EIC transfusio-therm 2000 User manual

transfusio-therm

®

2000

Quick Reference Guide

Status: June 2013 Page 1 of 5

The Quick Reference Guide must be kept directly on the transfusio-therm

®

2000 in a

clearly visible manner. Be certain to observe the following sequence of operations and

suggestions when putting the transfusio-therm

®

2000 into operation and when using it.

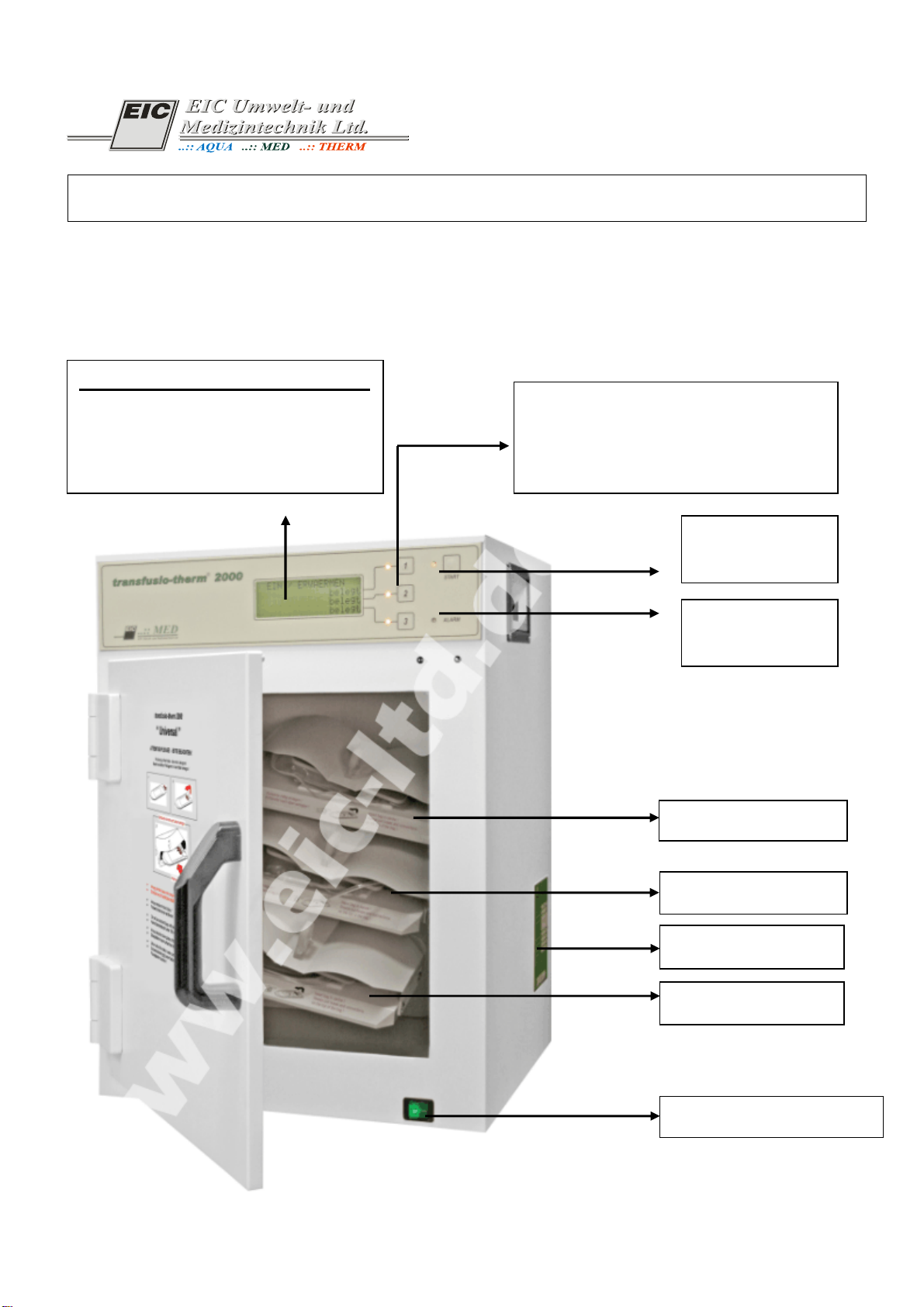

I. Overview

Compartment No. 1

Compartment No. 3

Compartment No. 2

ON / OFF Power Switch

Start Button

with LED

LED

Alarm Si nal

Confirmation Buttons with LED

Compartment No. 1

Compartment No. 2

Compartment No. 3

Operator-Prompting Display

Status Line

User Interface for Compartment No. 1

User Interface for Compartment No. 2

User Interface for Compartment No. 3

Nameplate

transfusio-therm

®

2000

Quick Reference Guide

Status: June 2013 Page 2 of 5

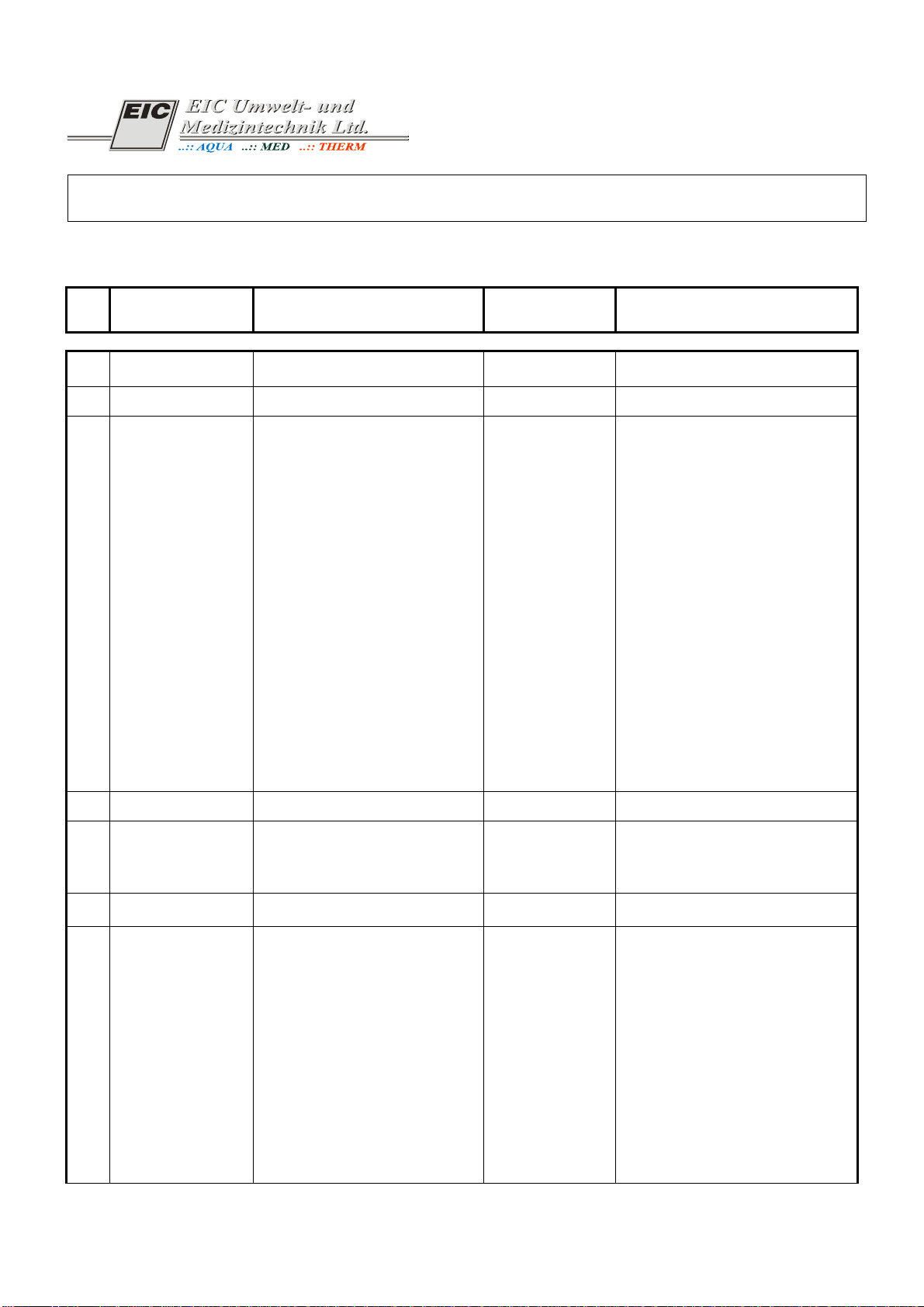

II. Start-up and Operation

Item

No.

Step

Activity

Display

Important:

Be Sure to Pay

Attention to the Comments Below.

01 Switching the

appliance on

Use the ON / OFF power switch to

switch the appliance on.

SELF-TEST; ON

VACANT Appliance carries out a self-test

(approx. 3 seconds).

02 Opening the door

Use the door handle to open the

door.

ON

03 Loading a

compartment

To load a blood bag into any vacant

compartment,

•prepare the bag, as shown in

the pictograms and described in

the instructions provided;

