ehb electronics MCflex User manual

Translation of the original operating instructions

Most recent revision: 08/05/2018

Version: 3.0

Engine controller

MCflex

2

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Device Engine controller MCflex

Serial number Enter the serial number of your device here:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

ehb product

number

ehb5200x

Publisher ehb electronics gmbh

Hans-Böckler-Straße 20

30851 Langenhagen

GERMANY

Tel: +49( 0)511 12 32 07 - 0

Fax: +49( 0)511 12 32 07 - 77

E-mail: [email protected]

www: www.ehb-electronics.de

www.ehbservice.de

www.ehbshop.de

The document is protected by copyright. All rights reserved. Copying, reproduc-

tion, translation or conversion into an electronic medium or into a machine-read-

able form, as a whole document or in partial sections, is not permitted without the

approval of ehb electronics gmbh.

Subject to change without notice.

Suggestions and

tips

... about this document or the device can be sent to the above address.

Last modification 08/05/2018

Version 3.0

Table of Contents

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

3

1 DEVICE INFORMATION _________________________________________________________ 6

1.1 SPECIFICATIONS ................................................................................................................... 6

1.2 TYPE PLATE ......................................................................................................................... 6

1.3 SCOPE OF DELIVERY ............................................................................................................ 6

1.4 INTENDED USE...................................................................................................................... 7

1.5 IMPROPER USE ..................................................................................................................... 7

1.6 FUNCTIONAL DESCRIPTION.................................................................................................... 7

1.7 TECHNICAL DATA ................................................................................................................. 8

1.8 SPARE PARTS ...................................................................................................................... 9

1.9 EU DECLARATION OF CONFORMITY .................................................................................... 10

2 INFORMATION FOR THE READER _______________________________________________ 12

2.1 VALIDITY ............................................................................................................................ 12

2.2 TARGET GROUP.................................................................................................................. 12

2.3 ILLUSTRATIONS .................................................................................................................. 12

2.4 ABBREVIATIONS USED ........................................................................................................ 13

2.5 HIGHLIGHTING IN THE TEXT ................................................................................................. 14

2.5.1 PICTOGRAMS AND SYMBOLS ............................................................................. 14

2.5.2 NAVIGATION PATH ............................................................................................ 15

2.5.3 SAFETY INFORMATION ...................................................................................... 15

2.5.4 WARNINGS....................................................................................................... 15

2.5.5 HANDLING INSTRUCTION ................................................................................... 15

3 SAFETY _____________________________________________________________________ 16

3.1 SAFETY INFORMATION ........................................................................................................ 16

3.1.1 INFORMATION ABOUT OPERATIONAL SAFETY ...................................................... 16

3.1.2 INFORMATION ABOUT INITIAL COMMISSIONING .................................................... 16

3.1.3 INFORMATION ABOUT OPERATION ...................................................................... 16

3.1.4 INFORMATION ABOUT DECOMMISSIONING AND STORAGE..................................... 16

3.1.5 INFORMATION ABOUT MAINTENANCE AND REPAIRS ............................................. 17

3.1.6 INFORMATION ABOUT ENVIRONMENTAL PROTECTION .......................................... 17

3.1.7 IMPERMISSIBLE OPERATING CONDITIONS ........................................................... 17

3.2 DUTIES OF THE OPERATOR ................................................................................................. 18

3.3 LOCAL REGULATIONS ......................................................................................................... 18

3.4 QUALIFICATION OF PERSONNEL .......................................................................................... 19

3.5 PICTOGRAMS AND SYMBOLS ON THE DEVICE ....................................................................... 19

3.6 RESIDUAL RISK .................................................................................................................. 20

