EG&G ORTEC Gamma-X Service manual

PID

L

n

Gamma-X®

High-Purity

Germanium

(HPGe)

Coaxial

Detector

Systems

Preliminary

Operating

and

Service

Manual

Operating

and

Service

Manual

PRELIMINARY

®Trademark

owned

by

EG&G

ORTEC.

ii

Gamma-X

IMPORTANT

INFORMATION

1.

Read

carefully

the

standard

instructions

for

unpacking

the

system

and

filling

it

with

liquid

nitrogen,

and

the

checkout

procedures

that

are

included

in

Sections

2

and

3

of

this

manual.

2.

Fill

the

dewar

with

liquid

nitrogen

and

allow

at

least

six

hours

for

cooling

before

connecting

the

system

to

any

external

electronics.

ALWAYS

disconnect

the

system

from

external

electronics

before

allowing

it

to

warm

up.

NEVER

connect

the

system

to

external

electronics

before

the

detector

has

been

cooled

properly.

If

high

voltage

is

applied

to

the

detector

at

any

time

when

the

detector

is

not

at

liquid

nitrogen

temperature,

the

input

FET

of

the

preamplifier

may

be

damaged,

voiding

the

warranty.

A

damaged

input

FET

will

be

considered

"prima

facie"

evidence

that

high

voltage

has

been

applied

when

the

system

was

not

properly

cooled.

3.

NEVER

accelerate

a

warmup

of

the

cryostat

by

heating

it

with

an

external

source.

4.

The

plastic

bag

of

desiccant

pellets

over

the

cryostat-

preamplifier

assembly

absorbs

moisture

that

condenses

when

the

system

is

moved

from

a

cold

area

into

a

warm

area.

Leave

this

bag

in

place

until

the

system

has

been

in

the

warmer

atmosphere

long

enough

to

eliminate

any

danger

of

condensation.

5.

The

cylindrical

protrusion

(3/4

in.

diam

by

1

in.

long)

that

is

on

the

cryostat

is

the

vacuum

pump

attachment.

Do

not

tamper

with

this

at

any

time.

6.

Unlike

other

types

of

coaxial

germanium

detectors,

the

EG&G

ORTEC

Gamma-X

detector

requires

negative

bias.

7.

NEVER

warm

to

room

temperature

a

Gamma-X

detector

that

shows

signs

of

radiation

damage

(see

Sections

4

and

5

of

this

manual).

,

1^0

■'

'

G-11

SQUARE

10

X

10

TO

THE

HALF

INCH

SPECIFY

TRACING

OR

DRAWING

PAPER

ES

GRAPHIC

CONTROLS

CANADA

LTD,

MADE

IN

CANADA

tniiTrrji

i

:5c-

z:^7

-A

WZMST/W

^^/Ae:/

>.

_

n

f^V

<^^AA'J'AAr'M

/A/d//y

/r/(^

^

M/W

ff

'Af

7f

'

s:f£/

'

■

-/f.'

•

V

-

■

;

■■

...r

3-

\

■

-

..

■■

..

'•

,

•:-•

\

•

•

■'•:

.

H

^

,

■■■

■

■'

■

■

^

.

•

■

,

-

■'

■

■

.

.V

.

v:^::

'

"■

•

■■

. ..

.

..

;

^

,,

:,

.v...

.

-

.v

,

■■

X

K-

V

•

yy-,#^v

•

<

"-s-

■•■

"i

-

"isi^

'■•

■>

.

.^\

"-.

.

1-

■

,

^

X.

...;..

,

^>v.

.

.

.>

1

.

J

•

V,

'

--1#

.,

.

;

-■

■•

•-

•

'

•

■

V

...

••-

.

:,..y

-

■:

y.^

-y.

,

. ,

, .

.v.

.

Jar

.

■;.'

.

j.-

V-

■

'

•

,

V

•

■

'

V.""

"■

>

■-•

.

•'

•■

,,-

.

;■

,

'•..

,

■

•

'

.

■

•«

■-■>•:■

'■■'.

'

■-X

,

-

■ ■

'5sj

;

;

T:

'If

"i

'.x'

Nt

i

.

