Eguana AC05U-PP Max Installation and operation manual

DO 86073Rev1

AC05U-PP / -SP Max & ACB05-PB Max

Installati n & Startup Manual

F r use nly with battery m dels

•

Pyl ntech US3000C

DO 86073Rev1

Revisi n

Date

Status

Auth r

C mments

1.0

26.July.2022

Draft

RWM

Initial release

DO 86073Rev1

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

The ESS c mp nents described within this manual are intended t be used as part f the Ev lve LFP Max Energy St rage

system and installed per all l cal building c des and regulati ns in additi n t the Nati nal Electrical C de, ANSI/NFPA 70

(f r US) and Canadian Electrical C de (f r Canada).

The f ll wing sub-assembly c mp nents are c vered within this d cument:

ACB05U-PP Master PCS system

ACB05U-SP Sync PCS system

Ev lve PB Battery system

CAUTION: Hazardous Voltages! This inverter contains hazardous voltage and energy that may be lethal. It

may nly be installed by qualified pers nnel wh have read this manual and are familiar with its perati n and

hazards. The f ll wing safety pr cedures sh uld be f ll wed:

Only c nnect the PCS cabinet t a c mpatible electrical service as defined in the m del specificati ns. The PCS must be

c nnected t a dedicated branch circuit in the main electrical panel.

An external disc nnect switch shall be pr vided in the end installati n by thers f r the AC Grid utput circuit.

CAUTION! This e uipment contains high energy lithium batteries. Qualified and trained pers nnel sh uld

wear pr tective cl thing and equipment when w rking inside the battery cabinet and/ r with battery m dules.

CAUTION! The batteries provided with this system must be charged only by the PCS included as part of the

energy storage system. D n t attempt t charge batteries with any ther charger device r c nnect any

devices directly t the DC battery bus.

Ensure pr per electrical gr unding in acc rdance with c de requirements.

Ensure pr per airfl w path f r active c ling.

Never perate system in a manner n t described by this manual.

Only qualified pers nnel sh uld service this pr duct.

Ensure all c vers are securely fastened after installati n is c mplete.

This pr duct must be st red ind rs in an envir nmentally c nditi ned l cati n pri r t installati n, pr tected fr m rain

and exp sure t any hazard us chemicals.

D n t attempt t perate this pr duct if there is any physical evidence f damage t any f the cabinets r internal

c mp nents.

CAUTION! This e uipment is heavy. Mechanical lifts are rec mmended f r safe installati n.

California Proposition 65

WARNING! This pr duct can exp se y u t chemicals including bis (2-ethylhex-yl)phthalate, which is kn wn t

the State f Calif rnia t cause birth defects r ther repr ductive harm. F r m re inf rmati n g t

https://www.p65warnings.ca.gov/.

TABLE OF CONTENTS

1 SAFETY ......................................................................................................................................................................................... 1

1.1

I

N CASE OF EMERGENCY

.............................................................................................................................................................................. 1

1.2

B

ATTERY MODULE SAFETY PRECAUTIONS

................................................................................................................................................. 1

1.3

G

ENERAL SAFETY PRECAUTIONS

................................................................................................................................................................ 2

1.4

D

ISPOSAL AND

R

ECYCLING

........................................................................................................................................................................ 2

2 INTRODUCTION .......................................................................................................................................................................... 3

2.1

A

BOUT THIS

M

ANUAL

–

T

ARGET

A

UDIENCE

............................................................................................................................................ 3

2.2

I

NSTALLATION

P

LANNING

&

S

YSTEM

C

OMMISSIONING

-

S

UPPORTING

D

OCUMENTS

......................................................................... 3

2.3

G

LOSSARY

.................................................................................................................................................................................................... 3

2.4

P

RODUCT MARKINGS

................................................................................................................................................................................... 3

2.5

S

PECIAL TOOLS

&

HARDWARE

................................................................................................................................................................... 3

2.6

I

NITIAL

I

NSPECTION OF

M

ATERIAL

L

IST

–

TOP LEVEL SYSTEM COMPONENTS

........................................................................................ 4

2.6.1 LFP Max install kit – mechanical parts and manuals.......................................................................................................... 5

2.6.2 LFP Max install kit – battery cables ......................................................................................................................................... 6

3 INSTALLATION SITE PREPARATION .................................................................................................................................... 7

