eibe fantallica 552024143 Series Quick guide

Scope of delivery • Ground work • Assembly • Maintenance

Article pass / Guarantee certificate

Attention: Guarantee

Keep these documents in a safe place.

Please indicate the workshop order number (RM-Nummer) in all inquiries and complaints.

No: UK-

Hexagon swing

RM-Nummer:

552024143..

1502-V-01 buck SCH F5 22 1 / 10

Certificate of Warranty

Item number:

Name:

Completion note number:

_________________________

(please enter Completion note number)

Warranty acceptance from date of invoice:

_________________________

(please enter date of invoice)

µ grants the following warranty periods:

The present information reflects the status as valid at the time this document was issued. For updated information, please see our website www.eibe.de

• Wear parts are excluded from this warranty. On wear parts we grant a 2-year warranty. All

wear parts included in the consignment are marked with the wear-part symbol .

• Our willow products, sun roofs, textiles and canvas covers as well as rubber tensioner

elements are excluded from the warranty and subject to the legal terms of warranty.

• Powder coatings are excluded from the warranty and subject to what guaranteed in the valid

µ terms of delivery and payment.

In case of rightful warranty claims, eibe shall have the right to rework or replace the goods in

question.

Prerequisites for valid warranty claims:

• Regular and professional maintenance and inspections as prescribed in the µ maintenance

instructions.

• Professional repair jobs using original spare parts only.

• Evidence of proper maintenance and inspections has to be provided by the customer.

Warranty exclusion:

• normal wear due to everyday use

• vandalism

• deliberate destruction

• unprofessional assemblies (not according to the µ Assembly Instructions or EN-1176/77)

Hexagon swing

<V>

552024143..

2 / 10

You have decided in favor of an µ item. is significantly delayed. This System is firmly

Congratulations on your choice! All µ anchored in the surface, so no extensive

items are produced of select materials and flaking will appear. Instead after years the

subjected to severe quality checks. gloss level will decrease, the colour will fade

and a slight algae cover will appear. This is

All µ items are fabricated in such a way as not a quality problem, the surface finish can

to allow easy do-it-yourself assembly. We are, be renewed with a refresh.Depending on the

of course, ready to do that for you. Just let us place of installation, after several years might

know in advance.To make assembly of your appear: chalk powdery dust at the surface,

new µ item easy for you, we have fissures or damage by hail yet without

prepared these assembly instructions. Step by discolouring of the wood. In this stage a

step you will be guided through the various refresh should be carried out, to prevent the

assembly stages up to the finished play Positioning on the Playground:

wood from permanent damages. Sanding the

equipment.Should you encounter any Please remember that exposure to strong solar

surface in preparation for the refresh is not

unforeseen problems during assembly, please radiation and thus heating up of the product

necessary. It is sufficient to apply the oil on

get in touch with our service department. Our should by all means be avoided. This is true

the well-cleaned and dry surface. It is

representatives will be happy to help you. especially for slide bars and slides. Position the

important that the refresh is carried out before

The occupational health and safety equipment in natural shadows e.g. of trees or

the following damages appear: clearly visible

regulations at the site of installation must facing certain directions. We do advise you not

fissures, discolouring of the wood, infection

be observed. to position the slides towards south-east, south

with wood destructive fungi or insects. or south-west as the slide surfaces are likely to

Assembly Instructions: Space Requirements: heat up very strongly. If you use large-area

Knock round-sheath screws with a rubber and flexible components such as sun sails or

The first two numbers indicate the minimum

hammer only in order not to damage the similar shadow-creating elements on your

space required for your µ equipment,

corrosion protection.Use washers under all playground, make sure to secure them against

including the impact area (formerly safety

nuts and tighten all nuts with "feeling". If you the effects of wind. Please remove them in case

area). Our floor type recommendations apply

tighten them too strongly, an unnecessary of strong winds or storms.

to this area.Independently of our

high amount of wood fibers tear off recommendations, you have to allow for an Surrounding Area Requirements:

underneath the screw head. Recesses are obstacle-free area of at least 1.50 m all around

provided for the countersinking of the screw The area within the safety zone must be even.

the device. This area must be absolutely free of

nuts. For easy positioning of the nuts in the Please adhere to the indications in our tender

hard or sharp-edged or protruding parts a

recesses, put one or two of them into the documents and the foundation plan.

child could fall onto. This area is not subject to

wrench and slip onto the screw. any regulations regarding impact-attenuating Please make sure that all assembly equipment

Use a two-way drill with enough pull for flooring. has been removed before you open the

assembly. A battery-driven screwdriver is equipment to the children.