4 PARTS OF THE DEVICE________________________________________________________ 22

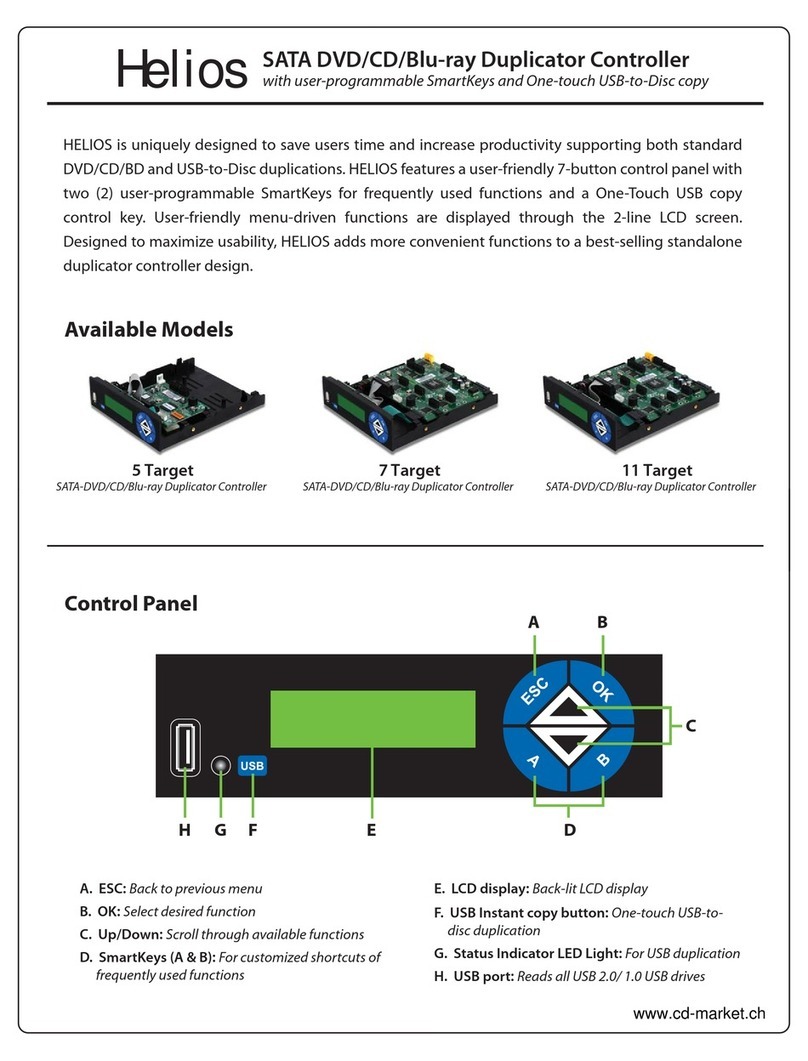

4.1 FRONT OF DEVICE .............................................................................................................. 22

4.2 DISPLAY VIEWS .................................................................................................................. 23

4.2.1 OPERATING PARAMETERS................................................................................. 23

4.2.2 DAILY OPERATING DURATION ............................................................................ 24

4.2.3 TOTAL OPERATING DURATION ........................................................................... 24

4.3 REAR OF DEVICE ................................................................................................................ 24

4.4 BOTTOM OF DEVICE............................................................................................................ 25

4

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

5 UNPACKING, CONNECTING AND INSTALLING_____________________________________ 26

5.1 UNPACKING ........................................................................................................................ 26

5.2 CONNECTING ...................................................................................................................... 27

5.2.1 CONNECTION DIAGRAM AND PIN ASSIGNMENT .................................................... 27

5.2.2 CIRCUIT DIAGRAM............................................................................................. 28

5.2.3 CONNECTING THE DEVICE ................................................................................. 29

5.3 MOUNTING ......................................................................................................................... 30

5.3.1 TECHNICAL DRAWING........................................................................................ 30

5.3.2 MOUNTING THE DEVICE..................................................................................... 30

6 PARAMETRIZATION ___________________________________________________________ 34

6.1 DESIGN OF THE DISPLAY IN PARAMETRIZATION MODE........................................................... 34

6.2 NAVIGATING IN PARAMETRIZATION MODE ............................................................................. 34

6.3 PARAMETRIZING THE DEVICE ............................................................................................... 34

7 MENUS IN PARAMETRIZATION MODE____________________________________________ 35

7.1 OVERVIEW.......................................................................................................................... 35

7.2 MAIN MENU ........................................................................................................................ 36

7.3 SUBMENU – SETTINGS ........................................................................................................ 36

7.3.1 [1] SETTINGS.................................................................................................... 36

7.3.2 SUBMENU LANGUAGE........................................................................................ 37

7.3.3 SENSOR SUBMENU ........................................................................................... 38

7.3.4 HIGH-POWER OUTPUT SUBMENU ....................................................................... 40

7.3.5 GLOW TIMES SUBMENU ..................................................................................... 46

7.3.6 GENERATOR.ER SUBMENU................................................................................ 49

7.3.7 AUTOSTART SUBMENU ...................................................................................... 49

7.3.8 FAULT EVENT SUBMENU .................................................................................... 51

7.3.9 FAULT TIMES MENU........................................................................................... 54

7.3.10 LIMIT VALUES SUBMENU .................................................................................... 57

7.3.11 INPUTS/OUTPUTS SUBMENU .............................................................................. 59

7.4 SUBMENU – SERVICE.......................................................................................................... 61

