Eguana Evolve LFP Installation and operation manual

DO 82013Rev1

Evolve LFP

Installation & Startup Manual

For use only wit battery models

•Pylontec US3000 /US3000C

DO 82013Rev1

DO 82013Rev1

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

T is manual contains important instructions for t e Eguana Evolve™ LFP, including t e Power Control System (PCS) and base

model battery cabinet installation and operation, erein defined as t e ESS. T e ESS is expandable wit t e addition of up to two

more battery cabinets. Refer to t is manual in Appendix A for more details if your system contains additional battery capacity

beyond t e base model. T e ESS components described by t is manual are intended to be used as part of an Energy Storage

system and installed per all local building codes and regulations in addition to t e National Electrical Code, ANSI/NFPA 70 (for US)

and Canadian Electrical Code (for Canada).

CAUTION: Hazardous Voltages! This inverter contains hazardous voltage and energy that may be lethal. It may only

be installed by qualified personnel w o ave read t is manual and are familiar wit its operation and azards. T e

following safety procedures s ould be followed:

Only connect t e PCS cabinet to a compatible electrical service as defined in t e model specifications. T e PCS must be connected

to a dedicated branc circuit in t e main electrical panel.

An external disconnect switc s all be provided in t e end installation by ot ers for t e AC Grid output circuit.

CAUTION! This e uipment contains high energy lithium batteries. Qualified and trained personnel s ould wear

protective clot ing and equipment w en working inside t e battery cabinet and/or wit battery modules.

CAUTION! The batteries provided with this system must be charged only by the PCS included as part of the energy

storage system. Do not attempt to c arge batteries wit any ot er c arger device or connect any devices directly to t e

DC battery bus.

Ensure proper electrical grounding in accordance wit code requirements.

Ensure proper airflow pat for active cooling.

Never operate system in a manner not described by t is manual.

Only qualified personnel s ould service t is product.

Ensure all covers are securely fastened after installation is complete.

T is product must be stored indoors in an environmentally conditioned location prior to installation, protected from rain and

exposure to any azardous c emicals.

Do not attempt to operate t is product if t ere is any p ysical evidence of damage to any of t e cabinets or internal components.

CAUTION! This e uipment is heavy. Mec anical lifts are recommended for safe installation.

TABLE OF CONTENTS

1 SAFETY ......................................................................................................................................................................................... 1

1.1

I

N CASE OF EMERGENCY

.............................................................................................................................................................................. 1

1.2

B

ATTERY MODULE SAFETY PRECAUTIONS

................................................................................................................................................. 1

1.3

G

ENERAL SAFETY PRECAUTIONS

................................................................................................................................................................ 2

1.4

D

ISPOSAL AND

R

ECYCLING

........................................................................................................................................................................ 2

2 INTRODUCTION .......................................................................................................................................................................... 3

2.1

A

BOUT THIS

M

ANUAL

–

T

ARGET

A

UDIENCE

............................................................................................................................................ 3

2.2

I

NSTALLATION

P

LANNING

&

S

YSTEM

C

OMMISSIONING

-

S

UPPORTING

D

OCUMENTS

......................................................................... 3

2.3

G

LOSSARY

.................................................................................................................................................................................................... 3

2.4

P

RODUCT MARKINGS

................................................................................................................................................................................... 3

2.5

S

PECIAL TOOLS

&

HARDWARE

................................................................................................................................................................... 3

2.6

I

NITIAL

I

NSPECTION OF

M

ATERIAL

L

IST

–

TOP LEVEL SYSTEM COMPONENTS

........................................................................................ 4

2.6.1 LFP install kit – mechanical parts and manuals ................................................................................................................... 5

2.6.2 LFP install kit – battery cables ................................................................................................................................................... 6

3 INSTALLATION SITE PREPARATION .................................................................................................................................... 7

3.1

O

VERVIEW OF

PCS

AND

B

ATTERY COMPONENTS

................................................................................................................................... 7

3.2

I

NSTALLATION

A

REA

R

EQUIRED TO

W

ALL

M

OUNT

PCS

AND

B

ATTERY

: ............................................................................................. 7

4 PCS AND BATTERY CABINET WALL-MOUNTING INSTRUCTIONS ............................................................................... 8

