EIP 451 User manual

1

.

.

.

ure

P

ING1 MOLO.L. 451

1,mcfroyvmea PIA-5

71'6

6

P

,

1 .1tokApi

91

,

6.5

--,

e

(i'y

Telephone: ;=

j9I 1

7

.4

X :

910-338-0 I

Elf' Microwave

C

1

arq

-

CA

-

95064-

i

Manual Part Number: 5580010

Manual printed in U.S.A. — OCT 1978

CCN

Or)q-

MANUAL CHANGE INFORMATION

MODEL 451

At EIP we continually strive to keep up with the latest electronic developments by adding

circuit and component improvements to our instruments as soon as they are developed

and tested.

Sometimes, due to printing and shipment requirements, we cannot get these changes im-

mediately into printed manuals. As a result, your instrument may contain some or all of

the changes listed below.

PAGE NUMBER:

0-3.

A109

7,5K.

caler (5500079), Change R33 to 7,5K, 1/4 W.

Change R34 to 10K, 1/4 W.

.0-5.

A111 BCD Output/Remote Prog., Signal from P1 pin 15 to AS should be inhibit.

3-1.

Paragraph 3-8, line 4, should read "925 MHz - 18 GHz, or Band A (Option P2) for frequencies".

3-1.

Paragraph 3-15, last line should read "produce 1.5V at the INPUT INHIBIT thus enabling the 451".

8-7.

Al Basic Counter, Change FAN part number to 5000151.

8-7.

AMica.

ontrol (2020074), Change C5 to Mica, 200 pF, part number 2250009.

Add CR18, General Purpose diode, part number 2704154.

Delete R20.

8-8, A107 Power Supply (2020077), Change Cl to part number 2200016.

Change C5 to part number 2200018.

A106 High Frequency (2020081), Change R47 to part number 4130999.

8-9.

A107 Power Supply (2020077) Change R20 to part number 4130999.

8-9

A109 Prescaler (2020079) Change R33 to 4130752.

Change R34 to 4010103.

9-5.

A100, (5500070) Rear panel MIN PRF switch should be labeled 0 (not ON) and 50 Hz (not OFF). The blue

and green wires from J1 should be transposed so the green wire goes to 0.

9-9.

A103 Cou

U17.

hain schematic (5500083-A) U16, U17, and U18 - change pin 14 to pin 1.

9-13. A104 Control (5500074-0), Change C5

to 200

pF.

Replace R20 with CR18 (anode side to ground).

C2 should.be 6.3

V.

9-15.

A105 Gate Generator, Signal from P1M

to.

U14C pin 2 should be clo

(5500077).

.

9-19. A107 Power Supply (5500077), Change Cl value to 9500 uF .25V.

Change C5 value to 44,000 uF .15V.

Change 1920 to 5.6K, 2%.

9-33, A203 Converter Sequencer schematic - delete line between U7 pin 3 and U9 pin 2.

-add line bet

03.n U9 pin 2 and U4 pin 1.

-change 03, now shown as NPN, should be PNP,

-change C4 to .005 value.

4-1,

Paragraph 4-4, line 6 should read " 100us (or 1 ms)."

8-12. A204 IF Processor (2020094) - Note the following part number changes.

C25 is 2150003 R41 is 4130151

C33 is 2150003 R43 is 4130431

R32 is •4130431

R44 is 4130221

R34

is 4130271

R76 is 4130471

R35 is 4130221

.1

and make the following changes to your

R41 is now 150 ohm, 2%

R43 is now 270 ohm, 2%

R44 is now 220 ohm, 2%

R76 is now 470 ohm, 2%

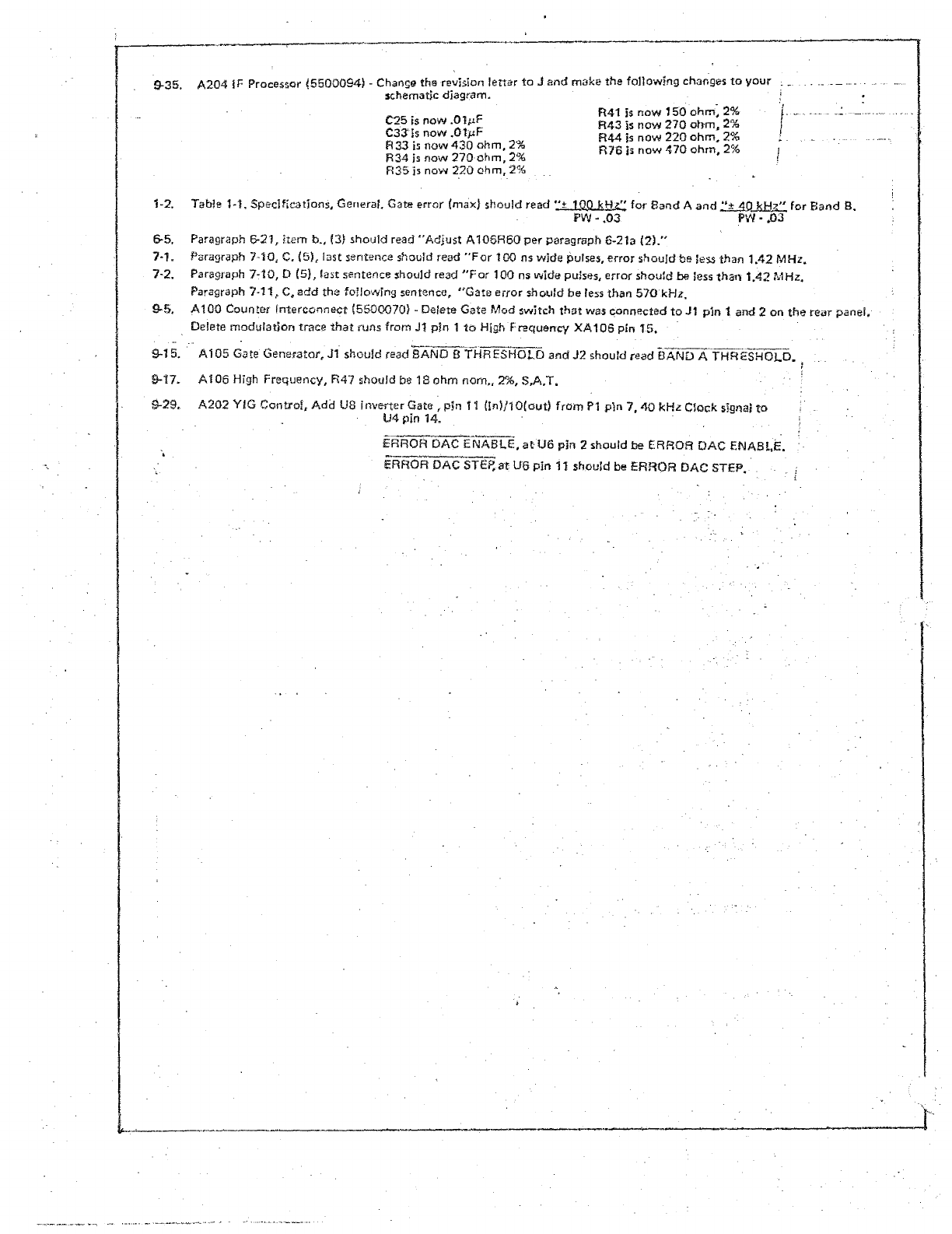

9-35. A204 IF Processor (5500094) - Change the revision letter to

schematic diagram.

C25 is now .01µF

C33 is now .01µF

R33 is now 430 ohm. 2%

R34 is now 270 ohm. 2%

R35 is now 220 ohm. 2%

1-2. Table 1-1, Specifications

,

General. Gate error (max) should read "± 1§),014-1z." for Band A and "± 40kHz" for Band B.

PIN - .03

- .03

6-5. Paragraph 6-21, item b., (3) should read "'Adjust A106R60 per paragraph 6-21a (2)."

7-1. Paragraph 7-10, C. (b), last sentence should read "For 100 ns wide pulses. error should be less than 1.42 MHz,

7-2. Paragraph 7-10. 0 (51, last sentence should read "For 100 ns wide pulses, error should be less than 1.42 MHz.

Paragraph 7-11, C, add the following sentence, "Gate error should be less than 570 kHz.

9-5, A100 Counter Interconnect (5500070) - Delete Gate Mod switch that was connected to J1 pin 1 and 2 on the rear panel.

Delete modulation trace that runs from J1 pin 1 to High Frequency XA106 Pin 15,

9-15. A105 Gate Generator, J1 should read BAND B THRESHOLD and J2 should read BAND A THRESHOLD.

9-17. A106 High Frequency, R47 should be 18 ohm nom.,

2%, S.A.T.