3.1

O

VERVIEW OF

PCS

AND

B

ATTERY COMPONENTS

................................................................................................................................... 7

3.2

I

NSTALLATION

A

REA

R

EQUIRED TO

W

ALL

M

OUNT THE

ESS: ............................................................................................................... 7

4 PCS AND BATTERY CABINET WALL-MOUNTING INSTRUCTIONS ............................................................................... 8

5 BATTERY MODULE ASSEMBLY ............................................................................................................................................ 10

5.1

B

ATTERY CABINET GROUND BUS

............................................................................................................................................................. 10

5.2

DC

NEGATIVE

&

POSITIVE POWER BUS TERMINATIONS

........................................................................................................................ 10

5.3

P

REPARING BATTERY MODULES FOR INSTALLATION

............................................................................................................................. 11

5.4

M

OUNTING AND GROUNDING THE BATTERY MODULES IN THE BATTERY CABINET

.............................................................................. 12

5.5

W

IRING THE BATTERY MODULES

............................................................................................................................................................. 13

5.5.1 Battery module C -/+ jumper cable wiring ...................................................................................................................... 13

5.5.2 BMS communication jumper cable wiring .......................................................................................................................... 13

5.5.3 PCS to BMS communication cable ....................................................................................................................................... 14

6 SYSTEM ELECTRICAL WIRING .............................................................................................................................................. 15

6.1

AC

POWER CONNECTIONS

...................................................................................................................................................................... 15

6.2

E

XTERNAL

AC

C

IRCUIT

P

ROTECTION

D

EVICE

....................................................................................................................................... 15

6.3

C

HASSIS

G

ROUNDING

.............................................................................................................................................................................. 16

7 BATTERY MODULE BMS DEFINITIONS AND OPERATING STATES ............................................................................. 16

8 ESS STARTUP PROCEDURE .................................................................................................................................................. 17

8.1

S

YSTEM OPERATION

................................................................................................................................................................................. 17

9 PCS DISPLAY PANEL .............................................................................................................................................................. 18

9.1

LED

D

ISPLAY

I

NDICATORS

...................................................................................................................................................................... 18

9.2

PCS

DISPLAY PANEL INDICATOR SUMMARY

.......................................................................................................................................... 18

9.3

S

ERVICE

B

UTTON

...................................................................................................................................................................................... 18

9.4

B

ACKUP

P

OWER

O

PERATION

................................................................................................................................................................. 19

9.4.1 Backup Power isplay Modes ............................................................................................................................................... 19

9.5

R

ESTARTING THE BATTERY SYSTEM AFTER LOW BATTERY SHUTDOWN

............................................................................................. 20

10 MAINTENANCE & SERVICE .................................................................................................................................................. 20

11 SERVICEABLE PARTS – BATTERY MODULE REMOVAL/REPLACEMENT ................................................................ 20

12 TROUBLESHOOTING ............................................................................................................................................................ 21

13 DECOMMISSIONING THE ESS ............................................................................................................................................. 21

14 SPECIFICATIONS.................................................................................................................................................................... 22

Table 1: PCS Electrical / Mechanical Ratings ............................................................................................................................... 22

Table 3: Battery Cabinet Electrical / Mechanical Ratings ......................................................................................................... 23

Table 4: Battery Cabinet Field Wiring Ratings – AWG / Torque ........................................................................................... 23

14.1

UL

1741

SA

G

RID

S

UPPORT

U

TILITY

I

NTERACTIVE

I

NVERTER

S

PECIFICATIONS

.......................................................................... 24

Table 5: UL1741 SA grid support functions. ................................................................................................................................ 24

Table 6: SA9 Low and high voltage ride through settings. ..................................................................................................... 24

Table 7: SA10 Low and high frequency ride through settings. ............................................................................................. 25

Table 8: SA11 Ramp rate settings. .................................................................................................................................................. 25

Table 9: SA12 Specified power factor settings. .......................................................................................................................... 26

Table 10: SA13 Volt VAR Mode ....................................................................................................................................................... 27

Table 11: SA14 Frequency-Watt settings. ................................................................................................................................... 28

Table 12: SA15 Volt-Watt Settings. ............................................................................................................................................... 28

14.2

T

HERMAL PERFORMANCE

:

C

HARGE

/

D

ISCHARGE

C

URVES

.............................................................................................................. 29

1

1 Safety

The c mp nents described by this manual are intended t be used as part f an energy st rage system and installed per all

l cal building c des and regulati ns in additi n t the Nati nal Electrical C de, ANSI/NFPA 70 (f r US) and Canadian

Electrical C de (f r Canada).