7.4.1 [2] SERVICE ..................................................................................................... 61

7.4.2 [1] SERVICE SETTINGS ...................................................................................... 62

7.4.3 [2] FAULT LIST.................................................................................................. 62

7.4.4 [3] F.L. DELETE ................................................................................................ 63

7.5 SUBMENU – SAFETY ........................................................................................................... 63

7.5.1 [3] SAFETY....................................................................................................... 63

7.5.2 SUBMENU – PIN NUMBERS ............................................................................... 63

7.5.3 SUBMENU – SELF-TEST .................................................................................... 64

7.6 SUBMENU – DAILY OPERATING HOURS COUNTER ................................................................ 65

7.6.1 [4] DAY COUNTER............................................................................................. 65

7.6.2 SUBMENU – DAY COUNTER ............................................................................... 65

7.7 SUBMENU – OPERATING HOURS COUNTER .......................................................................... 65

7.7.1 [5] OHC COUNTER ........................................................................................... 65

7.7.2 SUBMENU – OHC – MENU ............................................................................... 66

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

5

8 CANBUS FUNCTIONS _________________________________________________________ 67

8.1 FUNCTIONS AND DISPLAY DEVICES ...................................................................................... 67

8.2 MESSAGE ON DEN CANBUS ............................................................................................... 67

8.2.1 PGN 61444 ELECTRONIC ENGINE CONTROLLER 1 - EEC1 ............................... 67

8.2.2 PGN 65253 ENGINE HOURS, REVOLUTIONS - HOURS..................................... 67

8.2.3 PGN 65262 ENGINE TEMPERATURE 1 - ET1.................................................... 68

8.2.4 PGN 65263 ENGINE FLUID LEVEL/PRESSURE 1 - EFL/P1 ................................ 68

8.2.5 PGN 65271 (R) VEHICLE ELECTRICAL POWER 1 - VEP1.................................. 68

8.2.6 PGN 65269 AMBIENT CONDITIONS – AMB....................................................... 68

8.2.7 PGN 65276 DASH DISPLAY - DD..................................................................... 68

8.2.8 PGN 65278 AUX WATER PUMP PRESSURE- AWP ........................................... 69

8.2.9 ACTIVE DIAGNOSTIC TROUBLE CODES (DM1) ................................................... 69

8.2.10 PGN 42496 (R) AUXILIARY INPUT/OUTPUT STATUS 3 - AUXIO3 ...................... 69

8.3 MESSAGE FROM CANBUS .................................................................................................. 71

8.3.1 PGN 57344 CAB MESSAGE 1 - CM1 ............................................................... 71

9 OPERATION _________________________________________________________________ 72

9.1 SETTING PULSES PER ROTATION ......................................................................................... 72

9.1.1 SPEED MEASUREMENT USING AN INITIATOR (PICK UP) ........................................ 72

9.1.2 SPEED MEASUREMENT BASED ON THE PULSES OF THE "W” TERMINAL AT PIN 13. 73

9.2 INITIAL COMMISSIONING ...................................................................................................... 73

9.2.1 INFORMATION ABOUT INITIAL COMMISSIONING .................................................... 73

9.2.2 CARRYING OUT INITIAL COMMISSIONING............................................................. 74

9.3 OPERATING THE DEVICE ..................................................................................................... 74

9.4 SETTING THE DEVICE MODE ................................................................................................ 74

9.5 COMMISSIONING ................................................................................................................. 75

9.5.1 REQUIREMENTS FOR COMMISSIONING ............................................................... 75

9.5.2 SWITCHING ON THE DEVICE .............................................................................. 75

9.6 SWITCHING OFF THE DEVICE ............................................................................................... 75

9.7 OPERATIONAL FAULTS........................................................................................................ 76

10 MAINTENANCE, REPAIR AND DISPOSAL _________________________________________ 77

10.1 INFORMATION ABOUT MAINTENANCE AND REPAIRS .............................................................. 77

10.2 FAQ.................................................................................................................................. 77

10.3 REPAIR .............................................................................................................................. 77

10.4 CLEANING .......................................................................................................................... 78

10.5 COMMUNICATION WITH PC (OPTIONAL) ............................................................................... 78

10.6 DISPOSAL .......................................................................................................................... 78

10.6.1 DISPOSAL OF DEVICES...................................................................................... 78

10.6.2 DISPOSAL OF BATTERIES AND RECHARGEABLE BATTERIES ................................. 79

Specifications

Device information

6

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

1 Device information

1.1 Specifications

Enter the serial number of your device in the field with the dashed line.

