efes otomasyon IS300 Series User manual

IS300 Series User Manual Preface

1

Preface

IS300 series servo drive is a servo drive which is specially designed for drive permanent

magnet synchronous servo motor (PMSM). IS300 series servo drive has a wide capacity range

(the rated current is 5A to 300A).Itÿs able to provide not only servo pump control, but also the

general functional requirements. And it is a high-power servo drive which is value-for-money in

the present market.

This manual is a guide to the operations of IS300 series servo drive.

This manual provides the user with related precautions and instructions for the prototyping,

installation, parameter setup, and on-site trial run, and routine repair and maintenance of servo

drive. In order to use this series of drive correctly, please read this manual carefully prior to

operation and keep it properly for future using. The supporting equipment customers shall

distribute this manual together with the equipment to the final users.

Unpacking and inspection:

Please confirm carefully when unpacking the box:

If the model and drive rated values on the nameplate are the same as your order. The box

contains the equipment, certificate of conformity, user manual and warranty card.

If the product is damaged during the transportation. If there is any omission or damage, please

contact our company or the supplier immediately.

First time use:

The users who use this product for the first time shall read this manual carefully. For any doubt

on certain functions and performances, please contact the technical support personnel of our

company for help so as to use this product properly.

With commitment to the constant improvement of the servo drive, our company may change

the information provided without additional notice.

IS300 series servo drive complies with the following international standards, and some products

have passed the CE certification.

IEC/EN61800-5-1:2003 ĀSafety Regulations on Commissionable Electric Drive Systemāand

IEC/EN 61800-3:2004 Commissionable Electric Drive System: The third Part: Electromagnetic

Compatibility Standard and Specific Testing Method for the Product.

efesotomasyon.com

Content

Preface ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 1

Chapter 1 Product Information ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 4

1.1 IS300 Servo Drive Designation Rules ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 4

1.2 IS300 Servo Drive SeriesĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 5

1.3 IS300 Servo Drive Brake Components Prototyping Table ĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 6

1.4 IS300 Servo Drive External Electrical Parts Table ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 7

1.5 Physical Appearance and Installation Dimensions ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 8

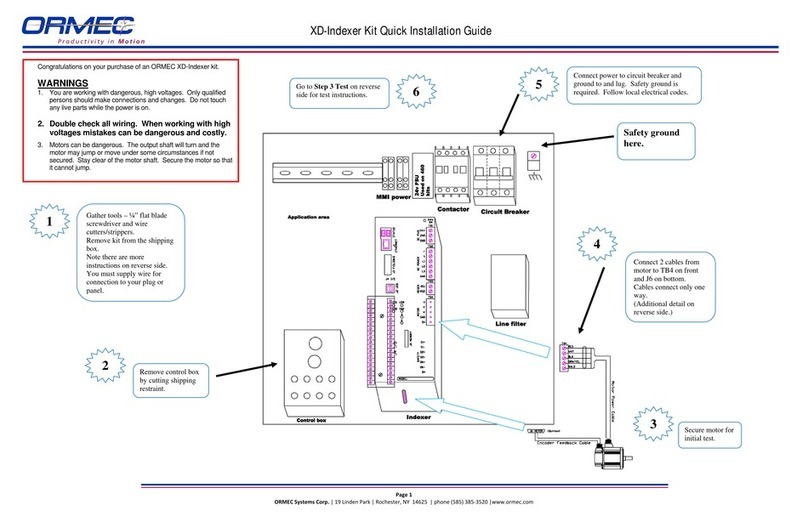

Chapter 2 Wiring ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 2

2.1 Connection Mode ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ12

2.2 Main Circuit Terminals and Connections ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ13

2.3 Control Terminals and Connections ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ13

2.4 IS300 Servo Drive Jumper Function Description ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ15

2.5 Function Instructions of Servo Drive PG Card Terminals ĂĂĂĂĂĂĂĂĂĂĂĂĂĂ16

Chapter 3

Servo Pump Trial Run Steps and Prototyping of Servo Pump Optional Parts

Ă18

3.1 Servo Pump Trial run ProcessĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ18

3.2 Motor Trail Run ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ19

3.3 Servo Pump Application Trail Run ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ20

Chapter 4 Failure Diagnosis and Solution ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 24

4.1 Failure Diagnosis and Solution ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ24

4.2 Common Fault and Resolution ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ36

ISMG Servo Drive Using Instruction ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ37

Chapter 5 ISMG Servo Drive Using Instruction ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ38