5 BATTERY MODULE ASSEMBLY ............................................................................................................................................ 10

5.1

B

ATTERY CABINET GROUND BUS

............................................................................................................................................................. 10

5.2

DC

NEGATIVE POWER TERMINAL ASSEMBLY

......................................................................................................................................... 10

5.3

P

REPARING BATTERY MODULES FOR INSTALLATION

............................................................................................................................. 11

5.4

M

OUNTING AND GROUNDING THE BATTERY MODULES IN THE BATTERY CABINET

.............................................................................. 12

5.5

W

IRING THE BATTERY MODULES

............................................................................................................................................................. 13

5.5.1 Battery module DC /+ jumper cable wiring ...................................................................................................................... 13

5.5.2 BMS communication jumper cable wiring .......................................................................................................................... 13

5.5.3 PCS to BMS communication cable ....................................................................................................................................... 14

5.6

DC-

BATTERY MODULE TO CABINET

DC-

CONNECTIONS

..................................................................................................................... 15

5.7

PCS

DC+

POWER AND BREAKER ASSEMBLY WIRING

.......................................................................................................................... 16

6 SYSTEM ELECTRICAL WIRING .............................................................................................................................................. 17

6.1

AC

POWER CONNECTIONS

...................................................................................................................................................................... 17

6.2

C

HASSIS

G

ROUNDING

.............................................................................................................................................................................. 18

6.3

C

OMMUNICATION

W

IRING TO THE

E

NERGY

M

ANAGEMENT

S

YSTEM

–

RJ45

P

IN

-

OUT

.................................................................... 18

6.4

AK1

E

VOLVE

H

UB CONTROL CABLE

...................................................................................................................................................... 18

7 BATTERY MODULE BMS DEFINITIONS AND OPERATING STATES ............................................................................. 19

8 ESS STARTUP PROCEDURE .................................................................................................................................................. 20

8.1

S

YSTEM OPERATION

................................................................................................................................................................................. 20

9 PCS DISPLAY PANEL .............................................................................................................................................................. 21

9.1

LED

D

ISPLAY

I

NDICATORS

...................................................................................................................................................................... 21

9.2

PCS

DISPLAY PANEL INDICATOR SUMMARY

.......................................................................................................................................... 21

9.3

S

ERVICE

B

UTTON

...................................................................................................................................................................................... 22

9.4

B

ACKUP

P

OWER

O

PERATION

................................................................................................................................................................. 22

9.4.1 Backup Power Display Modes ............................................................................................................................................... 22

9.5

R

ESTARTING THE BATTERY SYSTEM AFTER LOW BATTERY SHUTDOWN

............................................................................................. 23

10 MAINTENANCE ....................................................................................................................................................................... 23

11 SERVICEABLE PARTS – BATTERY MODULE REMOVAL/REPLACEMENT ................................................................ 23

12 TROUBLESHOOTING ............................................................................................................................................................ 24

13 SPECIFICATIONS.................................................................................................................................................................... 25

Table 1: PCS Electrical / Mechanical Ratings ............................................................................................................................... 25

Table 2: PCS Field Wiring Ratings – AWG / Torque ................................................................................................................. 26

Table 3: Battery Cabinet Electrical / Mechanical Ratings ......................................................................................................... 26

Table 4: Battery Cabinet Field Wiring Ratings – AWG / Torque ........................................................................................... 26

13.1

UL

1741

SA

G

RID

S

UPPORT

U

TILITY

I

NTERACTIVE

I

NVERTER

S

PECIFICATIONS

.......................................................................... 27

Table 5: UL1741 SA grid support functions. ................................................................................................................................ 27

Table 7: SA9 Low and high voltage ride through settings. ..................................................................................................... 27

Table 8: SA10 Low and high frequency ride through settings. ............................................................................................. 28

Table 9: SA11 Ramp rate settings. .................................................................................................................................................. 29

Table 10: SA12 Specified power factor settings. ....................................................................................................................... 29

Table 11: SA13 Volt VAR Mode ....................................................................................................................................................... 30

Table 12: SA14 Frequency Watt settings. ................................................................................................................................... 31

Table 13: SA15 Volt Watt Settings. ............................................................................................................................................... 31

13.2

T

HERMAL PERFORMANCE

:

C

HARGE

/

D

ISCHARGE

C

URVES

.............................................................................................................. 32

APPENDIX A: BATTERY EXPANSION CABINET INSTALLATION – BATTERIES #5 TO #8 ......................................... 34

A.1

I

NITIAL

I

NSPECTION OF

M

ATERIAL

L

IST

–

TOP LEVEL SYSTEM COMPONENTS

.................................................................................... 34

2.6.1 LFP expansion install kit – mechanical parts .................................................................................................................... 34

2.6.2 LFP install kit – battery cables ................................................................................................................................................ 35

A.2

W

ALL BRACKET INSTALLATION

.............................................................................................................................................................. 36

A.3

M

OUNTING THE CABINET TO THE WALL

................................................................................................................................................. 36

A.4

B

ATTERY MODULE ASSEMBLY

................................................................................................................................................................. 36

A.5

B

ATTERY MODULE WIRING

...................................................................................................................................................................... 36

APPENDIX B: ELECTRICAL BLOCK DIAGRAM – INTERNAL .............................................................................................. 37

1

1 Safety

T is manual contains important instructions for t e Eguana Evolve™ LFP. T e components described by t is manual are intended

to be used as part of an energy storage system and installed per all local building codes and regulations in addition to t e National

Electrical Code, ANSI/NFPA 70 (for US) and Canadian Electrical Code (for Canada).

T roug out t is manual, t e following symbols will be used to ig lig t important information and procedures:

Symbol

Definition

Symbol

Definition

WARNING! A dangerous voltage or other

condition exists. Use extreme caution

when performing these tasks.

Meter measurement required.

AUTION! This information is critical to the

safe installation and or operation of the

inverter. Follow these instructions closely.

Torque rating critical to operation.

NOTE: This statement is important. Follow

instructions closely.

Login to t e remote monitoring system for

operating status

1.1 In case of emergency

In all cases:

•If safe to do so, switc off t e AC breakers (external to t e system).

•Contact t e fire department or ot er required emergency response team.

•Evacuate t e area, and if applicable, follow your emergency evacuation plan if ot ers are in proximity to t e installed

location.

In case of fire:

•W en safe, use a fire extinguis er suitable for use; including A, B, and C dry c emical fire extinguis ers or carbon dioxide

extinguis ers.

In case of flooding:

•Stay out of water if any part of t e system or wiring is submerged.

•Do not attempt to operate batteries t at ave been submerged in water even after t ey ave been dried.

In case of unusual noise, smell or smoke:

•If safe to do so, ventilate t e area.

1.2 Battery module safety precautions

T is product is integrated wit Pyltontec US3000 / US3000C series battery modules. Refer to t e Pylontec product manual for

complete safety instructions regarding andling of battery modules.

EMS

2

1.3 General safety precautions

Important! Installation, service, and operating personnel must read t is document in its entirety,

and observe all safety and installation procedures as described in t is manual. Never operate

system in a manner not described by t is manual.

Only qualified personnel s ould service t is product.

Ensure all covers are securely fastened after installation is complete.

Personal Protective Equipment (PPE) in compliance wit local work place safety standards must be worn

w en working inside t e cabinet.

Risks of Fire

Do not expose t e system to temperatures exceeding 60 degrees Celsius.

Avoid installation in direct sunlig t.

Do not store objects on top of t e cabinet.

Do not obstruct t e airflow pat s of t e cabinet air intake.

Do not obstruct t e ex aust of cabinet ex aust.

Do not store combustible objects and corrosive c emicals directly adjacent to t e system.

Risks of Shock

WARNING! Hazardous Voltages.

The Inverter contains hazardous voltage and energy that may be lethal

. It

may only be installed by qualified personnel w o ave read t is manual and are familiar wit its operation and

azards.

Only connect t e PCS cabinet to a compatible electrical service as defined in t e model specifications. T e PCS

must be connected to a dedicated branc circuit in t e main electrical panel.

Ensure proper electrical grounding in accordance wit code requirements.

CAUTION! Both

AC

and

DC

voltage sources are terminated inside this e uipment. Each circuit must be

individually disconnected before servicing

Risks of Damage

T e PCS is configured for t e Pylontec US3000 / US3000C battery module only. Do not attempt to connect any

ot er battery to t e system.