1.2 Type plate

The type plate is located on top of the housing of the device.

Representation of the type plate

1.3 Scope of delivery

The following parts are included in the scope of delivery of the device:

•one device "MCflex”

•two ignition keys

•one label "Do not clean with high-pressure cleaner”

•two mounting brackets

Specifications of the device

Device name Engine controller

Device type MCflex

Serial number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

ehb product number ehb5200x

Legend

No. Designation Function

1Serial number Represents a unique and unambiguous number for

identification of the device.

2Date of manufacturer Represents the date of manufacturer in the "month -

year” format.

3ehb product number Represents the ehb product number of the device

series.

4Operating voltage Represents the operating voltage with which the device

may be operated.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

7

Intended use

Device information

1.4 Intended use

This device is exclusively used to start and monitor mechanically controlled combustion

engines in machines.

The device is for the following use only:

•starting and monitoring the mechanically controlled combustion engines of mobile and

stationary construction machines

•starting and monitoring the mechanically controlled combustion engines of inland ships

Intended use also includes compliance with all specifications in these Translation of the orig-

inal operating instructions.

1.5 Improper use

Any use not mentioned in section "Intended use" (Page 7) is considered improper and may

result in personal injury and property damage.

The device is expressly not intended for the following:

•starting and monitoring the mechanically controlled combustion engines of road vehicles

•starting and monitoring the mechanically controlled combustion engines of aircraft

•starting and monitoring the mechanically controlled combustion engines of helicopters

•starting and monitoring the mechanically controlled combustion engines of deep-sea

vessels

•Unauthorised structural changes

•Unauthorised repairs

Info

The manufacturer is not liable for damage caused by improper use of the device. The risk for

this is borne solely by the user or operator.

The guarantee expires in the event of improper use.

1.6 Functional description

The device offers a multitude of functions for the control and monitoring of conventionally

controlled combustion engines. You can individually configure the settings for very diverse

applications and different engine variants. The device is capable of pre-glowing, by-glowing

and after-glowing the engine to up to 70 A, using time or temperature variables. Oil pressure

and engine temperature can be monitored with switches or sensors. One additional input is

provided for monitoring the generator. The operating magnet is actuated by the outputs for

excitation and pick-up winding. There is also an alarm output available. The engine can be

switched off via an "external stop” input (hood switch , cover switch / housing switch, for

example).

Technical data

Device information

8

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

In the event of a fault, the display returns a corresponding message after an adjustable delay

time and an LED illuminates. If a corresponding function is programmed, the engine is

switched off. The input lock allows the clear identification of the cause of error and requires an

active acknowledgement of the fault message.

By pressing the arrow keys of the device, the operating hours, oil pressure, temperature and

number of revolutions of the engine are displayed in sequence on the two-line display. Other

parameters can be displayed using customised software.

1.7 Technical data

Electrical data

Voltage range 6 V to 32 V (typically 12 V to 24 V)

Current consumption typically 50 mA (for UB 8 V to 24 V)

Operating temperature -20°C to+70°C

Storage temperature -30°C to+80°C

Inputs Inputs:

•PIN 01 | Oil pressure as NO/NC, programmable,

switching or analogue sensor

•PIN 02 | Generator monitoring, terminal D+

•PIN 03 | Temperature as NO/NC, programmable,

switching or analogue sensor

•PIN 04 | Diverse, NO/NC

•PIN 07 | Autostart, NO/NC

•PIN 09External stop, NO/NC

•PIN 13 | Speed monitoring, terminal W, sensor or

magnetic pick-up

Outputs Outputs:

•all outputs are short circuit-proof

•PIN 02 | Generator excitation, terminal D+, 0.5 A

•PIN 06 | Freely parametrisable, 7.5 A (maximum 1s)