5.1 ISMG Servo Drive Naming Rules ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ38

5.2 ISMG Servo Motor Performance ParameterĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ39

5.3 ISMG Servo Motor Physical Dimension DiagramĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ41

5.4 Instructions of Supporting Board of ISMG Servo Motor Base Installation ĂĂĂĂĂĂĂ43

5.5 ISMG Servo Motor Wiring Instructions ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ43

Appendix ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ 45

Appendix 1 Common Parameters Table ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ46

Appendix 2 Servo Motor Code Table ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ52

efesotomasyon.com

Product Information

1

efesotomasyon.com

Product Information IS300 Series User Manual

4

Chapter 1 Product Information

1.1 IS300 Servo Drive Designation Rules

IS300 T 030 C L

IS300

Mark

SThree-phase 380V

Mark Voltage level

Rated output current 9A

Mark 005

13A

010

17A

015

25A

020

32A

030

37A

035

45A

040

60A

050

75A

070

91A

080

112A

100

150A

140

176A

170

210A

210

253A

250

304A

300

Rated output current

Mark

Rated output current

Corresponding relationship

2T Three-phase 220V

5T Three-phase 480

Universal servo oil pump drive

Series code

CMotor temperature overheating

protection PTC sensor with CAN

communication

Mark Interface board type

Null Forced air cooling in default

Mark Cooling method

LWater cooling

Note: With the rotary transformer

PG card as standard

efesotomasyon.com

IS300 Series User Manual Product Information

5

1.2 IS300 Servo Drive Series

Caution: Models in grey shading are custom models (water cooling drive)

Servo drive model Input voltage Power supply capacity

(kVA)

Input current

(A)

Rated output current

(A)

IS300T005-C

Three -phase

380V

Range˖

-15%20%

5.9 10.5 9.0

IS300T010-C 8.9 14.6 13.0

IS300T015-C 11.0 20.5 17.0

IS300T020-C 17.0 26.0 25.0

IS300T030-C 21.0 35.0 32.0

IS300T035-C 24.0 38.5 37.0

IS300T040-C 30.0 46.5 45.0

IS300T050-C 40.0 62.0 60.0

IS300T070-C 57.0 76.0 75.0

IS300T080-C 69.0 92.0 91.0

IS300T100-C 85.0 113.0 112.0

IS300T140-C 114.0 157.0 150.0

IS300T170-C 134.0 180.0 176.0

IS300T210-C 160.0 214.0 210.0

IS300T250-C 192.0 256.0 253.0

IS300T300-C 231.0 307.0 304.0

IS300T140-C-L 114.0 157.0 150.0

IS300T170-C-L 134.0 180.0 176.0

IS300T210-C-L 160.0 214.0 210.0

IS300T250-C-L 192.0 256.0 253.0

IS300T300-C-L 231.0 307.0 304.0

efesotomasyon.com

Product Information IS300 Series User Manual

6

1.3 IS300 Servo Drive Brake Components Prototyping Table

Caution: Models in grey shading are custom models (water cooling drive)

Servo drive model Recommended

rower of brake

resistor

Recommended

resistance value of

brake resistor Braking unit Remarks

IS300T005 300W ≥130¡

Built-in as

standard No special

specification

IS300T010 400W ≥90¡

IS300T015 500W ≥65¡

IS300T020 800W ≥43¡

IS300T030 1000W ≥32¡

IS300T035 1300W ≥25¡

IS300T040 1500W ≥22¡

IS300T050 2500W ≥16¡

IS300T070 3.7 kW ≥16¡Externally

connected MDBU-35-B

IS300T080 4.5 kW ≥16¡Externally

connected MDBU-35-B

IS300T100 5.5 kW ≥8¡Externally

connected MDBU-70-B

IS300T140 7.5 kW ≥8¡Externally

connected MDBU-70-B

IS300T170 4.5 kWh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T210 5.5 kWh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T250 6.5 kWh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T300 16kW ≥2.5¡Externally

connected MDBU-210-B

IS300T140-C-L 5000W ≥8¡Externally

connected MDBU-70-B

IS300T170-C-L 5000Wh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T210-C-L 5000Wh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T250-C-L 5000Wh2≥8¡h2Externally

connected MDBU-70-Bh2

IS300T300-C-L 5000Wh3≥8¡h3Externally

connected MDBU-70-Bh3

Note: h2 refers to two Braking units paralleled with their respective brake resistor; the meaning

of h3 is the same with h2.

efesotomasyon.com

IS300 Series User Manual Product Information

7

1.4 IS300 Servo Drive External Electrical Parts Table

Caution: Models in grey shading are custom models (water cooling drive)

