EIC Solutions ThermoTEC T 146 Series User manual

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

EIC SOLUTIONS, INC.

Thermoelectric Air conditioner installation and

operation manual

FOR 1000 Btu MODEL #’S

AAC-146-4XT-E

AAC-146-4XT-E-HC

AAC-146-XXXXX

Cooling Solutions for

Mission-Critical Electronics

2

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

TABLE OF CONTENTS

1.

GENERAL INFORMATION

1.1

PRINCIPLES OF OPERATION............................................................................................. 3

2. INSTALLATION

2.1

CHOOSING A LOCATION .......................................................................... 4

2.2

ORIENTATION............................................................................................. 4

2.3

PREPARING THE ENCLOSURE ................................................................ 6

2.4

INSTALLING THE AIR CONDITIONER ..................................................... 6

INSTALL THE DRIP PAN ........................................................................... 7

APPLY POWER............................................................................................ 7

3. OPERATION

3.1

thermostat set points and heating cooling units ............... 9

3.2

maintenance............................................................................................ 9

4. APPENDIX...................................................................................................... 10

EIC SOLUTIONS INC.

700 VETERANS WAY, SUITE 200

WARMINSTER, PA 18974

PHONE 1-215-443-5190 or 1-800-497-4524

FAX 215-443-9564

EMAIL [email protected]

VISIT US ON THE WEB AT www.eicsolutions.com.

D-20 Rev. A 8/19/2015

3

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

1. GENERAL INFORMATION

1.1 PRINCIPLES OF OPERATION

n 1834 Jean Peltier discovered that by passing a current through two dissimilar conductors the

junction of those materials will either absorb or release heat depending on the direction of the

current flow. Thirteen years earlier Thomas Seebeck had discovered that current would flow

when you placed a temperature gradient across the junction of two dissimilar metals. These

two discoveries were the basis of thermoelectrics. With the advent of modern semiconductors

thermoelectric devices became practical for real world applications and are now found in

everything from consumer goods to spacecraft.

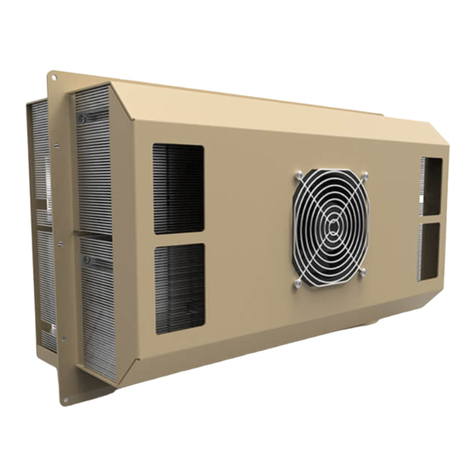

Your EIC Solutions Thermoelectric Air Conditioner operates on this principle so there is no

compressor and no expensive, ozone depleting CFC’s. EIC’s air conditioners use Thermoelectric

“modules” sandwiched between high performance aluminum heat sinks, high CFM axial fans, and a

patented electronic design to “pump” the heat from the inside of your enclosure to the outside,

without exposing your delicate electronics to any outside air or contaminates. See Figure 1.1.

EIC uses only the highest quality components in our air conditioners and you can expect

years of trouble free cooling from these solid-state devices. Every unit we sell is backed by our

one year parts and labor warranty.

FIGURE 1.1

AMBIENT AIR

REMOVES HEAT

FROM HOT SIDE

HEAT SINKS

COLD AIR

CIRCULATED

WITHIN THE

ENCLOSURE

HOT

SIDE

HEAT

SINKS

COLD

SIDE

HEAT

SINKS

COLD AIR

CIRCULATED

WITHIN THE

ENCLOSURE

AMBIENT AIR

REMOVES HEAT

FROM HOT SIDE

HEAT SINKS

HOT

SIDE

HEAT

SINKS

COLD

SIDE

HEAT

SINKS

FANS FANS

I

4

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

2. INSTALLATION

2.1 CHOOSING A LOCATION ON YOUR ENCLOSURE

When choosing a mounting location for your unit, be sure to keep air flows of both the

interior and exterior heatsinks and fans in mind. Adequate clearance between the fans/heatsinks

and nearby surfaces is required for unrestricted air flows which will ensure optimal performance

and long, trouble free operation. The general rule is to allow a minimum of two inches between

the fans or heatsinks and any surface. Refer to figure 1.1 for an air flow diagram.