/ 6.0 A

•PIN 08 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

•PIN 10 | Freely parametrisable, 70 A (maximum 1s)

/ 35 A

•PIN 11 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

•PIN 12 | Freely parametrisable, 70 A (maximum 1s)

/ 35 A

•PIN 15 | Freely parametrisable, 3.5 A (maximum 1s)

/ 3.0 A

•PIN 18 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

CAN bus interface PIN 17 / 19, CAN2.0B, 250kBit, SAE J1939, EEC1, ET1,

EFL/P1, VEP1, AMB, DM1 fault alarms/auto start, speed

adjustment, optionally adaptable

Operating hours counter Integrated

Daily operating hours counter Integrated

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

9

Spare parts

Device information

1.8 Spare parts

No spare parts are available for this device. If the device is faulty, contact the manufacturer.

Visualisation

Display type Dot matrix LCD, transflective, dark-blue representation,

grey background

Resolution 16 x 2 characters, 5 x 8 dots per character

Brightness >1,000 cd/m²

Contrast ratio (CR) 8.24

Background lighting LED, white

Mechanical data

Housing dimensions (L x W) 72 mm x 72 mm

Installation dimensions (W x H x

D)

66 mm x 66 mm x 130 mm

Installation cut-out (W x H) 66 mm x 66 mm

Housing material PA 6 30 GB, black, UV-stabilised

Weight 340 g

Installation Mounting bracket or screw-fastening, 3 x M6

Protection class IP67

Connection Deutsch connector type HDP24-24-19PE

Test standards

Humidity DIN EN 60068-2-3

Vibration DIN EN 60068-2-6

Shock DIN EN 60068-2-27

CE marking According to Directive 2014/30/EU

Accessories

Connection cable, 19-pole, 3 m ehb2268

Deutsch plug set ehb1469

CANdongle with PC software

ehbTools

ehb5365

MCflex starter kit

CAN dongle, ehbTools,

connecting cable, power supply

unit

ehb5378

EU Declaration of Conformity

Device information

10

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

1.9 EU Declaration of Conformity

EU Declaration of Conformity according to EMC Directive (1/2)

(8'HFODUDWLRQRI&RQIRUPLW\

DFFRUGLQJWR'LUHFWLYH(8$QQH[,9

'HYLFHW\SH (QJLQHFRQWUROOHU0&IOH[

HKESURGXFWQXPEHU HKE[

0DQXIDFWXUHU HKEHOHFWURQLFVJPEK

+DQV%|FNOHU6WUDH

/DQJHQKDJHQ

7KHPDQXIDFWXUHULVVROHO\UHVSRQVLEOHIRULVVXLQJWKLVGHFODUDWLRQRIFRQIRUPLW\

7KHVXEMHFWPDWWHURIWKHGHFODUDWLRQGHVFULEHGDERYHFRPSOLHVZLWKWKHUHOHYDQW

KDUPRQLVDWLRQOHJLVODWLRQRIWKH8QLRQ

(8 (OHFWURPDJQHWLFFRPSDWLELOLW\

(8 /RZYROWDJH'LUHFWLYH

(8 5R+6'LUHFWLYH

(8 :DVWH(OHFWULFDODQG(OHFWURQLF(TXLSPHQW'LUHFWLYH

(& 3URGXFW6DIHW\'LUHFWLYH

7KHGHYLFHFRPSOLHVZLWKWKHVWDQGDUGVOLVWHGEHORZ

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW*HQHULF

VWDQGDUGV(PLVVLRQVWDQGDUGIRULQGXVWULDOHQYLURQPHQWV

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(PLVVLRQDQGLPPXQLW\WHVWLQJLQ

WUDQVYHUVHHOHFWURPDJQHWLF7(0ZDYHJXLGHV

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(OHFWURVWDWLFGLVFKDUJHLPPXQLW\

WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV5DGLDWHGUDGLRIUHTXHQF\

HOHFWURPDJQHWLFILHOGLPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(OHFWULFDOIDVWWUDQVLHQWEXUVW

LPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV6XUJHLPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV,PPXQLW\WRFRQGXFWHG

GLVWXUEDQFHVLQGXFHGE\UDGLRIUHTXHQF\ILHOGV

',1(1 (QYLURQPHQWDOWHVWLQJ3DUW7HVWV7HVW)F9LEUDWLRQ

VLQXVRLGDO

,62 5RDGYHKLFOHV9HKLFOHWHVWPHWKRGVIRUHOHFWULFDOGLVWXUEDQFHV

IURPQDUURZEDQGUDGLDWHGHOHFWULFHQHUJ\3DUW*HQHUDO

SULQFLSOHVDQGWHUPLQRORJ\

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

11

EU Declaration of Conformity

Device information

EU Declaration of Conformity according to EMC Directive (2/2)

As soon as the device is improperly used, this declaration and the guarantee claim will expire.