9-29, A202 YIG Control, Add US Inverter Gate , pin 11 (in)/10(out) from P1 pin 7, 40 kHz Clock signal to

U4 pin 14,

EFIROR DAC ENABLE, at U6 pin 2 should be ERROR DAC ENABLE.

ERROR DAC STJ

-

P

-

,at U6 pin 11 should be ERROR DAC STEP.

CERTIFICATION

EIP Microwave certifies that this instrument was throroughly inspected and

tested, and found to be in conformance with the specifications noted herein

at time of shipment from factory .

WARRANTY

EIP Microwave warrants this counter to be free from defects in material and

workmanship for one year from the date of delivery. Damage due to accident,

abuse, or improper signal level, is not covered by the warranty. Removal,

defacement, or alteration, of any serial or inspection label, marking, or seal,

may void the warranty. EIP Microwave will repair or replace at its option,

any components of this counter which prove to be defective during the warranty

period, provided the entire counter is returned PREPAID to EIP or its authorized

service facility. In-warranty counters will be returned freight prepaid; out-of-

warranty units will be returned freight COLLECT . No other warranty other than

the above warranty is expressed or implied.

ASSISTANCE

For assistance, contact the EIP representative in your area, or EIP Microwave.

iii

TABLE OF CONTENTS

PARA-

GRAPH

TITLE

PAGE

SECTION 1 - GENERAL INFORMATION AND SPECIFICATIONS

1-1

Description

1-1

1-9

Instrument Identification

1-i

1-11

Specifications

1-1

SECTION 2 -- INSTALLATION

2-1

Unpacking

2-1

2-4

Installation

2-1

2-6

Incoming Operational Check

2-1.

SECTION 3 - OPERATION

3-1

Introduction

3-1

3-3

Controls, Indicators and Connectors

3-1

3-5

Numerical Display Brightness Adjustment

3-1

3-7

Operation in the Automatic Mode

3-1

3-10

Operation in the Manual_ Mode

3-1

3-12

Externally Enabled Operation

3-1

3-14

Input inhibit Requirements

3-1

3-16

Pulse Profile Measurements

3-1

3-18

Dynamic Characteristics of Time Varying Signals

3-4

3-20

Multiple Pulse Signal Measurements

3-4

3-22

Timing Considerations

3-4

3-24

Accuracy

3-5

3-23

Time Base Errors

3-5

3-31

Averaging Error

3-5

3-33

Gate Error

3-6

3-35

Techniques For Improving Accuracy

3-6

3-37

Time Base Calibration

3-6

3-39

Long Term Averaging

3-6

3-41

Gate Error

3-6

SECTION 4 - GENERAL THEORY OF OPERATION

4-1

General

4-1

4-8

Microwave Converter

4-1

4-18

350 MHz Direct Counter

4-3

4-23

Gate Generator

4-4

4-27

Accuracy

4-4

An Introduction to YIG Filters

4-5

SECTION 5 - MAINTENANCE & SERVICE

5-1

General

5-1

5-3

Fuse Replacement

5-1

5-5

Air Circulation

5-1

5-7

Counter Servicing

5-1

5-8

Recommended Service Procedure

5-1

5-9

Servicing Precautions

5-I

.

5-10

Factory Service

5-1

5-12

TROUBLESHOOTING

5-2

5-13

Malfunction at Turn-On

5-2

5-15

Failure to Indicate All Zeros

5-2

5-17

Malfunction in Self Test

5-2

iv

TABLE OF CONTENTS (Continued

PARA-

GRAPH

TITLE

PAGE

SECTION 5 (CONTINUED)

5-19

Malfunction in Band A (Option P2)

5-2

5-21

Malfunction in Band B

5-2

5-23

Module Failure Verification

5

-

3

5-24

Source/Amplifier Power Output Check

5-3

5-25

Source/Amplifier. Spurious Signal Check

5-3

5-26

Front End Check

9-3

5-27

Mixer Check

5-3

5-28

PIN

Limiter/Attenuator Check

5-3

5-29

YIG Comb Generator Check

5-4

5-30

IF Processor Check

5-5

SECTION 6

-

ADJUSTMENTS & CALIBRATION

General

6-1

6-3

Generating and Measuring Narrow RF Pulses

6-1

6-8

Power Supply Adjustment

6

-

3.

6-10

Time Base Calibration

6

-

1.

6-12

RTO Calibration Procedure

6-3

6-13

TeX() Calibration (Option P1)

6-3

6-18

TCXO Calibration Procedure

6

-

3

6-19

Band A (Option P2) Adjustments

6-3

6-20

Band B Adjustments

6

-

3

6-21

High Frequency (A106) Adjustment

6-5

SECTION 7 - PERFORMANCE TESTS

7-1

General

7

-

1

7-3

Variable Line Voltage

7-1

7-5

Recommended Test Equipment

7-1

7-7

PERFORMANCE TESTS

7

-

1

7-8

Range, Sensitivity, and Minimum Pulse Width - Band A (Option P2)

7

-

1

7-9

Range, Sensitivity, and Minimum Pulse Width - Band B

7-1

7-10

Gate Error - Band A (Option P2)