Thr ugh ut this manual, the f ll wing symb ls will be used t highlight imp rtant inf rmati n and pr cedures:

Symbol

Definition

Symbol

Definition

WARNING! A dangerous voltage or other

condition exists. Use extreme caution

when performing these tasks.

Meter measurement required.

AUTION! This information is critical to

the safe installation and or operation of the

inverter. Follow these instructions closely.

T rque rating critical t perati n.

NOTE: This statement is important. Follow

instructions closely.

L gin t the rem te m nit ring system f r

perating status

Gr und, GND, PE

1.1 In case of emergency

In all cases:

•

If safe t d s , switch ff the AC breakers (external t the system).

•

C ntact the fire department r ther required emergency resp nse team.

•

Evacuate the area, and if applicable, f ll w y ur emergency evacuati n plan if thers are in pr ximity t the

installed l cati n.

In case of fire:

•

When safe, use a fire extinguisher suitable f r use; including A, B, and C dry chemical fire extinguishers r carb n

di xide extinguishers.

In case of flooding:

•

Stay ut f water if any part f the system r wiring is submerged.

•

D n t attempt t perate batteries that have been submerged in water even after they have been dried.

In case of unusual noise, smell or smoke:

•

If safe t d s , ventilate the area.

1.2 Battery module safety precautions

This pr duct is integrated with Pylt ntech US3000C series battery m dules. Refer t the Pyl ntech pr duct manual f r

c mplete safety instructi ns regarding handling f battery m dules.

EMS

2

1.3 General safety precautions

Important! Installati n, service, and perating pers nnel must read this d cument in its

entirety, and bserve all safety and installati n pr cedures as described in this manual.

Never perate system in a manner n t described by this manual.

Only qualified pers nnel sh uld service this pr duct.

Ensure all c vers are securely fastened after installati n is c mplete.

Pers nal Pr tective Equipment (PPE) in c mpliance with l cal w rk place safety standards must be

w rn when w rking inside the cabinet.

Risks of Fire

D n t exp se the system t temperatures exceeding 60 degrees Celsius.

Av id installati n in direct sunlight.

D n t st re bjects n t p f the cabinet.

D n t bstruct the airfl w paths f the cabinet air intake.

D n t bstruct the exhaust f cabinet exhaust.

D n t st re c mbustible bjects and c rr sive chemicals directly adjacent t the system.

Risks of Shock

WARNING! Hazardous Voltages.

The Inverter contains hazardous voltage and energy that may be lethal

.

It may nly be installed by qualified pers nnel wh have read this manual and are familiar with its perati n

and hazards.

Only c nnect the PCS cabinet t a c mpatible electrical service as defined in the m del specificati ns. The

PCS must be c nnected t a dedicated branch circuit in the main electrical panel.

Ensure pr per electrical gr unding in acc rdance with c de requirements.

CAUTION! Both

AC

and

DC

voltage sources are terminated inside this e uipment. Each circuit must be

individually disconnected before servicing

Risks of Damage

The PCS is c nfigured f r the Pyl ntech US3000C battery m dule nly. D n t attempt t c nnect any ther

battery t the system.

D n t c nnect any ther l ads directly t the battery p wer bus.

D n t dr p, tip, r

puncture the cabinet during transp rt and installati n. Visible damage t the cabinet

and/ r internal c mp nents sh uld be rep rted t the manufacturer immediately.

D n t st re this system f r peri ds l nger than six m nths with ut a battery maintenance charge. This may

result in permanent damage t the batteries.

1.4 Disposal and Recycling

D n t disp se f the system r any f the c mp nents within the cabinet. Batteries, electr nics, cables, and

metal parts are recyclable. C nsult y ur municipal waste management auth rity t determine required meth ds

f c mp nent recycling.

3

2 Introduction

2.1 About this Manual – Target Audience

This manual is intended t be used by qualified service and installati n pers nnel f r the purp ses f pr duct installati n.

This manual c ntains instructi ns f r the installati n f Eguana Ev lve™ energy st rage c mp nents required t assemble

the Ev lve LFP Max ; including the CB. This pr duct is permanently wired t the h me electrical service, and must be

installed by a licensed electrician nly.