Servo drive

model

Circuit

breaker

(MCCB)

A

Recom-

mended

contactor

A

Recom-

mended

input filter A

A

Recommend-

ed conducting

Wire of main

circuit at the

input side

mm2

Recom-

mended

conducting

wire of main

circuit at the

output side

mm2

Recom-

mended

conducting

wire of control

circuit

mm2

IS300T005 25 16 25 4 4 1.5

IS300T010 32 25 35 4 4 1.5

IS300T015 40 32 35 4 4 1.5

IS300T020 63 40 50 4 4 1.5

IS300T030 63 40 50 6 6 1.5

IS300T035 100 63 80 6 6 1.5

IS300T040 100 63 80 10 10 1.5

IS300T050 125 100 100 16 10 1.5

IS300T070 160 100 120 16 16 1.5

IS300T080 200 125 150 25 25 1.5

IS300T100 200 125 150 35 25 1.5

IS300T140 250 160 200 50 35 1.5

IS300T170 250 160 200 70 35 1.5

IS300T210 350 350 250 120 120 1.5

IS300T250 400 400 300 150 150 1.5

IS300T300 500 400 400 185 185 1.5

IS300T140-C-L 250 160 200 50 35 1.5

IS300T170-C-L 250 160 200 70 35 1.5

IS300T210-C-L 350 350 250 120 120 1.5

IS300T250-C-L 400 400 300 150 150 1.5

IS300T300-C-L 500 400 400 185 185 1.5

efesotomasyon.com

Product Information IS300 Series User Manual

8

1.5 Physical Appearance and Installation Dimensions

1.5.1 Physical appearance and installation dimensions of forced air cooling servo drive

Schematic Diagram for Physical Dimensions and Installation Dimensions

of IS300T005IS300T030

Schematic Diagram for Physical Dimensions and Installation Dimensions

of IS300T005IS300T030

efesotomasyon.com

IS300 Series User Manual Product Information

9

Model Mounting hole Physical dimensions Diameter of

mounting hole Weight (kg)

ABHH1 W D

IS300T005

148 236 248 / 160 183 ¶52.5

IS300T010

IS300T015

190 305 322 / 208 192 ¶66.5IS300T020

IS300T030

IS300T035

235 447 432 463 285 228 820IS300T040

IS300T050

IS300T070

260 580 549 600 385 265 ¶10 32IS300T080

IS300T100

IS300T140

343 678 660 700 473 307 ¶10 47

IS300T170

IS300T210

449 905 880 930 579 375 ¶10 90IS300T250

IS300T300

1.5.2 Physical appearance and Installation Dimensions of water cooling servo drive

Schematic Diagram for Physical Dimensions and Installation Dimensions of IS300T140-C-L

and IS300T170-C-L

efesotomasyon.com

Product Information IS300 Series User Manual

10

Schematic Diagram for Physical Dimensions and Installation Dimensions of IS300T210-C-L,

IS300T250-C-L and IS300T300-C-L

efesotomasyon.com

Wiring

2

efesotomasyon.com

Wring IS300 Series User Manual

12

Chapter 2 Wiring

2.1 Connection Mode

8

9

˳

3* FDUG

˄0 ' 3 * ˅

&15

( [WHUQDONH\ERDUG

LQ WH U ID F H

23

9

',

',

',

',

',

&20

$,

$,

*1'

3UHVVXUHFRP P DQGa9

)ORZ FRP P DQGa9

9

$,

*1'

3UHVVXUHVHQVRUVLJQDO

*1'

9

28738 7

3 7 & 3

37&1 7 KHUP LVWR U˄37&hhh˅

&$1+ &*1'

&$1/

% $

2LOSXP S

HQDEOHG

3,' VHOHFWLR Q WH U P LQDO

3,' 6HOHFWLR Q WH U P LQDO

) DXOWUHVHW

&$1&RP PXQLFDWLRQ( QDEOHGXVHZ KHQ

0XOWLSXP SSDUDOOHOIORZ

0 RWRURYHUKHDWLQJ

SURWHFWLRQWHUP LQDO

a9aP $

$FWXDOSUHVVXUH

RXWSXW a 9 aP $

(;&

(;&

6,1

6,1/2

&26

3 7& 35HVHUYHG

3 7& 15HVHUYHG

&26/2

37& 3

37& 1

37& 3

37& 1

8

9

:

/

/

/

(;&

(;&

6,1

6,1/2

&26

&26/2

5HGZKLWH

< HOORZ Z KLWH

\ H OOR Z

EOXH

UH G

EODFN

76 1 (

7KHFRORUHGOLQH

FRUUHVSRQGVWR7DP D

UR WDU\WUDQVIRUP HU

0 RGHO

76 1 )

3OHDVHFRQQHFW

WKHUPLVWRU

GHYLFHV7KHUP DO

JDOYDQLFGHYLFHV

FRQQHFWWRWKH

UHVLVWDQFHUX OHU

ORFDWLRQRIWKH

V\VWHP FRP SXWH U

7 RURLGDO& RUH DURXQG RQH FLUFOH

6KLHOGHG

QHWZRUN

6KLHOGHG1HWZRUN

& RQQHFWRUPHWDOVKHOO

* HQHUDOO\WKHPRWRU

WKHUPLVWRUFRQQHFWVWR

3 7& 3DQG37&1

6 \VWHP & RP SXWHU

*1'

) HUULWH% HDG ,QWKHVDP H

GLUHFWLRQDURXQGWZ RFLUFOHV

) HUULWH% HDG ,QWKHVDP H

GLUHFWLRQDURXQGWZ RFLUFOHV

) HUULWH% HDG ,QWKHVDP H

GLUHFWLRQDURXQGWZ RFLUFOHV

a9aP $

$FWXDOIORZ RXWSXWa9 aP $

*1'

) HUULWH% HDG ,QWKHVDP HGLUHFWLRQ

DURXQGWZ RFLUFOHV

$2

$2

*1'

7$

7%

7&

7$

7&

7$

7&

˄5 (/$<)DXOWRXWSXW˅

˄5(/$<˖6ZDVKSODWHVZ LWF K LQ J R I

GRXEOHGLVSODFHP HQWSOXQJHUSXP S˅

˄5(/$<˖

Pressure control status

output

˅

6(1625

5

6

7

5

6

7

)LOWH U

& RQWDFWRU0 &

&LUF X LW%UHDNHU

0 &&%

7 RURLGDO& RUH

D URXQG RQH FLUFOH

/

/

/

3

(

/

/

/

3

(

6KLHOGHG

QHWZRUN

6KLHOGHGQHWZRUN

% UDNH& LUFXLW

& RQQHFWLRQ

˄˅ ˄ ˅ 3 %

% UDNH5 HVLVWRU

,6 7,6 7

˄˅ ˄˅

%UDNH

5 HVLVWRU

0'%8

,6 7,6 7

˄˅ ˄˅

%UDNH5 HVLVWRU

0'%8

3

([WHUQDO

5 HDFWRU

,6 7,6 7

6 FKHP DWLF' LDJUDP

IRU & RQQHFWLRQRI

0 DLQ& LUFXLWDQG

& RQWURO7HUP LQDOV

% UHDN& LUFXLW& RQQHFWLRQV

6KLHOGHGWZLVWHG SDLU

FDEOLQJ

6KLHOGHGWZLVWHG

SDLUFDEOLQJ

9

$,

*1' *1'

9

28738 7 6(1625

6KLHOGHG

QHWZRUN

3 RZ HU6 XSSO\

*1' 9

$ GRSWWKHFRQQHFWLRQ P RGHRIWKH H[WHUQDOSRZ HUVXSSO\

SUHVVXUHVHQVRUUHFRP P HQHG

) HUULWH% HDG ,QWKHVDP HGLUHFWLRQ

DURXQGWZ RFLUFOHV

) HUULWH% HDG ,QWKHVDP H

GLUHFWLRQDURXQGWZ RFLUFOHV

) HUULWH% HDG ,QWKHVDP HGLUHFWLRQ

DURXQGWZ RFLUFOHV

) HUULWH% HDG ,QWKHVDP H

GLUHFWLRQDURXQGWZ RFLUFOHV

) H UULWH%HDG,QWKHVDPH

GLUHFWLRQDURXQGWKHWZRFLUF OHV

6KLHOGHG

QHWZ RUN

+ DQJLQWKHDLU

efesotomasyon.com

IS300 Series User Manual Wring

13

2.2 Main Circuit Terminals and Connections

Terminals Name Description

RǃSǃT

RǃS and T

Input terminal of three-

phase power supply AC single-phase 220V power connection point

(+)ǃ(-)(+)

and (-)

Negative and positive

terminals of DC bus

Shared DC bus input point (connection point of external

braking unit of above IS300T070˄included˅

(+)ǃPB(+)

and PB

Connecting terminal of

brake resistor

Connection point of brake resistor of below

IS300T050(included)

Pǃ(+)P and

(+)

Connection terminal of

external reactor

Connection point of external reactor above

IS300T140(included)

UǃVǃW U,

V and W

Output terminal of

servo drive Connect the three-phase motor

Earth terminal Earth terminal

2.3 Control Terminals and Connections

Type Terminal Terminal name Function description

power supply

+10V-GND 10V power supply

Provide 10Vf10% power supply for external-

units, and the maximum output current is 10mA.