7-1

7-11

Gate Error - Band B

7-2

7-12

Rear Panel Output Levels

7-2

7-13

Rear Panel Input Inhibit Levels

7-2

SECTION 8 - PARTS LISTS

8-1

General

8-1

8-3

List of Tables

8-1

8-4

To Order Replacement Parts

8-1

SECTION 9

-

CIRCUIT SCHEMATICS S DESCRIPTIONS

-

COMPONENT LOCATORS

9

-

1

General

9

-

1

SECTION 0

-

OPTIONS

0-2

Option P1 - TCXO

0-1

0-4

Option P2 - Prescaler

0-1

0-6

Option P3 - Rear Panel Inputs

0-1

0-8

To Field Change Band B to Rear Input

0

-

1

0-9

To Field Change Bands A and B to Rear Input

0-1

0-10

Option P4 BCD Output/Remote Programming

0-1

0-12

BCD Outputs

0-1

0-15

YIG Preset

0-1

0-17

Remote Programming

0-1

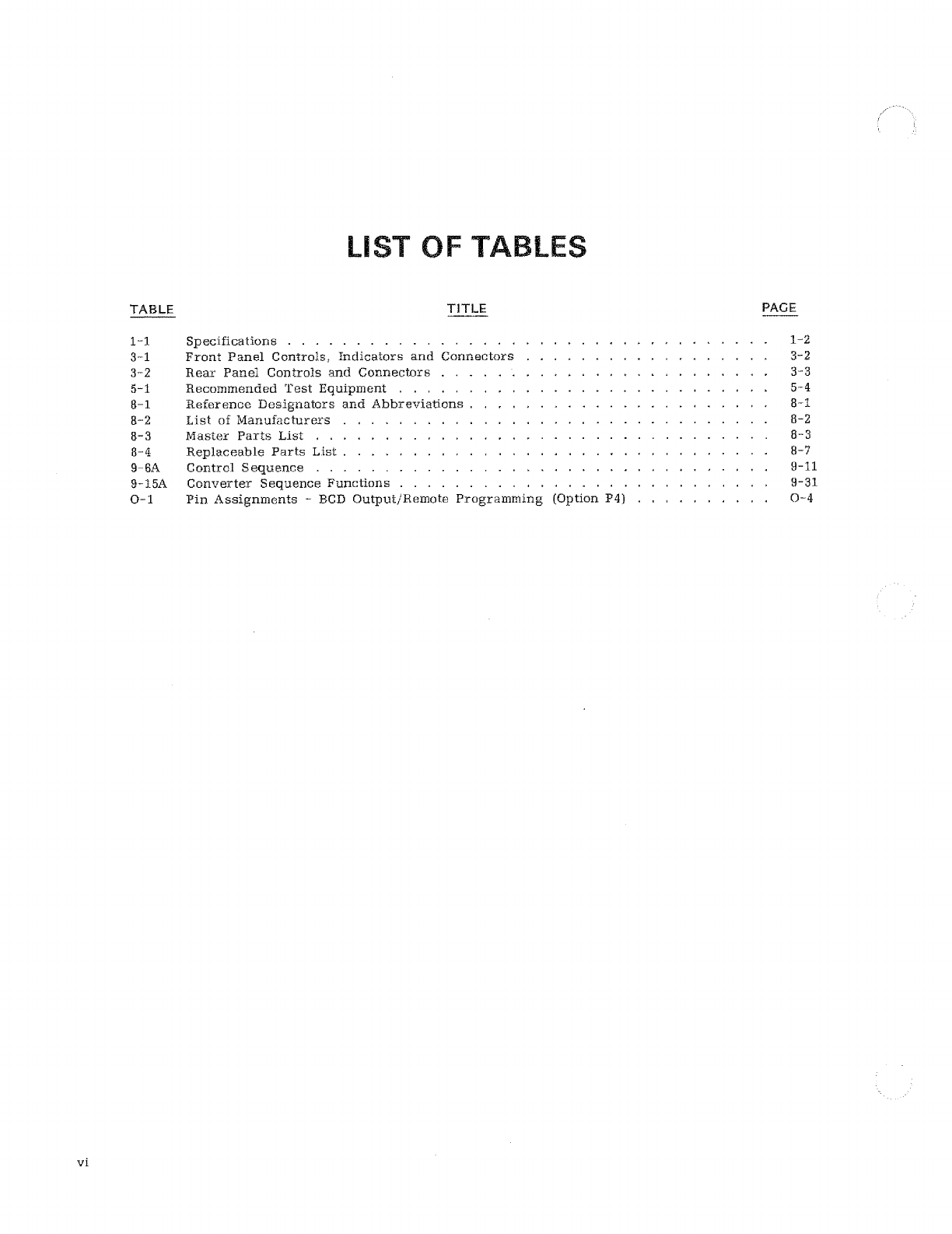

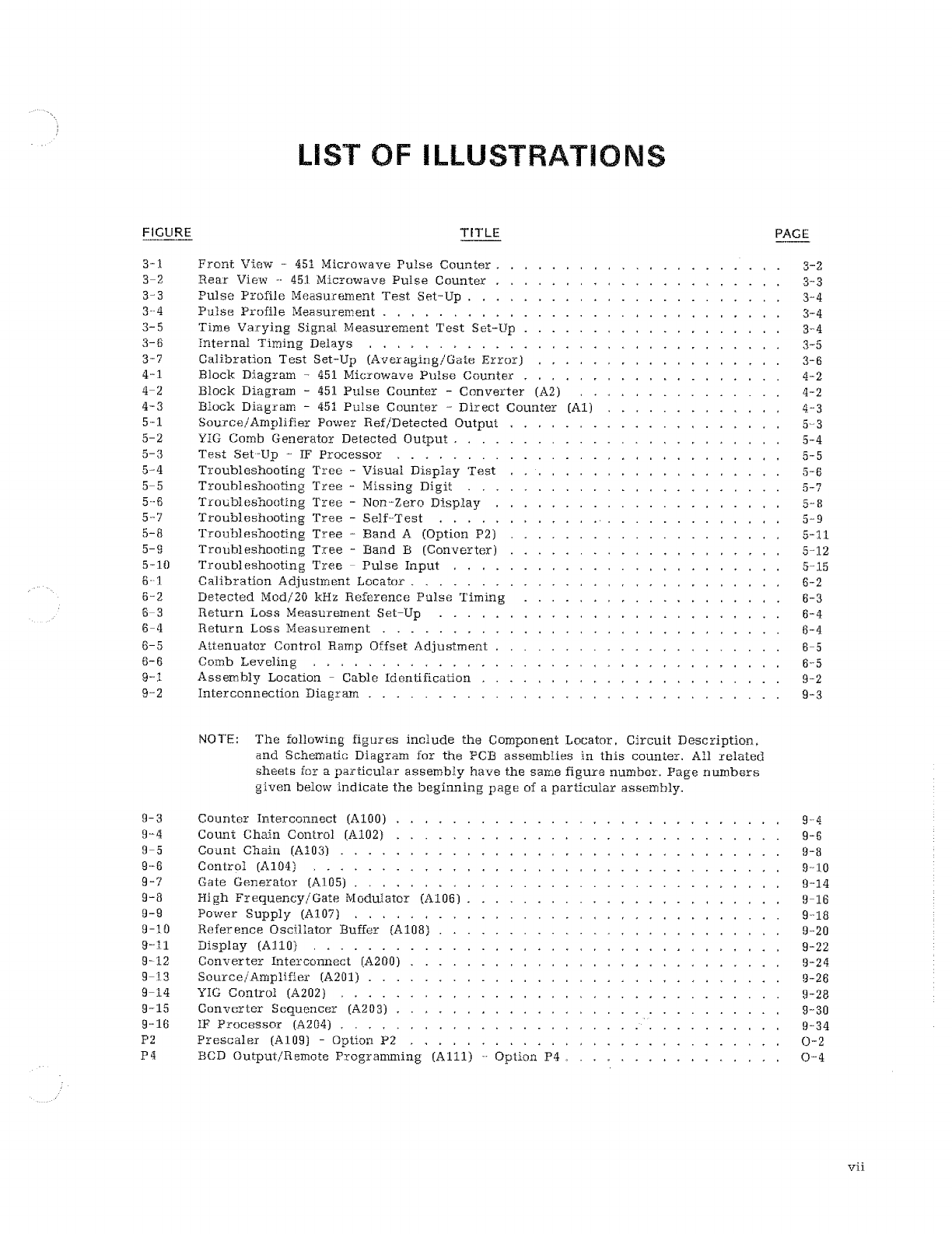

LIST OF TABLES

TABLE

TITLE

PAGE

1-i,

Specifications

1-2

3-1

Front Panel Controls, indicators and Connectors

3-2

3-2

Rear Panel Controls and Connectors

3-3

5-1

Recommended Test Equipment

5-4

8-1

Reference Designators and Abbreviations

8-1

8-2

List of Manufacturers

8-2

8-3

Master Parts List

8-3

8

-

4

Replaceable Parts List

8-7

9

-

6A

Control Sequence

9-11

9-15A

Converter Sequence Functions

9-31

0-1

Pin Assignments - BCD Output/Remote Programming (Option P4)

0-4

vi

LIST OF ILLUSTRATIONS

FIGURE

TITLE

PAGE

3-1

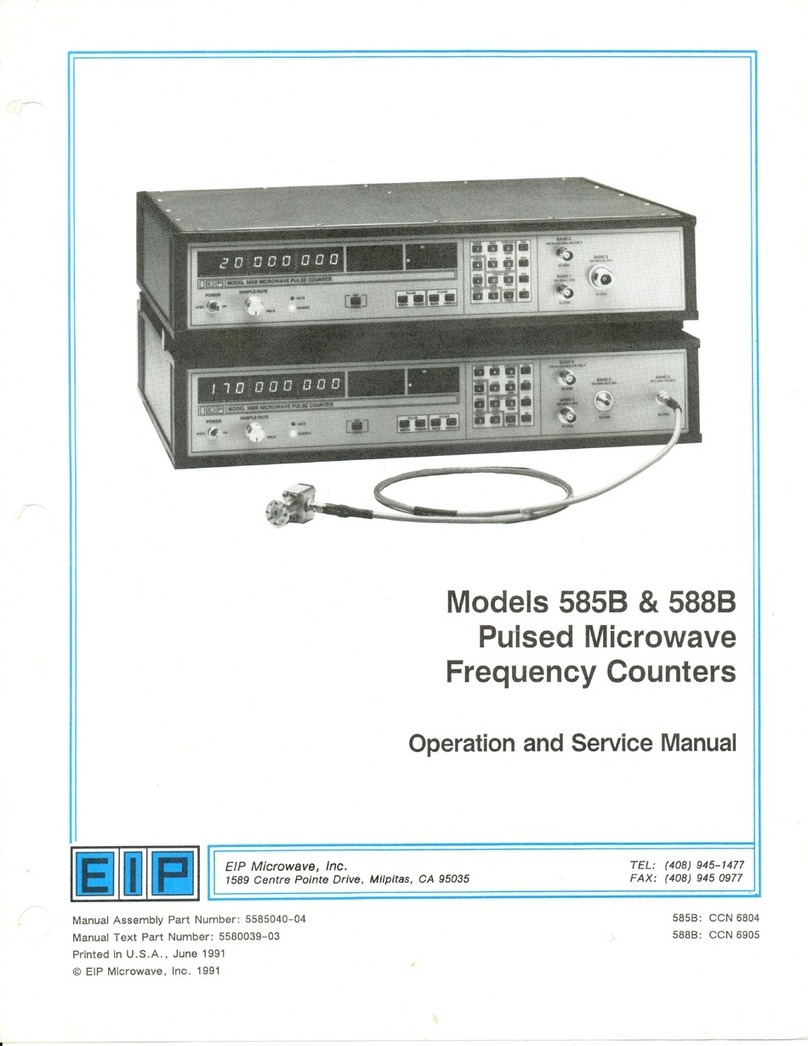

Front View - 451 Microwave Pulse Counter

3-2

3-2

Rear View -- 451 Microwave Pulse Counter

3

-

3

3-3

Pulse Profile Measurement Test Set-Up

3-4

3-4

Pulse Profile Measurement

3-4

3-5

Time Varying Signal Measurement Test Set-Up

3-4

3

-

6

Internal Timing Delays

3-5

3-7

Calibration Test Set-Up (Averaging/Gate Error)

