CHIAROSCURO SLIDE.80 Technical specifications

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 1di 16

S

LIDING

S

HUTTERS

A

CTUATOR

U

SE AND

I

NSTALLATION

M

ANUAL

English Version

This manual isa part ofthe kit and has to be warded in a adequate wayin order to maintain its integrity and to

permit the consultation during the entire life of device.

Have a precise consulting of this manual before any intervention to the device.

The Fabricator has the capabilitydi afford changes to the production and to the manual , without the onus of

updatingto the precedent versions of productions and manuals.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 2di 16

Indice

1. INTRODUCTION.........................................................................................................................................3

2. GENERAL INFORMATIONS...................................................................................................................3

2.1 D

EFINITIONSAND

S

YMBOLS

..................................................................................................................3

3. PRODUCER ID CODES..............................................................................................................................4

3.1 T

ECHNICAL ASSISTANCE AND ORDINARY MAINTENANCE

....................................................................4

4. FEATURESAND DATA SHEETS............................................................................................................5

4.1 L

AW

R

EFERENCE

...................................................................................................................................6

5. GENERALITY...............................................................................................................................................7

6. RECEIVINGANDSTORAGING..............................................................................................................7

6.1 T

O CONTROL AT THE RECEIVING OF DEVICE

.........................................................................................7

6.2 S

TORAGING

............................................................................................................................................7

7. MECHANIC MOUNTING INSTRUCTIONS.........................................................................................8

7.1 N

ECESSARY FOR

I

NSTALLATION

............................................................................................................8

7.2 T

O

V

ERIFY FOR AGOOD INSTALLATION

................................................................................................8

7.3 S

IZES

V

ERIFY

..........................................................................................................................................9

7.4 M

OTOR INSTALLATION

........................................................................................................................10

7.4.1 Fixing the motor to the rail......................................................................................................10

7.4.2 Positioning and fixing the belt ................................................................................................10

7.4.3 Completion of the mechanic installation of sliding system...................................................11

7.4.4 Fixing the dragging bracket to the shutter.............................................................................11

7.5 ELECTRICAL

CONNECTIONS......................................................................................................12

7.5.1 Electrical scheme.....................................................................................................................12

7.5.2 Configuration Slide.80.............................................................................................................13

7.5.3 Dead Man Program.................................................................................................................13

7.5.4 Automatic Program..................................................................................................................13

8. MAINTENANCE.........................................................................................................................................14

8.1 P

ERIODICALMAINTENANCE

.................................................................................................................14

8.2 S

PECIAL MAINTENANCE

.......................................................................................................................14

9. DRAWBACKS ANDANOMALIES........................................................................................................14

10. DISPATCHING......................................................................................................................................15

11. -ATTACHED.1 – SERVICE REQUEST - SUPPLIES...................................................................15

12. COMPATIBILITY CERTIFICATION TO CE MARK................................................................16

13. WARRANTY..........................................................................................................................................16

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 3di 16

1.

I

NTRODUCTION

Dear Customer,

Giving thanks to You choosing our product, we recommend to You to follow meticulously the indications of this

manual that will give to You an optimal support for a good using and to maintain the device characteristics

unchanged in time. CHIAROSCURO SAS by Girelli Marco & C.

2. GENERAL

INFORMATIONS

This users manual is an integral part of the device kit and is an essential support during the montage and during the

use of this device. Read it all and meticulously before starting the montage. In case of resale this manual has to

attend with the device. Is FORBIDDEN the partial or total replication of this document without a specific written

authorization of CHIAROSCURO SAS.

2.1 Definitions and Symbols

The following paragraphs relates a series of definitions, terminologies and symbols that You will find during the

reading of this manual .

Symbol Description

Operator: (O.) Operator without specific competences, who can use the device in normal condition of

using and can do simple operations of maintenance.

Electromechanical Dealer: (E.D.) technician who has the competences to install mechanical -

hydraulic – pneumatic devices and who can accomplish regulations, maintenances or repairs and can

work in presence of High Voltage inside , derivation boxes and electrical installations .

Homebuilder Technician: (H.T.) Qualified technician commissioned by the homebuilder disposal to do

complicated operations in particular situations or, however, what arranged with the user. Expertness

depends by the cases, mechanic and/or electric and/or electronic and/or software.