Other considerations in deciding on a mounting location include; allowing access to

thermostat (this will be inside the enclosure) if frequent adjustments are to be made; allowing

access to the hot side heat sinks (this will be on the outside of the enclosure) for cleaning if the

unit will be used in a harsh, dirty environment.

2.2 ORIENTATION

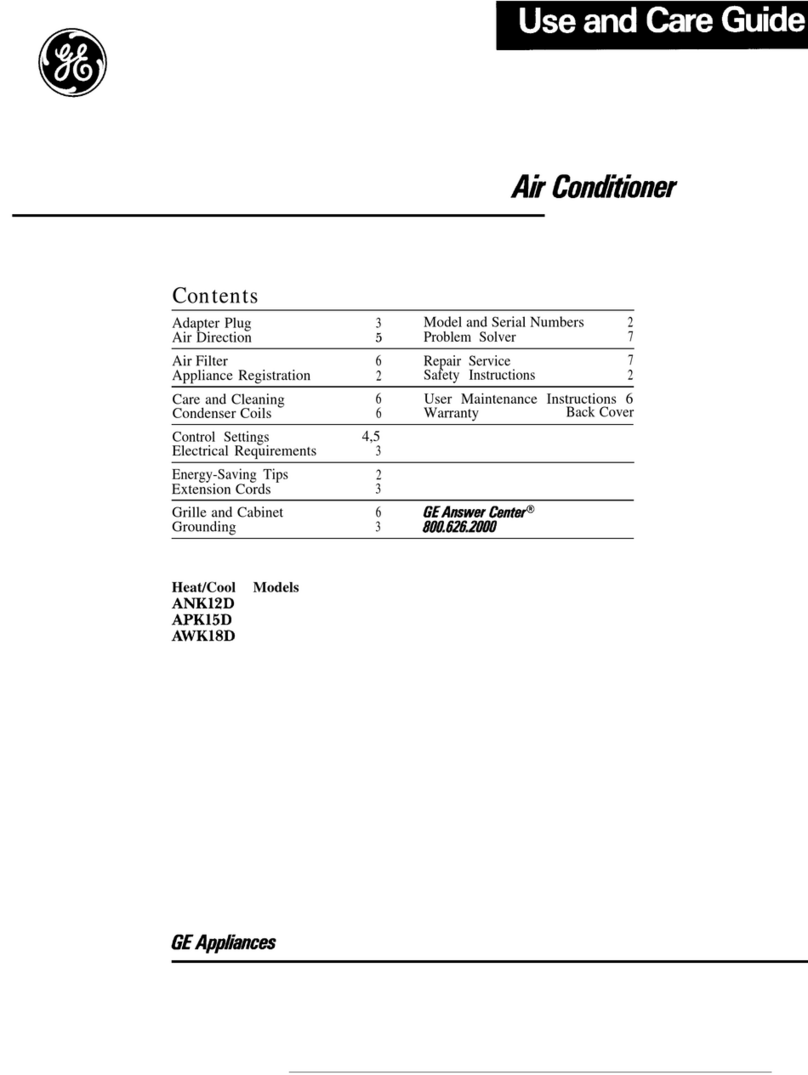

Your AC unit can be mounted either vertically on the front, rear or side of your enclosure or

horizontally on the top of your enclosure. See Figure 2.1 and 2.2.

Vertically mounted 1000 Btu units are always mounted with the exposed heatsink fins facing

up and down, never left and right. (Fig. 2.1) Vertical installations often require the use of a

Condensate Drip Pan (part # DP-V) depending on a number of factors including internal enclosure

temperatures and ambient temperatures, humidity levels, quality of enclosure seals, and

frequency of enclosure opening. We strongly recommend the use of a drip pan to protect the

electronics from dripping condensate. (Fig. 2.1)