3-6

4-1

Block Diagram - 451 Microwave Pulse Counter

4

-

2

4-2

Block Diagram - 451 Pulse Counter - Converter (A2)

4-2

4-3

Block Diagram - 451 Pulse Counter - Direct Counter (A1)

4-3

5-1

Source/Amplifier Power Ref/Detected Output

5

-

3

5-2

YIG Comb Generator Detected Output

5-4

5

-

3

Test Set-Up - IF Processor

5-5

5-4

Troubleshooting Tree - Visual Display Test

5-6

5-5

Troubleshooting Tree - Missing Digit

5-7

5-6

Troubleshooting Tree - Non-Zero Display

5

-

8

5-7

Troubleshooting Tree - Self-Test

5-9

5-8

Troubleshooting Tree - Band A (Option P2)

5

-

11

5-9

Troubleshooting Tree - Band B (Converter)

5-12

5-10

Troubleshooting Tree - Pulse Input

5-15

6-1

Calibration Adjustment Locator

6-2

6-2

Detected Mod/20 kHz Reference Pulse Timing

6-3

6-3

Return Loss Measurement Set-Up

6-4

6-4

Return Loss Measurement

6-4

6

-

5

Attenuator Control, Ramp Offset Adjustment

6

-

5

6-6

Comb Leveling

6-5

9-1

Assembly Location - Cable Identification

9-2

9-2

Interconnection Diagram

9-3

NOTE: The following figures include the Component Locator, Circuit Description,

and Schematic Diagram for the PCB assemblies in this counter. All related

sheets for a particular assembly have the same figure number. Page numbers

given below indicate the beginning page of a particular assembly.

9-3

Counter Interconnect (A100)

9-4

9-4

Count Chain Control (A102)

9-6

9-5

Count Chain (A103)

9

-

8

9-6

Control (A104)

9-10

9-7

Gate Generator (A105)

9-14

9-8

High Frequency/Gate Modulator (A106)

9-16

9-9

Power Supply (A107)

9-18

9-10

Reference Oscillator Buffer (A108)

9-20

9-11

Display (A110)

9-22

9-12

Converter Interconnect (A200)

9-24

9-13

Source/Amplifier (A201)

9-26

9-14

YIG Control (A202)

9-28

9-15

Converter Sequencer (A203)

9-30

9-16

IF Processor (A204)

9-34

P2

Prescaler (A109) - Option P2

0-2

P4

BCD Output/Remote Programming (A111) Option P4

0-4

vli

SECTION 1

GENERAL INFORMATION & SPECIFICATIONS

1-1. DESCRIPTION

1-2, The MP Model 451. Microwave Pulse Counter auto-

matically and directly measures the frequency of pulse

modulated microwave signals between 300 MHz - 18 GHz.

Pulse widths can be as narrow as 100 nanoseconds, with

no minimum or maximum pulse repetition frequency limits.

1-3. The 451 also measures the frequency of CW micro-

wave signals. and carrier signals with FM modulation up

to 40 MHz peak-to-peak deviation at 10 MHz modulation

rates. No manual switching is required to measure CW or

pulsed frequencies — the counter will automatically mea-

sure either type of signal. Sensitivity is -10 dBm

,

to 10

GHz; -5 dBm to 18 GHz. A built-in limiter provides over-

load protection of up to 1 watt peak from 925 MHz - 18 GHz.

1

-

4. All front panel controls except SAMPLE RATE are

externally programmable, One input to the counter (Band

B) accepts signals over the range of 925 MHz - 18 GI-1z,

Option P2 provides a second input (Band A) to cover the

range of 300 MHz - 950 MHz.

1-5. The display on the 451 Counter provides a direct

readout of the measured frequency over the entire oper-

ating range of the counter with 10 kHz resolution. The

counter also includes automatic suppression of leading

zeros, except during a no signal input condition.

1-6. The frequency readout of the 451 is displayed in a

fixed position format that is conveniently sectionalized in

GHz and MHz. Gate times are 100 us and 1 ms.

1-7. For applications where less resolution is required,

pushbutton display blanking (RESOLUTION) is provided

to simplify the readout.

1-8. To assure trouble-free performance, the 451 Pulse

Counter is completely solid-state. For ease of repair and

maintenance, the major portion of the counter circuitry is

contained on plug-in printed circuit boards or in easily

removed modules. Special test points allow monitoring of

critical circuit functions,

1-9. INSTRUMENT IDENTIFICATION

1-10. The 451 Pulse Counter is identified by two number

sets: the Model and Configuration Control Number (e .g:

451

-

CCN1001), and a specific Serial Number (e.g: 12345).

Both sets of numbers should be mentioned in any corre-

spondence or parts orders relating to the counter,

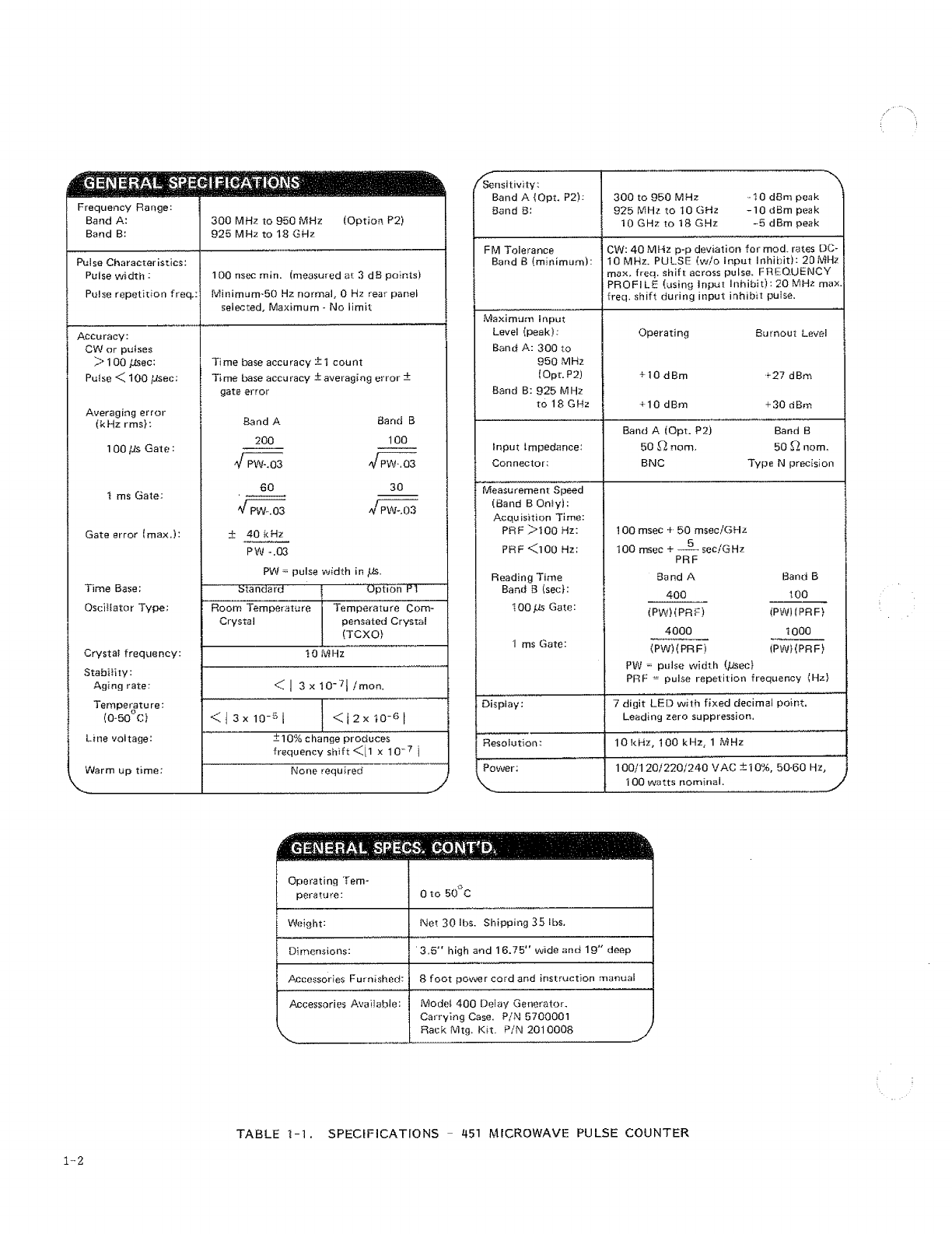

1-11. SPECIFICATIONS

1-12. Model 451 Microwave Pulse Counter specifications

are given in Table 1-1,

1-1

GENERAL SPECS,

coNro

0 to 50

°

C

Net 30 lbs. Shipping 35 lbs.