•raise the spring plate of the

compartment;

•place the bag in the middle of

the compartment;

•make sure that tube ends /

connectors are located on the

right-hand side and on top of

the bag;

•release the spring plate.

•IMPORTANT

Bag filling volume:

100 ml to 600 ml

ON

---------- Place the bag in the middle of the

compartment, with tube ends

located on the right-hand side and

on top of the bag.

Always make sure that tubes do

not protrude from the

compartment.

When it comes to bags containing

plasma / FFP, tube connectors

frozen in a bent position must be

located on the right-hand side and

on top of the bag. If the

connectors are frozen in a straight

position, the bag is to be inserted

with the connectors located on the

right-hand side.

It is possible to thaw a blood bags

inserted into protective bags,

provided the above instructions

are observed.

04 Closing the door

Use the door handle to close the

door.

ON

05 Confirming loading

When prompted by the yellow

flashing LED and the text appearing

in the display, press the confirmation

button of the compartment just

loaded.

ON

CONFIRM

LOADING

06 Start

When prompted by the yellow

flashing LED, press the start button.

ON / START

LOADED

07 Thawing /

heating

A star symbol will appear in the

Universal model and when fresh

frozen plasma (FFP) bags are

inserted. This star will be

extinguished when approximately

+20° C are reached, with an acoustic