X

X-j

■

^

■

....

vsiwfeysar

'Si

-Z"''

...*

.

.

. .

.

-

1-.

>

u

Gamma-X

111

QUALITY

ASSURANCE

DATA

Gairana-X

High-Purity

Ge

Coaxial

Detector

System

GENERAL

DATA

Model

No.6A)X-3oaiO-5

Serial

No.

3l|-M-74^B

Shipping

Date

^-3

i

PHYSICAL

MEASUREMENTS

mm

{

Absorbing

Layers:

mm

j

Aluminum

^

^

cc

ISO

Ge

Dead

Layer

D.

"hM-

Window

to

Detector

5.0mm

Teflon

O

mm

Diameter

Length

Active

Vol

mm

Total

Capacitance

—'

ELECTRICAL

DATA

pF

at

V.

Recommended

Operating

Bias,

NEGATIVE

j"

ooo

V.

Preamplifier

Input

FET

(Cooled)

(Not

coolod).

PERFORMANCE

SPECIFICATIONS

Warranted

Measured

Efficiency

at

1.33

MeV

(1)

30

%

Resolution

at

1.33

MeV

.(1)

(

Resolution

at

88

keV

1)

Resolution

at

122

keV

(

_keV

eV

1)

^keV

Ratio

of

22

keV

counts

to

109

88

keV

counts

from

Cd

31.3

%

I

6

keV

eV

170

eV

OH

Amplifier

Time

Constant

(fi

PS

(o

us

us

(p

us

uS

(1)

Measured

in

accordance

with

IEEE

Standard

645-1977

(Supplement

to

IEEE

Standard

645-1977

(Supplement

to

IEEE

Std

325-1971,

Reaff

1977)

using

EG&G

ORTEC

standard

electronics.

Data

Certified

by

HJa

Date

CAUTION

Models

20

and

21

cryostats

can

be

damaged

by

unnecessary

overfilling

if

it

is

continued

long

enough

to

lower

the

temperature

of

the

flange

appreciably.

Never

allow

an

automatic

filling

to

proceed

without

supervision.

Any

extended

overfilling

of

the

LN2

can

freeze

the

Viton

0-

ring

and

cause

loss

of

vacuum,

which

may

seriously

damage

the

detector.

Gamma-X

is

a

Trademark

owned

by

EG&G

ORTEC

iv

Gairana-X

GAMMA-X

HIGH-PURITY

GERMANIUM

(HPGe)

COAXIAL

DETECTOR

SYSTEMS

Warranty

Statement

EG&G

ORTEC

warrants

its

Gamma-X

HPGe

Coaxial

Detector Systems

to

be

free

from

defects

in

material

and

workmanship

for

a

period

of

one

year

after

shipment.

EG&G

ORTEC

guarantees

that

the

detector

system

will

operate

within

the

warranted

specifications

regardless

of

the

number

of

thermal

cycles

between

liquid

nitrogen

temperature

and

room

temperature

to

which

the

system

has

been

subjected

and

regardless

of

how

long

the

system

has

been

stored

at

room

temperature

during

the

one-year

period.

This

warranty

is

subject

to

the

following

customer

obligations:

1.

The

cryogenic

FET

has

not

been

damaged.

2.

The

system

has

not

been

physically

or

electrically

abused.

3.

The

detector

has

not

been

subjected

to

neutron

damage.

Should

the

detector

system

fail,

through

no

fault

of

the

customer,

during

the

warranty

period,

and

having

at

all

times

been

handled

in

accordance

with

the

above

described

customer

obligations,

it

will

be

repaired

or

replaced

without

charge,

at

EG&G

ORTEC's

option,

and

will

be

fully

warranted

to

within

the

original

specifications

for

three

months

or

for

the

remainder

of

the

warranty

period,

whichever

is

longer.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

or

use

of

any

item

or

services

covered

by

this

agreement

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

EG&G

ORTEC

makes

no

other

warranties,

expressed

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

Gamma-X

v

Instructions

for

Returning

a

Gamma-X

HPGe

Detector

Coaxial

Detector

System

If,

for

any

reason,

it

becomes

necessary

to

return

a

Gamma-X

Coaxial

Detector

System

for

repair

or

replacement,

please

note

the

following

Instructions

and

precautions

regarding

shipment.