Weight:

Dimensions:

3.5" high and 16.75" wide and 19" deep

Accessories Furnished:

8 foot power cord and instruction manual

I

,

„...., ...„

Accessories Available:

Model 400 Delay Generator.

Carrying Case. P/N 5700001

Rack Mtg. Ka. P/N 2010008

TABLE 1-1. SPECIFICATIONS - 451 MICROWAVE PULSE COUNTER

GENERAL SPECIFICATIONS.

Frequency Range:

Band A:

Band B:

300 MHz to 950 MHz

(Option P2)

925 MHz to 18 GHz

Pulse Characteristics:

Pulse width:

Pulse repetition freq.:

100 nsec mm. (measured at 3 dB points)

Minimum-50 Hz normal, 0 Hz rear panel

selected, Maximum - No limit

Accuracy:

CW or pulses

>100 bisec:

Pulse <100 psec:

Averaging error

(kHz rmsl:

100 gs Gate:

1 ms Gate:

Gate error (max.):

Time Base:

Oscillator Type:

Crystal frequency:

Stability:

Aging rate:

Temperature:

(0-50 C)

Line voltage:

Warm up time:

\---

Time base accuracy ±1 count

Time base accuracy ± averaging error ±

gate error

Band A

selected.

100

ni

200

PW-.03

VPW-.03

. _

60

30

Al PW-.03

±

40 kHz

Ai PW-.03

width in /15.

PW -.03

PW - pulse

Standard

Option P1

Room Temperature

Crystal

Temperature Corn-

pensated Crystal

(TCX0)

10 MHz

< I 3 x 10

-7

1 /mon.

<I 3 x10

-5

1

<1 2 x 10

-6

1

±10% change produces

frequency shift <VI x 10

-7

1

None required

Sensitivity:

Band A (Opt. P2):

Band B:

300

to 950 MHz

-10 dBm peak

925 MHz to 10 GHz

-10 dBm peak

10 GHz to 18 GHz

-5 dBm peak

FM Tolerance

Band B (minimum):

CW: 40 MHz p-p deviation for mod. rates DC-

10 MHz. PULSE (w/o Input Inhibit): 20MHz

max. freq. shift across pulse. FREO.UENCY

PROFILE (using input Inhibit): 20 MHz max.

freq. shift during input inhibit pulse.

Ma

ximum Input

Level (peak):

Band A: 300 to

950 MHz

(Opt.P2)

Band B: 925 MHz

to 18 GHz

Operating

Burnout Level

+10 dBm

+27 dBm

+10 dBm

+30

dBm

Input Impedance:

Connector:

Band A (Opt. P2)

Band B

50

2

nom.

50

2

nom.

BNC

Type N precision

Measurement Speed

(Band B Only):

Acquisition Time:

PRE >100 Hz:

PRF <100 Hz:

Reading Time

Band B (sec):

100

ps

Gate:

1 ms Gate:

100 msec + 50 msec/GHz

100 msec + —

5

sec/GHz

PRF

Band A

Band B

400

100

(PW)(PRF)

(PWI(PRF)

4000

1000

(PW)(PRF)

IPW)(PRF)

PW

-.

pulse width (11sec)

PRF --- pulse repetition frequency (Hz)

Display:

7 digit LED with fixed decimal point.

Leading zero suppression.

Resolution:

10 kHz, 100 kHz, 1 MHz

Power:

100/120/220/240 VAC ±10%, 50-60 Hz,

100 watts nominal.

1-2

FRONT PANEL

Controls:

Sample Rate/Hold:

Test-200 MHz:

Display Test:

Resolution:

1 ms Gate:

Band Select (A or 13):

Varies display reading time from 0.1 sec/

reading to 10 sec/reading. "Hold" displays

last reading.

Displays 200 MHz internal test frequency.

Tests all LED numeral se

position.

(1 MHz, 100 kHz, 10 kHz):

Sets display

resolution.

Selects 1 ms gate.

Switch selects either Band A (Opt. P2) or

Band B input.

Auto/Manual (Band B):

Auto Mode:

Manual Mode:

Band B searches upward for input signal be-

ginning 100 MHz above preset number.

Inhibits search.

Signal must lie between

100 MHz and 325 MHz above preset

number.

Thumbwheel Switch

(Band B):

Auto

inhibit.

Manual Mode:

Sets start point of frequency sweep (100

MHz above preset number.)

Sets operating frequency range (100 MHz

to 325 MHz above preset number.)

Indicators:

LeveI:

Lock:

Gate:

Remote:

Reduce Signal

(Band B):

Indicates

sufficient input level.

Indicates signal acquired.

Indicates

measurement in process.

Indicates Remote Programming (Option

P4

Or

PS)

active.

Indicates excess signal level.

Connectors:

Band A input:

BkHz.

B input:

Type BNC female - 300 to 950 MHz

(Option P2)

Type N precision female - 925 MHz to

18 GHz

Controls:

Power input:

Power module containing AC connector,

fuse, and voltage control for 100, 120,

220, or 240 VAC.

Storage (On/Off):

Normally on. In off position,

display up-

dates

continuously during measurement

cycle.

Min. PRF = (50 Hz/

0):

Normally

in

50 Hz position. In 0 position,

allows measurements of very low

PRF

signal.

Connectors:

10 MHz reference

output:

1 V peak-to-peak min. into 50

2

Gate Output:

-0.5v min. into 50

2

corresponding to

counter gate.

Signal Threshold

Output:

-0.5v min. into 50

2

corresponding to

signal exceeding threshold.

Inhibit Input:

ECL high (-0.9v) inhibits. ECL low (-1.7v)

enables. From

50 CZ

source, 0 volts will

inhibit,

-

1v

will enable.

Input impedance: 50

2to -2 volts.

MODEL / OPTIONS:

Model 451

Microwave Pulse Counter

P1:

TCXO - temperature compensated crystal

oscillator

P2:

Band

A:

300 -

950

MHz

P3:

Rear panel inputs: Band A and B

P4:

BCD output/remote programming

Remote programming: provides rear

panel programming of all front panel

controls except SAMPLE RATE.

Requires ground contact closure; one

control line per function (T

2

L and DTL

compatible).

Digital output:

7 data digits in parallel

form. 1-2-4-8 "1" state positive.

P5

GPIB: System interface per IEEE STD

488-1975.

----)

TABLE 1

-

1 (Continued) SPECIFICATIONS

-

451 MICROWAVE PULSE COUNTER

1-3

SECTION 2

INSTALLATION

2-1. UNPACKING

2-2. The EIP Model 451 Microwave Pulse Counter arrives

ready for operation. Carefully inspect the shipping carton

before opening for any evidence of visible or concealed

damage. If any seems apparent, ask that the shipper's

agent be present when the counter is unpacked.

2-3. Remove the packing carton and supports, being

careful not to scar or damage the counter. Make a com-

plete visual inspection of the counter. checking for any

damage or missing components. Check that all switches

and controls operate mechanically. Report any damage

to EIP immediately.

2-4. INSTALLATION

2-5. There are no special installation instructions for

the 451 Pulse Counter. The unit is

a

self-contained bench

or rack mounted instrument. which only requires connec-

tion to a standard, single-phase, 100/120 or 220/240 volt,

50-60 Hz power line for operation. CAUTION: Check cur-

rent rating of counter fuse and voltage range PC board in

power module (on rear panel of counter) before applying

power to the counter, Module PC board should show the

correct nominal line voltage when installed in the module.

2-6. INCOMING OPERATIONAL CHECK

2-7. The following procedure outlines an operational

check of the counter which may be conducted without

special tools. signal generators, or test equipment. The

internal Time Base Clock is used as the input signal to

the Direct Counter, therefore it cannot check the opera-

tion of the Band A Prescaler or the Band B Converter.

a. Turn counter POWER switch off. Check fuse rat-

ing and card in power module (see paragraph 2-5),

b.

Connect counter power cord to the voltage source

specified in paragraph 2-5. The ground terminal on

the power cord plug should connect to a reliable earth

ground.

c.

Press POWER switch (on front panel) to turn

counter on. The counter display should light, and the

internal cooling fan should operate.

d.

Partially depress either of the two RESOLUTION

switches and release it. so neither switch remains in

the depressed position. All digits in the display should

indicate "0" (zero).

e.