signal indicating that the bag has

thawed and may be removed, as

required. If the bag is not removed,

heating will continue until the target

temperature is reached.

ON / HEATING

LOADED

Star symbol if the

bag contains

FFP

The appliance will automatically

recognize bags that are already

heated. If this is the case, the

appliance will shut down. An

intermittent alarm tone will be

sounded. A read flashing signal

will appear on the compartment

concerned, and the display will

show REMOVE / CHECK BAG.

Remove the bag. Check the

temperature of the bag and/or

reinsert the bag. Once the loading

of the bag has been confirmed

and the start button pressed, the

heating process will continue.

transfusio-therm

®

2000

Quick Reference Guide

Status: June 2013 Page 3 of 5

08 Target temperature

reached

Automatic acoustic signal and green

flashing LED on the compartment

concerned

ON

x °C / CONFIRM

DEFROSTED /

CONFIRM

The set target temperature will be

displayed.

09 Confirming the

removal

Press the confirmation button of the

compartment concerned.

ON

REMOVE BAG

10 Opening the door

Use the door handle to open the

door.

ON

LOADED

11 Removing the bag

Follow the steps below to remove

the bag:

•Raise the spring plate of the

compartment.

•Remove the bag.

•Release the spring plate.

ON

--------- Once the bag has been removed,

the compartment can be loaded

again. To do so, start with Item 03.