Depending on the place of

not suitable! If the mounting site provides conditions that

installation, after several years are out of the ordinary, e.g. peaty soil or

Marker Holes: might appear: chalk powdery dust frozen ground, such conditions absolutely

The column bases bear bore holes indicating at the surface, fissures or damage have to be taken into account.

up to what height they have to be planted by hail yet without discolouring of All changes on parts of the equipment or on

and covered with the bulk material (e.g. sand, its construction which may affect the basic

the wood. In this stage a refresh

tree bark mulch). You should plant the column safety of the device are subject to prior

bases in such a way as to allow the marker should be carried out, to prevent manufacturer approval.

holes to remain clearly visible from the outside the wood from permanent

of your µ product. Have fun with your play equipment!

damages. Sanding the surface in µ Produktion + Vertrieb GmbH & Co. KG

Materials Used: preparation for the refresh is not Industriestr. 1

wood is a natural product. Temperature necessary. It is sufficient to apply D-97285 Röttingen

fluctuations may therefore cause minor cracks the oil on the well-cleaned and dry

and deformations which do, however, neither Germany

surface. It is important that the

affect the load carrying capacity of the wood Tel. +49-(0)93 38/89-0

nor represent a reason for complaints. Being a refresh is carried out before the Fax +49-(0)93 38/89-199

recognized impregnation company, µ is following damages appear: clearly

authorized to carry the RAL quality mark and E-Mail eibe@eibe.de

visible fissures, discolouring of the

is therefore subject to regular third-party www.eibe.net

inspections. You can therefore rely on all wood, infection with wood

batches being impregnated correctly. µ destructive fungi or insects.

uses core-separated wood as it is less prone to

cracks than boxed heart (wood with core). Please adhere to the occupational

health and safety regulation that

Wood protection: apply to the installation site

you need not refresh the wood protection

carried out by means of the µ Disposal:

impregnation. Due to climatic influences / UV • Impregnated waste wood: thermal disposal

radiation, the outer cell structure slowly • Metals, noble metal, GRP, plastics: textile

decomposes, constituents such as tannic acid disposal

are extracted, the wood is being leached and

takes on a gray color. This is a purely external Labeling:

effect and does not constitute any all µ products are marked with a label or

deterioration of quality, stability or wood sticker. Label or sticker inform on delivery date

protection. If you are bothered by the fading •(1), the feedback number (2)‚ (in few cases the

colors, you can freshen up the wood by way of product article number), and the valid

a transparent, water-based shade equalizer standard (3). Please indicate both delivery

which needs not contain fungicides or date and feedback number in all complaints

biocides. Varnished components, however, and repeat orders.

need to be repainted after two years, then

every year.

eibe resistant playground timber (rpt) is

treated with a protective oil based surface

finish. Due to enclosed pigments and special

ingredients the natural process of weathering

<P>

1

2

3

552024143..

3 / 10

supporting pole (e.g. rope trees) only or checked O

General Maintenance Information: supporting poles aligned one after the other • Are components overly worn and torn?

All children's playground equipment requires (e.g. horizontal three-level bar) are subject to Please pay particular attention to moving

regular inspections and maintenance works. the following maintenance procedures:The parts such as chains, swing joints.

This applies in particular to all those units supporting poles are essential to the stability

which are mounted outdoors (throughout the and safety of the equipment and therefore checked O

whole year) and which incorporate moving require your particular attention. These poles • Pay particular attention to the absence of

parts or parts that are subject to wear and must be checked for their stability both during pointed objects within the area of impact

tear. the "Major Annual Inspection” and on (make sure that there are no glass splinters or

The long life or our µ products can be occasion of the "Monthly Operational similar!). The flooring of the impact zone (e.g.

guaranteed only if you provide regular Inspections”. Whether your µ equipment sand, pebbles, bark mulch, fall protection

maintenance and service. This is the best and remains safe to play with for many years tiles) must be absolutely intact and have the

only way to permanently maintain the play depends solely on your expert maintenance. correct height. Please observe the markings on

value for your children and the safety of your The wall thickness/corrosion on the inside of the poles and column bases.