2.2 Installation Planning & System Commissioning - Supporting Documents

The Ev lve LFP Max energy st rage system is perated by the Ev lve Hub. Please c nsult the Ev lve Hub Installati n

Manual f r full installati n planning details, including c nduit lay ut plans and sample single line diagrams f r a c mplete

s lar plus st rage system installati n. The Ev lve Hub installati n manual als describes in m re detail the vari us

perating m des and c nfigurati ns f r AC c upled PV s lar plus st rage systems.

A c mplete list f Installer res urces is available at www.eguanatech.c m under the Ev lve™ pr duct banner.

2.3 Glossary

2.4 Product markings

The ratings label is l cated n the b tt m face f each

cabinet. The serial number / date c de labels f r the

system are l cated as sh wn (right) with the fr nt

c vers rem ved.

2.5 Special tools & hardware

The f ll wing t ls are required t c mplete the

installati n f the ESS:

•

T rque wrench

•

17mm s cket wrench (DC- main p wer

c nnecti n).

•

10mm s cket wrench (battery +/- m dule

p wer c nnecti ns).

•

3/8” s cket wrench (DC+ main p wer

c nnecti n).

•

L ad bearing hardware f r wall bracket

m unting. 5/16” (M8)

Term Definiti n Term Definiti n

AC

/ DC

Alternating Current

/ Direct Current

LED

Light Emitting Di de

ARC

Aut Rec very Circuit

NC

/ NO

N rmally Cl sed

/ N rmally Open

CPU

Central Pr cessing Unit

PCS

P wer C ntr l System (Inverter)

EMC

Energy Management C ntr ller

PE

Pr tective Earth

EMS

Energy Management System

PV

Ph t

-

V ltaic

ESD

Electr static Discharge

RF

Radi Frequency

ESS

Energy St rage System

SOC

State Of Charge (Battery)

GND

Gr und

SOH

State f Health (Battery)

All cabinets:

ratings label

PCS cabinet:

s/n, date c de

Battery cabinet:

s/n, date c de

4

2.6 Initial Inspection of Material List – top level system components

The system c mp nents supplied with the system are sh wn bel w. Each c mp nent sh uld be inspected visually f r any

damage that may have been caused by shipment. If damage is present, please c ntact y ur l cal distribut r.

Item Eguana P/N Description

1 ACB05U-PP/SP Max PCS cabinet (and c ver)

2 ACB05-PB Max Battery Cabinet (and c ver)

3* --------- Wall m unt rail – PP m del

3* --------- Wall m unt rail – SP m del

4 US3000C 4 battery m dules

5 LFP Max install kit Assembly parts kit, cables, and manuals.

1

2

3

4

5

Figure

1

: Top level system

components.

5

2.6.1 LFP Max install kit – mechanical parts and manuals

Item Qty Eguana P/N Description

Battery Cabinet

1 1 PB kit Incl. cabinet c upler assembly, tw levelling brackets, and tw plugs

2 8 801003244 Adhesive backed battery m dule pads

3 1 801003757 Battery rack partiti n bracket (includes attached battery retaining clip 801003044)

PCS Cabinet

4 1 LP Max kit

Incl. levelling bracket, cabinet c upler end plate, plug, and PCS

-

BMS c mmunicati n

cable.

- 1 D c 82013 Ev lve LFP Max Installati n and Startup Manual

- 1 D c 58159 Ev lve LFP Max System Owner’s Manual

4

SP/PP Max kit

US3000C

PB

Max

kit

1

2

3

8x

Figure

2

: LFP Max install kit

-

mechanical parts.

6

2.6.2 LFP Max install kit – battery cables

Item Qty Eguana P/N Description Pylon p/n

1 2 801003792 BMS jumper sh rt 210 mm WI0SRJ458025

2 1 801003794 BMS jumper l ng 700 mm WI0SUS300002

3 4 801003791 Chassis GND cable GRN/YEL 1 m WI0GUS300001

BMS

GND

1

2

3

Figure

3

: LFP Max install kit

-

battery cables.

7

3 Installation Site Preparation

Bef re installing the pr duct, read all instructi ns and warnings in this manual. This pr duct is wall-m unted nly, and can

be installed b th utd rs (in c mpliance with NEMA Type 3R installati ns) and ind rs, either attached r detached

garages, and ind r l cati ns m re than 5 feet fr m dwelling units. This pr duct is n t t be installed in habitable spaces.