12 Closing the door

Use the door handle to close the

door.

ON

VACANT The appliance is ready for use. For

longer periods of non-use, turn

the appliance off, using the ON /

OFF power switch.

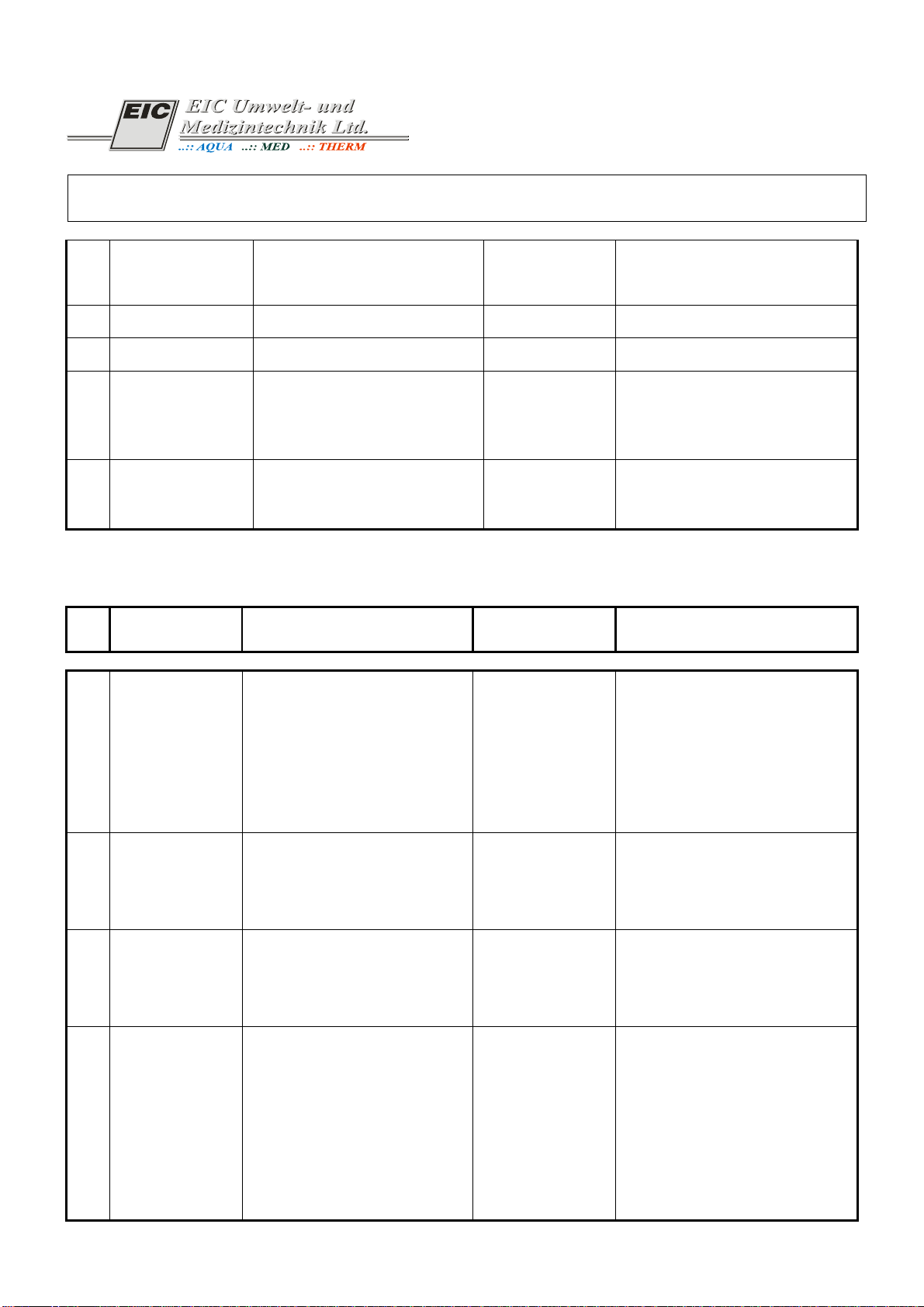

III. Safety Comments

Item

No.