!•

Contact

EG&G

ORTEC

Contact

the

nearest

EG&G

ORTEC

representative

[in

the

U.S.

call

Customer

Services,

EG&G

ORTEC

Physical

Sciences

Division,

(615)

482-4411]

for

specific

Instructions

and

authorization

for

returning

the

detector.

Any

detector

that

Is

returned

without

prior

notification

having

been

given

to

EG&G

ORTEC

could

result

In

loss

or

damage

and

would

be

automatically

considered

out-of-warranty.

2.

Proper

Packing

A

detector

"returns

kit"

must

be

utilized

for

return

shipment.

The

kit

contains

the

necessary

Instructions

and

material

to

ensure

proper

packing.

Contact

the

nearest

EG&G

ORTEC representative

for

the

correct

returns

kit

for

your

particular

detector

before

attempting

return.

Improper

packing

could

result

In

shipment

damage

that

would

not

be

covered

under

the

EG&G

ORTEC

warranty

or

the

freight

forwarder's

Insurance

policy.

3.

Shipment

Coordination

and

Communications

Detectors

should

be

returned

through

the

freight

forwarder

collect.

For

out-of-warranty

repairs,

the

shipping

charges

will

be

billed

to

the

customer.

For

In-warranty

repairs,

the

reshlpment

charges

will

be

paid

by

the

customer.

Weekend

delays

In

transit

should

be

avoided;

thus

an

early

weekday

shipment

Is

recommended.

We

highly

recommend

that

the

customer

utilize

the

EG&G

ORTEC

preferred

forwarder

who

Is

familiar

with

shipment

of

HPGe

Coaxial

detectors.

EG&G

ORTEC

must

be

notified

of

specific

details

of

the

returning

shipment

(I.e.

,

freight

forwarder,

air

freight

carrier,

date,

time,

airway

bill

number,

etc.)

at

the

time

of

shipment

to

ensure

attention

upon

receipt

at

the

repair

facility.

The

Instructions

and

precautions

stated

herein

are

to

ensure

proper

attention

In

handling

the

shipment

of

an

expensive

radiation

detector.

Do

not

be

apprehensive

because

of

these

precautions.

Detectors

are

shipped

successfully

all

over

the

world

when

just

these

few

precautions

are

followed.

When

In

doubt

about

any

of

the

above-mentioned

precautions

or

Instructions,

please

contact

the

nearest

EG&G

ORTEC

representative

for

assistance.

vi

Gamma—X

TABLE

OF

CONTENTS

1.

GENERAL

1

1.1.

The

Gamma-X

Detector

Concept

1

1.2.

Cryostat Configuration

2

1.3.

Accidental

Warm

Up

Protection

4

1.4.

Spectroscopy

with

Gamma-X

Detectors

5

2.

RECEIVING,

UNPACKING,

AND

FILLING

WITH

LIQUID

NITROGEN

7

2.1.

General

7

2.2.

Unpacking

and

Filling

with

Liquid

Nitrogen

7

3.

CHECKOUT

AND

OPERATION

11

3.1.

General

11

3.2.

Test

Before

Application

of

Bias

13

3.3.

Detector

Resolution

Measurements

14

3.4.

Peak-to-Compton

Measurements

16

3.5.

Efficiency

Measurement

17

3.6.

^'^^Cd

Source

Measurements

18

4.

NEUTRON

RADIATION

DAMAGE

19

4.1.

General

19

4.2.

Neutron

Radiation

Damage

in

the

Gamma-X

Detector

19

5.

MAINTENANCE

AND

TROUBLESHOOTING

21

5.1.

Liquid

Nitrogen

21

5.2.

Packing

for

Reshipment

22

5.3.

Troubleshooting

Suggestions

22

APPENDIX

-

REFERENCES

29

Ganma-X

1.

GENERAL

1.1.

THE

GAMMA-X^

DETECTOR

CONCEPT

The

EG&G

ORTEC

Gainina-X

Detector

is

based

on

a

new

concept

in

coaxial

germanium

detector

geometries.^

Therefore

a

brief

description

of

this

concept

will

facilitate

the

use

of

this

instruction

manual.