Depress the front panel 200 MHz TEST switch. The

display should indicate "200.00" (200 MHz). Note that

the two leading zeros are blanked (not lit).

f.

Blank the 10 kHz digit by pressing the right hand

RESOLUTION switch.

g.

Depress the 200 MHz TEST button again. The dis-

play should indicate "200,0".

h.

Test both RESOLUTION switches. Note that the dig-

it immediately above the switch, and any digit to the

right will be blanked.

i.

Unblank all display digits (see "d" above).

j.

With no input signal, the entire display should show

all zeros in both positions of the BAND switch.

k.

Depress the DISPLAY TEST switch. All display dig-

its should show "8" (all segments of each digit lighted).

1. This completes the counter operational check.

SECTION 3

OPERATION

WARNING

DO NOT APPLY A SIGNAL EXCEEDING

THE MAXIMUM INPUT SPECIFICATION

TO ANY INPUT. EXTENSIVE DAMAGE

NOT COVERED BY THE WARRANTY

WILL OCCUR, EVEN IF THE COUNTER

IS TURNED OFF, OR APPEARS TO BE

INOPERATIVE.

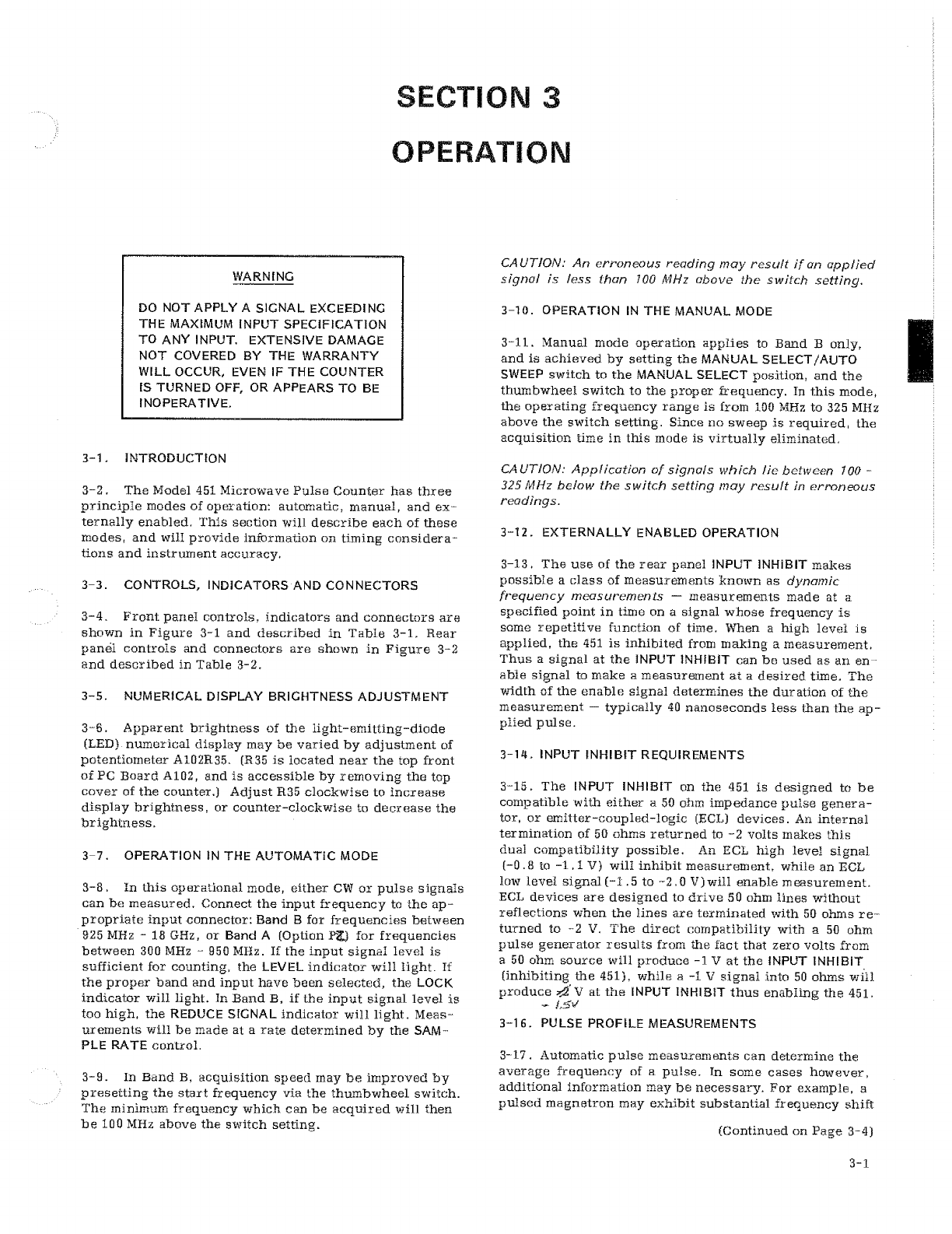

3-1. INTRODUCTION

3

-

2.

The Model 451 Microwave Pulse Counter has three

principle modes of operation: automatic, manual, and ex-

ternally enabled. This section will describe each of these

modes, and will provide information

on

timing considera-

tions and instrument accuracy.

3

-

3.

CONTROLS, INDICATORS AND CONNECTORS

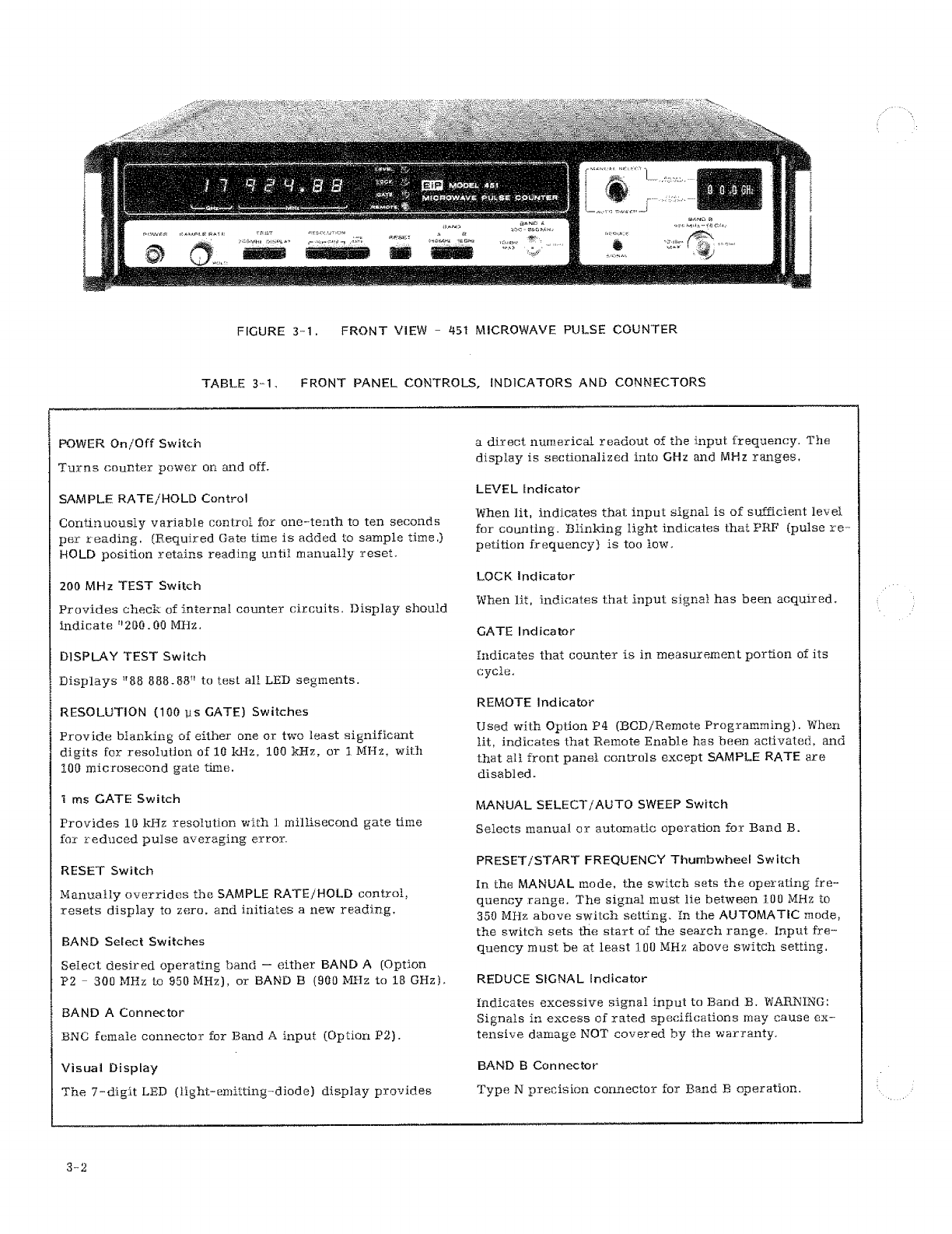

3-4. Front panel controls, indicators and connectors are

shown in Figure 3-1 and described in Table 3-1, Rear

panel controls and connectors are shown in Figure 3-2

and described in Table 3-2,

3

-

5.