Note: Indicate important indications or information contained in the users manual, for the best way to

use the device.

Danger:Indicate a situation that could cause injuries, at least lethal, or serious damages to health.

Attention: Indicate a situation that could cause, directly or indirectly, damages to people, things and

circumambiency withphysical and economic consequences.

Advertence: Indicate that is necessary to follow with particular attention the manual in that moment.

Inobservance of this indication couldcause malfunctions or danger conditions or damages.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 4di 16

3. P

RODUCER IDCODES

The label fixed on lateral side of device, contain all the identify data of the product SLIDE 80. Fig.3.1 Example of

label ( the data on it are fictional, real data are reported on the real label on the device).

3.1 Technical assistance and ordinary maintenance

To indicate faults of device contact the Customer service:

CHIAROSCURO SAS by Girelli Marco & C.

C.So General A.Cantore 23 - 38068 Ala (TN) Italy.

Tel: +39 0464 424715 fax: +39 0464 712027

email: info@chiaroscuro.eu site: www.chiaroscuro.eu

For communications or information requests or replacement parts send us the module “order replacement parts,

fault indications, information” reported on the Attached # 1. (Pag. 17)

Pic. 3.1

Production Week and Year of selling

Model Commercial name of device

Electrical protection Identifygraduation of IP

Strenght Identify the maximum strength (in

Newton)

Power Supply Kind of electric supply in Volt

Power Identify the maximum absorbed power in

Watt

Temperature of operation Identify the

temperature of operation

It’s forbidden to remove or modify the label. In case of damaged label contact the producer.

For the maintenance of warranty the customer has to follow scrupulously le instructions of the users

manual. In other cases the warranty will expire (read the warranty rules atthe end of manual).

The producer, in order to adapt the device to the technologic progress andfor productive requirements

can, unannounced, afford modifications without the updating of the production and the foregoing

manuals.

Also if the illustrations in this manual are a little bit different by the device that you have, the safety and

the functioning instructions of the device are guaranteed.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 5di 16

4. F

EATURES AND DATASHEETS

110 ÷ 230Vac 24Vdc

Maximumpushing and traction strength 145 N

Maximum Width 7,5 m

Powersupply 110 ÷ 230 Vac 24 Vdc

Currency absorption at nominalload ~ 0,18 ÷ 0,08 A ~ 0,83 A

Wide traslation speed ~ 90 mm/s

Acceleration/deceleration ramp Yes

Impact force detecting obstacle < 150 N

Dual electrical isolation Yes LowVoltage

Duty cicle 20 Cicles / Hour

Temperature of operation -20 °C / +60 °C

Protection degree electrical device IP 55

Stroke-ends regulation Auto determinating position

Parallel powering of motors Max 10

Dead man functioning Yes, requesting

Reversible pulley Yes, requesting

Positional contact Yes, Requesting

Lenght of power cable 1,5 m

Dimensions 200 x 54 x 38 mm 150 x 50 x 38 mm

Weight 0,830 Kg 0,620 Kg

Maximumlenght of command cable < 3 m

Radio control Yes, requesting

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 6di 16

4.1 Law Reference

The lawreferences producing this device are the sequels:

National and harmonized technicalLaws applies respectingthe laws above are:

On request of Customer is available a version ofthe SLIDE 80 system equipped with radio receiver module and n.

2 radio controller at 433MHz band that has all the characteristics specified in the directive 1999/5/CE (Radio

devices and telecommunications devices).

1

The articles of law EN 60335 related to the electric risks are not applied because our devices are power supplied with a

very low tension system security type SELV.

Slide 80 230 Vac Slide 80 24 Vdc

−2004/108/CE Directive EMC

−2006/95/CE Directive LVD

−2006/42/CE Machines Directive

−2011/65/CE Directive RoHS2

−2004/108/CE Directive EMC

−2006/42/CE Machines Directive

−2011/65/CE Directive RoHS2

Slide 80 230 Vac Slide 80 24 Vdc

−EN 60335-1 (2008_07)

−EN 60335-2-103 (2003_08)/A11(2009_07).

−EN 55014-1 (2008_01)/A1 (2010_10)/A2

(2012_02)

−EN 55014-2 (1998_10)/A1 (2002_09)/A2

(2009_09)

−EN 60335-1 (2008_07)

1

−EN 60335-2-103 (2003_08)/A11(2009_07).