Four

different

configurations

of

germanium

detectors,

both

Ge(Li)

and

HPGe,

are

shown

in

Fig.

1.1.

It

is

immediately

apparent

that

the

Gamma-X

detector

structure

is

the

only

one

in

which

the

outer

contact

is

sufficiently

thin

to

allow

low

energy

x-rays

to

penetrate

into

the

active

volume

of

the

detector.

For

practical

reasons,

this

type

of

structure

is

presently

the

best

implemented

by

using

N-

rather

than

P-type

HPGe

material.

500-1000

MICRONS

300

600

MICRONS

RADIATION

RADIATION

P-TYPE

CORE

CONVENTIONAL

COAXIAL

HP

G«

CLOSED

END

G*(Li)

0.3

MICRONS

N-TYPE

HP

Ge

100-200

MICRONS

RADIATION

RADIATION

P-TYPE

CORE

P-TYPE

HP

G«

TRUE

COAXIAL

G«<Li)

Very

Thick

Contact

-300-1000

MIcront

Thick

Contact

-100-

200

Microns

Very

Thin

Contact

0,3

Microns

Fig.

1.1.

Four

Different

Configurations

of

Coaxial

Germanium

Detectors

In

the

Gamma-X

structure,

a

"thick"

strongly

N-type

(Li-diffused)

contact

is

used

as

the

inner

electrode

while

a

thin,

ion

implanted,

strongly

P-type

contact

is

used

as

the

outer

electrode.

Bias

voltage

for

all

the

coaxial

detectors

shown

in

Fig.

1.1

is

applied

to

the

outer

electrode,

while

the

signal

is

picked

up

from

the

inner

electrode.

Since

the

positions

of

the

P-type

and

N-type

materials

2

Gamma-X

are

reversed

in

the

Ganma-X

detector,

this

type

of

detector

requires

a

negative

bias

voltage.

Consequently,

the

polarity

of

the

signal

from

the

inner

electrode

is

always

negative,

rather

than

positive

as

in

other

types

of

coaxial

germanium

detectors.

Except

for

the

negative

bias

voltage

polarity

and

the

negative

charge

signal

polarity,

the

operation

of

a

Garama-X

detector

is

identical

to

the

operation

of

any

other

germanium

coaxial

detector.

More

details

on

the

Gamma-X

detector

can

be

found

in

reference

1

and

in

EG&G

ORTEC

catalogs

and

Product

News

literature.

Another

outstanding

feature

of

the

Gamma-X

detector

is

its

high

degree

of

resistance

to

neutron

radiation

damage.

This

is

discussed

in

Section

4.

1.2.

CRYOSTAT

CONFIGURATION

A

standard

EG&G

ORTEC

Gamma-X

Coaxial

Detector

system

may

have

any

of

the

basic

configurations

shown

in

Fig.

1.2.

The

main

difference

between

these

systems

is

the

location

of

the

active

detector

element.

In

each

configuration

the

HPGe

coaxial

detector

element

is

located

concentrically

in

the

end

cap

with

its

front

face

approximately

5

mm

from

the

outer

surface

of

the

end.cap.

The

preamplifier

and

the

high-voltage

filter

are

connected

electrically

to

the

detector

through

vacuum

seals.

The

cryostat

is

designed

to

keep

the

detector

at

liquid

nitrogen

temperature

and

in

a

sealed

vacuum

for

many

years,

if

normal

precautions

are

taken.

In

most

HPGe

Coaxial

Systems

the

first

FET

of

the

preamplifier

is

mounted

inside

the

end

cap

and

cooled

to

achieve

the

best

possible

resolution.

If

this

be

the

case,

it

is

so

indicated

on

the

Quality

Assurance

Data

Sheet

on

page

iii

of

this

manual.

Gamma-X

ff

t*

ORTEC

GAMMA"*

'....

-A.

^4gBgf3

ORTEC

GAMMA;£J

4\

Ti

I

iiiH

Fig.

1.2.

Physical

Appearance

of

Typical

Gamma-X

Detectors

4

Gamma-X

1.3.