It is generally used as the operating power

supply for the external potentiometer.

The potentiometer resistance range is 1 k¡to

5k¡.

+13V-GND Pressure sensor power

supply

Provide 13Vf10% power supply for external

units.

The maximum output current is 10mA.

It is generally used as the operating power

supply for pressure sensor.

+24V-COM ˇ24V power supply

Provide +24V power supply for external units. It

is generally used as the operating power supply

for digital input/output terminals.

24Vf10%, no-load virtual voltage can not

exceed 30V.

The maximum output current is 200mA. It is

internally insulated with GND.

OP External power input

terminal

COM and 24V is internally insulated .Connect to

24V by default upon delivery.

When external signal is used to drive DI1toDI5,

OP needs to connect to the external power

supply and disconnect from the +24V power

terminal.(It is determined by the J7 jumper on

the control board.)

efesotomasyon.com

Wring IS300 Series User Manual

14

Type Terminal Terminal name Function description

Analog Input

AI1-GND

Analog input terminal 1

˄default pressure

setting˅

1ǃInput Voltage range˖f10V

The resolution is 12 bit.

The correction precision is 0.5%.

2ǃInput resistance˖100k¡DŽ

AI2-GND Analog input terminal 2

˄default flow setting˅

1ǃThe resolution is 12 bit, the correction

precision is 0.5 %.

2ǃInput resistance˖100k¡DŽ

AI3-GND

Analog input terminal 3

˄default pressure sensor

signal input˅

1. Input range: f10V/0 to 20mA, which is

determined by J5 jumper on the control board.

There is 12-bit resolution; the correction

precision is 0.5 %.

2. Input impedance: It is 100k¡at the time of

voltage input and 500¡at the time of current

input.

Digital Input

DI1DI5-

COM

Digital input 1

1ǃInsulate drain-to-source input programmable

terminals, input frequency is less than 100 Hz;

2ǃInput resistance˖3.3k¡

3ǃVoltage range for level input˖9Vto 30V.

PTCP-PTCN Motor overheating

protection input

Motor overheating protection PTC sensor,

support PTC130 ǃPTC150 etc.

Communication

Terminal

CANH/

CANL/

CGND

CAN Communication

terminal

The highest communication speed is 1Mbps.

Whether to connect terminal resistance is

determined by the J8 jumper on the control

board.

485B/

485A

485 Communication

terminal

Retain the terminal without the function by

default, the highest communication speed is

230Kbps with isolation. Whether to connect

terminal resistance is determined by the J9

jumper on the control board.

Analog

Output

AO1-GND Analog output 1

The voltage or current output is determined by

the J4 jumper on the control board.

Output range: 0V to 10V and 0mA to 20mA.

There is 12-bit resolution.

The correction precision is 1 %.

The maximum load resistance value is not less

than 500¡.

AO2-GND Analog output 2

The voltage or current output is determined by

the J6 jumper on the control board.

Output range: 0V to 10V and 0mA to 20mA.

There is 12-bit resolution.

The correction precision is 1 %.

The maximum load resistance value is not less

than 500¡.

Relay

output

T/A1-T/B1 Normally closed terminal Contact driving capacity:

AC250Vˈ3AˈCOS¶=0.4DŽ

DC 30Vˈ1ADŽ

T/A1T/A

3-T/C1T/C 3

Normally open terminal

Auxiliary

interface

CNR1 External keyboard

interface

External keyboard and parameter copy unit

interface

efesotomasyon.com

IS300 Series User Manual Wring

15

2.4 IS300 Servo Drive Jumper Function Description

Jumper

number

Jumper

position Function description Jumper

position Function description

J2

GND terminal connect-to-

ground capacitance(Adopt

when the drive connect-to-

ground)

GND terminal connect-to-ground

capacitance(Adopt when the

drive connect-to-ground)

J3

GND terminal connect-to-

ground capacitance(Adopt

when the drive connect-to-

ground)

GND terminal connect-to-ground

capacitance(Adopt when the

drive connect-to-ground)

J4 AO1 output in the form of

voltage˄DC0 to 10V˅

AO1 output in the form of voltage

˄0 to 20mA˅

J5 AI3 input in the form of voltage

˄DC-10 to +10V˅

AI3 input in the form of voltage˄0

to 20mA˅

J6 AO2 output in the form of

voltage˄DC0 to 10V˅AO2 output in the form of current

J7 Internal power supply drives

the input terminal DI1 to DI5

External power supply drives the

input terminal DI1 ~ DI5

J8

CAN communication connect to

terminal resistors, the terminal

equipment adopt when multi-

machine communications,.

