actuator that allows fan coil speed proportional control between da 0 a 100%.

Temperature Sensor Adjust

Options: -1,5°C….0,0…..+1,5°C

This parameter can be useful when a temperature adjustment is required by the

internal sensor (e.g. due to wrong or difficult installation). The adjustment should

be set using an external professional temperature sensor in order to check the

temperature variance that occurred.

Pagina

15 di 30

Temperature Coefficient Regulation

Options: ±0,1°C….±0,3…..±1,0°C

With this parameter is possible to select a level for the hysteresis (±∆T) by

which the setpoint fluctuates.

The HVAC plant is switched ON in case of an ON/OFF control when

temperature falls outside the hysteresis (see next fig. 4).

The hysteresis is based on how quickly the heating system can warm up the

room or how quickly the cooling system can lower the temperature in the room

as well as the customer’s sensitivity to temperature levels. The hysteresis should

not be set too low as otherwise the valve drive continually opens and closes. It

should be also not be set too high as the temperature fluctuations in the room

are then fairly considerable.

The correct hysteresis setting avoid continuous switching ON and OFF the

HVAC system around the setpoint threshold.

Next figure shows how the hysteresis works in a 2 step controlling.

Fig. 4: Esample of a 2 Step control with hysteresis

Temp.

+∆T

Setpoint

-∆T

ON OFF ON OFF

Pagina

16 di 30

4.3 Parameter Window “Setpoint Configuration”

This window allows parameter settings for all setpoints associated to every

mode (Comfort, Standby, Economy) and also for Heating (Winter) and Cooling

(Summer) operation.

The setpoint values can be modified also via bus in run time by a centralized

unit (e.g. visualization and management software).

Fig. 5: Parameter Window “Setpoint Configuration”

Setpoint Comfort Winter

Options: +5°C….+22°C…..+45°C

Comfort mode setpoint in Winter (Heating)

Setpoint Comfort Summer

Options: +5°C….+24°C…..+45°C

Comfort mode setpoint in Summer (Cooling)

Setpoint Standby Winter

Options: +5°C….+18°C…..+45°C

Standby mode setpoint in Winter (Heating)

Pagina

17 di 30

Setpoint Standby Summer

Options: +5°C….+26°C…..+45°C

Standby mode setpoint in Summer (Cooling)

Setpoint Economy Winter

Options: +5°C….+15°C…..+45°C

Economy mode setpoint in Winter (Heating)

Setpoint Economy Summer

Options: +5°C….+30°C…..+45°C

Economy mode setpoint in Summer (Cooling)

Next figure shows the setpoints settings in Summer/Winter (Heating/Cooling)

mode.

Fig. 6: Heating and Cooling (Summer/Winter) setpoints settings.

Pagina

18 di 30

Setpoint Antifreeze Winter

Options: +4°C….+7°C…..+10°C

Setpoint for frost protection (in Winter/Heating mode).

The frost protection is activated via bus with the 1 bit object “Antifreeze” or in

case the function “Window Switch” is associated to the binary input available. If

a window is opened and this status is detected through the binary input channel

interfaced with a window contact so the HVAC system is switched OFF

immediately.

In “Antifreeze” mode the thermostat refers to this setpoint switching OFF the

HVAC plant in order to avoid energy and heating waste.

The Heat protection for cooling function is not handled in this product version.

Guest Permit Regulation (+/- °C)

Options: No Variation, ±1°C….±3…..±5°C

With this parameter the setpont range of variation allowed to the user, using the

front push buttons, can be limited to a maximum of ±5°C.

Note: the user setpoint variation is stored and maintained inside in case of

change from Comfort to Standby mode and vice versa. In case the thermostat

pass from Comfort mode to Economy or Antifreeze mode or the setpoint is

changed via bus with the specific object than the user modification is cancelled

(i.e. the Comfort setpont is restored to value before user modification).

Pagina

19 di 30

4.4 Parameter Window “Input Configuration”

This window allows setting parameters for binary input operating functions.

Fig. 7: Parameter window for “Input Configuration” with Function = “Windows Switch”

and “Cyclic Send” = “ON” settings.

Function

This parameter allows setting of function associated to the binary input channel

as “Window Switch” or as “General Purpose”.

Options: Windows Switch

General Purpose

Option “Windows Switch”: the thermostat detects when the input contact is

closed in case a window has been opened. The next parameter “Window Switch

Mode” allows setting of “Normally Close” or “Normally Open” contact.

As the contact has been closed by an external window switch connected to the

binary input the thermostat start up the “Antifreeze” frost protection function

switching OFF the heating/cooling system and sending the 1 bit object “Window

Switch” to the bus just signalling the event to a centralized unit or to a

supervision system.

Option “General Purpose”: with this option the input channel can be used as a

standard binary input where the input signal detection based on rising or falling

edge or toggle ON/OFF can be selected with the parameter next.

Pagina

20 di 30

If the input is associated to “Windows Switch” function the following parameters are

visible and enabled.