C nsult l cal building c des f r m re details.

AUTION! All electrical installation work should be performed in accordance with local building and electrical codes.

WARNING! Isolate the PCS from all energy sources prior to electrical installation by means of disconnects, breakers

or connectors. Failure to properly isolate either AC or C sources may result in serious injury or death. This system

will generate an AC voltage at the off-grid terminals when C source is applied.

AUTION! The P S cabinet weighs up to 145 lbs. (65 kg), and the battery cabinet weighs up to 320 lbs. (145

kg) with four battery modules installed. Handle with care. The wall t which the system is m unted must be

l ad-bearing rated acc rding t the l cal building c de. Mechanical lifts are rec mmended t p siti n cabinets n the wall

bracket.

NOTE: All interc nnecting cables are limited in length, and designed specifically f r adjacent cabinet m unting using

the manufactured wall brackets.

CAUTION! o not install in direct sunlight. Battery performance is dependent upon operating ambient temperature.

Radiant heat absorbed in direct sunlight will greatly reduce the performance of the battery, and will prematurely

cause degradation of the display indicator panel on the PCS cabinet. The battery modules are rated for operating

temperature range between -10C to +50C.

NOTE: ESS systems installed ind rs may require the installati n f a sm ke alarm r heat detect r specific f r ESS

use. C nsult the l cal building c de f r m re details.

NOTE: This pr duct was n t evaluated in seismic envir nments.

NOTE: All external wiring must be pr tected by metallic c nduit, and all c nduit fittings installed n the ESS

cabinets must be rated Type 3R r better.

3.1 Overview of PCS and Battery components

1. The f rced air c ling f the PCS cabinet is designed t fl w air fr m b tt m t t p.

2. Wall m unting hardware n t

included. The l ad-bearing

wall bracket is pr visi ned f r

M8 hardware. Levelling

brackets are pr visi ned f r

M5 hardware.

3.2 Installation Area Required

to Wall Mount the ESS:

The physical installati n f the cabinets

requires lay ut planning and installati n

f the system c mp nents in the

available installati n space. The

rec mmended installati n height is

driven by the viewing angle f the

display panel n the PCS cabinet.

Figure

4

: Installation clearances for the Evolve LFP Max energy storage

system (ACB05U-PP model shown).

8

4 PCS and Battery Cabinet Wall-Mounting Instructions

N te: The f ll wing instructi ns apply t the –SP m del.

The -PP m del f ll ws the same instructi n set with the

battery cabinet placed t the left f the PCS cabinet.

1. M unt the wall rail t the wall. Use the available sl t pattern t

m unt t a l ad-bearing structure rated f r the weight f the final

system. The sl ts acc mm date a M8 (5/16”) b lt diameter.

IMPORTANT! Wall-stud m unting: A minimum f three wall

studs spanned within the width f the m unting rail are

required. A minimum f tw m unting b lts are required per stud

(t p/b tt m).

2. (n t sh wn) Rem ve the battery cabinet fr m the packaging, and

stand the cabinet upright. Rem ve the fr nt c ver.

3. M unt the tw leveling brackets t the back side f the cabinet.

Each side f the cabinet must have a rubber washer in direct

c ntact with the cabinet wall.

4. Lift the battery cabinet nt the wall m unt bracket, aligning the

wall h ks at the rear f the cabinet with the sl ts n the l ad-

bearing face f the bracket.

5. Slide the battery cabinet t wards the right end f the bracket t

all w f r clearance f r the PCS cabinet.

6. Fr m the rear side f the cabinet, adjust the uter wingnuts n the

levelling brackets until the cabinet is vertically plumb (level) t the

wall.

1

3

4

3

9

8

Figure

5

: Wall

-

mounting the cabinets.

6

-

P

P

-

SP

9

7. Rem ve the PCS cabinet fr m its packaging and

stand upright. (n t sh wn). Rem ve the fr nt

c ver.

8. Assemble and m unt the single l wer-center

leveling bracket as sh wn in steps 3 and 4 ab ve.

CAUTION! The PCS cabinet is heavy.

Mechanical lift r tw pers ns rec mmended.

9. Lift the PCS cabinet nt the wall m unting bracket.

10. Slide the PCS cabinet t the left such that it aligns

with the alignment tab n the m unting bracket.

