EG&G ORTEC 459 Service manual

4

n

Model

459

5

kV

Detector

Bias

Supply

Operating

and

Service

Manual

CHANGE

NOTICE

FOR

459

EON

459-53

june

28,

1988

On

schematic

dwg

#700030

change

flag

note

#8:

From

029

can

be

either

.0047

uF

6kV

or

.0015

uF

7.5

kV

To

029

canbe

either

.0022

uF

6kV

or

.0015

uF

7.5

kV

Model

459

5

kV

Detector

Bias

Supply

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

52"

on

rear

panel

WARNING

This

equipment

generates,

uses

and

can

radiate

radio

frequency

energy,

and

if

not

installed

and

used

in

accordance

with

the

instruction

manual,

may

cause

interference

to

radio

com

munications

As

temporarily

permitted

by

regulation

it

has

not

been

tested

for

compliance

with

the

limits

for

Class

A

computing

devices

pursuant

to

Subpart

J

of

Part

15

of

FCC

Rules,

which

are

designed

to

provide

reasonable

protection

against

such

interference

Operation

of

this

equipment

in

a

residential

area

is

likely

to

cause

interference,

in

which

case

the

user,

at

his

own

expense,

will

be

required

to

take

whatever

measures

may

be

required

to

correct

the

inter

ference

Printed

in

U.S.A.

ORTEC

Part

Number

733310

2811

3.0C

0388

standard

Warranty

for

EG&G

ORTEC

Nuclear

Electronic

Instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

two

years

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

orservicescovered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

[(615)

482-4411

]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

.grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

IV

E

BIAS

SUPPLY

0-5KV

■■■

■

■!

.■■.

OUTPUT

VOLTAGE

HIGH

VOLTAGE

p-_^

iiftiiii

fe

jsigsi?;*?

*

-tf'

'

!

SslSS

ORTEC

459

5KV

DETECTOR

BIAS

SUPPLY

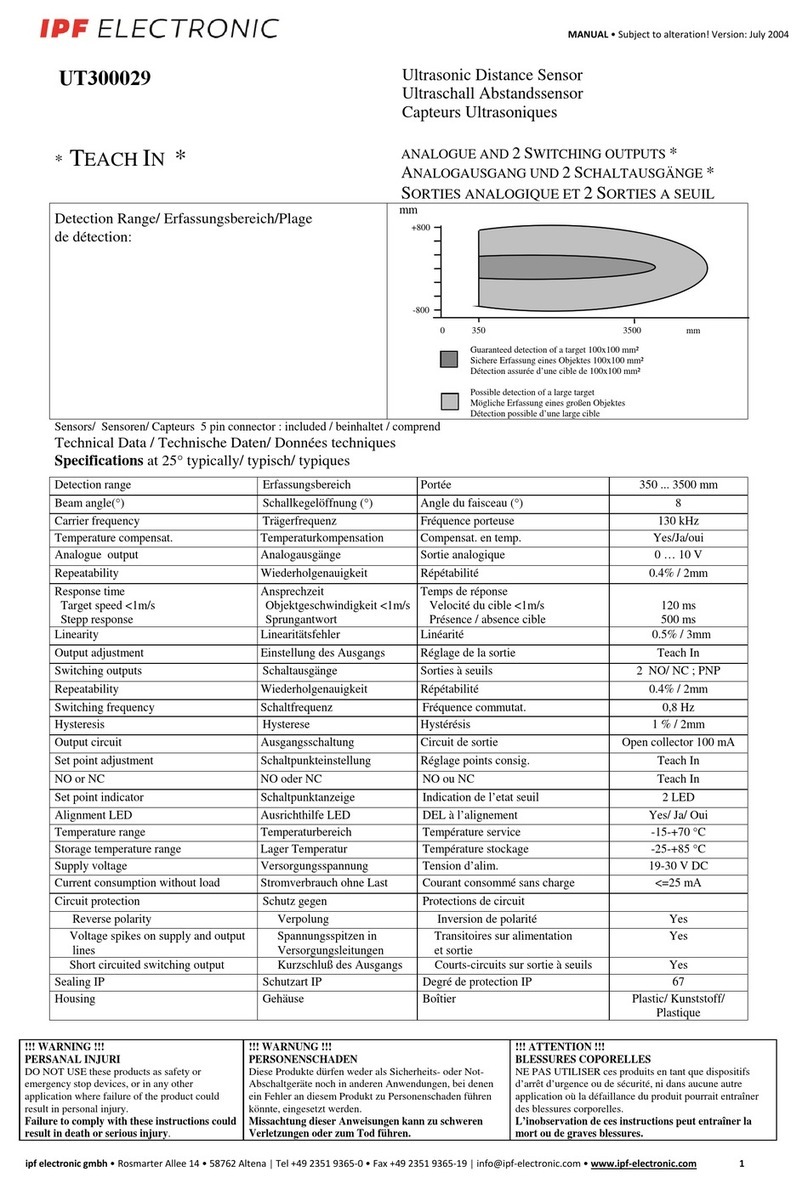

1.