ACCIDENTAL

WARM

UP

PROTECTION

EG&G

ORTEC

offers

a

liquid

nitrogen

level

monitor,

the

729A,

that

can

be

used

to

protect

the

detector

system

against

accidental

warmups

which,

in

a

HPGe

coaxial

detector

system,

may

cause

damage

to

the

first

FET

of

the

preamplifier,

if

the

high

voltage

has

not

been

removed.

This

type

of

failure

is

more

likely

to

occur

in

older

systems.

If

the

high

voltage

is

inadvertantly

left

on

during

a

warmup,

it

is

possible

that

the

increased

internal

pressure

may

cause

a

discharge

through

the

input

FET.

The

EG&G

ORTEC

729A

Liquid

Nitrogen

Level

Monitor

is

a

single-width

NIM

module

with

audio

and

visual

alarms

that

are

activated

when

the

level

of

liquid

nitrogen

in

the

dewar

falls

below

a

predetermined

level.

At

the

same

time

the

module

disconnects

the

high

voltage

supply

by

remote

shutdown.

The

module

includes

a

battery

that

will

activate

the

alarms

even

in

the

case

of

a

power

failure.

The

Gamma-X

Coaxial

Detector

System,

if

disconnected

from

all

external

electronics,

can

be

warmed

up,

stored

at

room

temperature

for

any

desired

period,

and

then

be

cooled

again.

While

this

can

be

done

repeatedly

without

incurring

damage,

it

is

recommended

that

such

temperature

cycling

be

kept

to

a

minimum.

As

previously

stated,

before

the

system

is

thermally

cycled

it

must

be

disconnected

from

all

external

electronics;

high

voltage

can

be

applied

to

the

detector

only

after

a

minimum

of

six

hours

of

cooling

time.

This

is

necessary

each

time

liquid

nitrogen

is

introduced

into

the

warm

dewar.

When

a

warmed-up

system

is

to

be

recooled,

be

careful

to

minimize

contact

between

the

cold

nitrogen

gas

and

the

cryostat,

the

preamplifier,

or

the

high

voltage

filter.

Gamma-X

5

1.4.

SPECTROSCOPY

WITH

GAMMA-X

DETECTORS

When

any

semiconductor

detector

is

used

in

an

energy

spectroscopy

system,

the

detector

element

absorbs

the

energy

from

an

incident

gamma

ray

or

x-ray

event

and

generates

a

current

pulse

whose

integral

in

the

time

domain

has

an

amplitude

that

is

proportional

to

the

absorbed

energy.

This

pulse

is

processed

through

the

preamplifier

that

is

attached

to

the

detector

assembly

and

then

through

the

main

amplifier

and

into

a

multichannel

analyzer

or

other

data

acquisition

system.

The

analyzer

measures

the

amplitude

of

each

pulse

and

stores

a

record

of

the

event

in

its

memory.

After

a

sufficiently

large

number

of

events

have

been

detected,

measured,

and

stored,

the

data

in

the

multichannel

analyzer

represents

a

spectrum

of

energies

vs

frequency

of

repetition.

60

For

reference.

Fig.

1.4

is

a

spectrum

that

was

obtained

for

Co,

using

a

typical

EG&G

ORTEC

Gamma-X

Coaxial

Detector.

The

range

of

energies

in

this

spectrum

is

from

0

to

about

1.5

MeV

and

the

two

principal

energy

lines

for

the

source,

at

1.17

and

1.33

MeV,

are

seen

clearly

as

high

peaks

in

the

spectrum.

The

vertical

deflections

in

the

display

are

logarithmic

rather

than

linear;

this

practice

is

standard

because

it

permits

observation

at

the

same

time

of

small

peaks,

resulting

from

relatively

few

counts,

and

major

peaks

that

result

from

very

high

count

levels.

Figure

1.5

shows

the

portion

of

interest

in

the

spectrum

of

Fig.

1.4.

Any

energies

outside

these

limits

are

simply

not

included

in

the

spectrum,

but

the

details

of

the

photopeaks

are

much

easier

to

discern

in

this

partial

spectrum.

Gamma-X

MMMW—

Fig.

1.4.

Full

Spectrim

Taken

with

Fig.

1.5.

Expanded

Portion

of

Interest

EG&G

ORTEC

Gamma-X

Coaxial

Detector

in

the

®°Co

Spectrum

of

Fig.