11. Fr m the rear side f the cabinet, adjust the uter

wingnut n the single levelling bracket until the

cabinet is vertically plumb (level) t the wall. (see

image – step 6).

12. Insert the PCS cabinet c upling gasket between the

tw cabinets (l wer-fr nt). Slide the battery cabinet

t wards the left until mating t the gasket.

13. Place the c upling plate inside the PCS cabinet and

insert the f ur m unting b lts and washers thr ugh

t the battery cabinet side.

14. Place star washers n the b lts n the battery side

f the cabinet.

15. M unt the battery cabinet side c upling plate, and

fasten with the l ck nuts. T rque t 10 – 15 in-lbs.

WARNING! The mounting bolts of the flange

assembly are required to be fully secured, as

they provide the chassis grounding for the battery

cabinet. Torque nuts as shown in the specification

tables provided in this manual.

16. Continuity test: Check the c ntinuity

between the cabinets using an Ohm meter. The

test reading must be zer Ohms at a bare metal

p int inside each f the PCS and battery cabinets.

17. Install the cabinet c upler end plate (see- LP kit) t

seal the h le n the battery cabinet.

18. Opti nal: (This is n t a l ad bearing anch r –

anch red c nduit runs t the PCS are satisfact ry).

Install screws in leveling plates f r PCS and battery

cabinets by inserting a screwdriver thr ugh the h le

n the backside f the cabinets.

19. Plug h le n back f cabinet using by inserting the

h le plug fr m the fr nt side.

Opti nal (

hardware

n t included)

12

16

thru

18

19

17

10

Figure

6

: PCS cabinet and inter

-

cabinet coupler installation.

10

5 Battery Module Assembly

The f ll wing instructi ns include:

•

Interc nnecti n f the PCS DC and c mmunicati n cables t

the battery cabinet.

•

Preparati n and assembly f the battery cabinet m dules and

internal wiring.

Note: Overcurrent protection of the C source is provided

internally as part of the integrated battery system. No

external C disconnect is required.

5.1 Battery cabinet ground bus

CAUTION! A tor ue wrench is re uired to ensure the

power cables are terminated to their specifications. Over-

t rque can damage the DC breaker and/ r strip the threads

n the c pper bus bar p sts. Under-t rque can result in an arc fault

hazard, and risk f fire. Damage as a result f impr per terminati n is

n t c vered by the manufacturer warranty.

1. M unt the f ur gr und wires pr vided in the battery m dule

gr unding kit int the 4-p siti n gr und distributi n bl ck.

5.2 DC negative & positive power bus terminations

N te; MAX -S m del sh wn. See fr nt view f the MAX-P

m del bel w.

2. R ute the DC- cable fr m the DC- bus t the battery

disc nnect DC- p st. T rque the nut t 35 in/lbs.

3. R ute the DC+ cable fr m the DC+ bus t the

battery disc nnect DC+ p st. T rque the nut t 35 in/lbs.

P/N

Description

-----

PCS DC

-

battery disc nnect cable

-----

PCS DC+ battery disc nnect cable

1

3

2

Figure

7

: Battery

cabinet module grounding wires and

C negative/positive terminations

11

5.3 Preparing battery modules for

installation

The PCS cabinet is n t sh wn in the f ll wing steps.

CAUTION! Ensure the battery m dule p wer

switches are in the OFF p siti n thr ugh ut

the f ll wing pr cedure.

N te: Observe the r tati n f the m dules

n the l wer and upper racks. The l wer

rack is r tated such that the chassis gr und

terminal is at the b tt m f the m dule, while the

upper rack chassis gr und terminal is at the t p.

1. (n t sh wn) Rem ve a battery fr m its

packaging. Rem ve the rackm unt ears, if

supplied with the battery.

2. Attach tw adhesive-backed m dule pads

(included in the battery m dule hardware kit)

t the battery m dules as sh wn. F r the

l wer rack f m dules, the pads are installed

n the t p face f the battery. F r the upper

rack, the pads are installed n the b tt m

face f the battery.

u

pper rack

l wer

rack

Figure

8

: Attaching adhesive pads to the battery modules.

12

5.4 Mounting and grounding the battery modules in the battery cabinet

1. Slide the l wer rack battery int the cabinet as sh wn, and c nnect the gr und cable t the ring terminal gr und

c nnect r n the battery m dule as sh wn.