DESCRIPTION

The

ORTEC

459

0—5

kV

Detector

Bias

Supply

provides

a

bias

voltage

of

either

polarity

for

a

semiconductor

detector

or

for

a

very

low

current

voltage

divider

in

a

photo-

multiplier

tube

and

scintillation

detector

assembly.

Two

outputs

are

provided

simultaneously:

one

for

a

range

of

0

to

5

kV

for

high

voltage

requirements

and

one

for

a

range

of

0

to

500

V

for

lower

voltage

detectors.

Both

output

voltages

are

adjusted

by

a

5-turn

direct-reading

control

for

a

potentiometer

located

on

the

front

panel.

Either

polarity

is

available

through

both

outputs.

The

polarity

is

selected

by

the

orientation

of

a

plug-in

printed

circuit

that

can

be

attached

to

the

main

board

in

either

of

two

positions.

The

selected

polarity

is

indicated

by

a

light,

Neg

or

Pos,

on

the

front

panel.

A

front

panel

meter

also

indicates

the

selected

polarity

and

the

approximate

voltage

available

through

the

5-kV

output;

the

500-V

output

automatically

provides

10%

of

the

level

through

the

5-kV

output.

The

Detector

Bias

Supply

receives

its

required

operating

power

from

an

ORTEC

401A/402A

Bin

and

Power

Supply

in

which

it

is

installed

for

operation.

All

of

the

input

power

is

supplied

through

the

rear

panel

module

connector.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

Bias

Voltage

Outputs

Two

output

circuits,

ranges

0

to

5

kV

and

0

to

500

V.

Bias

Control

5-turn

direct-reading

precision

potenti

ometer.

Bias

Polarity

Either

positive

or

negative

for

both

outputs

(both

outputs

same

polarity),

selected

by

internal

switch

and

indicated

on

front

panel.

Noise

and

Ripple

<10

mV

peak

to

peak

from

2

Hz

to

50

MHz.

Temperature

Instability

<±0.08%/°0

through

10

to

50°

0

operating

range.

Voltage

Instability

<±0.1%/h

variation

in

output

voltage

with

constant

input

voltages

from

bin

supply,

constant

temperature,

and

constant

load.

Output

Current

0

to

100

/LiA.

Output

Linearity

Within

±3%

of

dial

setting

from

10%

to

full

range.

2.2.

CONTROLS

Output

Voltage

5-turn

direct-reading

potentiometer

with

500

dial

divisions

adjusts

the

output

levels

for

both

the

5-kV

and

500-V

outputs

simultaneously.

Higti

Voltage

On/Off

Toggle

switch

and

indicator

lamp

show

when

the

instrument

circuits

are

turned

on

to

pro

vide

an

output.

The

lamp

turns

off

when

the

remote

shut

down

circuit

isgrounded

and

high

voltage

is

notavailable.

Polarity

+/-

Internal

plug

board

selects

either

polarity

for

both

outputs,

and

front

panel

indicators

show

which

has

been

selected.

2.3.

INPUTS

Power

All

input

power

is

furnished

through

the

rear

panel

module

connector.

Remote

Shutdown

(ORTEC)

Rear

panel

BNC

con

nector.

Shorting

the

center

contact

to

ground

reduces

the

output

voltage

to

zero.

Input

source

must

be

capable

of

driving

—2.5

mA.

Under

normal

HV

operation,

center

pin

voltage

is

—24

V.

Remote

Shutdown

(.Other)

Rear

panel

BNC

connector.

Shorting

the

center

contact

to

ground

reduces

the

output

voltage

to

zero.

Input

source

must

be

capable

of

sinking

—800

/uA.

Under

normal

HV

operation,

center

pin

voltage

is

-+12

V.

2.4.

OUTPUTS

0-5KV

(Zo

=

2

MQ)

Rear

panel

SHV

connector

furnishes

the

adjusted

output

voltage

in

theO-

to

5-kV

range

through

an

output

impedance

of

—2

MO.