µ products. You should make sure that pipes can be verified with the following test

experts carry out all maintenance and service checked O

procedure:

works. Inexpert inspections or repairs may • Have all climbing handles been screwed

• Electromagnetic test procedures such as

endanger the safety of your children! tightly? Loose handles need to be tightened

eddy current or magnetic leakage flux

The maintenance of your µ products immediately. Unused fixing points on the

measurement

according to these instructions is prerequisite climbing wall MUST be closed.

• ultrasound

to the µ warranty. checked O

µ Equipment With Metal Posts:

Basis to these maintenance recommendations We strongly recommend the daily inspection of

are our many years of experience. If your local The posts are of aluminum / zinc-coated steel. heavily used or high-vandal-risk playgrounds.

conditions and directives, your particular Please check whether particular conditions Daily inspections may also become necessary

playground equipment or your own expertise (e.g. salt water, electrolytic corrosion) have in case of playgrounds that are close to the

and experience require different inspections caused pitting or a weakening of the posts coast or located in highly air-polluted areas,

and maintenance performances, please (e.g. vandalism). The instable posts have to be or which have already been in service for a

adhere to the definitions given in the EN- repaired by an expert, or be replaced certain period of time.

standard 1176-7. checked O The following pages of this documentation

EN 1176-7 Excerpts: µ Rope Trees: may comprise other information that must be

7 Inspection schedule considered during the operational inspections,

Check the bottom plastic bearing between net for example in the step-by-step installation

7.1 To avoid accidents, the owner has to make connection and metal post for wear and tear. instructions and the sheets on details.

sure that an adequate inspection schedule is If the central ring can be moved horizontally

developed and adhered to for each by more of 1.5cm towards the post (see All damages and defects have to be eliminated

playground. In such schedule, all local illustration below), the plastic bearing has to immediately in order to guarantee the safety

conditions and manufacturer's indications be replaced. and functional reliability of your µ

that may have an influence on the necessary products.

checked O

maintenance frequency, have to be taken into Access to the playground equipment has to be

consideration.The inspection schedule should Plastic bearing okay: denied in the following cases:

list all parts, which have to be checked during • The equipment has not been fully or safely

the different inspections, and the inspection installed

procedures according to 6.2. [µ describes

the execution of the inspection according to • The shock-absorbing surface has not been

the procedures explained in 6.2 on the fully installed

following pages]. • The safety of operation cannot be

7.2 If severe and safety-endangering defects guaranteed by maintenance works

are discovered during an inspection, they Operational Inspection:

should be eliminated immediately. If they Plastic bearing not okay:

cannot be repaired or replaced at once, the Inspections once every

respective equipment has to be excluded from

use, e.g. by dismantling or closing it down.If 6 months

an equipment component has to be removed, In addition to those of the "Visual Routine

e.g. for maintenance works, all anchoring or Inspection”, the following checks are required:

foundations that remain in the ground have • Are all wooden components okay? (e.g. fast

to be removed also or be made inaccessible by and safe connection of the ladder rungs, no

means of covers. The construction site should splinters or other damages)

then be secured. Merry-go-rounds:

checked O

The EN 1176-7 requires a visual routine The distance between outer bottom edge of the

inspection for playgrounds. In the case of • Are all metal parts well connected and not

merry-go-round and the shock-absorbing

heavily frequented playgrounds or those worn down? ( please pay particular attention

flooring may be between 6 cm and 11 cm. This

endangered by vandalism, daily checking may to swing joints and chain connections and

distance has to remain the same at all times,

be necessary. Sites in the vicinity of coasts, air make sure they are not worn through)

i.e. must not lessen through turning and

pollution and the age of the facilities may also spinning. The wall thickness/corrosion on the inside of

render daily checking necessary. In the pipes can be verified with the following test

checked O

operative inspection, eibe specifies how often procedure:

which areas must be inspected on this piece of • Check your µ product for visible Electromagnetic test procedures such as eddy

equipment in order to maintain safety damages and loose parts current or magnetic leakage flux

standards for normal usage. After 12 months checked O measurement

at the latest (preferably following the winter

months) a “main annual inspection“ will be • Does the ground show hard or pointed ultrasound

required. objects (e.g. splinters of glass) and/or are the checked O

play, fall, swing or slide areas dirty?

At the very end of these maintenance • Are all screwed connections and bolted joints

instructions you are offered a maintenance checked O well fit? If not, please tighten them. Moving

report sheet for the entry of your equipment • Are there any exposed foundations? parts may require greasing or oiling.

maintenance results.

checked O checked O

Visual Routine Inspection: • Do you identify sharp edges, broken or • Are all ropes and rope ladders okay? Frayed

One-Pole Playground Equipment: missing parts? steel ropes must be replaced immediately.