−EN 55014-1 (2008_01)/A1 (2010_10)/A2

(2012_02)

−EN 55014-2 (1998_10)/A1 (2002_09)/A2

(2009_09)

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 7di 16

5. G

ENERALITY

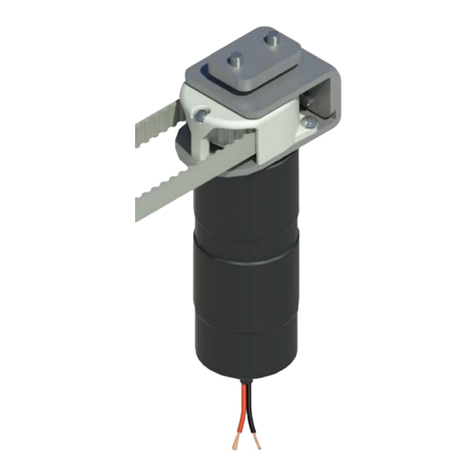

The SLIDE 80 is an automatic actuator to open – close sliding shutters, is an high performances not reversible

motor paired with high endurance resin gears.

The possibility to open/close the shutters with very simple remote controls or with an home automation system, can

permit the user to optimize the protection offer by the shutters in several weather conditions (ex. hot, cold, rain,

snow).

6.

RECEIVINGAND STORAGING

6.1 To control at the receiving of device

Remove the packaging when receive the device ensuring the integrity of content.

Kit includes:

-Motor with plate for rails with internal defile max 15mm Pcs 1

-Belt T5H10 M 10

-Dragging straight bracket Pcs 2

-Tensioner with free return pinion Pcs 1

-Users Manual Pcs 1

6.2 Storaging

At receiving, if the product is damaged and/or with missing and/or with defect or malfunctions, don’t try to

repair it but contacting the Customer Care reporting model, code and device serial number (see Pic.3.1.

Label at pg. 6).

Not using the device for long periods, store the device in a dry, clean place.

To store for more than 24 month by the matriculation ,CHIAROSCURO SAS give the warranty

expected by GeneralSelling Conditions.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 8di 16

7. M

ECHANICALMOUNTINGINSTRUCTIONS

The montage has to be done by a certified Electromechanical Dealer. CHIAROSCURO SAS doesn’t have

responsibilities for bad installations and/or installations done by not certified operators.

7.1 Necessary for Installation

To proceed with installation needs thesequelinstruments:

-Screwdriver for hexagonal screw #4 ;

-Screwdriverfor slotted screw 1 x5,5 ;

-Electrician clippers ;

-Tester screwdriver ;

-Permanent marker fine ;

-DIN 7505/B Chipboard screw with cylindricalhead 3,5 x 25 Pz 2 ;

-Single pole terminal 2,5 ;

-Cables probe .

7.2 To Verify for a good installation

Once verified the package content, it’s possible to proceed to verify the dimensions required to install our

automation.

If during the design phase was not followed the automation measures and data sheet, will be the Electromechanical

Dealer (E.D.) to find a possible solution and adapt to the situation.

In case of doubtscontact theHomebuilder Technician (H.T.) that will give support in order to find a solution.

Electromechanical Dealer: (E.D.) technician who has the competences to install mechanical - hydraulic -

pneumatic devices and who can accomplish regulations, maintenances or repairs and can work in

presence of High Voltage inside, derivation boxes and electrical installations.

The SLIDE 80 is not equipped of the instruments above, but are necessary for a good workbench

installation.

P.P.E. or other are responsibility of E.D. in function of the field installation

SLIDE 80 is a specific product for sliding shutters. Any other use is not warranted the functioning and the

compatibility with CE mark

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 9di 16

7.3 Sizes Verify

Verify that the engine housing groove or the space over the rail are enough install the product, otherwise the

installation could abridgethe run of shutter.

Verify that the electrical preparation and all the parameters are respected like the technical schedule

at page 7

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 10di 16

7.4 Motor Installation

In the next steps it will explained the necessary operations to install correctly the automation on the rails.