0-500V

(Zo

=

700

kO)

Rear

panel

SHV

connector

fur

nishes

the

adjusted

output

voltage

in

the

0-to

500-V

range

through

an

output

impedance

of

—700

kO.

2.5.

ELECTRICAL

AND

MECHANICAL

Power

Required

for

Maximum

Load

+24

V,

80

mA;

+12

V,

12

mA;

-24

V,

65

mA;-12

V,

0

mA.

Dimensions

Standard

single-width

8.714

in.)

perTID-20893.

NIM

module

(1.35

by

3.

INSTALLATION

3.1.

GENERAL

The

Detector

Bias

Supply

is

normally

used

in

conjunction

with

other

modular

electronics

and

is

installed

in

a

401A/402A

Bin

and

Power

Supply.

The

Bin

and

Power

Supply

is

intended

for

rack

mounting.

Therefore

any

other

equipment

that

may

be

installed

in

the

same

rack

must

be

sufficiently

cooled

by

circulating

air

to

prevent

any

localized

heating

in

the

circuits

in

the

459.

The

temperature

of

equipment

operating

in

racks

can

easily

exceed

the

recommended

maximum

of

50°C

(120°F)

unless

these

precautions

are

taken.

3.2.

SELECTION

OF

OUTPUT

POLARITY

The

polarity

of

the

output

voltage

of

the

459

is

determined

by

the

location

of

a

rectangular

plug

board

on

the

main

printed

circuit.

Access

to

the

plug

board

is

obtained

by

removing

the

left

side

panel

of

the

module

(viewed

from

the

front).

Its

two

alternate

locations

are

marked

on

the

main

printed

circuit.

3.3.

CONNECTION

TO

POWER

This

instrument

obtains

its

dc

operating

power

from

the

standard

Bin

and

Power

Supply

in

which

it

is

installed.

Always

turn

off

power

for

both

the

Bin

Power

Supply

and

the

459

before

inserting

or

removing

the

module.

When

the

Bin

and

Power

Supply

switch

is

then

turned

on,

the

polarity

selection

will

be

indicated

on

the

459

before

high

voltage

is

actually

furnished

from

its

output

connectors.

The

adjusted

high

voltage

is

then

available

through

the

output

connectors

as

soon

as

the

459

high-voltage

switch

is

turned

on.

3.4.

OUTPUT

CONNECTIONS

The

Detector

Bias

Supply

is

compatible

with

all

ORTEC

preamplifiers

that

include

provisions

to

accept

the

high

voltage

for

the

detector.

The

output

controls

are

located

on

the

front

panel,

and

the

output

connectors

are

located

on

the

rear

panel.

The

output

cables

wil

l

require

a

type

SHV

connector

at

the

power

supply

end,

which

is

the

type

furnished

with

each

ORTEC

preamplifier

for

this

purpose.

4.

OPERATION

CAUTION

Always

have

the

high

voltage

turned

off

before

connecting

the

cable

to

or

disconnecting

it

from

the

preamplifier.

After

the

high

voltage

is

turned

on,

allow

approxi

mately

30

min

for

high-voltage

stressing

of

the

capacitor

to

subside

before

attempting

to

take

data

with

high-resolution

systems.

4.1.

SILICON

SURFACE-BARRIER

DETECTORS

Operating

bias

voltage

for

a

silicon

surface-barrier

detector

should

not

be

applied

as

a

large

step,

but

should

be

advanced

gradually

from

zero

up

to

the

recommended

operating

potential.

With

the

459,

set

the

front-panel

control

at

zero

before

switching

on

the

power.

Then

gradually

advance

the

setting

of

the

5-turn

potentiometer

to

the

recommended

level

for

the

detector.

To

remove

the

detector

bias,

reduce

the

setting

of

the

5-turn

control

to

zero

at

the

459

while

the

output

cable

is

still

connected

to

the

preamplifier.

4.2.

OTHER

TYPES

OF

DETECTORS

Operating

bias

for

germanium

or

scinti

llation

detectors

can

be

applied

as

a

step

from

zero

to

the

full

operating

value.

For

these

applications

the

5-turn

potentiometer

can

be

adjusted

to

the

required

output

voltage

level

while

the

power

switch

is

turned

off,

and

then

power

can

be

appl

ied

by

simply

turning

on

the

power

with

the

high-voltage

switch.

4.3.

LOADING

EFFECTS

The

actual

output

voltage

depends

on

the

current

that

is

drawn

from

the

459

by

its

external

circuit.