Do not connect any ot er loads directly to t e battery power bus.

Do no

t drop, tip, or puncture t e cabinet during transport and installation. Visible damage to t e cabinet and/or

internal components s ould be reported to t e manufacturer immediately.

Do not store t is system for periods longer t an six mont s wit out a battery maintenance c arge. T is may result

in permanent damage to t e batteries.

1.4 Disposal and Recycling

Do not dispose of t e system or any of t e components wit in t e cabinet. Batteries, electronics, cables, and metal parts

are recyclable. Consult your municipal waste management aut ority to determine required met ods of component

recycling.

3

2 Introduction

2.1 About this Manual – Target Audience

T is manual is intended to be used by qualified service and installation personnel for t e purposes of product installation.

T is manual contains instructions for t e installation and start up sequence of t e Eguana Evolve™ LFP; including t e PCS and

master battery cabinets. T is product is permanently wired to t e ome electrical service, and must be installed by a licensed

electrician only. T e battery capacity of t is system can be expanded by adding additional cabinets adjacent to t e base battery

cabinet. Refer to Appendix A for battery expansion installation instructions.

2.2 Installation Planning & System Commissioning - Supporting Documents

T e Evolve LFP energy storage system is operated by t e Evolve Hub. Please consult t e Evolve Hub Installation Manual for full

installation planning details, including conduit layout plans and sample single line diagrams for a complete solar plus storage

system installation. T e Evolve Hub installation manual also describes in more detail t e various operating modes and

configurations for AC coupled PV solar plus storage systems.

T e Evolve Hub’s energy management system & gateway requires installer administration and device commissioning prior to

operation of t e Evolve LFP energy storage system. Refer to t e Fleet Installer Administration Guide and t e Evolve Hub Install

and Commission Quick Guide for furt er details.

A complete list of Installer resources is available at www.eguanatec .com under t e Evolve™ product banner.

2.3 Glossary

2.4 Product markings

T e ratings label is located on t e bottom face of eac

cabinet. T e serial number / date code labels for t e system

are located as s own (rig t) wit t e front covers removed.

2.5 Special tools & hardware

T e following tools are required to complete t e installation

of t e ESS:

•Torque wrenc

•17mm socket wrenc (DC- main power

connection).

•10mm socket wrenc (battery +/- module power

connections).

•3/8” socket wrenc (DC+ main power connection).

•

Load bearing ardware for wall bracket mounting.

5/16” (M8)

Term Definition Term Definition

AC

Alternating Current

LED

Lig

t Emitting Diode

ARC

Auto Recovery Circuit

NC

/ NO

Normally Closed

/ Normally Open

CPU

Central Processing Unit

PCS

Power Control System (Inverter)

DC

Direct Current

PE

Protective Eart

EMS

Energy Management System

PV

P oto

-

Voltaic

ESD

Electrostatic D

isc arge

RF

Radio Frequency

ESS

Energy Storage System

SOC

State Of C arge (Battery)

GND

Ground

SOH

State of Healt (Battery)

All cabinets: ratings label

PCS cabinet:

s/n, date code

Battery cabinet:

s/n, date code

4

2.6 Initial Inspection of Material List – top level system components

T e system components supplied wit your Eguana Evolve™ LFP are s own below. Eac component s ould be inspected visually

for any damage t at may ave been caused by s ipment. If damage is present, please contact your local distributor.

Item Eguana P/N Description

1 ACB05U-LP PCS cabinet (and cover)

2 ACB05-PB Battery Cabinet (and cover)

3 - Wall mount bracket

4 US3000C / US3000 4 battery modules (US3000C model s own).

5 LFP install kit Assembly parts kit, cables, and manuals.

- Evolve Hub

Not s own

–

t is is an accessory. Model m

ay vary. Refer to documentation included wit

t e Evolve Hub as equipped.

1

2

3

4

5

Figure

1

: Top level system components.

5

2.6.1 LFP install kit – mechanical parts and manuals

Item Qty Eguana P/N Description

Battery Cabinet

1 1 PB kit Incl. cabinet coupler assembly, two levelling brackets, and two plugs

2 1

Breaker

Assembly DC breaker assembly

3 8 801003794 Ad esive backed battery module pads

4 1 801003757 Battery rack partition bracket (includes attac ed battery retaining clip 801003044)

PCS Cabinet

5 1 LP kit

Incl. levelling bracket, ca

binet coupler end plate, plug, and PCS

-

BMS communication cable.