2. Push the m dule inward until making c ntact with the rear face f the cabinet.

3. Repeat steps 1 and 2 ab ve with the 2

nd

l wer rack m dule.

4. M unt the l wer rack retaining clip.

5. Install the battery rack partiti n bracket as sh wn using the tw M5 keps nuts pr vided.

N te: Rem ve the retaining clip fr m the bracket if m unted n the partiti n bracket bef re pr ceeding with the

f ll wing steps:

6. Repeat steps 1 thru 3 ab ve with the upper level battery rack.

7. M unt the tw upper rack retaining clips.

2

4

5

3

6

Upper rack

l wer rack

1

7

Figure

9

: Installing and grounding the battery modules.

13

5.5 Wiring the battery modules

F ll w the battery m dule p wer and

c mmunicati n jumper wiring bel w.

5.5.1 Battery module C -/+ jumper cable

wiring

The battery cables are fact ry terminated at the

DC- and DC+ bus. All cables are the same length.

C nnect each m dule (push-t -click) c nnect r

as sh wn (right).

5.5.2 BMS communication jumper cable

wiring

Install the cables in the f ll wing sequence.

IMPORTANT! All m dule interc nnecting

BMS jumpers terminate at the [Linkp rt]

terminals. N te the Linkp rt reference, 0 an 1, f r

each p rt c nnecti n.

1. Terminate the BMS jumper cable C2 between

batteries #2 - 3.

2. Terminate the BMS jumper cables C1

between batteries #1-2 and #3-4.

Ref

P/N

Description

Pylon p/n label

C1 #3792

BMS jumper

sh rt 210 mm WI0SRJ458025

C2 #3794

BMS jumper

l ng 700 mm WI0SUS300002

Figure

10

: Installing the battery jumper cables.

14

5.5.3 PCS to BMS communication cable

This cable is specific t the battery m del. Refer t the instructi n that applies nly t the battery m dule suppled.

Terminate the PCS-BMS cable in battery #1 as sh wn bel w. This battery is herein referred t as the “Master” battery

m dule. All ther m dules sync t the master.

1. Terminate the PCS – BMS / C ns le Y cable jumper in the [A/CAN] and [C ns le] p rts f battery #1.

2. R ute the ther end f the cable thr ugh the PCS p rt h le and terminate in the cable in the [BMS OUT] p rt.

BMS OUT

1

US3000C

#3810

Figure

11

: PCS to BMS communication cable connection.

15

6 System Electrical Wiring

Note: This pr duct is capable f pr viding utility interactive and

islanded back up p wer, and can be AC c upled t a utility interactive

ph t v ltaic inverter. Wiring meth ds must be in acc rdance with

l cal electrical c des. The installer is resp nsible f r ensuring that ver-

current pr tecti n is installed and sized appr priately f r the AC grid

and ff-grid utput circuits, in acc rdance with the Nati nal Electrical

C de, ANSI/NFPA 70, Canadian Electrical C de and l cal c des.

All field wiring c nnecti ns t the battery system are at the PCS cabinet nly.

The kn ck ut l cati ns f r c nduit entry int the PCS are categ rized as AC

p wer and signal level circuits.

IMPORTANT! Drilling holes anywhere in the battery or PCS cabinet

renders the warranty null and void. Use the kn ck uts pr vided at the

b tt m face f the PCS cabinet nly! D n t drill h les anywhere in the

battery system. Use c nduit fitting reducers, if applicable.

6.1 AC power connections

Note: The PCS pr vides galvanic separati n between AC and

DC S urces.

AUTION! To reduce the risk of fire, connect only to a

dedicated circuit provided with appropriate branch circuit over-

current protection in accordance with local electrical codes.

WARNING! Improper connection of the wiring panel may

result in equipment damage and cause personal injury.

isconnect all AC and C Sources prior to installation.

Note: The AC utput’s Neutral terminal is n t b nded t

gr und. The Neutral is c nnected t gr und when perating in

backup (stand-al ne) m de.

AC Grid Port:

1. Terminate the AC grid c nnecti n wires as f ll ws:

L = Line

N = Neutral

PE = Gr und.