7.4.1 Fixing the motor to the rail

7.4.2 Positioning and fixing the belt

Before to proceed it’s necessary to understand how is built the belt tensioner and its function with the dragging

bracket. The belt tensioner is made by:

-Dragging straight bracket Pz 2 ;

-Free pulley block Pz 1 ;

-Contrast clamp Pz 1 ;

The belt dragging has triple functions: junction function between the two edges of belt (dragging bracket), belt

tensioner (free pulley block + contrast clamp) as well as shutter fixing to transmit the sliding movement (dragging

bracket).

Caution, following the users manual of sliding shutters system chosen, proceed to the mechanic installation

of the shutters. Is binding to insert the wheels and the stoppers at reverse way or cutting the wheel retaining

clips, in order to prevent the block of the wheels into the stopper. Without this shrewdness, wheels will stick

around the stoppers and at the start the SLIDE.80 will recognize that block like an obstacle. The order to

follow is: stopper/wheel/wheel/stopper.

The order of the components inserting into the rail is :

-Single shutter : stopper/wheel/wheel/stopper ;

-Double shutters: stopper/wheel/wheel/stopper/wheel/wheel .

Open the clamp and insert the motor in the rail. Respect parallelism between

the lower part of the rail and the motor, screw the EN ISO 4762 M5x16 with

the n°4 hexagonal screwdriver until the screws are totally clenched.

Repeat the same operation with the tensioner pulley at the opposite extremity,

going inside the rail 2cm from the border.

Caution, fix just the part without pulley (the internal one without pulley) and leave the screws of the

block with pulley unfixed (the external one with pulley). Afterwards tension the belt acting on the

extremely part of the block with a screwdriver for slotted screws.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 11di 16

Disassemble the anti-bounce cap of the free pulley and the same with cap of motor.

Put the belt on the motor pulley taking care to assemble again the cap. Do the same operation with the free pulley.

The caps will clamp the belt.

Bring the motor-side edge of belt ( edge A ) to the center of rail and clasp it in the middle of the dragging bracket,

starting right this the belt trip. Going on with the belt trip bring theedge B (theone who comes from the free pulley)

arrive at the dragging bracket.

From the interception of the edges of belt, cut with clippers the edge B adjacent at the edge A

Close the clamp of the dragging bracket with the n°4 hexagonal screwdriver.

To tension the belt trip, has to unscrew with the screwdriver for slotted screws 1X5,5 the treaded shaft (M8 screw

dimension) that made up the belt tensioner, in order to turn awaythe free pulley block from the clamp contrast block

which wasfixed beforeand now make a contrast.

Reached the correct tension of belt, fix with the n°4 hexagonal the free pulley block.

7.4.3 Completion of the mechanic installation of sliding system

To complete the mechanic installation it’s enough to proceed following the users manual of the sliding shutters

paying attention and avoiding to make damages at the automation.

7.4.4 Fixing the dragging bracket to the shutter

Fin in a middle position, with the chipboard screws 3,5 x 25 - DIN 7505/B, the bracket to the shutter. Fora double

shutters system make the same operation on the opposite side of the belt in order to have a correct movement of the

shutters.

For the double shutters system, if the shutters doesn’t have the same run, the automation will do the

shortest run.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 12di 16

7.5 ELECTRICAL

CONNECTIONS

This work has to be done by a qualified Electromechanical Dealer. CHIAROSCURO SAS doesn’t have

responsibilities in the case of bad installation and/or mistakes made by not qualified operators.

7.5.1 Electrical Scheme

2

ORDINANCE 22 January 2008 - , n. 37 Rule in reference to the execution of the article 11-quaterdecies, subparagraph

13, letter a) of thr law n. 248 of 2 December 2005, describing reorgasnization of disposal about installation activities of

implants inside the buildings.

The proper functioning of device and the safety requirements are guaranteed only if it’s connected to

certified electrical system that respect the applicable laws (in Italy DLgs. 37/2008

2

).

The producer doesn’t have responsibilities for any damage to the device or at other people caused by

the use of a non-compliant electrical system, or caused by an electrical system that doesn’t respect the

applicable laws .

If the device behavior doesn’t reflect what is reported above, don’t use the automation and contact the

Customer Care service of CHIAROSCURO SAS. It’s hardly forbidden to open the case of the device

except written authorizations of CHIAROSCURO SAS. Not respecting this rule will cause the

immediately decay of warranty.

The predisposition of the electrical system is responsibility if the electromechanical dealer.