To

determine

the

actual

voltage

at

the

"0-5

KV"

connector,

consider

the

amount

of

voltage

drop

in

the

2-MJ2

series

output

resistance,

which

will

be

a

function

of

the

output

current.

The

output

voltage

can

be

calculated

with

the

formula

V.

=

\/h

-

1(2

X

IQS),

where

=

output

voltage,

*^diai

~

setting

indicated

by

5-turn

control

,

I

=

output

current

in

amperes.

If

the

output

current

is

expressed

in

microamperes,

the

formula

is

simplified

to

=

^dial

-

2/.

For

example,

if

/

=

50

/tA

and

the

setting

is

at

maximum

for

5000

V,

=

5000

-

2(50)

=

4900

V.

The

actual

output

voltage

at

the

"0-500

V"

connector

can

be

found

in

a

similar

manner

by

considering

the

approxi

mately

700

kS7

output

resistance.

The

formula

will

then

be

^o

=

\^dlal-/(7X105),

where

the

definitions

are

the

same

as

before.

To

find

the

actual

voltage

applied

to

a

detector,

the

resistance

between

the

459

output

and

the

detector

itself

must

be

identified.

Since

the

bias

voltage

is

usually

connected

through

a

load

resistor

in

the

pream.plifier

and

then

to

the

detector,

the

resistance

can

usually

be

identified

from

the

preamplifier

schematic.

The

actual

detector

voltage

can

then

be

found

with

the

formula

where

voltage,

1^

V„

is

the

459

output

is

the

detector

voltage,

is

the

detector

current,

and

R

is

the

series

resistance

between

the

459

and

the

detector.

5.

CIRCUIT

DESCRIPTION

The

459

uses

a

dc-to-dc

converter

to

charge

a

Cockcroft-

Walton'

multiplier

circuit.

The

primary

of

the

transformer

is

driven

from

an

astable

multivibrator

operating

at

approxi

mately

20

kHz.

Transistors

Q1

and

Q2

form

the

multi

vibrator

circuit,

while

Q3

through

Q6

serve

as

drivers

and

switching

transistors

for

transformer

T1.

The

output

voltage

is

adjusted

by

controlling

the

voltage

applied

to

the

primary

of

the

transformer.

Resistor

R23

controls

the

primary

voltage

through

transistors

Q7

and

Q8.

The

circuitry

in

the

transformer

secondary

consists

of

a

7-stage

Cockcroft-Walton

multipl

ier

circuit.

Polarity

selec

tion

is

made

with

a

plug-in

board

that

completes

the

necessary

circuits

for

either

polarity

by

its

orientation

on

the

main

printed

circuit.

In

schematic

459-0101-S1

at

the

back

of

this

manual

the

alternate

circuit

connections

are

shown

as

sections

of

a

double-throw

switch,

S2.

For

polarity

reversal

the

input

and

output

terminals

of

the

Cockcroft-Walton

circuit

are

interchanged.

The

0—500

V

is

'

Everhart

and

Lorrain,

"The

Cockcroft-Walton

Voltage

Multiplying

Circuit,"

Rev.

Sci.

Instr.

24(3),

221

(1953).

taken

from

the

first

stage

of

the

multipl

ier

circuit

so

that

this

output

will

always

have

the

same

polarity

as

the

0—5

kV

output.

The

output

voltage

can

be

adjusted

with

trim

potenti

ometer

R22.

This

adjustment

should

be

made

with

an

insulated

screwdriver

through

one

of

the

holes

in

the

top

cover.

The

calibration

of

the

front

panel

meter

is

made

with

trim

potentiometer

R40,

and

this

adjustment

is

also

avai

lable

through

one

of

the

holes

in

the

top

cover.

The

meter

is

intended

as

an

approximate

indication

of

the

output

voltage,

and

also

shows

the

polarity

of

the

output.

If

the

remote

shutdown

circuit

is

used,

it

wil

l

clamp

the

output

voltage

through

both

of

the

459

output

circuits

to

zero

when

the

external

circuit

grounds

the

center

contact

of

the

BNC

connector

with

lOOOO

impedance

or

less.

This

turns

on

both

Q10

and

Q11.

With

Q10

turned

on,

Q7

and

Q8

cannot

furnish

any

reference

drive

to

the

primary

of

transformer

T1

and

high

voltage

cannot

be

generated.

With

Q11

turned

on,

Q12

is

turned

off

and

the

front

panel

HV

On

indicator

will

not

light.