1.4

on

®^Co

As

previously

noted,

contrary

to

all

other

types

of

coaxial

Ge

detectors,

the

Gamma-X

detector

is

a

very

useful

spectroscopy

tool

on

X—

or

gamma—ray

"energies

down

to

below

10

keV.

This

feature

is

discussed

in

more

detail

in

Section

3.

Gamma-X

7

2.

RECEIVING,

UNPACKING,

AND

FILLING

WITH

LIQUID

NITROGEN

2.1.

GENERAL

Each

EG&G

ORTEC

Gamma-X

Coaxial Detector

System

is

shipped

in

a

crate

designed

to

protect

all

of

the

system

elements.

The

systems,

shipped

at

room

temperature,

must

be

unpacked

and

then

filled

with

liquid

nitrogen

to

be

put

into

operation.

In

the

side-looking

models,

this

is

done

easily

and

quickly

by

simply

pouring

the

liquid

nitrogen

from

another

dewar

(See

Section

2.2).

A

different

procedure

is

suggested

in

Section

2.2

for

filling

the

dipstick

models

(Models

20

and

21).

2.2.

UNPACKING

AND

FILLING

WITH

LIQUID

NITROGEN

1.

Remove

any

external

strapping

from

around

the

crate.

If

the

crate

has

a

heavy

cardboard

top,

remove

the

screws

that

hold

the

top

to

the

base

of

the

pallet.

If

the

crate

has

a

plywood

top,

remove

the

six

wing

nuts

that

are

accessible

through

the

crate

sides

near

the

floor.

In

either

case,

when

the

top

cover

is

free

from

the

pallet

base,

lift

it

carefully

straight

up

to

uncover

the

detector-

preamplifier-dewar

assembly.

The

system

will

look

like

that

in

Fig.

2.1.

2.

Cut

and

remove

the

strapping

that

secures

the

cryostat

and

preamplifier

to

the

dewar

handles.

Inspect

the

aseembly

for

physical

damage

that

might

have

occurred

during

shipment.

3.

Cut

the

straps

that

hold

the

dewar

to

the

floor

of

the

crate

and

remove

the

complete

detector

assembly

from

the

crate.

Save

the

pad

under

the

dewar

and

use

it

as

a

shock

mounting

at

its

intended

operating

location.

Store

the

crate

for

possible

re-use

at

a

later

date.

Gamma-X

'i

SSiSmi

Fig.

2.1.

A

T3^ical

Gamma-X

Detector

System,

Showing

Method

of

Packing

Inside

the

Crate

4.

Fill

the

dewar

with

liquid

nitrogen.

For

a

side-looking

detector

system,

cover

the

detector

and

preamplifier

with

a

sheet

of

plastic

or

other

protection

to

prevent

any

liquid

nitrogen

from

being

accidentally

spilled

on

these

components.

Then

pour

the

liquid

nitrogen

from

a

supply

dewar

into

the

operating

dewar;

keep

top

caps

in

place

on

both

dewars

at

all

times

except

when

the

transfer

is

actually

being

made

so

that

moisture

absorption

and

icing

are

minimized.

For

a

Model

20

or

21

system,

a

nitrogen

transfer

collar

is

included

between

the

top

of

the

dewar

and

the

cryostat

assembly.

The

two

stainless

steel

tubes

that

project

through

the

molded

collar

are

for

filling

and

venting,

and

these

are

interchangeable.

Attach

a

length

of

tubing

to

the

tube

that

will

be

used

as

a

vent

and

allow

it

Gamma-X

9

to

hang

over

the

side

of

the

dewar

to

carry

the

cold

gas

and

overflow

away

from

the

preamplifier

so

that

moisture

condensation

on

and

in

its

components

is

prevented.

Attach

A

short

length

(3

ft)

of

tubing

from

the

outlet

of

a

filling

dewar

to

the

fill

tube

on

the

nitrogen

transfer

collar

of

the

detector

assembly.

To

initiate

the

transfer,

pressurize

the

filling

dewar

with

no

more

than

3

to

5

psig

of

dry

nitrogen

gas.