Subject

Information

Display

Important:

Be Sure to Pay

Attention to the Comments Below.

13 Special operating

note If a bag has been inserted into

the compartment, with no

operating action taking place

(with the door open or closed),

although a relevant prompt has

appeared in the display, an

acoustic signal sounded after

approximately 5 minutes will

remind the operator to resume

work on the appliance.

Whenever an acoustic signal is

sounded, it is imperative that you

go to the appliance and act upon

the prompt.

14 Safety shutdown If the two-channel monitoring

system of the appliance detects

an error in any compartment

area, the compartment will be

blocked, as signaled by a steady

red light of the LED.

ON / SERVICE

BLOCKED Do not use the blocked

compartment.

Proceed as described in Item 16,

which addresses a protective

shutdown.

15 Inadvertent

loading of a

compartment

following a safety

shutdown (13)

If a shutdown compartment is

loaded inadvertently, the red

LED will change from a steady

light to a flashing one.

ON / SERVICE

REMOVE BAG After pressing the confirmation

button and removing the bag from

the blocked compartment, you can

continue using those

compartments of the appliance

which are not blocked.

16 Protective

shutdown All the compartments are shut

down whenever the two-channel

monitoring system of the

appliance detects a malfunction

in the overall system. The

compartment LEDs and the

alarm LED will show steady red

light.

OFF

PROTECTIVE

SHUTDOWN

NOTIFY SERVICE

In the event of a protective

shutdown, please be sure to turn

the appliance off, using the ON /

OFF power switch.

Open the door and check that all

the bags are inside the

compartments and that they are

not damaged. If necessary,

remove all the bags from the

compartments. Check the

temperature of the bags. Destroy

transfusio-therm

®

2000

Quick Reference Guide

Status: June 2013 Page 4 of 5

them if they are found to be

warmer than 41° C or show any

visible signs of external damage.

Clean the appliance whenever any

bag leakage has occurred.

Use the ON / OFF power switch to

turn the appliance on again.

If the self-test (1) is successful,

the appliance can continue to be

operated in the usual manner.

Notify the Service Department

immediately if the self-test

triggers a protective shutdown.

IV. Suggestions for Cleaning and Disinfection

Item

No.

Subject

Actions

Activities

Important:

Be Sure to Pay

Attention to the Comments Below.

17 Initial

cleaning

OUTSIDE SURFACES: Exclusively use a wet cloth and a mild

detergent.

SEALING SURFACES (the four sides of the front face of the

housing around the interior and on the inside of the door):

Exclusively use a wet cloth and a mild detergent. Do not turn

the appliance on when sealing surfaces or the door are

damaged.

INTERIOR: Exclusively use a wet cloth soaked with a

conventional disinfectant approved under applicable medical

regulations.

ROTATING UNIT: To facilitate cleaning, the rotating unit can

be taken out as a whole. To this end, remove the safety hook

and pull the rotating unit off frontwards. To remove the

spring plates, loosen the four screws with which they are

fastened.

To prevent damage, proceed with particular care when

cleaning temperature measuring points (silver plates). After

cleaning, wipe all parts dry and screw the spring plates on

again tightly. Push the complete rotating unit, from the front,

onto the drive shaft as far as it can go. Then, reinsert the

safety hook. Before putting the appliance into use again,

check that the rotating unit is properly fitted.

Be sure to clean the motor shaft and the plug-in device of the

rotating unit dry only.

Always pull the power plug

before cleaning the appliance.

Do not use any scouring agents

or scratching or pointed objects

for cleaning.

WARNING:

Never rinse the rotating unit with

running water or clean it with the

aid of washers or disinfectors.

Never operate the appliance

when the rotating unit is not

properly and securely positioned

and/or the safety hook is not

fully inserted.