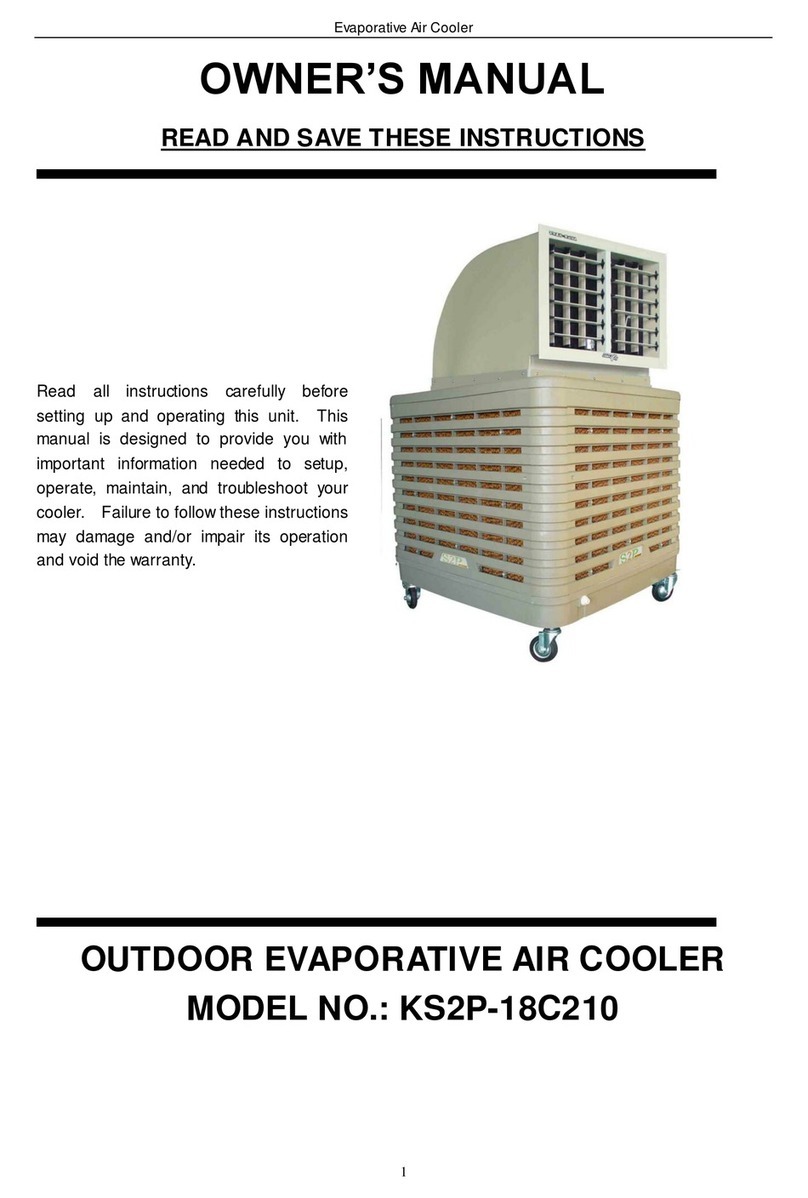

Mounting the unit horizontally on the side of an enclosure, will cause condensate to drip in

an uncontrolled manner, possibly damaging electronic equipment within the enclosure. If this

orientation is the only possible configuration, contact the Engineering Dept. at EIC for a custom

solution.

Horizontally mounted 1000 Btu units always require a factory installed drip pan (part #

DP-146H) to prevent dripping condensate from damaging electronic equipment. (Fig. 2.2)

In either orientation, issues regarding access should be considered and minimum clearances

must be maintained as outlined in Section 2.1 of this manual.

5

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

FIGURE 2.1

FIGURE 2.2

VERTICAL INSTALLATION OF 1000 BTU UNIT WITH

DP-V VERTICAL DRIP PAN AND DRAIN TUBE

HOT SIDE OF AC

(OUTSIDE OF

ENCLOSURE)

COLD SIDE OF

AC (INSIDE OF

ENCLOSURE)

DRAIN

TUBE

ENCLOSURE

DP-V DRIP

PAN

HOT SIDE FANSCOLD SIDE FANS

HOT SIDE HEAT

SINKS

COLD SIDE

HEAT SINKS

COLD SIDE

HEAT SINKS

HOT SIDE HEAT

SINKS

HORIZONTAL INSTALLATION OF 1000 BTU UNIT WITH

INTERNALLY MOUNTED DP-146H DRIP PAN AND DRAIN TUBE

ENCLOSURE

HOT SIDE OF AC (OUTSIDE

OF ENCLOSURE)