6.

MAINTENANCE

AND

TESTING

CAUTION

THE

HIGH

VOLTAGES

THAT

ARE

PRESENT

IN

THIS

INSTRUMENT

ARE

HAZARDOUS.

DO

NOT,

ATTEMPT

ANY

ADJUSTMENTS

OR

MAINTE

NANCE

UNLESS

YOU

ARE

EXPERIENCED

IN

HANDLING

HIGH-VOLT

AGE

CIRCUITS.

Test

Equipment

Required:

Nuclear

Standard

Bin

and

Power

Supply

such

as

ORTEC

401A/402A

Oscilloscope

with

sensitivity

of

10

mV

or

better

Voltmeter

with

input

impedance

of

100

or

more

on

5000-V

range

Schematic

diagram

of

the

459

Detector

Bias

Supply

6.1.

PERFORMANCE

TESTS

1.

Install

the

459

in

the

401A/402A

Bin

and

Power

Supply.

2.

Leave

the

High

Voltage

switch

set

at

Off

and

connect

the

0-5

KV

output

to

the

voltmeter,

set

for

a

5000-V

range.

3.

Set

the

High

Voltage

switch

at

On

and

increase

the

5-turn

control

slowly

to

maximum

for

5000

V.

Consider

the

loading

effect

of

the

voltmeter

on

the

high-voltage

supply

and

observe

the

output

voltage.

For

example,

a

voltmeter

with

a

100-MJ2

input

impedance

will

have

a

50-mA

current

at

full

scale.

This

will

cause

a

100-V

drop

across

the

2-MJ2

internal

resistance

in

the

power

supply

and

the

meter

will

read

only

4900

V

maximum.

4.

Return

the

output

voltage

control

to

zero

and

check

the

potentiometer

linearity

by

comparing

the

output

voltages

to

dial

readings

at

several

points.

5.

To

check

ripple

and

noise

it

is

necessary

to

place

a

capacitor

that

will

withstand

5000

V

in

series

with

the

0-5

KV

output

of

the

459

and

to

connect

this

to

an

oscilloscope.

Set

the

oscilloscope

for

a

dc

input

and

the

lowest

available

sensitivity

until

the

Detector

Bias

Supply

output

has

been

increased

slowly

to

5000

V.

Then

the

oscilloscope

sensitivity

can

be

increased

to

observe

the

ripple

and

noise,

which

should

not

exceed

10

mV.

6.2.

TROUBLESHOOTING

SUGGESTIONS

1.

Ensure

that

the

proper

dc

input

voltage

is

being

sup

plied

to

the

459.

It

requires

-1-24

V,

-24

V,

and

+12

V.

Quies

cent

currents

are

typically

+24

V,

32

mA;

-24

V,

18

mA;

and

+12

V,

12

mA.

2.

With

an

oscilloscope,

check

carefully

for

a

square

wave

at

the

collectors

of

Q1

and

02.

If

no

square

wave

is

present,

replace

the

transistors

01

and

02.

3.

Check

for

a

square

wave

at

the

collectors

of

05

and

06.

This

square

wave

should

vary

in

amplitude

with

the

setting

of

the

output

voltage

control.

If

no

variation

is

seen,

check

07

and

08.

6.3.

FACTORY

REPAIR

SERVICE

This

instrument

can

be

returned

to

the

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

Our

standard

procedure

for

repair

ensures

the

same

quality

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

Cus

tomer

Services

at

ORTEC,

(615)

482-4411,

before

sending

in

an

instrument

for

repair

to

obtain

shipping

instructions

and

so

that

the

required

Return

Authorization

Number

can

be

assigned

to

the

unit.

Write

this

number

on

the

address

label

and

on

the

package

to

ensure

prompt

attention

when

it

reaches

the

ORTEC

factory.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

(Rev

4)

(adopted

by

DOE)

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

-3

volts

24

Reserved

3

Spare

Bus

25

Reserved

-4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

*28

+24

volts

7

Coaxial

*29

-24

volts

8

200

volts

do

30

Spare

Bus

9

Spare

31

Spare

*10

+6

volts

32

Spare

*11

-6

volts

*33

117

volts

ac

(Hot)

12

Reserved

Bus

*34

Power

Return

Ground

13

Spare

**35

Reset

(Sealer)

14

Spare

**36

Gate

15

Reserved

**37

Reset

(Auxiliary)

*16

+12

volts

38

Coaxial

*17

-12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

*41

117

volts

ac

(Neut.)