7KHQRWLILHGERG\0DUWLQ3IHLO75$:,'*PE+5HIKDVSHUIRUPHGDQ

HOHFWURPDJQHWLFFRPSDWLELOLW\WHVWDQGLVVXHGWKHIROORZLQJ(8W\SHH[DPLQDWLRQ

FHUWLILFDWH

'HYLFH 0&IOH[

$FFHVVRULHV

6LJQDWRULHVIRUDQG

RQEHKDOIRI

HKEHOHFWURQLFVJPEK

+DQV%|FNOHU6WUDH

/DQJHQKDJHQ

/DQJHQKDJHQGDWH

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

3ODFHGDWH %HUQG5HLQPROG0DQDJHU

Validity

Information for the reader

12

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

2 Information for the reader

2.1 Validity

Safety information: Carefully read the Translation of the original operating instructions

Carefully read through these Translation of the original operating instructions before use.

Keep these Translation of the original operating instructions for future consultation.

These Translation of the original operating instructions contain information and rules of

conduct for the safe use of the device.

Please hand over the Translation of the original operating instructions when passing on the

device.

To operate the device effectively, the Translation of the original operating instructions provide

you with information on the following topics, among others:

•Connecting and mounting the device

•Putting the device into operation

•Making settings on the device

•Maintaining the device

•Disposing of the device

2.2 Target group

These Translation of the original operating instructions are intended for the operator, user and

service personnel of the machine with integrated device "MCflex”.

Info

The service personnel must have certain qualifications in order to work on or with the device.

You can find the qualification of personnel in chapter "Safety" > "Qualification of personnel"

(Page 19).

2.3 Illustrations

The illustrations in these operating instructions show the device in simplified form in some

cases.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

13

Abbreviations used

Information for the reader

2.4 Abbreviations used

The following abbreviations are used in these operating instructions:

Abbreviations used

°C Degrees Celsius

AAmpere

AW Pick-up winding

bar Unit of pressure [force/area]

OHC Operating hours counter

Cd Cadmium

ECU Electronic Control Unit

FMI Failure Mode Identifier

GND Ground

hhours

Hg Mercury

HW Excitation winding

ID Identification

PPR Pulses per rotation

kg kilogram

LCD Liquid Crystal Display

LED Light Emitting Diode

mA Milliampere

NC Normally Closed

NO Normally Opened

NTC Negative Temperature Coefficient

Pb Lead

PC Personal Computer

PTC Positive Temperature Coefficient

ssecond

SPN Suspect Parameter Number

rpm revolutions per minute

VVolt

ZSS Ignition starter switch

Highlighting in the text

Information for the reader

14

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

2.5 Highlighting in the text

In these Translation of the original operating instructions, important information is highlighted

with pictograms, symbols or special notations. The following examples show the most impor-

tant highlights.

2.5.1 Pictograms and symbols

Pictograms and symbols

Pictogram /

symbol

Meaning

Further useful information.

Conditions that must be met to perform an action.

Tool or material required to perform an action.

The disposal of electrical and electronic equipment with household waste is

not permitted.

The disposal of rechargeable batteries and other batteries with household

waste is not

permitted.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

15

Highlighting in the text

Information for the reader

2.5.2 Navigation path

The following representation helps you to navigate through the menus. Here you can see the

path of the menus that must be selected one after the other in order to reach the desired

submenu. In the digital version of the operating instructions, you can jump to the menu item

by clicking on the relevant path.

Main menu (page 0) > Submenu (page 0) > Current submenu (page 0)

2.5.3 Safety information

Safety information: Special note for an informative section.

Explanation of the note.

•This item indicates measures to take the note into account.

2.5.4 Warnings

WARNING

Warning of serious injuries.

Failure to follow the warning may result in serious damage to health or even death.

►The arrow indicates a precautionary measure that you must take to avert the hazard.

NOTICE

Warning of material damage.