CAUTION

Provide

a

pressure

relief

at

not

more

than

5

psig

on

the

supply

dewar

so

that

it

will

not

become

over-pressurized

in

the

event

that

the

tubes

should

become

blocked

with

ice.

For

safety

reasons,

air

or

oxygen

should

not

be

used

for

pressurization.

Since

the

system

is

shipped

at

room

temperature,

initially

the

liquid

nitrogen

will

vaporize

instantly

as

it

cools

the

walls

of

the

dewar

and

the

dipstick,

and

liquid

nitrogen

will

be

emitted

from

the

vent

tube

of

the

detector

system.

When

the

walls

of

the

dewar

and

the

dipstick

begin

to

be

sufficiently

cold,

the

liquid

nitrogen

will

begin

to

collect

in

the

dewar.

The

transfer

should

continue

until

liquid

nitrogen

exhausts

from

the

vent

tube.

By

then

the

vehement

bubbling

of

the

liquid

nitrogen

in

the

dewar

of

the

detector

system

should

have

largely

subsided.

Six

hours

later,

proceed

to

top

off

the

dewar,

thus

replacing

the

liquid

nitrogen

that

will

have

been

used

to

bring

the

system

temperature

down

to

equilibrium.

On

older

systems,

there

may

be

some

condensation

of

moisture

on

the

end

cap

if

a

plastic

bag

of

fresh

silica

gel

desiccant

is

not

tightly

in

place,

covering

the

end

cap

and

cryostat.

10

Gamma-X

5.

Although

EG&G

ORTEC

does

not

reconmend

this

practice,

it

is

possible

to

fill

and

empty

the

dewar

of

a

Model

20

or

21

system

through

the

dewar

top

when

the

dipstick

has

been

removed.

If

this

is

done,

always

hold

the

cryostat

in

its

normal

orientation

(i.e.,

with

the

end

cap

lower

than

the

cooling

rod);

otherwise

some

molecular

sieve

could

fall

down

from

the

cooling

rod

into

the

end

cap

and

result

in

detector

malfunction.

6.

As

previously

stated,

external

electronics

should

be

connected

to

the

detector

system

only

when

the

detector

has

been

properly

cooled.

Gamma-X

11

3.

CHECKOUT

AND

OPERATION

3.1.

GENERAL

After

the

dewar

has

been

filled

to

its

capacity

and

the

subsequent

steps

have

been

taken

as

described

In

Section

2,

Install

the

detector

In

an

energy

spectroscopy

system

and

operate

the

system

to

check

the

specifications

that

are

Included

In

the

Quality

Assurance

Data

Sheet

on

page

111

of

this

manual.

This

will

accomplish

two

purposes;

assure

that

no

damage

was

Incurred

during

shipment

and

provide

the

basic

orientation

to

the

use

of

radioactive

sources

for

testing

the

system.

The

basic specifications

are

based

on

spectral

measurements

made

with

^^^Co

and

^'^^Cd

sources.

The

electronic

system

to

be

used

for

the

measurements

Includes

the

detector

with

Its

attached

preamplifier

and

high-voltage

filter,

a

main

amplifier,

an

optional

biased

amplifier,

a

multichannel

analyzer,

a

precision

pulse

generator,

a

detector

bias

power

supply,

and

an

oscilloscope.