CAN communication does not

connect to terminal resistors, the

middle equipment adopt when

multi-machine communications.

J9

485 communication connect

to the terminal resistors, the

terminal equipment adopt

when multi-machine communic

ations,

485 communication does not

connect to the terminal resistors,

the middle equipment adopt when

multi-machine communications,

Note: Jumper position indicates the position of connection terminals observation

efesotomasyon.com

Wring IS300 Series User Manual

16

2.5 Function Instructions of Servo Drive PG Card Terminals

Item Name Description

1 EXC Excitation Signal

2 /EXC

3SIN

SIN Feedback Signal

4 SINLO

5COS

COS Feedback Signal

9COSLO

6

-- --7

8

Note˖Description of Specialized signal Lines for IS300 Servo Drive (for reference)

Signal Definition EXC- EXC+ SIN+ SIN- COS+ COS- PTC+ PTC-

Color of Encoder Cable

Line Specialized for IS300

Servo Drive

Red Blue Pink Grey Yellow Green White Brown

Corresponding

ĀMD38PG4āPG Card Pin

12345967

efesotomasyon.com

Servo Pump Trial Run Steps and Prototyping

of Servo Pump Optional Parts

3

efesotomasyon.com

Servo Pump Trial Run Steps and Prototyping of Servo Pump Optional Parts

IS300 Series User Manual

18

Chapter 3 Servo Pump Trial Run Steps and

Prototyping of Servo Pump Optional Parts

3.1 Servo Pump Trial run Process

6HUYRGULYHU

FRPPLVVLRQLQJ

6 H WWK H UH OHYDQWSDUDP HWHUVFRUUHFWO\

0 RWRUSDUDP HWHUWXQLQJ

0 RWRUFRP P LVVLRQLQJDGMXVWSDUDP HWHUV

RIWKHVSHHGDQGFXUUHQWORRS

2LOS UH V V X UH F R Q WUR OP RGHVHWXS

0 RWRUSDUDP HWHU˄)˅

& RQWUROSDUDP HWHU

˄$ǃ)ˉ˅

0RWRU

FRPPLV

VLRQLQJ

$ ,] H UR G ULIWDXWRP DWLFFRUUHFWLRQ

)XQFWLRQSDUDP HWHUVHWXS

,Q MHFWLRQP ROGLQJP DFKLQHFRP P LVVLRQLQJ

DGMXVWSUHVVXUHORRSSDUDP HWHU

6HUYR

SXP S

DSSOLFDWL

RQ

)LQLVK

0 RWRUSDUDP HWHUWXQLQJ

˄)˅

0 RWRUUHVSRQVHSDUDP HWHU

˄)˅

2LOS UH V V X UH F R Q WUR OP RGH

˄$ ˅

$,]HURGULIWDXWRFRUUHFWLRQ

˄$ ˅

)ORZ DQGRLOS UH V V X UH

FRP P DQG˄$ǃǃ˅

3 UHVVXUHUHOLHI˄$˅

0LQLPXPIORZ ˄$˅

0LQLP XP SUHVVXUH˄$˅

2LOS UH V V X UH 3 ,' ˄ $ ˅

1RWH˖˄˅'HWDLOHGLQVWUXFWLRQVSOH D V H UH IH UWR WK H IR OORZ LQJFRUUHVSRQGLQJFRQWHQWV

˄˅'RQRWFRQGXFWWKHFRP P LVVLRQLQJVWHSVZ LWK LWFDQDOV R V WD UWWK H LQMHFWLRQP ROGLQJP DFKLQHDFWLRQ

ǃ

ǃ

efesotomasyon.com

IS300 Series User Manual

Servo Pump Trial Run Steps and Prototyping of Servo Pump Optional Parts

19

3.2 Motor Trail Run

3.2.1 Set motor parameters of group F1˄F1-00 to F1-05ˈF1-15˅

3.2.2 Set pole-pairs number of the rotary encoder

3.2.3 Set the drive to non-oil pressure control mode˖A3-00 ˙Ā0ā

3.2.4 Set the drive to operation panel control mode, at this time the light of LOCAL/REMOT is

off.