When the message "Important:

Check Mounting of Rotating

Unit" appears on the display,

switch off the appliance and

recheck that the rotating unit is

properly fitted.

18 Bag

leakage Clean the affected surfaces and/or the rotating unit, as

described in Item 17. Be sure to heed the instructions

furnished in Item 17.

19 Regular

cleaning and

disinfection;

maintenance

Follow your in-house hygiene routines and regulations. Pay

particular attention to the cleanliness of the temperature

measuring points (silver plates).

Do not apply oil and other lubricants to the motor shaft and

plug-in device, as this may adversely affect electrical

conduction.

Be certain to heed the

instructions provided in Item 17.

transfusio-therm

®

2000

Quick Reference Guide

Status: June 2013 Page 5 of 5

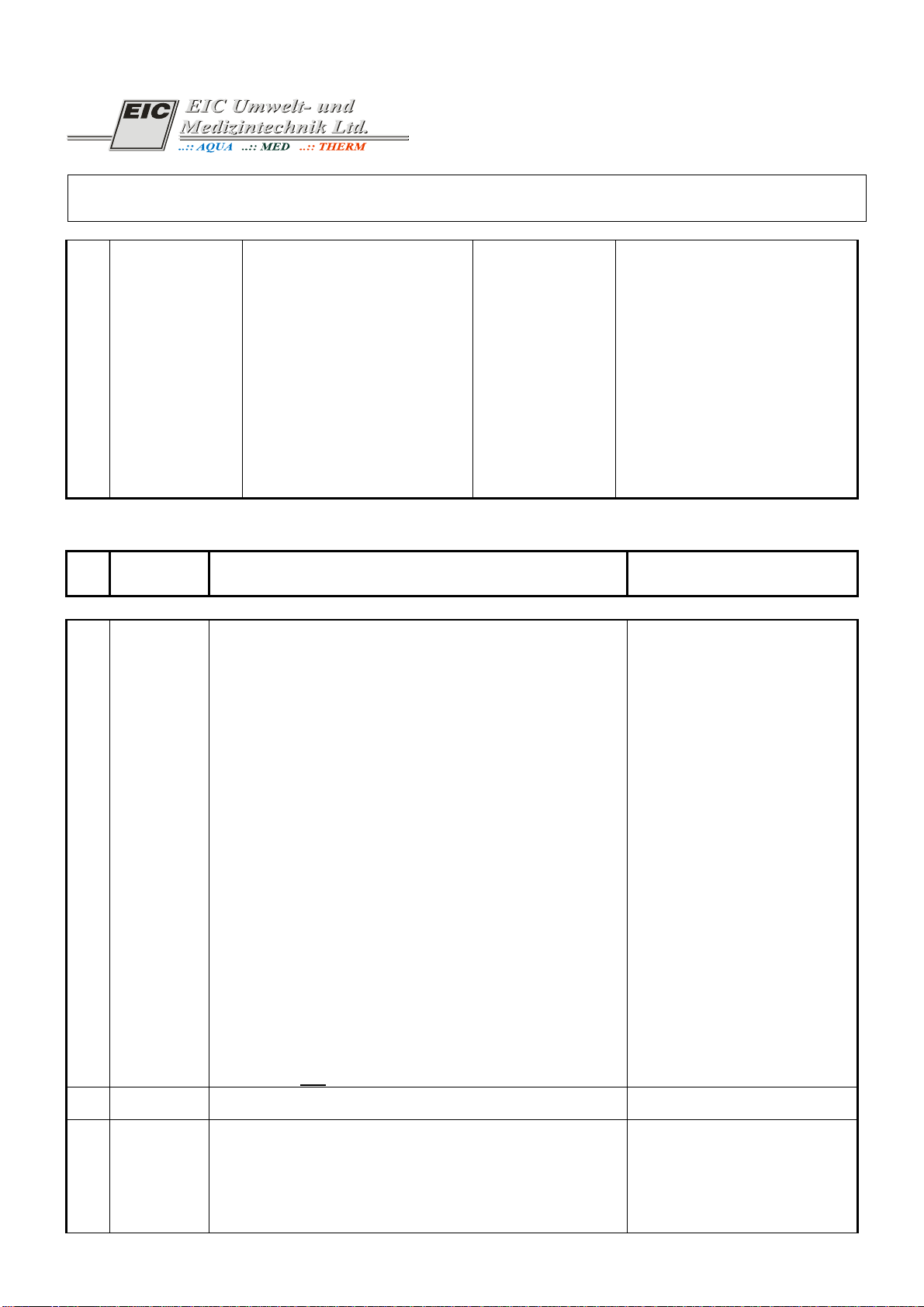

20 Readout of

the error

code

Error

message

When switching the appliance on, keep button no. 3

depressed until the error code appears in the display. Button

no. 1 lets you browse through the errors all the way to error

no. 31. To get the number of bags heated, press button no. 2.

Record the read-out error code, together with the serial

number of the appliance (see nameplate attached on the

right-hand side of the appliance), in a fault report form and

fax or e-mail this form to EIC Ltd.

EIC Umwelt- und Medizintechnik Ltd., Rudolf-Diesel-Strasse 5, D-37308 Heilbad Heiligenstadt, Germany

Telephone: +49 3606 607925, Fax: +49 3606 5071353, E-mail: eic-ltd.mail@t-online.de

!"#$"%"&'(')