Failure to observe the warning notice can result in considerable damage to the device or its

surroundings.

►The arrow indicates a precautionary measure that you must take to avert the hazard.

2.5.5 Handling instruction

Complete the following work steps: = Start of a handling instruction.

1. First step in a sequence of actions.

Required settings . . . . . . . . . . . . . .

Setting values

2. Second step in a sequence of actions.

▼Result of this step.

» Done Handling is completed, the goal is achieved.

Safety information

Safety

16

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

3 Safety

3.1 Safety information

This safety information is addressed to the operator, user and service personnel of the

device.

3.1.1 Information about operational safety

The device is safe to operate. It was built according to the current state of science and tech-

nology.

However, the device may constitute a hazard:

•if the device is used not as intended.

•if the device is improperly used.

•If the device is operated under impermissible conditions.

Safety information: Protect against unauthorised opening!

The device has a protective seal to prevent it being opened without authorisation. Note that

any unauthorised opening of the device will lead to it being irreparably damaged.

The following information applies to everyone who works on or with the device:

•Never insert any objects into the device openings not intended for this purpose. There is

a risk of interfering with the electronics.

•Protect the locking cylinder of the ignition starter switch from penetrating dirt and water.

•Only open a battery master switch in an emergency or when the engine is at standstill

and the device is switched off.

•When operating the device, comply with the general accident prevention regulations.

•Operate the device under the conditions specified by the manufacturer (see page 8:

Device information > Technical data).

•Never open the housing of the device. The device does not contain components that can

be serviced, replaced or repaired by the customer or third-party service personnel.

3.1.2 Information about initial commissioning

The following principles apply for initial commissioning:

•Make sure that the device is only connected and installed by personnel qualified for this.

•Make sure that no one can be injured when switching on the device.

3.1.3 Information about operation

Safety-conscious and precautionary behaviour of personnel avoids dangerous situations

during operation.

Observe the following points when handling the device:

•The device may only be connected and installed by personnel qualified for this. Observe

the information from the manufacturer of the plugs and cable harnesses.

•The environment must be free of interfering electrical installations (high frequency) and

electromagnetic compatibility (EMC Directive) must be observed.

•Never make any structural changes to the device.

•Only operate the device with accessories approved by the manufacturer.

3.1.4 Information about decommissioning and storage

The following principles apply for decommissioning and storage:

•Clean all dirt from the device.

•Store the device according to the specifications of the manufacturer (see page 8: Device

information > Technical data).

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

17

Safety information

Safety

3.1.5 Information about maintenance and repairs

The following principles apply for maintenance and repairs:

•The device requires no maintenance and no special actions.

•Only clean the device with a mild cleaning agent.

•Never clean the device with a high-pressure cleaner.

•The device is to be shipped either in its original packaging or in suitable sturdy alternative

packaging. Improper packaging is regarded as negligence and results in any claims for

repair under guarantee being forfeited.

3.1.6 Information about environmental protection

Safety-conscious and precautionary behaviour of personnel avoids adverse effects on the

environment.

All packaging materials and devices are equipped with markings and test seals for proper and

professional disposal.

The following principles apply for environmentally-friendly actions:

•Always comply with the regulations for the prevention, disposal and recycling of waste.

•Always dispose of packaging materials and electrical devices and their components

through collection points or disposal companies authorised for this.

•Used electrical devices and electronic devices must not be disposed of with household

waste.

The devices comply with legal requirements, in particular the Electrical and Electronic Equip-

ment Act and the REACH Regulation.

3.1.7 Impermissible operating conditions

Operational safety cannot be guaranteed under impermissible operating conditions. Always

avoid impermissible operating conditions.

Do not operate the device under the following conditions:

•Operation could injure persons.

•Objects could be damaged or destroyed unintentionally during operation.

•Malfunctions have been detected.

•Damage has been detected.

•Impermissible changes to operating parameters have been made.

•For example, the device has been modified.

Duties of the operator

Safety

18

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

3.2 Duties of the operator

This chapter contains information on the duties of the operator of the machine in which the

device is installed.

It is the operator’s duty of care to plan safety measures and to check their implementation.

The following principles apply to minimise the risk of injury:

•Make sure that damaged devices are no longer used.

•Make sure that the device is installed and connected by authorised specialist personnel.

The following principles apply for faultless operation:

•Only use the device for its intended purpose.

•Only operate the device when it is in a perfect and functional condition.