3.2.5 Motor parameter tuning( automatic identification) ˄F1-16˅

F1-16˙Ā0ā: No operation. It doesnÿt conduct the motor parameters tuning.

F1-16˙Ā1ā: Static tuning. Adopt when the motor back EMF is known. Run the motor at the

low speed without opening the overflow valve during tuning.

F1-16˙Ā2ā˖Dynamic tuning. Adopt it when the motor back EMF is unknown. Run the motor

at the high speed with opening the overflow valve during tuning. Carrier tuning will affect the

precision of the motor parameters tuned, affecting the system control effectiveness.

a)If correctly set F1 group motor parameters (F1-00 to F1-05ǃF1-15)and the rotary encoder

number of pole-pairs(A1-04), just only conduct F1-16˙Ā1ā(static tuning).

b) If it is only able to correctly set F1 group motor parameters (F1-00 to F1-05), rotary encoder

number of pole-pairs (A1-04) was unable to determine the F1-15 (back EMF), you must

conduct F1-16 =āĀ1ā(dynamic tuning).

The numerical value of parameter F1-16 will restore to zero automatically after tuning.

If the drive alarm Err43 in the tuning process, it indicates that the encoder feedback signal is

wrong, please check the encoder signal wiring and installation precision.

3.2.6 When at trial run, set running frequency (F0-08), run by using the operation panel, while

detecting whether the output current is normal, whether the motor is running quietly, and the

way of using the operator .Please refer to the operation and display of Chapter 4.

Look into whether the running direction of the drive is correct, if it is correct, please swap motor

wiring arbitrary two-phase UVW and recheck motor parameters tuning. Then trial run.

If there is abnormal running, please check the motor parameters (F1 groups) and rotary

encoder number of pole-pairs (A1-04) setup, and then restart the motor parameters tuning,

then trial run.

Motor has oscillation when running or sends a low voice, please weaken the speed

loop(F2-00ǃF2-01ǃF2-03ǃF2-04) and current loop(F2-13ǃF2-14ǃF2-15ǃF2-16)

appropriately˄reduce the value of F2-00ǃF2-03ǃF2-13ǃF2-14ǃF2-15ǃF2-16ˈincrease

the value of F2-01ǃF2-04˅.

Motor running speed is not steady, please enhance speed loop(F2-00ǃF2-01ǃF2-03ǃF2-04)

and current loop(F2-13ǃF2-14ǃF2-15ǃF2-16) appropriately.(Increase the value of F2-00ǃ

F2-03ǃF2-13ǃF2-14ǃF2-15ǃF2-16.Reduce the value of F2-01ǃF2-04)

NOTE: The slow response of the speed and current loop will affect the pressure stability

directly, if the condition allows, please set the stronger speed loop and current loop response.

efesotomasyon.com

Servo Pump Trial Run Steps and Prototyping of Servo Pump Optional Parts

IS300 Series User Manual

20

3.3 Servo Pump Application Trail Run

3.3.1 AI zero drift auto-correction (A3-20)˖

Note: Make sure that the drive runs at zero speed before Al zero drift auto-correction

F00-08= Ā0ā, start ĀRUNāsignal. Please make sure F00-02= Ā0ā

Set AI zero drift auto correction parameter A3-20 to 1, the drive will conduct an AI zero drift auto

correct operation:

Write the detection value zero drift of three analog channel into the parameters, they are F4-18

(AI1 is the minimum input), F4-23 (AI2 is the minimum input), F4-28 (AI3 is the minimum input).

The detection value of zero drift can be found at U1-07, U1-08, and U1-09.

3.3.2 Oil pressure control mode selection˄A3-00˅:

A3-00˙Ā0ā˖Non- Oil pressure control modea)

A3-00˙Ā1ā˖Drive oil pressure control mode 1.CAN provides oil pressure commandb)

and flow command, AI3 analog Channel provides oil pressure feedback command, the

drive conducts oil pressure control.

A3-00˙Ā2ā˖Drive oil pressure control mode2. AI1 provide oil pressure command,c)

AI2 analog channel provide flow command, AI3 analog Channel provides oil pressure

feedback command, and the drive conducts oil pressure control.

A3-00˙Ā3ā˖ Oil pressure control mode (special use), the control parameters ofd)

group A3 servo pump control group are inactive.

A3-00˙Ā4ā˖Reserved.e)

3.3.3 Auto-setup of the parameters in the oil pressure control mode

When the non-oil pressure mode switches to the oil pressure mode (A3-00ĮĀ0ā), the

relevant parameters will be automatically set. See the following table for details.

