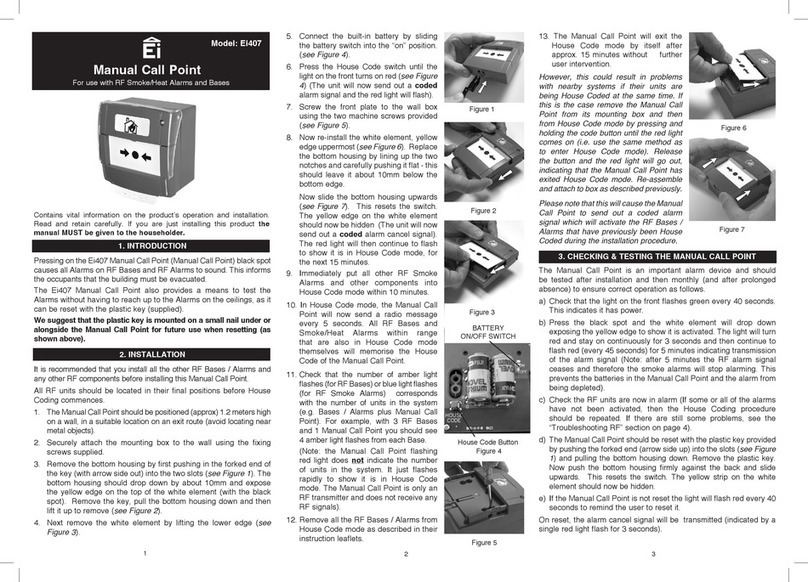

4

The Ei413 RadioLINK Panel Module is a device that switches

a relay upon receipt of an alarm or a fault RF signal from a

compatible Ei Smoke, Heat or Carbon Monoxide (CO) Alarm.

Although it is mainly designed to interface with a suitable

security or fire panel system, the electrically isolated contacts

can also be used in other applications.

The Ei413 RadioLINK Panel Module is powered by 11 – 30V DC

from an external source (panel).

It decodes “Fire”, “CO” and “Fault” signals from the RF Alarms

and activates the relevant relay. The relays are wired to input

terminals on the panel. The wiring will differ depending on the

type of panel used (see installation section).

Note: The Ei413 can only receive fault signals (such as sensor

degradation, low battery and Alarm removal) from Alarms with

which it has a direct RF connection/signal path. The ability

of an Alarm to transmit a fault depends on the RF module’s

capability. For more information on the type of fault that can

be reported depending on the RF module used, see table A.

Introduction