6.2 External AC Circuit Protection Device

An external AC circuit pr tecti n device, either breaker r fused disc nnect, that is lates all ungr unded c nduct rs, shall

be pr vided by thers f r the AC Grid utput circuit. F r utd r wall m unt installati ns, the disc nnect must be rated f r

utd r use and include fuse pr tecti n f ungr unded c nduct rs (2 p le). The maximum fuse / breaker rating f r the

external disc nnect is determined by the use applicati n f the ESS:

Grid interactive nly perati n (with ut backup): 50 Amp

Grid interactive & backup perati n: 60 Amp

PE

N

L

Grid

PCS cabinet

–

b tt m view

AC p wer

Signal

Figure

12

:

PCS knockout detail.

Figure

13

:

AC power connections.

This manual suits for next models

2

Table of contents

Other Eguana Switch manuals

Popular Switch manuals by other brands

Endress+Hauser

Endress+Hauser Liquiphant M FTL50 operating instructions

S&C

S&C Alduti-Rupter Switches Outdoor Distribution Installation and operation

NETGEAR

NETGEAR 748TP Hardware installation guide

Western Telematic

Western Telematic AFS-16-1 user guide

MaxiiNet

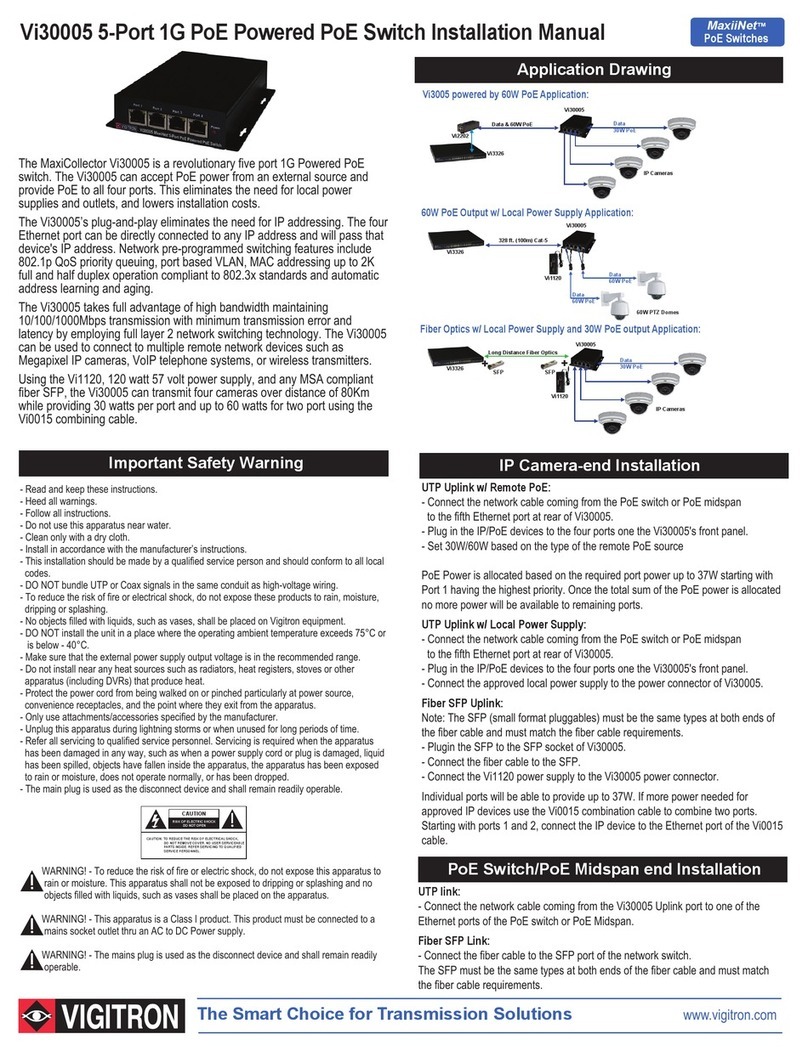

MaxiiNet Vi30005 installation manual

Ask

Ask ADSW0012M1 user manual

Linksys

Linksys FENSK05 - EtherFast Network Starter user guide

Dynex

Dynex DX-B7PORT Guía de instalación

LEGRAND

LEGRAND 3 109 77 quick start guide

Extreme Networks

Extreme Networks Summit Summit24 Installation and user guide

Acuity Brands

Acuity Brands nLight UNITOUCH user manual

Sun Oracle

Sun Oracle ES1-24 Safety and compliance guide