Function

Code Function Code Description Setup

F0-01 Control mode 1(Vector control mode)

F0-02 Command source 1(Terminal command source)

F0-03 Frequency source

If A3-00˙Ā2ā, F0-03˙Ā3 ā(A I2 is frequency

source).If A3-00˙Ā1āor Ā3ā, F0-03˙

Ā9ā(Communication setup is frequency source)

F0-07 Frequency source

selection 0 (Non-auxiliary frequency source)

F0-17 Speed-up time 0.0s

F0-18 Speed-down time 0.0s

F1-00 Motor type

selection 2(Synchronous motor)

F4-00 DI1 terminal

function selection 11˄Running enabled˅

efesotomasyon.com

This manual suits for next models

37

Table of contents

Popular Servo Drive manuals by other brands

Panasonic

Panasonic MINAS A6 Series operating instructions

Lenze

Lenze PROFINET 9400 Communications manual

SYNAPTICON

SYNAPTICON SOMANET Node 400 Documentation

Delta Electronics

Delta Electronics ASDA-B2 series user manual

THORLABS

THORLABS DDSM50 Series user guide

Rockwell Automation

Rockwell Automation Allen-Brandley Kinetix 3 Original instructions

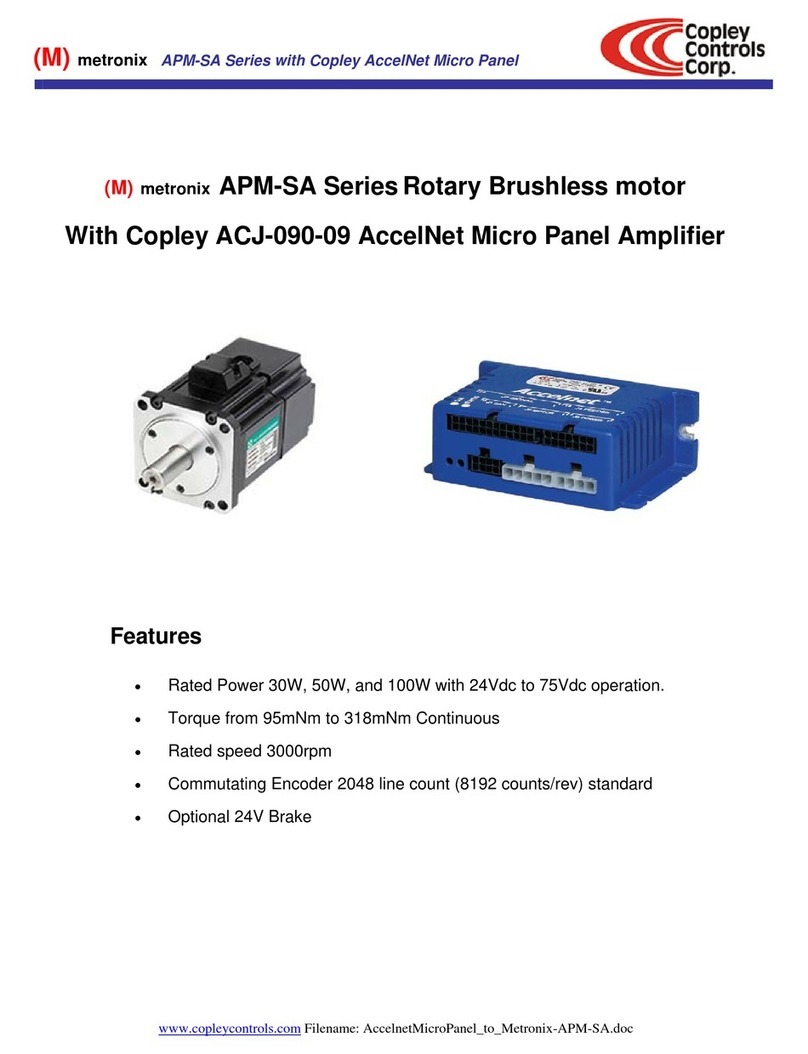

Metronix

Metronix APM-SA Series quick start guide

Honeywell

Honeywell MT4000 Series instruction sheet

YASKAWA

YASKAWA SERVOPACK Sigma 7S Series Supplementary manual

Nidec

Nidec Unidrive M700 Parameter guide

Mitsubishi Electric

Mitsubishi Electric Melservo-Jet HG-SNS Series user manual

Inovance

Inovance IS580 Series user guide