The P S-BMS cable provided will match the battery type supplied with the equipment.

- 1 Doc 82013 Evolve LFP Installation and Startup Manual

- 1 Doc 58159 Evolve LFP System Owner’s Manual

5

LP kit

US3000C

U

S3000

PB kit

M4 x 25 mm

1

2

3

4

8x

Breaker assembly

M5

Figur

e

2

: LFP install kit

mechanical parts.

6

2.6.2 LFP install kit – battery cables

Item Qty Eguana P/N Description Pylon p/n

1 2 801003790 DC- module jumper BLK 180 mm WI0BSC1000B2

2 1 801003793 DC- module jumper BLK 400 mm WI0CUS300004

3 2 801003798 DC- terminal jumper BLK 400 mm WI0CUS300002

4 3 801003789 DC+ module jumper RED 180 mm WI0BSC100001

5 1 801003796 DC+ terminal jumper RED 400 mm WI0CUS300001

6 1 801003797 DC+ terminal jumper RED 700 mm WI0PUS300001

7 2 801003792 BMS jumper s ort 210 mm WI0SRJ458025

8 1 801003794 BMS jumper long 700 mm WI0SUS300002

9 4 801003791 C assis GND cable GRN/YEL 1 m WI0GUS300001

DC

-

DC +

BMS

GND

1

2

3

4

5

6

7

8

9

Figure

3

: LFP install kit

battery cables.

7

3 Installation Site Preparation

Before installing t e product, read all instructions and warnings in t is manual.

AUTION! All electrical installation work should be performed in accordance with local building and electrical codes.

WARNING! Isolate the PCS from all energy sources prior to electrical installation by means of disconnects, breakers or

connectors. Failure to properly isolate either AC or DC sources may result in serious injury or death. This system will

generate an AC voltage at the off grid terminals when DC source is applied.

AUTION! The P S cabinet weighs up to 145 lbs. (65 kg), and the battery cabinet weighs up to 320 lbs. (145 kg)

with four battery modules installed. Handle with care. T e wall to w ic t e system is mounted must be load-bearing

rated according to t e local building code. Mec anical lifts are recommended to position cabinets on t e wall bracket.

NOTE: All interconnecting cables are limited in lengt , and designed specifically for adjacent cabinet mounting using t e

manufactured wall brackets.

CAUTION! Do not install in direct sunlight. Battery performance is dependent upon operating ambient temperature.

Radiant heat absorbed in direct sunlight will greatly reduce the performance of the battery, and will prematurely cause

degradation of the display indicator panel on the PCS cabinet. The battery modules are rated for operating temperature

range between 10C to +50C. Indoor installation is recommended where ambient temperatures are outside of this range.

NOTE: T e Evolve LFP energy storage system was not evaluated in seismic environments.

3.1 Overview of PCS and Battery components

1. T e cabinets can be installed in an indoor and outdoor non-corrosive environment (not marine environment).

2. T e forced air cooling of t e PCS cabinet is designed to flow air from bottom to top.

3. T e PCS and Battery cabinets are rated Type 3R.

4. Wall mounting ardware not included. T e load-bearing wall bracket is provisioned for M8 ardware. Levelling brackets

are provisioned for M5 ardware.

3.2 Installation Area Required to Wall Mount PCS and Battery:

T e p ysical installation of t e cabinets requires t e layout planning and installation of t e system components in t e available

installation space. T e recommended installation eig t is driven by t e viewing angle of t e display panel on t e PCS cabinet.

Figure

4

: Installation clearances for the Evolve LFP energy storage system.

8

4 PCS and Battery Cabinet Wall-Mounting Instructions

1. Mount t e wall bracket to t e wall. Use t e available slot pattern to

mount to a load-bearing structure rated for t e weig t of t e final

system. T e slots accommodate a M8 (5/16”) bolt diameter.

IMPORTANT! Wall-stud mounting: A minimum of t ree wall

studs spanned wit in t e widt of t e mounting bracket are

required. A minimum of two mounting bolts are required per stud

(top/bottom).