20

Spare

*42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

Pins

marked

(*)

are

Installed

and

wired

in

EG&G

ORTEC's

4001

A,

4001B,

4001C,

401

A.

and

4018

Modular

System

Bins.

Pins

marked

(*)

and

(")

are

installed

In

EG&G

ORTEC-HEP-M250/N

and

M350/N

NIMBINS.

^

JO

C

I'saHC

//»/?•*■

—

0O6SK)

/4

-9-f

ssr

laaovi

0C84.6

a388aNN3X'30aiU

MVO

'OVOU

ONViailM

OOi

^

io?o-cstr

SYr/^

aiawnn

onj/waa

—[+?/0

—

O/D+l—

3EiZT-

r»)|

H

O

-CZI53—

Rl2iy

d.!0<^

sea/

L£?<f

^-

i'P^/

—

—

era/

A

©

u-)

©

O

!

ioir^

a

■«

—H

—•

-CSZ}-

-£^

i

N

T

Fl

^0

H

5

0

o

o

B

u

—.

fl

N

q

<r>

0

•H.

0

Y

o

Y

U

—f

6'?<^

)—

CZZEII>

0£^}—

-GEiH-

(D

1^

Table of contents

Other EG&G Security Sensor manuals

Popular Security Sensor manuals by other brands

Theben

Theben theRonda P360-100 WH GST quick start guide

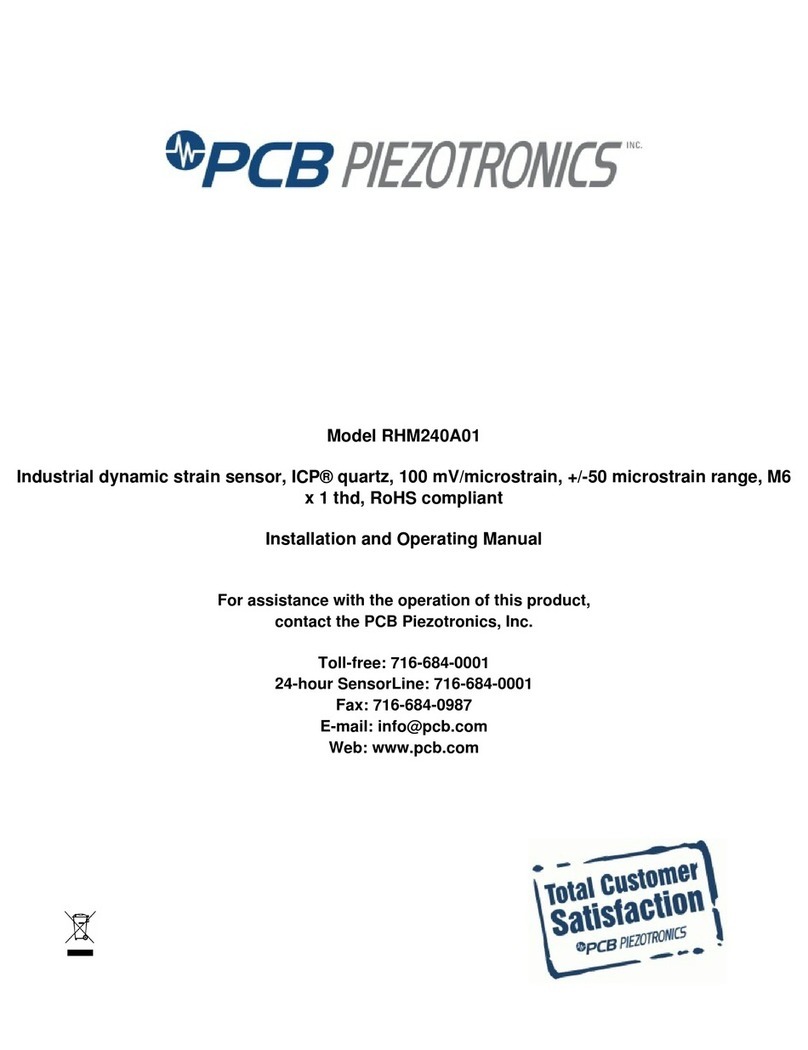

PCB Piezotronics

PCB Piezotronics ICP RHM240A01 Installation and operating manual

Kutai electronics

Kutai electronics V-DOG2 user manual

Visonic

Visonic K-980 installation instructions

GMI

GMI PS1 User handbook

Pyronix

Pyronix XDL15TT-AM installation manual