CHIAROSCURO SAS doesn’t have the responsibility for system lacks. All the information to make a

good work are at disposal, it’s a buyer burden request it in a formal way.

Version110 ÷ 230Vac Motor cable Description

Brown Line 110-230 Vac

Blue Neutral / Common

White Key 1 rot.clockwise

Red Key2 rot.anticlockwise

Program Contact

Automatic N.O. impulsive 1sec.

Dead man N.O.

Version24Vdc Motor cable Description

Red + 24 Vdc

White -24 Vdc / Common

Cable 1 Key1 rot. clockwise

Cable 2 Key2 rot. anticlockwise

Program Contact

Automatic N.O. impulse 1sec.

Dead man N.O.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 13di 16

7.5.2 ConfigurationSlide.80

SLIDE.80 has 6 different configurations.

7.5.3 Dead Man Program

In the following list will be described in order all the phases about the Dead Man program that will be execute at

everypower on. Normally opened contact.

7.5.4 Automatic Program

In the scheme beneath will be explain, all the phases of the Automatic programthat the device will perform at every

power on. Impulsive contact 1 sec. Normally opened.

Product Code Power Supply Program Command

SL.80-230 110 – 230Vac Automatic Wire

SL.80-230R 110 – 230Vac Automatic Wire + Radio

SL.80-230UP 110 – 230Vac Dead man Wire

SL.80-24 24Vdc Automatic Wire

SL.80-24R 24Vdc Automatic Wire + Radio

SL.80-24UP 24Vdc Dead man Wire

Phase Proper Operation

Error Acustic Error Description

Phase 1

Power -ON

At power on for the first 3” the

device will make a test. During this

fase the devicewill emit a BEEP for

2” Commandswill not accept in this

phase.

No BEEP No power supply or

motor broken

Long BEEP 5” Fault

Siren 4” Overcoming safety

threshold

Phase 2

Run

T1= clockwise rotation

T2= anticlockwise rotation

Running at costant speed Long BEEP 5” Fault

Phase Proper Operation

Error Reports Error Description

Phase 1

Power -ON

At power on for the first 3” the

device will make a test.During this

fase the device will emit a BEEP

for 2” Commands will not accept

in this phase.

No BEEP No power supply or

motor broken

Long BEEP 5” Fault

Siren 4” Overcoming safety

threshold

Phase 2

Learning

At the first command (Open or

Close) device will make an

automatic movement in both

directionsimpossibletointerrupt

Long BEEP 5” Fault

Phase 3

Run

T1= clockwise rotation

T2= anticlockwise rotation

run < 50cm slow move

run >50cm speed profile

Long BEEP 5” Fault

4” Siren emitted Overcoming safety

threshold

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 14di 16

8. M

AINTENANCE

8.1 Periodical maintenance

8.2 Special maintenance

9. DRAWBACKS

AND

ANOMALIES

Faults List :

E.D. has to keep updated this list makingmaintenanceoperations

In cases of error contactour Customer Care service reporting model, product code and serial number (look

at pic.3.1. Device Label).

In cases of defects and/or malfunctioning , don’t try to repair the device but contact our Customer Service

reporting model, product code and serial number (look at pic.3.1. Device Label).

All the operations described in the next paragraphs has to be carry out with the device turned off (switch

attributable to device OFF position).

Exploiter : Clean periodically the device casing using a soft cloth with moisten with neutral and not

aggressive soaps and wipe up with a dry soth.

To maintain clean and without obstacles the shutters moving area.

Electromechanical Dealer : Verify the tension ofbelt.

Adjust and regulate possible beddings of the shutters.

Exploiter :Contact the Electromechanical Dealer in of breakages or malfunctioning

Electromechanical Dealer : Find the malfunction and, if it’s necessary contact our Customer Care

reporting model, product code and serial number (look at pic.3.1. Device Label).

Use the form “service request– supplies” at page 26

Date Operator Drawback Possible cause

If the service intervention didn’t solve the problem stop all the operations and contact the Customer

Care.

It’s hardly forbidden to open the case of the device except written authorizations of CHIAROSCURO

SAS. Not respecting this rule will cause the immediately decay of warranty.

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 15di 16

10. DISPATCHING

11. -A

TTACHED

.1

–

SERVICE REQUEST

-

SUPPLIES

For the kind attention

CHIAROSCURO SAS di Girelli Marco& C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy.