2. (not s own) Remove t e battery cabinet from t e packaging, and stand

t e cabinet uprig t. Remove t e front cover.

3. Mount t e two leveling brackets to t e back side of t e cabinet. Eac

side of t e cabinet must ave a rubber was er in direct contact wit t e

cabinet wall.

4. Lift t e battery cabinet onto t e wall mount bracket, aligning t e wall

ooks at t e rear of t e cabinet wit t e slots on t e load-bearing face of

t e bracket.

5. Slide t e battery cabinet towards t e rig t end of t e bracket to allow

for clearance for t e PCS cabinet.

6. From t e rear side of t e cabinet, adjust t e outer wingnuts on t e

levelling brackets until t e cabinet is vertically plumb (level) to t e wall.

1

3

4

3

9

8

Figure

5

: Wall

mounting the cabinets.

6

9

7. Remove t e PCS cabinet from its packaging and stand

uprig t. (not s own). Remove t e front cover.

8. Assemble and mount t e single lower-center leveling

bracket as s own in steps 3 and 4 above.

CAUTION! T e PCS cabinet is eavy. Mec anical lift

or two persons recommended.

9. Lift t e PCS cabinet onto t e wall mounting bracket.

10. Slide t e PCS cabinet to t e left suc t at it aligns wit

t e alignment tab on t e mounting bracket.

11. From t e rear side of t e cabinet, adjust t e outer wingnut

on t e single levelling bracket until t e cabinet is vertically

plumb (level) to t e wall. (see image – step 6).

12. Insert t e PCS cabinet coupling gasket between t e two

cabinets (lower-front). Slide t e battery cabinet towards

t e left until mating to t e gasket.

13. Place t e coupling plate inside t e PCS cabinet and insert

t e four mounting bolts and was ers t roug to t e

battery cabinet side.

14. Place star was ers on t e bolts on t e battery side of t e

cabinet.

15. Mount t e battery cabinet side coupling plate, and fasten

wit t e lock nuts. Torque to 10 – 15 in-lbs.

WARNING! The mounting bolts of the flange

assembly are required to be fully secured, as they

provide the chassis grounding for the battery

cabinet. Torque nuts as specified in the specification

tables provided in this manual.

16. Continuity test: C eck t e continuity between

t e cabinets using an O m meter. T e test reading

must be zero O ms at a bare metal point inside eac

of t e PCS and battery cabinets.

17. Install t e cabinet coupler end plate (see- LP kit) to seal

t e ole on t e battery cabinet.

18. Optional: (T is is not a load bearing anc or – anc ored

conduit runs to t e PCS are satisfactory). Install screws in

leveling plates for PCS and battery cabinets by inserting a

screwdriver t roug t e ole on t e backside of t e

cabinets.

19. Plug ole on back of cabinet using by inserting t e ole

plug from t e front side.

10

Optional (

ardware

not included)

12

16

t ru

18

19

X4

17

Figure

6

: PCS cabinet and in

ter

cabinet coupler installation.

10

5 Battery Module Assembly

T e following instructions include:

•Preparation and assembly of t e battery cabinet modules and

internal wiring.

•Interconnection of t e PCS DC and communication cables to

t e battery cabinet.

Note: Overcurrent protection of the DC source is provided

internally as part of the integrated battery system. No

external DC disconnect is required.

5.1 Battery cabinet ground bus

CAUTION! A tor ue wrench is re uired to ensure the

power cables are terminated to their specifications. Over-

torque can damage t e DC breaker and/or strip t e t reads

on t e copper bus bar posts. Under-torque can result in an arc fault

azard, and risk of fire. Damage as a result of improper termination is

not covered by t e manufacturer warranty.

1. Mount t e four ground wires provided in t e battery module

grounding kit into t e 4-position ground distribution block.

5.2 DC negative power terminal assembly

2. Route t e DC negative power cable from t e PCS t roug t e

cabinet port and mount to t e DC negative power terminal.

3. Mount t e two DC negative battery module power cables,

referenced A3, (as provided in t e battery cable kit) to t e DC

negative power terminal. Offset eac power lug so t at a flus

electrical contact is made between eac of t e lugs.

4. Secure t e DC negative power cables to t e power

terminal using t e was er, lock was er, and ex nut

provided. Torque t e nut to 35 in/lbs.