COLD SIDE OF AC (INSIDE OF

ENCLOSURE)

DRAIN

TUBE

COLD SIDE FANS

HOT SIDE FANS

COLD SIDE

HEAT SINK FINS

HOT SIDE HEAT

SINKS

HOT SIDE HEA

T

SINKS

COLD SIDE

HEAT SINK FINS

6

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

2.3 PREPARING THE ENCLOSURE

To mount the 1000 Btu unit you will need to cut an opening in your enclosure and drill

mounting holes. Cut-out drawings (see Appendix) showing the cut-out sizes and hole locations

have been included in this manual. The instructions for installing the air conditioner are printed

below.

TOOLS AND MATERIALS NEEDED:

•Pencil

•Scissors

•Tape Measure

•Jigsaw or suitable alternative

•Electric drill

•# 29 drill bit (.136”) (Not used for extension frame option)

•# 8-32 tap and tap handle (Not used for extension frame option)

•.203” drill bit (Extension frame option only)

•# 8-32 x 3/8” stainless machine screws (supplied)

•Nylon washers for NEMA 4X installations (supplied)

•One neoprene gasket (supplied)

CUT THE OPENING AND DRILL MOUNTING HOLES IN THE ENCLOSURE

1. Using the guidelines provided in the installation manual choose an appropriate location for

the air conditioner on your enclosure.

2. Layout the cut-out and hole pattern for the AC on the enclosure. Refer to Appendix A for

standard flange only. Standard flange air conditioners do not contain NF in the part

number, and the mounting flange measures 20.25” x 13”. Refer to Appendix B for narrow

flange models only. Air conditioners that are narrow flange units contain NF in the part

number, and the mounting flange measures 20.25” x 12”. Refer to Appendix C for

extension frame models.

3. Before cutting or drilling check that the location meets the clearance requirements as

specified in the installation manual.

4. Using a pencil, center punch or other method, mark the exact center point of each

mounting hole on the enclosure.

5. Using the jigsaw, cut the opening in the enclosure.

6. Using the appropriate drill size, drill a hole at each of the marks you made earlier.

7. Using the 8-32 tap, tap each of the holes you have drilled. (Non-Extension Frames Only)

2.4 INSTALLING THE AIR CONDITIONER

INSTALL THE AIR CONDITIONER

1. Lay the air conditioner down with the cold side (side with the thermostat) facing up.

2. Take the supplied gasket and lay it down on the flange.

3. Take one of the supplied mounting screws and, from the under side of the flange, push it up

through the top right mounting hole, and through the hole in the gasket. The gasket hole is

undersized and will hold the screw in place. Repeat this on the top left mounting hole.

4. Set the AC unit in the hole you’ve cut in the enclosure, and using a screwdriver, carefully

start the two screws you attached to the gasket to the tapped holes in the enclosure. Do

not tighten these at this time.

7

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

5. Install the rest of the screws in the flange placing a nylon washer on each fastener and

screw them into the tapped holes in the enclosure. Do not tighten them completely.

a. If you have purchased a vertical drip pan, you will need to install the three long

screws in the three center holes in the bottom flange.

6. Remove the two starter screws and place a nylon washer on each and reinstall.

7. Tighten all screws.

INSTALL THE DRIP PAN

1. Two hose fittings were provided with the drip pan, a right angle and a straight one. Choose

one and install it on the drip pan. Be sure if you use the right angle fitting it is facing the

desired direction prior to installing the drip pan.

2. There are three mounting holes in the drip pan, match these with the long mounting screws

protruding into the enclosure at the bottom of the AC unit. Push the drip pan onto these

screws.

3. Using the three 8-32 keps nuts provided, attach the drip pan to the air conditioner.

4. Attach the supplied PVC drain tube to the hose fitting on the drip pan. This tube should be

routed to the bottom of the enclosure and fed through a 3/8” hole to the outside.

5. If you purchased a horizontal drip pan, it is installed at the factory and you will only need to

install the hose fitting and PVC drain hose.