•Make sure that the device is never opened by personnel. Damage caused by opening the

device will void the warranty.

•Make sure that the device is properly transported and stored by personnel.

•Make sure that the device is never cleaned with a high-pressure cleaner. Give the service

personnel comprehensive instructions that cleaning with a high-pressure cleaner will

cause damage and that the warranty will be excluded.

Info

Carry out regular checks. This allows you to ensure that these measures are actually

followed.

3.3 Local regulations

In addition to these instructions, correct operation of the device is regulated by laws and regu-

lations.

The following regulations also apply for the operation of the device:

•Regulations for operating machines in which the device is installed (laws and regulations

not expressly mentioned here as well).

•Accident prevention regulations.

•Internal company regulations.

•Information on the device.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

19

Qualification of personnel

Safety

3.4 Qualification of personnel

All work on the device requires special training of the personnel.

Everyone working on the device must meet the following requirements:

•Persons between the ages of 14 and 18 may only work on and with the device under the

supervision of a person trained to use the device.

•Personally suitable for the respective activity.

•Sufficiently qualified for the respective activity.

•Trained to handle the device.

•Familiar with these operating instructions, especially with safety information and with the

sections that are relevant for the activity.

•Familiar with basic occupational safety and accident prevention regulations.

These operating instructions distinguish between the following user groups:

3.5 Pictograms and symbols on the device

Pictograms and symbols are attached to the device. The following table explains the mean-

ings of the pictograms and symbols.

User groups

Personnel Qualification

Operating

personnel

Training by the operator of the machine in which the device is installed.

The following topics must be covered in this training:

•Intended operation of the device

•Correct behaviour in the event of malfunctions, errors, damage

•Cleaning the device

•Competences and responsibilities for the activity

The required knowledge for the operating personnel is given in these

operating instructions. The operator must train the user to use the

machine in which the device is installed. Operating personnel must have

read and understood the operating instructions.

Service

personnel

Training as a mechatronics engineer or at least equivalent training.

The tasks of the service personnel include the following activities:

•Connecting the device

•Mounting the device

•Parametrizing the device

Service personnel must have sound knowledge of the design and func-

tion of the device and must have read and understood the operating

instructions.

Pictograms and symbols on the device

Pictogram /

symbol

Meaning

Prohibited: Cleaning with a high-pressure cleaner is prohibited.

Residual risk

Safety

20

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

3.6 Residual risk

The device is built according to the currently valid rules of technology and is safe to operate.

The device has been tested and has left the factory in a perfectly safe condition.

Residual hazards cannot be completely ruled out. Safety-conscious and precautionary behav-

iour of personnel avoids dangerous situations. Read and observe the safety information and

warnings to prevent risks.

Residual risks at the device and measures

Danger Cause Measure

Material damage due to

missing protective func-

tion of the starter!

The starter of the

engine can be damaged

due to the missing

signal. The signal is

required for the inte-

grated protective func-

tion of the starter.

Make sure that a speed signal is

connected to pin 13 (terminal "W”).

Make sure that the transmission ratio

(PPR) and the maximum start speed are

set correctly.

Material damage due to

incorrect wiring of the

outputs!

If the outputs are

connected in parallel,

there is a risk that tran-

sistors may blow.

Never connect the outputs in parallel.

Risk of injury due to

misuse of pin 9

(external stop) for the

emergency stop func-

tion of the engine!

Misuse of pin 9

(external stop) for the

engine emergency stop

function may cause

serious injury at parts of

the engine. The input is

not designed for this

purpose. This can result

in delays of up to one

second.

Never use pin 9 (external stop) for the

emergency stop function of the engine!

Material damage due to

incorrect type of instal-

lation!

Installation with

mounting brackets is

intended exclusively for

locations without the

influence of vibrations. If

the device with

mounting brackets is

mounted at locations

subject to vibration,

there is a risk of serious

damage to the device!

Mount the device at locations subject to

vibration with rubber-bonded metals

(accessories).

Only carry out installation with mounting

brackets if you can ensure that no vibra-

tions can have an effect! (For example,

in a switch cabinet)

Material damage due to

load on ignition starting

switch!

If weight is attached to

the ignition key (e.g.

heavy keychain,...),

there is a risk of

damaging the ignition

lock.

Do not hang any other weight or other

objects on the ignition key.

Table of contents

Other ehb electronics Controllers manuals