Ref

P/N

Description

Pylon p/n label

A3 #3798

DC

-

terminal jumper

BLK 400 mm WI0CUS300002

P- #2925 PCS DC- power cable -

3/8”

A3

A3

1

4

2

3

3

Figure

7

: Battery cabinet ground wire and DC

negative terminal assembly.

11

5.3 Preparing battery modules for installation

T e PCS cabinet is not s own in t e following steps.

CAUTION! Ensure t e battery module power

switc es are in t e OFF position t roug out t e

following procedure.

Note: Observe t e rotation of t e modules on t e

lower and upper racks. T e lower rack is rotated

suc t at t e c assis ground terminal is at t e

bottom of t e module, w ile t e upper rack c assis ground

terminal is at t e top.

1. (not s own) Remove a battery from its packaging.

Remove t e rackmount ears, if supplied wit t e

battery.

2. Attac two ad esive-backed module pads

(included in t e battery module ardware kit) to

t e battery modules as s own. For t e lower rack

of modules, t e pads are installed on t e top face

of t e battery. For t e upper rack, t e pads are

installed on t e bottom face of t e battery.

u

pper rack

lower

rack

Figure

9

: Attaching adhesive pads to the battery modules.

12

5.4 Mounting and grounding the battery modules in the battery cabinet

1. Slide t e lower rack battery into t e cabinet as s own, and connect t e ground cable to t e ring terminal ground

connector on t e battery module as s own.

2. Pus t e module inward until making contact wit t e rear face of t e cabinet.

3. Repeat steps 1 and 2 above wit t e 2

nd

lower rack module.

4. Mount t e lower rack retaining clip.

5. Install t e battery rack partition bracket as s own using t e two M5 keps nuts provided.

Note: Remove t e retaining clip from t e bracket if mounted on t e partition bracket before proceeding wit t e following

steps:

6. Repeat steps 1 t ru 3 above wit t e upper level battery rack.

7. Mount t e two upper rack retaining clips.

2

4

5

3

6

Upper rack

lower rack

1

7

Figure

9

: Installing and grounding the battery modules.

13

5.5 Wiring the battery modules

Follow t e battery module power and communication jumper wiring

below.

5.5.1 Battery module DC /+ jumper cable wiring

Install t e cables in t e following sequence as s own.

1. Terminate t e two DC- module jumper cables referenced

A1.

2. Terminate t e DC- module jumper cable referenced A2.

3. Terminate t e two DC+ module jumper cables referenced

B1.

4. Terminate t e DC+ module jumper cable referenced B2.

5.5.2 BMS communication jumper cable wiring

Install t e cables in t e following sequence.

IMPORTANT! All module interconnecting BMS jumpers

terminate at t e [Linkport] terminals. Note t e Linkport

reference, 0 an 1, for eac port connection.

1. Terminate t e BMS jumper cable C2 between batteries #2 - 3.

2. Terminate t e BMS jumper cables C1 between batteries #1-2

and #3-4.

Ref

P/N

Description

Pylon p/n label

A1 #3790

DC

-

module jumper

BLK 180 mm WI0BSC1000B2

A2 #3793

DC

-

module jumper

BLK 400 mm WI0CUS300004

B1 #3789

DC+ module jumper

RED 180 mm WI0BSC100001

B2 #3796

DC+ breaker cable

RED 400 mm WI0CUS300001

C1 #3792

BMS jumper s ort 210

mm WI0SRJ458025

C2 #3794

BMS jumper long 700

mm WI0SUS300002

Figure

10

: Installing the battery jumper cables.

14

5.5.3 PCS to BMS communication cable

T is cable is specific to t e battery model. Refer to t e instruction t at applies only to t e battery module suppled.

1. Terminate t e PCS-BMS cable in battery #1 as s own in figure 11. T is battery is erein referred to as t e “Master” battery

module. All ot er modules sync to t e master.

Model US3000: Terminate t e PCS - BMS jumper cable in t e [CAN] port of battery #1.

Model US3000C: Terminate t e PCS – BMS / Console Y cable jumper in t e [A/CAN] and [Console] ports of battery #1.

2. Route t e ot er end of t e cable t roug t e PCS port ole and terminate in t e cable in t e [BMS OUT] port as s own in

figure 11.