NUMERICAL. DISPLAY BRIGHTNESS ADJUSTMENT

3

-

6. Apparent brightness of the light-emitting-diode

(LED) numerical display may be varied by adjustment of

potentiometer A102R35. (R35 is located near the top front

of PC Board A102, and is accessible by removing the top

cover of the counter.) Adjust R35 clockwise to increase

display brightness, or counter-clockwise to decrease the

brightness.

3

-

7. OPERATION IN THE AUTOMATIC MODE

3

-

8.

In this operational mode, either CW or pulse signals

can be measured. Connect the input frequency to the ap-

propriate input connector:

Band B

for frequencies between

825 MHz - 18 GHz. or Band A (Option Pa) for frequencies

between 300 MHz - 950 MHz. If the input signal level is

sufficient for counting, the

LEVEL

indicator will light. If

the proper band and input have been selected, the

LOCK

indicator will light. In Band B, if the input signal_ level is

too high. the

REDUCE SIGNAL

indicator will light. Meas-

urements will be made at a rate determined by the

SAM-

PLE RATE

control.

3-9. In Band B, acquisition speed may be improved by

presetting the start frequency via the thumbwheel switch.

The minimum frequency which can be acquired will then

be 100 MHz above the switch setting.

CAUTION: An erroneous reading may result if an applied

signal is less than 700 MHz above the switch setting.

3-10. OPERATION IN THE MANUAL MODE

3-11. Manual mode operation applies to Band B only,

and is achieved by setting the

MANUAL SELECT/AUTO

SWEEP

switch to the

MANUAL SELECT

position, and the

thumbwheel switch to the proper frequency. In this mode.

the operating frequency range is from 100 MHz to 325 MHz

above the switch setting. Since no sweep is required, the

acquisition time in this mode is virtually eliminated,

CAUTION: Application of signals which lie between 100 -

325 MHz below the switch setting may result in erroneous

readings.

3-12. EXTERNALLY ENABLED OPERATION

3

-

13. The use of the rear panel

INPUT INHIBIT

makes

possible a class of measurements known as

dynamic

frequency measurements

—

measurements made at a

specified point in time on a signal whose frequency is

some repetitive function of time. When a high level is

applied. the 451 is inhibited from making a measurement.

Thus a signal at the

INPUT INHIBIT

can be used as an en-

able signal to make a measurement at a desired time. The

width of the enable signal determines the duration of the

measurement — typically 40 nanoseconds less than the ap-

plied pulse.

3

-

14. INPUT INHIBIT REQUIREMENTS

3-15. The

INPUT INHIBIT

on the 451 is designed to be

compatible with either a 50 ohm impedance pulse genera-

tor. or emitter-coupled-logic (ECL) devices. An internal

termination of 50 ohms returned to -2 volts makes this

dual compatibility possible. An ECL high level signal

(

-

0.8 to -1,1 V) will inhibit measurement, while an ECL

low level signal (-1.5 to -2.0 V) will enable measurement.

ECL devices are designed to drive 50 ohm lines without

reflections when the lines are terminated with 50 ohms re-

turned to -2 V. The direct compatibility with a 50 ohm

pulse generator results from the fact that zero volts from

a 50 ohm source will produce -1 V at the

INPUT INHIBIT

.

(inhibiting the 451), while a -1 V signal into 50 ohms will

produce 4'V

at

the

INPUT INHIBIT

thus enabling the 451.

3

-

16. PULSE PROFILE MEASUREMENTS

3-17. Automatic pulse measurements can determine the

average frequency of a pulse. In some cases however,

additional information may be necessary. For example. a

pulsed magnetron may exhibit substantial frequency shift

(Continued on Page 3-4)

3-1

LiP

"QaE4-

CONTROLS.

faiRwAv.E. ovt.sE

:couNTER

f

'

FIGURE 3-1. FRONT VIEW - 451 MICROWAVE PULSE COUNTER

TABLE 3-1, FRONT PANEL CONTROLS, INDICATORS AND CONNECTORS

POWER On/Off Switch

Turns counter power on and off.

SAMPLE RATE/HOLD Control

Continuously variable control for one-tenth to ten seconds

per reading. (Required Gate time is added to sample time.)

HOLD position retains reading until manually reset.

200 MHz TEST Switch

Provides check of internal counter circuits. Display should

indicate "200.00 MHz.

DISPLAY TEST Switch

Displays "88 888.88

1

to test all LED segments.

RESOLUTION (100 is GATE) Switches

Provide blanking of either one or two least significant

digits for resolution of 10 kHz, 100 kHz, or 1 MHz, with

100 microsecond gate time.

I ms GATE Switch

Provides 10 kHz resolution with 1 millisecond gate time

for reduced pulse averaging error.

RESET Switch

Manually overrides the SAMPLE RATE/HOLD control,

resets display to zero, and initiates a new reading.

BAND Select Switches

Select desired operating band — either BAND A (Option

P2 - 300 MHz to 950 MHz). or BAND B (900 MHz to 18 GHz).

BAND A Connector

BNC female connector for Band A input (Option P2).

Visual Display

The 7-digit LED (light-emitting-diode) display provides

a direct numerical readout of the input frequency. The

display is sectionalized into GHz and MHz ranges.

LEVEL Indicator

When lit, indicates that input signal is of sufficient level

for counting. Blinking light indicates that PRE (pulse re-

petition frequency) is too low.

LOCK Indicator

When lit, indicates that input signal has been acquired.

GATE Indicator

Indicates that counter is in measurement portion of its

cycle.

REMOTE Indicator

Used with Option P4 (BCD/Remote Programming). When

lit, indicates that Remote Enable has been activated, and

that all front panel controls except SAMPLE RATE are

disabled.

MANUAL SELECT/AUTO SWEEP Switch

Selects manual or automatic operation for Band B.

PRESET/START FREQUENCY Thumbwheel Switch

In the MANUAL mode, the switch sets the operating fre-

quency range. The signal must lie between 100 MHz to

350 MHz above switch setting. In the AUTOMATIC mode,

the switch sets the start of the search range. Input fre-

quency must be at least 100 MHz above switch setting.

REDUCE SIGNAL Indicator

Indicates excessive signal input to Band B. WARNING:

Signals in excess of rated specifications may cause ex-

tensive damage NOT covered by the warranty.

BAND B Connector

Type N precision connector for Band B operation.

3-2

FIGURE 3-2. REAR VIEW - 451 MICROWAVE PULSE COUNTER

TABLE 3-2. REAR PANEL CONTROLS AND CONNECTORS

Rear Panel Inputs

(Option

P3) Allows modification of counter for rear panel

inputs.

ACCESSORY POWER OUT Connector

Provides power for 451 Pulse Counter accessories.

10 MHz OUTPUT Connector

Output of internal 10 MHz clock. 1 V p

-

p min into 50 ohms.

SIGNAL THRESHOLD OUTPUT Connector

Pulse output representing signal threshold level of input

pulse. Typically occurs 20 nanoseconds after

input

pulse,

and is used for frequency profile measurements.

GATE OUTPUT Connector

Provides Gate pulse representing actual time at which

measurement is being made. Used in frequency profile

measurement.

INPUT INHIBIT Connector

External pulse input for frequency profile measurements.

Remote Input/Output Connector

(Option P4) Connector for BCD/Remote Programming.

GPIB Input/Output Connector

(Option P5) For connection to General Purpose Interface

Bus (IEEE STD 488-1975). Refer to separate Instruction

Manual for EIP Model 451 Option P5.

STORAGE Switch

Normally ON. In the OFF position, display updates con-

tinuously

during measurement cycle.

MIN PRE Switch

Normally

in 50 Hz position. In 0 position, allows meas-

urement of very low PRE signal. NOTE: Reading

will

not automatically reset when signal is removed.

AC Power Module

Contains AC power line

receptacle, fuse. and PC board

for voltage selection.