All playground equipment featuring either one

<O>

<A>

< 1,5 cm

> 1,5 cm

552024143..

4 / 10

checked O

• Are the slide surfaces okay? Use our repair

kits Laminat (article number 5 63 036 0) to

touch up damages on the GRP slides and

Oberfläche (article number 5 63 035 0) to

revarnish the surface afterwards. The

Oberfläche repair kit is absolutely sufficient for

the elimination of minor damages.

checked O

• Are all plastic and rubber components okay?

checked O

• Certain parts (e.g. water pumps) have to be

shut down and dismantled prior to the frost

period, and stored according to instructions.

checked O

The following pages of this documentation

may comprise other information that must be

considered during the operational inspections,

for example in the step-by-step installation

instructions and the sheets on details.

All damages and defects have to be eliminated

immediately in order to guarantee the safety

and functional reliability of your µ

products.

Please remember to enter your results in the

maintenance report form!

Major Annual Inspection:

You should carry out the "Major Annual

Inspection” after the winter or at least after 12

months. In addition to those of the "Monthly

Operational Inspection”, the following checks

are required:

• Are all foundations okay and the equipment

well ancored?

checked O

• If necessary, provide all wooden, metal,

glazed and varnished parts and components

with a new finish.

checked O

• Replace joints that show severe corrosions or

heavy wear and tear.

checked O

• Wooden components: All wooden

components exposed to weather conditions

have to be checked. Please pay particular

attention to the parts planted underground as

well as to all those components, which are

essential to the static stability (e.g. cross bars

on swings, bridge supports, cableway struts)

of the playground equipment.

checked O

The following pages of this documentation

may comprise other information that must be

considered during the operational inspections,

for example in the step-by-step installation

instructions and the sheets on details.

All damages and defects have to be eliminated

immediately in order to guarantee the safety

and functional reliability of your µ

products.

Please remember to enter your results in the

maintenance report form!

552024143..

5 / 10

Symbolerklärung

Equipment data:

Surfacing inside the impact area:

sand, gravel, bark mulch, wood chips, inpact-attenuating tiles

Filling height for bulk material such as sand, gravel, wood chips and similar:

30 cm

Maximum free fall height:

Minimum equipment space:

Required mounting space:

For age groups of:

3 - 14 years

This equipment corresponds to

EN 1176 part 1 /

No: UK-

14 cmcm

øø

øø

ttG

adjust

see foundation plan

close drilled holes with

stoppers

Cast foundation in situ using

concrete type C20/25.

Dimensions in "cm”

Drill (t = drilling depth; ø =

bore diameter)

Drill (ø = bore diameter)

waiting time in days (e.g.

concrete hardening time)

tighten all screws

draw

This symbol indicates that dangerous traps and opening dimensions may

result from a non-expert assembly. Please give these assembly

instructions your utmost care especially in case of the specified

positions.

Symbol explanation:

552024143..

1502-V-01 buck SCH F5 22

1,4 m

12,4 x 12,4 x 3,2 m

12,4 x 12,4 x 3,2 m

2

6 / 10

Foundation plan showing in-situ concrete footings made from concrete.

(Leave foundations to harden for at least 14 days before mounting the equipment.)

C20/25

= impact area

Impact-attenuating surface according to EN 1176: for outdoor playground equipment only!

Please allow for a distance to other objects of at least 1.5 m all around the

equipment (EN 1176). This area must be absolutely free of hard or sharp-edged or

protruding parts a child could fall onto. mm

552024143..

7 / 10

Scope of delivery

Part subject to wear (not part of our warranty)

package circular

552024143..

70609-0002 (4x)

71702-0001 (6x)

70421-55500312000 (6x)

M 10 007-Z

SCH F2 BG04

SCH F5 BG01 (6x)

SCH F5 BG02 (6x)

12x M12 DIN985 24x M12 DIN125-A13

12x M12x45 DIN912

8 / 10

Align

Tighten all screw connections.

Wait 14 days.

Tighten all screw connections.

Watch

marking!

3.

4.

5.

6.

552024143..

2.

M12 DIN 125-A13

M8x30 DIN912-VA

M8 DIN986-VA

1.