Windows Switch Mode

This parameter allows the input contact usage setting if normally opened or

closed.

Options: Normally Open

Normally Close

Option “Normally Open”:

Window Close = contact open

Window Open = contact closed.

. Option “Normally Close”:

Window Close = contact close

Window Open = contact open.

Cyclic Send

Options: ON

OFF

This parameter enable the cyclical sending of current value of the binary Input

to the bus at a set interval.

Cycling send time (min)

Options: 1…10…200

The cyclic time for sending telegrams repeatedly on the bus with Input current

value is specified here. The time units are minutes.

Note: please see Input timing diagrams in “Application Notes”.

In case the binary input function selected is “General Purpose” so the following

parameter appears to allow planner to set the input signal handle based on

rising/falling edges or toggle ON/OFF.

Other manuals for TM11A01KNX

1

This manual suits for next models

1

Table of contents

Other Eelectron Thermostat manuals

Popular Thermostat manuals by other brands

Agilent Technologies

Agilent Technologies 1260 Infinity II user manual

Speedheat

Speedheat SH-SmartStat manual

Honeywell

Honeywell PROGRAMMABLE THERMOSTAT RTH6350 Quick installation guide

Honeywell

Honeywell RTH2510/RTH2410 Series operating manual

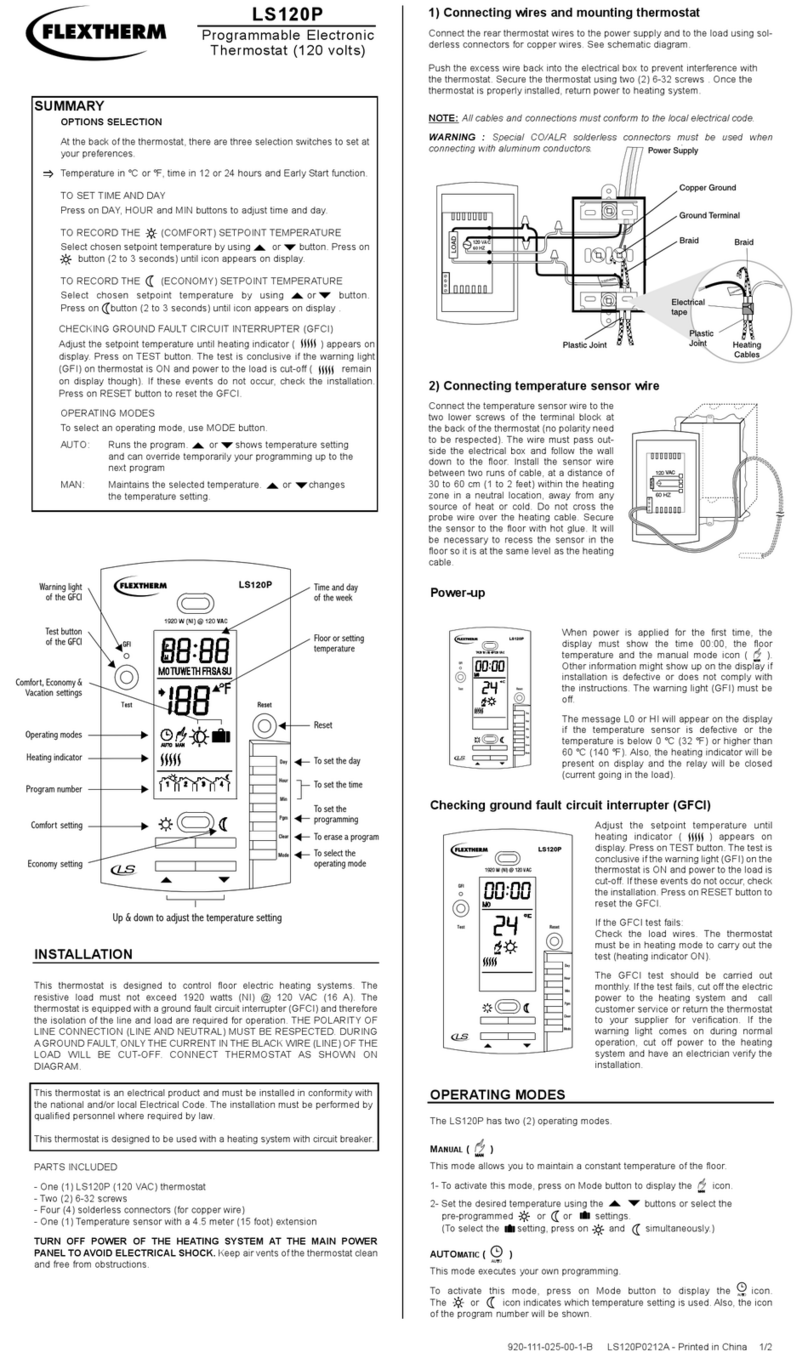

Flextherm

Flextherm LS120P user manual

OLBA

OLBA Thermotronic manual