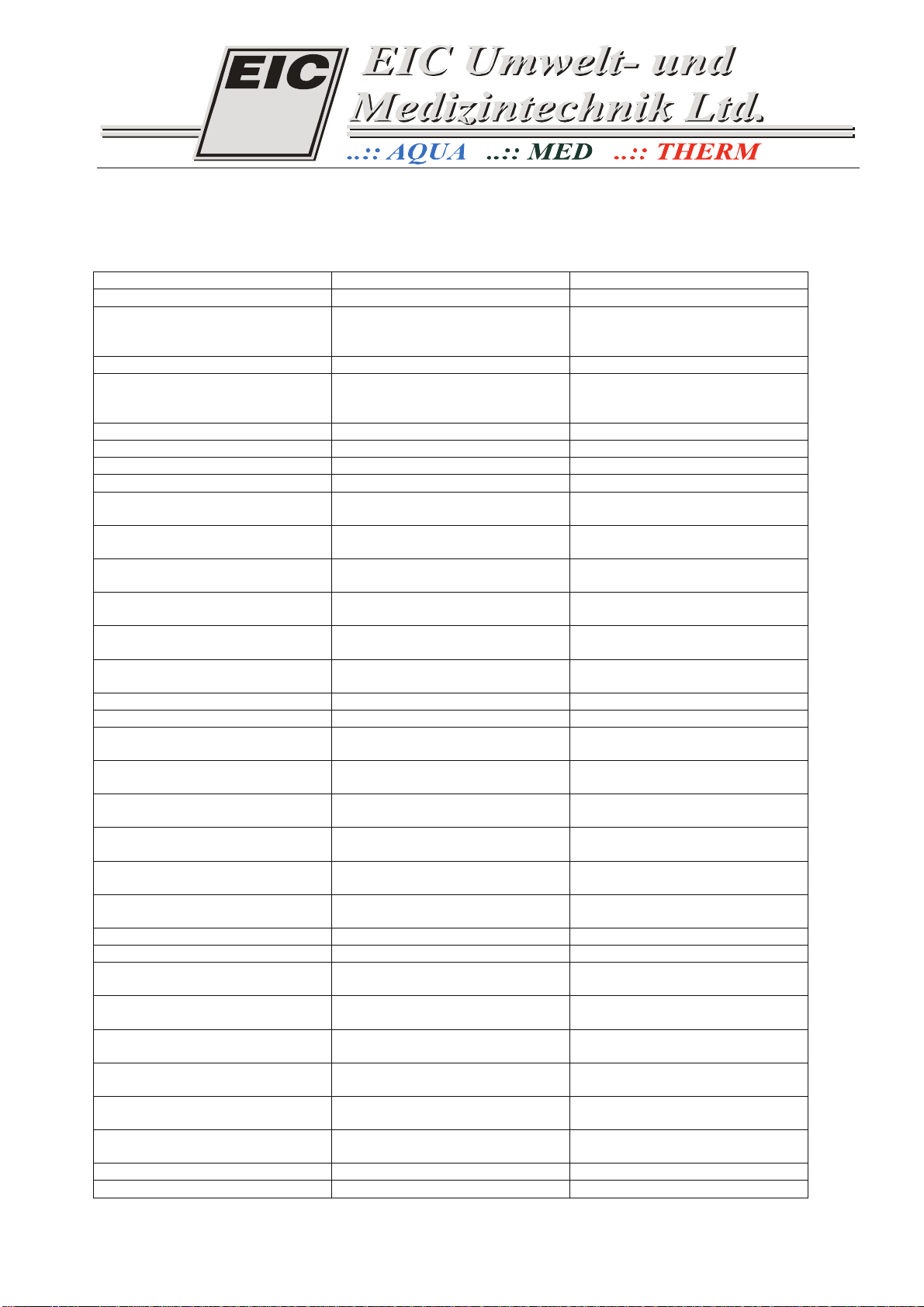

Meaning of the failure codes safety shutdown

„transfusio-therm 2000“ controller version 7 and 8

Code Error

0 Door switch, different signals Equipment protective cut-off

1 Error turning / blocked or protective

cut-off

2nd system

Equipment protective cut-off

2 Error turning / over-wound Equipment protective cut-off

3 Error magnetron / does not switch on or

protective switching

2nd system

Equipment protective cut-off

4 Error magnetron / does not switch off Equipment protective cut-off

5 Error antenna / turns too slowly Equipment protective cut-off

6 Deficient self-test Equipment protective cut-off

7 T1...T6 > 41

o

C Equipment protective cut-off

8 Full sensor 1 open,

Full sensor 2 closed

Equipment protective cut-off

Intake 1

9 Full sensor 2 open,

Full sensor 1 closed

Equipment protective cut-off

Intake 1

10 Temperature difference > 1

o

C Safety cut-off

Intake 1

11 Break in the temperature sensor cable Safety cut-off

Intake 1

12 T1 or T2 > 39

o

C Safety cut-off

Intake 1

13 Intake leaky (HF) Safety cut-off

Intake 1

14

15

16 Full sensor 1 open,