SCH F5 BG01

M12 DIN 985

G

0

2,20 m

M12x45 DIN 912

SCH F5 BG02

9 / 10

A8 DIN125-VA

Proof of maintenance and repair work

Day of

inspection

Person

responsible

Verification

OK Defects

Defects eliminated

(name, date, signature)

0,00 m

0,50 m

1,00 m

1,50 m

2,00 m

2,50 m

3,00 m

3,50 m

4,00 m

4,50 m

5,00 m

5,50 m

6,00 m

6,50 m

7,00 m

7,50 m

8,00 m

8,50 m

9,00 m

9,50 m

10,00 m

10,50 m

11,00 m

11,50 m

12,00 m

12,50 m

13,00 m

13,50 m

14,00 m

14,50 m

15,00 m

15,50 m

16,00 m

16,50 m

17,00 m

17,50 m

18,00 m

18,50 m

19,00 m

19,50 m

20,00 m

552024143..

10 / 10

Table of contents

Popular Baby Swing manuals by other brands

Courtyard Creations

Courtyard Creations RTS487X Assembly instructions

Fisher-Price

Fisher-Price DRG43 owner's manual

Fisher-Price

Fisher-Price BMK14 quick start guide

Graco

Graco 1A00BAN - Lovin Hug Easy Entry Open Top Swing... owner's manual

Graco

Graco ISPS002AC owner's manual

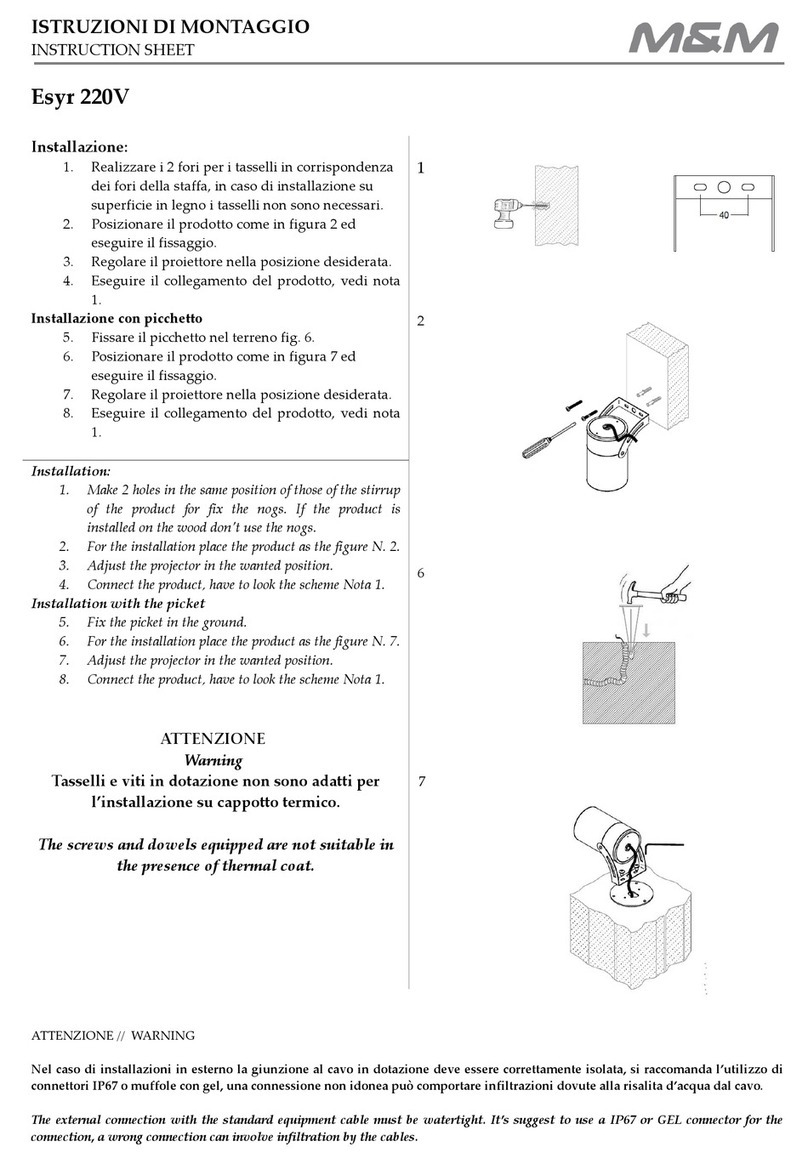

M&M

M&M Esyr 220V instruction sheet