3. Terminate t e two BMS jumper cables referenced C1 between batteries #1-2 and #3-4.

BMS

OUT

1

US3000C

U

S3000

#3810

#3787

Figure

11

: PCS to BMS communication cable connection.

15

5.6 DC- battery module to cabinet DC- connections

Note: T is is a continuation from section 5.2. T e cables referenced A3 s ould already be terminated at t e cabinet DC-

terminal.

1. Connect t e DC- power cables referenced A3 to t e DC-

terminals of batteries 1 and 4 as s own.

Ref

P/N

Description

Pylon p/n label

A3 #3798

DC

-

terminal jumper

BLK 400 mm WI0CUS300002

Figure

12

: DC

battery module to DC

cabinet

connections.

Table of contents

Other Eguana Switch manuals

Popular Switch manuals by other brands

LEGRAND

LEGRAND Radiant Series installation guide

Smartwares

Smartwares SH5-RBS-04A instruction manual

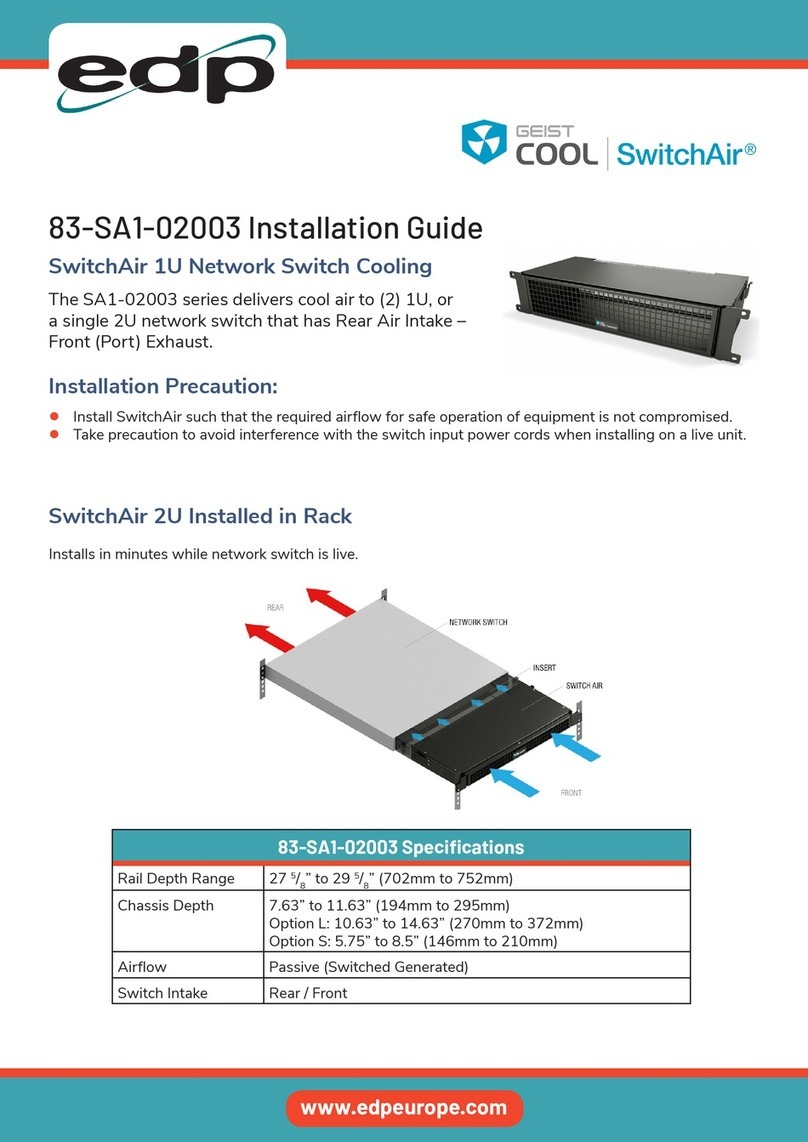

EDP

EDP GEIST COOL SwitchAir SA1-02003 Series installation guide

UWT

UWT RF 3000 Series Technical Information/Instruction manual

United Electric Controls

United Electric Controls B117 Installation and maintenance instructions

Cisco

Cisco Nexus 7000 Series Hardware Installation and Maintenance