Full sensor 2 closed

Protective cut-off

Intake 2

17 Full sensor 2 open,

Full sensor 1 closed

Protective cut-off

Intake 2

18 Temperature difference > 1

o

C Safety cut-off

Intake 2

19 Break in the temperature sensor cable Safety cut-off

Intake 2

20 T1 or T2 > 39

o

C Safety cut-off

Intake 2

21 Intake leaky (HF) Safety cut-off

Intake 2

22

23

24 Full sensor 1 open,

Full sensor 2 closed

Protective cut-off

Intake 3

25 Full sensor 1 closed,

Full sensor 2 open

Protective cut-off

Intake 3

26 Temperature difference >

1

o

C

Safety cut-off

Intake 3

27 Break in the temperature sensor cable Safety cut-off

Intake 3

28 T1 or T2 > 39

o

C Safety cut-off

Intake 3

29 Intake leaky (HF) Safety cut-off

Intake 3

30

31

Table of contents

Popular Medical Equipment manuals by other brands

Droper

Droper Field 1000 operating instructions

ProMedTek

ProMedTek Replexa+ instruction manual

Weinmann

Weinmann LIFE-BASE light XS Instructions for use

Proactive Medical

Proactive Medical Protekt Aire 6500 Operation manual

mychway

mychway MS-7008CX user manual

Smeed Technologies

Smeed Technologies MERK-EVAC instruction manual