YOU MUST USE THE FACTORY INSTALLED HORIZONTAL DRIP PAN IF YOU INSTALL THE AIR

CONDITIONER HORIZONTALLY (FIG 2.2) ON THE TOP OF YOUR ENCLOSURE. FAILURE TO DO SO

MAY ALLOW CONDENSATE TO DRIP IN AN UNCONTROLLED MANNER CAUSING DAMAGE TO YOUR

EQUIPMENT.

APPLY POWER

Once the air conditioner is mounted, check the serial label and confirm the voltage required

and then apply appropriate power as outlined below.

120 VAC units – plug into standard 120 volt, grounded outlet. Amperage for a 120 VAC unit is

9.4 amps.

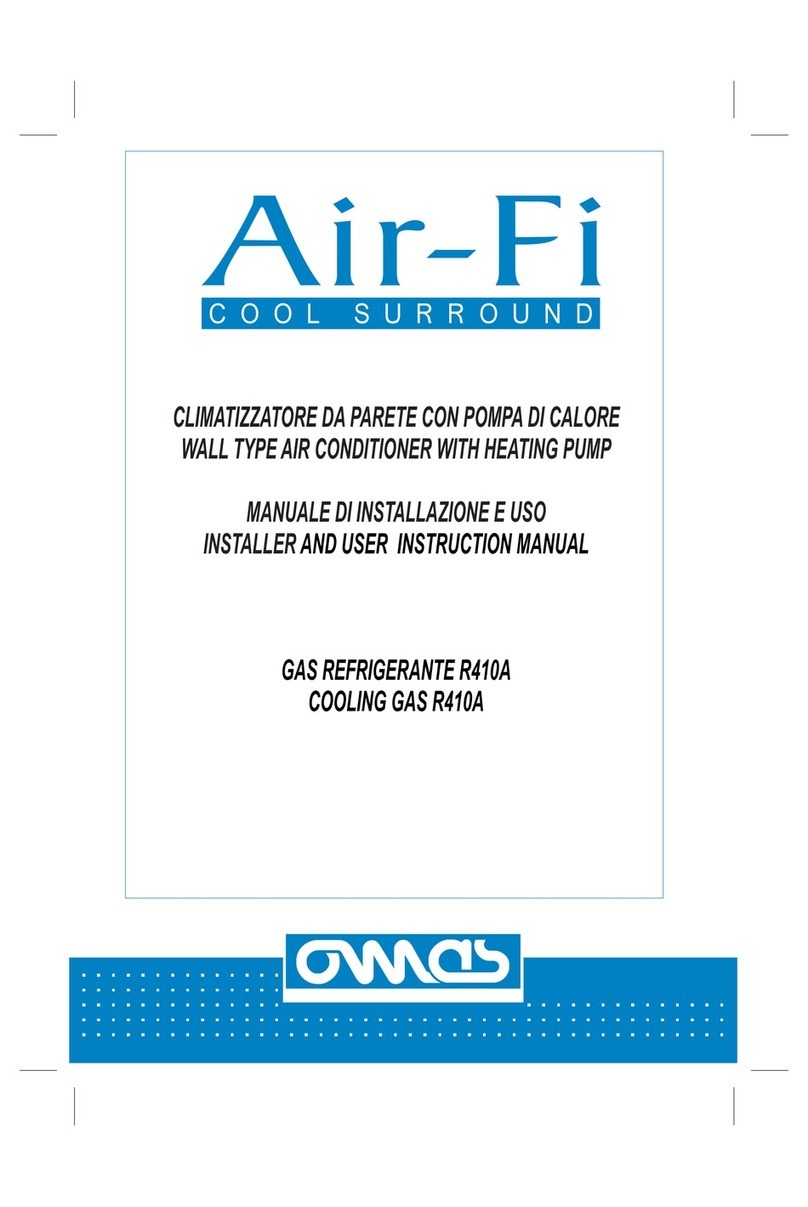

220 – 240 VAC units – this unit will not have a plug on the end. Connect the wires to an

appropriate power source using standard safe wiring methods. Wire colors are as follows:

Black or Brown – line

White or Blue – line/neutral

Green or Green/Yellow – ground

A wiring diagram is shown in Fig. 2.4. Amperage for a 220 VAC unit is 6.9 amps.