Tel: +39 0464 424715 fax:+39 0464 712027

email: info@chiaroscuro.eu sito: www.chiaroscuro.eu

Date __________________

Supplies List:

_________________________________

Buyer stamp and Signature

USERS INFORMATIONS

At the senses of art. 13 del Law Decree 25 July 2005, n. 151 “Execution of the

Directives 2002/95/CE, 2002/96/CE and 2003/108/CE, related to reduction

of using di dangerous substances inside electric and electronic devices, and

dispatching refuses” The symbol of striketrough dumpster on the device

denote that at the end of its life has to be dispatch a part by other refuses. For

this reason the user has to deliver the device, in all its integrity, at the suitable

electronic and electric devices recycling centers, or deliver to the retailer at

the moment of buying a new same type device in a one to one reason. A

condign dispatching to starting for the dismissed device a recycling process,

for an recycling compatibility dispatching contributes to avoid possible and

negative effect for the nature and for health and support the recycle of the

materials that this device is composed. Unauthorized dispatch of this product

imply the applicationof the administrative penalties expected by the law.

Customer: Model:

Locality: Code:

Address: Serial:

Phone:

Fax : Transmitted by

Article Code Q.ty Description/Note

SLIDE.80

110-230Vac / 24Vdc

Cod.

151116

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221

Pag. 16di 16

12. C

OMPATIBILITY

C

ERTIFICATIONTO MARK

CHIAROSCURO SAS di Girelli Marco & C.

C.So General A.Cantore 23 - 38061 Ala (TN) Italy.

Tel: +39 0464 424715 fax:+39 0464 712027

email: info@chiaroscuro.eu site: www.chiaroscuro.eu

Declares that the electric product

In accordance with the laws that transpose the following directives and following amendments:

The compatibility is legitimate provided that the actuator SLIDE 80 it’s exclusively used for expected applications

and the installation has to be done following step by step the users manual.

ALA, 27/08/2015 _________________________________

Marco Girelli

Legal Representat

13. WARRANTY

CONDITIONS AND RESTRICTIONS:

CHIAROSCURO SAS gives for this device 12 monthwarranty.

The warranty begins by the date of purchasing on the fiscal document at the moment of device delivering. CHIAROSCURO SAS agrees free

repair or substitution of the parts that, in the warranty period could present manufacturing defects, warranty not includes any way of refund by

direct or indirect damages to people or things. During the period of the warranty, if the Customer want a repair done by CHIAROSCURO SAS

technicians will be necessary to send a formal wrote request to CHIAROSCURO SAS. In that case all the related costs (travel, food and

accomodation) will be at Customer’s burden. For technical interventions caused by defects or failures non clearly attributable to the materials or to

the manufacture, all the cost of transfer, di repair and/or substitution of all parts will be charged to the Customer. CHIAROSCURO SAS exclude

the extension of warranty after a technical intervention on device. In case of return of some device parts, customer could send this partsonly after

an explicit wrote authorization by CHIAROSCURO SAS. Costs relates to packaging and shipping are Customer burdens (except different

accordance with CHIAROSCURO SAS). In the same way are excluded by warranty accidental shippingdamages, carelessness, inappropriate use,

a use different by the users manual rules or for any other phenomena that it doesn’t depends by a normal use of this device. Warrantywilldecayif

the device will be repaired by unauthorized people or if will be used unauthorized equipmentor unauthorized accessories not approved before by

CHIAROSCURO SAS or in case of removingor changingof the serial number during the warranty period. Warranty will decay immediately in

case of delay of missing payment (partial included) by Customer CHIAROSCURO SAS doesn’t have any responsability for accidental damages

to people or things, caused by a bad use, non-compliant use or imperfect use of this device.

For any possible dispute the competence is delegate to Jurisdiction of TRENTO (ITALY).

Model SLIDE 80

Description Actuator designed to move sliding shutters systems

Slide 80 230 Vac Slide 80 24 Vdc

−2004/108/CE Directive EMC

−2006/95/CE Directive LVD

−2006/42/CE Machines Directive

−2011/65/CE Directive RoHS2

−2004/108/CE Directive EMC

−2006/42/CE Machines Directive 2011/65/CE

Directive RoHS2

Table of contents

Other CHIAROSCURO Controllers manuals