The

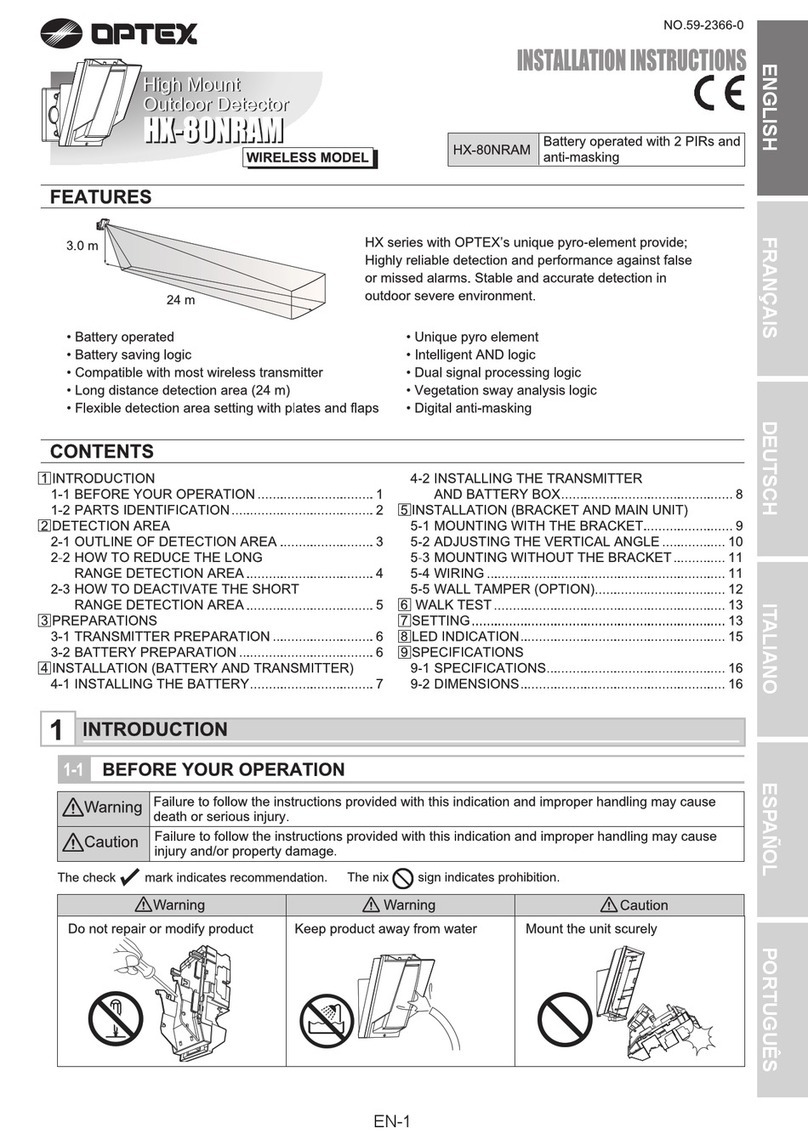

typical

system

arrangement

Is

shown

In

Fig.

3.1.

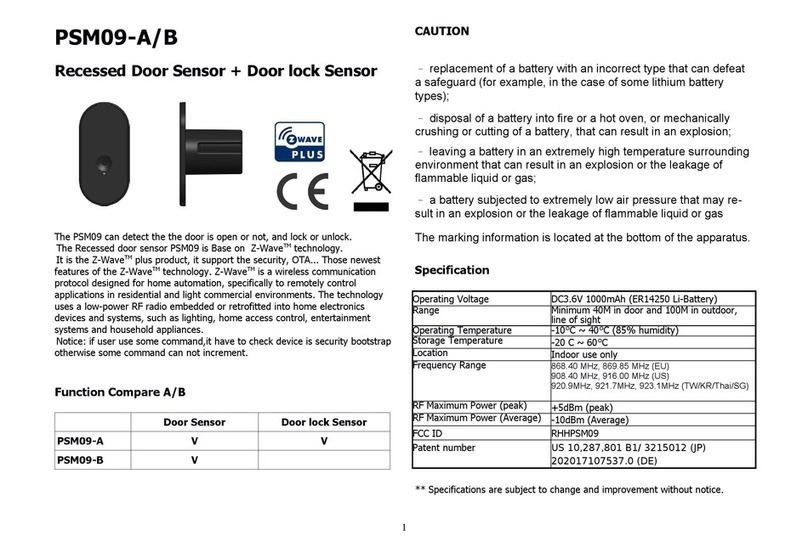

DETECTOR

BIAS

POWER

SUPPLY

PRECISION

PULSE

GENERATOR

n

HIGH

VOLTAGE

DETECTOR

PREAMPLIFIER

MAIN

OSCILLOSCOPE

1

,

MULTICHANNEL

FILTER

AMPLIFIER

ANALYZER

OPTIONAL

BIASED

AMPLIFIER

Fig.

3.1.

Interconnection

of

Components

In

a

Typical

Energy

Spectroscopy

Syst

em

Table of contents

Other EG&G Security Sensor manuals