02. GENERAL SAFETY REGULATIONS

-Only use this stove as described in this manual. Any other use not recommended by the manufacturer may

cause fires or accidents to people.

Make sure that the type of power supply complies with what is indicated on the data plate (220V~/50Hz). This

product is not a toy. Children must be adequately supervised so that they do not play with the appliance. This

appliance must not be used by people (including children) with reduced physical, sensory or mental capabilities, or

without the necessary experience and knowledge, unless a person responsible for their safety controls their use of

the appliance or gives them the pertinent instructions for use.

If the appliance is not used or for cleaning reasons, disconnect the power supply from the mains.

To disconnect the stove, place the switch in position O and remove the plug from the socket. Just pull the plug, not the

cord.

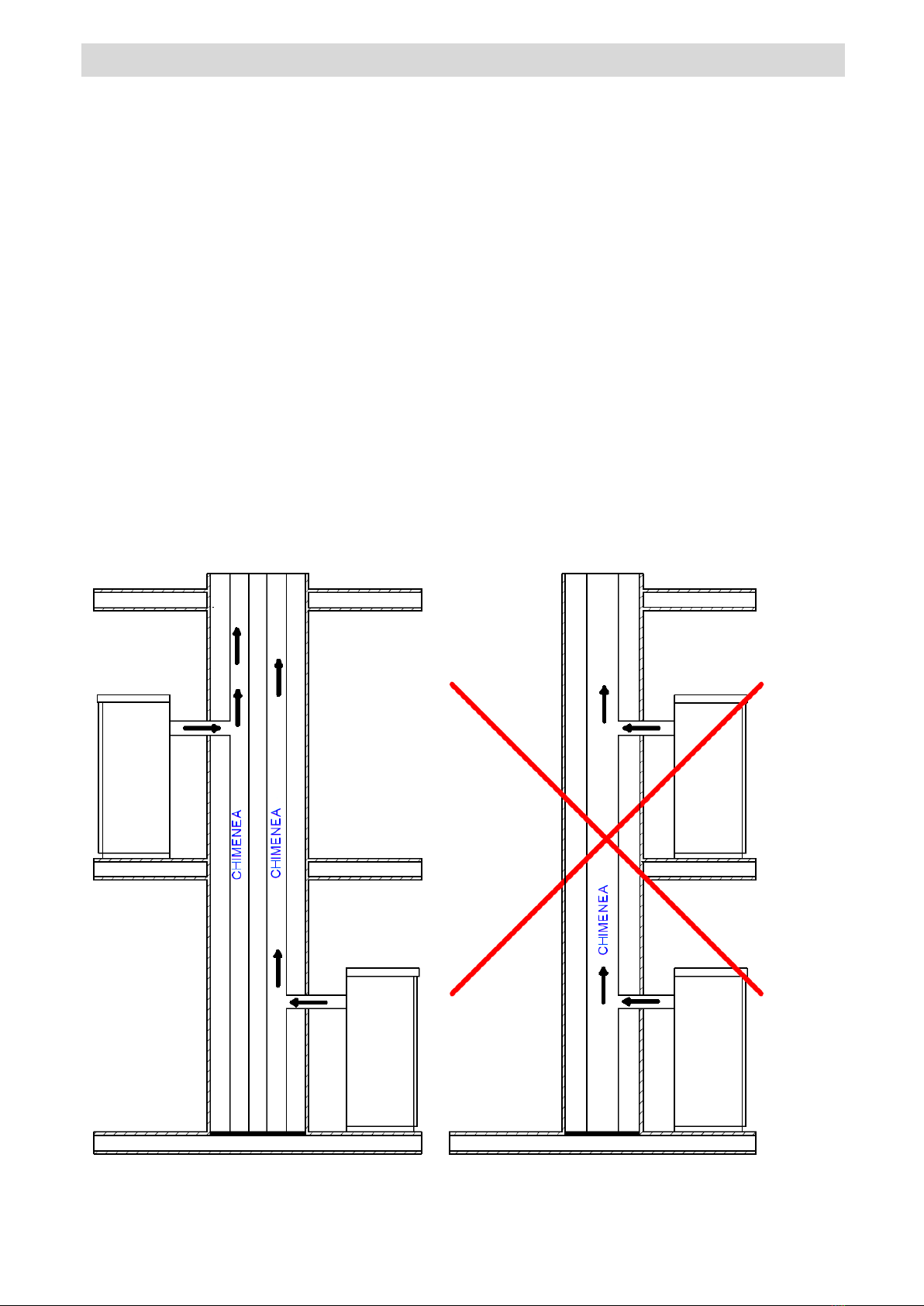

Under no circumstances close the combustion air inlet and smoke outlet openings.

Do not touch the stove with wet hands because it is equipped with electrical components.

Do not use the appliance with damaged cables or plugs. The appliance is classified as type Y, that is,

the power cord must be replaced by a qualified technician. If the power cord is damaged, it must be

replaced by the manufacturer, its technical assistance service, or similarly qualified personnel.

Do not put anything on the cable and do not bend it.

The use of extensions is discouraged, as the extension can become hot and cause a fire hazard. Never use a

single extension to run more than one appliance.

During normal operation, some parts of the stove, such as the door, the glass and the handle, can

reach high temperatures. Therefore, pay attention to the case, especially for children. Consequently,

avoid contact of unprotected skin with the hot surface.

ATTENTION! DO NOT TOUCH the DOOR WHERE THE FIRE IS, the GLASS, the HANDLE or the SMOKE OUTLET PIPE

without adequate protections DURING OPERATION: The strong heat developed by the combustion of the pellets

heats them up!

Keep flammable materials, such as furniture, pillows, blankets, papers, clothes, curtains, etc., at a distance of

1 m from the front and 30 cm from the sides and rear.

Do not immerse the cable, the plug or any other part of the appliance in water or other liquids.

Do not use the stove in dusty environments or with flammable vapors (for example, in a workshop or garage).

There is a risk of fire if, during operation, the stove is covered with materialflammable, including curtains, draping,

blankets, etc., or come into contact with this type of material.KEEP THE PRODUCT AWAY FROM THESE MATERIALS.

A stove has parts inside that generate arcs or sparks. It should not be used in areas that may be dangerous,

such as areas with risk of fire, explosion, areas loaded with chemical substances or atmospheres loaded with

humidity.

Do not use the appliance near bathtubs, showers, sinks or swimming

pools. Do not place the appliance under a socket. Do not use outdoors.

Do not attempt to repair, disassemble or modify the appliance. The appliance contains no user-serviceable parts. Turn

off the switch and remove the plug before carrying out maintenance, and only work when the stove is cold. WARNING:

WHEN PERFORMING MAINTENANCE, ALWAYS REMOVE THE PLUG.

ATTENTION! This stove works exclusively with pellets and hazelnut shell if the stove is designed; DO

NOT USE FUELS OTHER THAN PELLETS. Any other material that burns will cause a breakdown and

malfunction of the device.

Store the pellet in a cool, dry place. If it is kept in places that are too cold or humid, the thermal potential of the

stove can be reduced. Pay special attention to the storage and handling of the bags of pellets to prevent them from

being crushed and resulting in the formation of sawdust.

Regularly clean the burner with each ignition or with each refill of pellets.

The hearth must be kept closed, except during recharging or waste disposal, to prevent smoke from

escaping.

Do not intermittently turn the stove on and off as it is equipped with electrical and electronic components

that can be damaged.

Do not use the appliance as an incinerator or in any other way than that for which it has been designed.

Do not use liquid fuels.

Do not make any unauthorized modifications to the device.

Only use original spare parts recommended by the manufacturer...

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

7