Items Required to Complete This Model:

•50-70 cc gas engine with stock or

aftermarket exhaust systems

•Appropriate propeller for your engine

•All required engine and exhaust mounting

hardware

•Ignition battery and switch

•One quality throttle servo and appropriate

servo arm

•Four high quality metal gear servos of 180

in-oz or better for the ailerons and elevators

•One high quality rudder servo of least 240

in-oz or better

•Appropriate servo arms for the above

•Heavy duty servo wire extensions.

Recommended installation includes two 36”,

two 18”,, two 6” extensions. Your

installation though may vary.

•Two heavy duty switches with charging

jacks for the Rx

•Two high quality Rx batteries of high

capacity to power your choice of servos.

•Receiver of your choice

Shop Supplies/Tools

•Covering Iron and heat gun

•Assortment normal hobby tools such as

screwdrivers, hobby knife, drill and drill

bits, pliers, etc.

•Thick and Thin CA adhesives

•30 minute Epoxy

•Isopropyl alcohol

•Ruler or tape measure

•Blue thread-lock or equivalent

Note: As with all kits, to correctly understand the construction of your airplane it is

important that you read all the instructions and study the parts before you begin

construction. Handle the parts of this kit with care so you do not damage any of the

structure or covering. Inspect all the parts for any shipping damage and report any

issues to EG as soon as you can. Make sure you have a flat and sturdy workbench

and follow all safety rules for the tools and adhesives you plan to use.

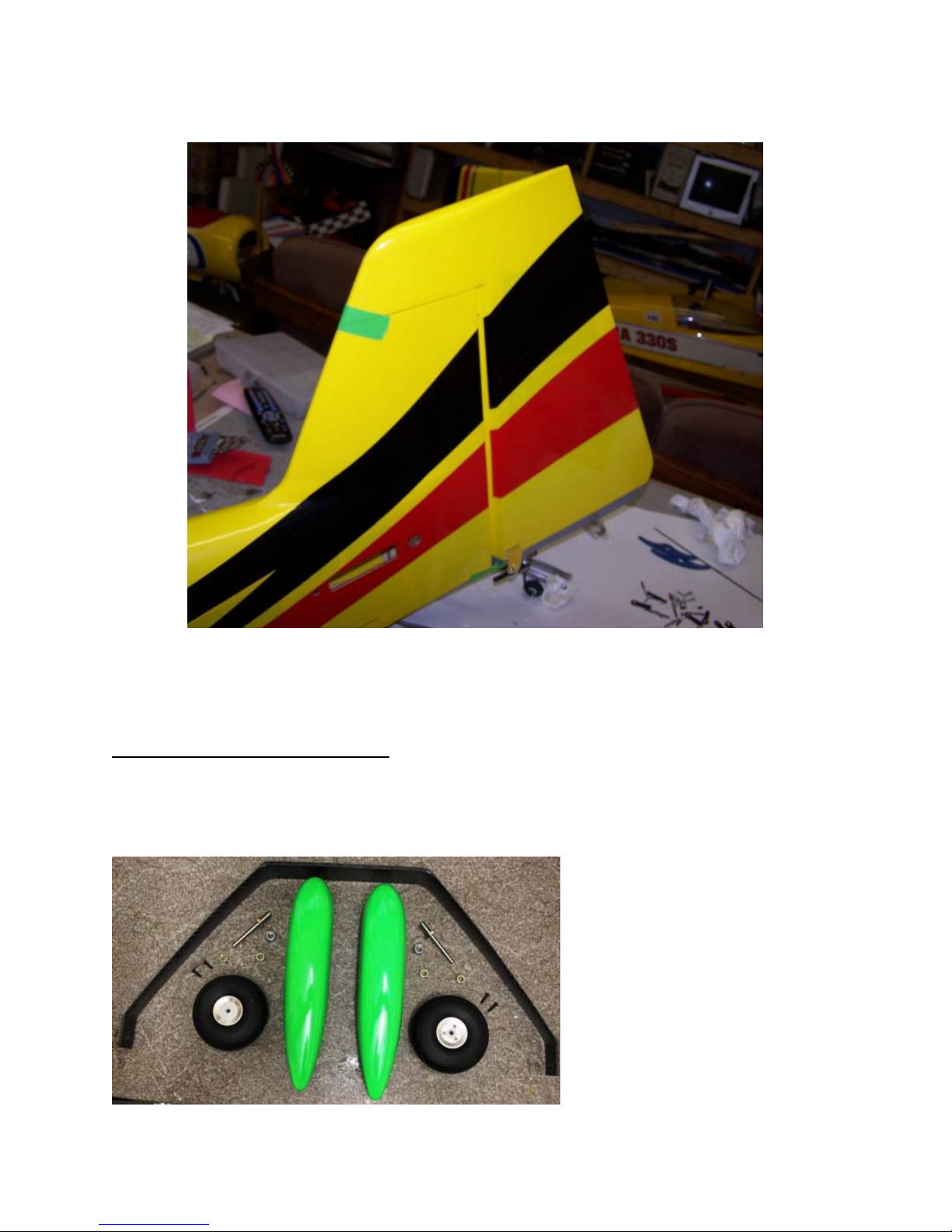

AIRCRAFT COVERING:

1. With all ARFs, varying temperatures and storage delays can cause covering material to loosen over

time and transportation. EG recommends lightly going over all the covering with a covering iron set

at medium temperatures. Be sure to use a soft cover over your iron so you do not scratch the covering

surface. Be sure you go over all seams and edges of the covering to assure it is secure to the airframe

and other covering. Be careful not to apply too much heat or you may cause bubbles or damage to the

covering. A heat gun may also be used along with a soft cotton cloth to shrink and adhere the

covering. Again, be extremely careful when using a heat gun.

2. Be sure to seal any exposed wood with a thin coating of epoxy to prevent engine oil from soaking

in. This is especially important around the engine compartment and servo openings with exposed

areas.

3. Some modelers prefer to seal the hinge gaps using strips of appropriate covering or clear trim tape.

We have found this to be helpful with models intended for higher speed flight or models with

unusually large hinge gaps. EG aircraft utilize a very tight double beveled hinge line and do not

normally require this step. Sealing the hinge gaps is therefore left as an option for the modeler.