8

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

Figure 2.4

If you purchased a Digital Temperature Controller with your AC unit, a separate wiring diagram

has been provided which will show the correct method of applying power to your particular air

conditioner.

Upon applying power to the air conditioner the fans on the cold side (inside the enclosure) will

come on. The hot side fans (outside the enclosure) may also run depending on where the

thermostat is set. The cold side fan always runs to circulate air within your enclosure thereby

eliminating any “hot spots”. The hot side fans will only run when the air conditioner is cooling –

they are “pumping” the heat from the inside of your enclosure to the outside air.

9

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

3. OPERATION

3.1 THERMOSTAT SET POINTS AND HEATING/COOLING UNITS

SETTING THE THERMOSTAT

Your EIC air conditioner is equipped with an adjustable thermostat. The set point you

choose should be based on the desired internal temperature of the enclosure. The air conditioner

will run until the set point temperature is achieved within the enclosure and then the hot side fans

and the thermoelectric cooling modules will shut down. The cold side fan will continue to run,

circulating the air to maintain a uniform temperature within the enclosure.

HEATING AND COOLING UNITS

If you purchased an HC unit (heating and cooling), the heater operation is controlled by a

fixed-point thermostat. This thermostat is set to turn the heaters on when the temperature within

the enclosure falls to approximately 45°F and turn the heaters off when the temperature rises to

approximately 55°F.

The cooling operation is controlled by the adjustable thermostat. To avoid having the

heating and cooling on at the same time, do not set the cooling thermostat below 70°F.

3.2 MAINTENANCE

MAINTENANCE

EIC Thermoelectric Air Conditioners are virtually maintenance-free. The only time

maintenance is required is when a unit is installed in an extremely dirty environment. In these

cases, the hot side heat sinks (outside the enclosure) should be inspected regularly for a build-up

of dust or dirt. If a build-up is present on the heat sink fins, it can be easily removed as follows:

1. Disconnect the power from the unit.

2. Dry dust/dirt can be removed using compressed air to blow out the heat sinks. Do not

direct any high-pressure air at the fans.

3. NEMA 4X models of our air conditioners are designed to allow for water wash down of the

hot side of the unit, which is outside of the enclosure (never the cold side which is inside

the enclosure). A pressure washer can be used to carefully clean the hot side heat sink

fins. Never direct high-pressure water at the fans or the joint formed by the mounting

flange, gasket and enclosure. Never allow the cold side of your unit to get wet. Always

check your serial label before proceeding with a water wash down.

Keeping the hot side heat sink fins free from any insulating build-up of dirt or dust will ensure

long, trouble-free operation of your air conditioner.

NEVER EXPOSE THE COLD SIDE OF ANY AIR CONDITIONER (INSIDE THE ENCLOSURE) TO

WATER.

If you have any questions about any aspect of your EIC air conditioner, don’t hesitate to call us at

the numbers listed below.

10

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

APPENDIX A and B

Enclosure cutout for

Standard Flange

models only, DO

NOT use with

Narrow Flange

models or Extension

Frame

Drawing A

Enclosure cutout

for Narrow Flange

models only, DO

NOT use with

standard models

or Extension

Frame

Drawing B

Holes to be 8-32 TAP

11

1-800-497-4524 EIC SOLUTIONS, INC.215-443-5190

APPENDIX C

Enclosure cutout for 1000 BTU air conditioner

EXTENSION FRAME ONLY

Holes to be .203”

This manual suits for next models

9

Table of contents

Other EIC Solutions Air Conditioner manuals

EIC Solutions

EIC Solutions AAC-140B-4XT User manual

EIC Solutions

EIC Solutions AAC-141-4XT-EP User manual

EIC Solutions

EIC Solutions AAC-145-4XT-EP User manual

EIC Solutions

EIC Solutions AAC-141A-4XT Series User manual

EIC Solutions

EIC Solutions AAC-151B Series User manual

EIC Solutions

EIC Solutions AAC-120-4XT Series User manual

EIC Solutions

EIC Solutions AAC-140C-4XT Series User manual

EIC Solutions

EIC Solutions AAC-161B Series User manual

EIC Solutions

EIC Solutions AAC-170 Series User manual

EIC Solutions

EIC Solutions AAC-140B-4XT-EP User manual