1

1

INPUT SIGNAL 300 N11-1.,

GFI

z

FREGUENCY PROFILE

AVERAGE

PROFILE

-

MEASURE

ENT WINDOW

•

•

•

•

• • •

NHIBIT

II

NPUT

MODULATOR

451

MICROWAVE

PULSE

COUNTER

DELAYING

PULSE

GENERATOR

PULSE

OUTPUT

MODULATED

MICROWAVE RE

OUTPUT

INPUT

SOURCE

TO BE

TESTED

II

FREQUENCY

MODULATION

f INPUT

MODULATION

OUTPUT

TRIGGER

_EL

INPUT

I

TRIGGER

OUTPUT

I

near the leading and trailing edges of the pulse, or

a

pulsed Gunn diode oscillator may exhibit frequency shift

during a pulse due to peak power thermal effects. Meas-

urements of these characteristics are easily made with

only the 451 and a delaying pulse generator (see Figure

3-3). The

SIGNAL THRESHOLD

output of the 451 is used

to trigger the pulse generator. The generator's output

pulse is used as an enable input to the 451. As the pulse

delay is varied, the measurement window can be "walked"

through the pulse. A plot of frequency-versus-delay

gives the frequency-versus--time profile of the pulse di-

rectly as shown in Figure 3-4. The width of the measure-

ment window is determined by the width of the pulse gen-

erator output. Measurement windows of 50 nanoseconds or

less can be used, although wider windows yield higher

accuracy.

SIGNAL

THRESHOL

451

MICROWAVE

INHIBIT

PULSE

COUNTER

INPUT

SIGNAL

INPUT

PULSE TRIGGER

OUTPUT INPUT

DELAYING

PULSE

GENERATOR

FIGURE 3-3.

PULSE PROFILE MEASUREMENT TEST SET-UP

FIGURE 3-4. PULSE PROFILE MEASUREMENT

3-18. DYNAMIC CHARACTERISTICS OF TIME VARYING

SIGNALS

3-19. Many complex signals are not pulses at all but

simply continuous signals whose frequency varies repeti-

tively with time. One example is the measurement of the

response of

a

device such as a voltage controlled oscil-

lator (VCO). A square wave applied to the tuning voltage

will produce a response curve of frequency-versus-time

allowing measurement of various settling times such as

post-tuning drift, Another possible application would be

the measurement of linearity and amplitude for frequency

modulated radar altimeter signals. Figure 3-5 shows

a

test set-up designed to make measurements on time vary-

ing signals. It is similar to the pulse profile test set-up,

except that in this case since

present.

always a signal

present, a trigger must be obtained from the modulating

source. This will trigger the pulse generator which con-

trols the measurement.

3-20. MULTIPLE PULSE SIGNAL MEASUREMENTS

3-21. Another type of measurement is that of a repetitive

sequence of pulses differing in frequency. In this case,

it is desirable to measure the frequency of each pulse in

the sequence separately. The same test set-up as shown

in Figure 3-5 is required, with the trigger pulse synchro-

nous with the sequence. In this measurement, the

INPUT

INHIBIT

is used simply to discriminate between pulses.

The enabling pulse can be slightly wider than the pulse

to be measured. The 451 will automatically restrict the

measurement window entirely within the pulse. By shift-

ing the delay time of

theenabling pulse, each input pulse

of the sequence can be separately measured.

FIGURE 3-5.

TIME VARYING SIGNAL MEASUREMENT TEST SET-UP

3-22. TIMING CONSIDERATIONS

3-23. Under most circumstances, internal timing within

the 451 would be of

no concern to the user. However, in

applications where a few nanoseconds are significant,

some details of internal operation are important. These

involve two areas: (a) measurement window width, and

(b) internal timing delays.

(a) Measurement Window Width

The measurement window is the period during which

the

GATE

is actually open to enable the counting of a

signal. This

GATE

width will typically be 30 nanosec-

onds narrower than the pulse applied to

the INPUT

3-4

INPUT MPCSOWAVE PULSE

I

-ulU

SIGMA PHRESNDLO

hi— -60ns

NHL

5- W.

t

ow

-30ns

DE

LAY ED iF

PULSE

GATE

INHIBIT. The width of the GATE is always an integral

number of clock periods (5 nanoseconds). For applica-

tions where the measurement window needs to be known

to an accuracy better than 20 nanoseconds, it is recom-

mended that the GATE output on the 451 rear panel be

observed directly on a high speed oscilloscope. The

desired CATE width may then be set by varying the IN-

PUT INHIBIT pulse width. For accurate pulse represen-

tation. the oscilloscope input should be terminated in a

50 ohm load.

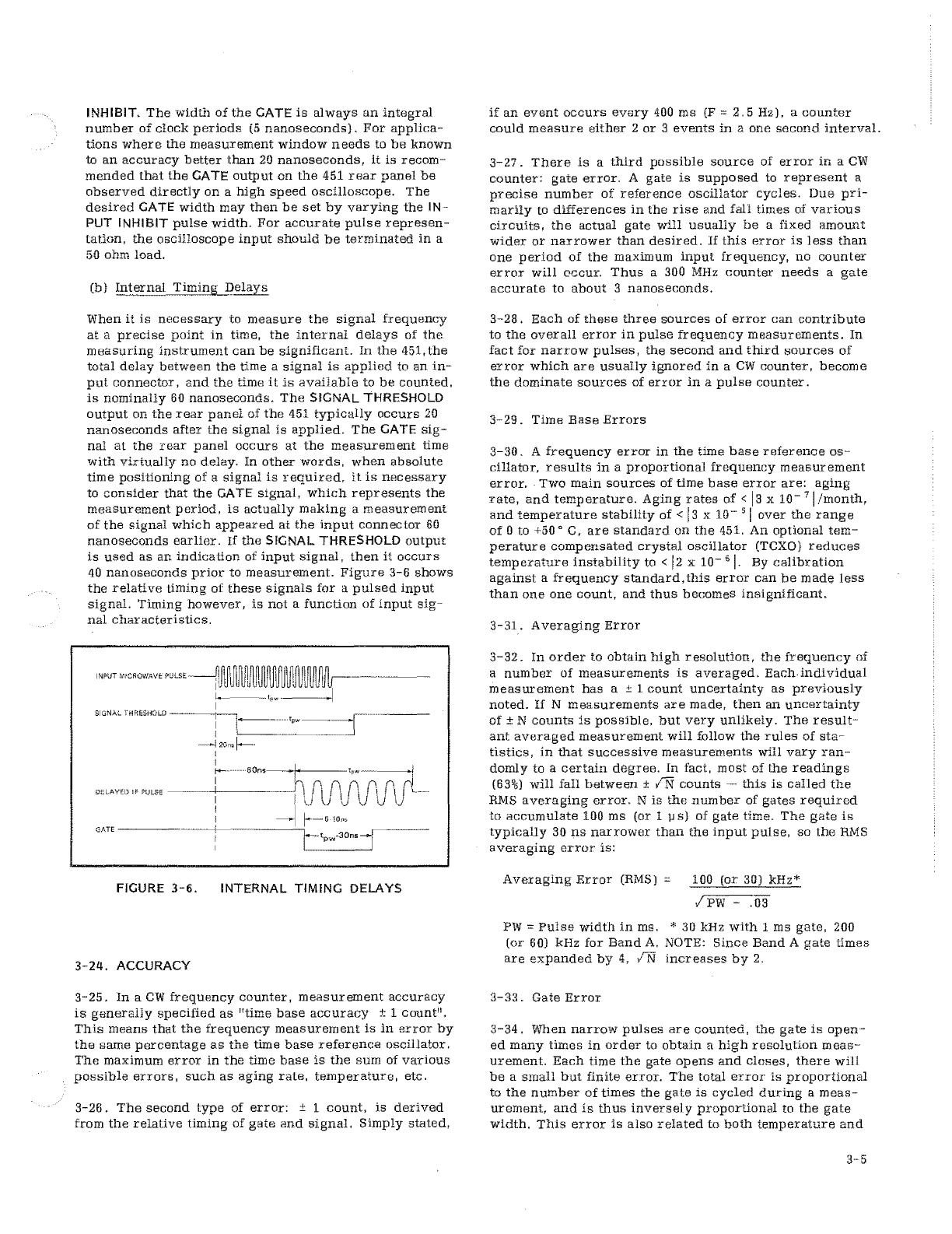

(b) Internal Timing Delays

When it is necessary to measure the signal frequency

at a precise point in time, the internal delays of the

measuring instrument can be significant. In the 451,the

total delay between the time a signal is applied to an in-

put connector. and the time it is available to be counted,

is nominally 60 nanoseconds. The SIGNAL THRESHOLD

output on the rear panel of the 451 typically occurs 20

nanoseconds after the signal is applied. The GATE sig-

nal at the rear panel occurs at the measurement time

with virtually no delay. In other words. when absolute

time positioning of a signal is required. it is necessary

to consider that the GATE signal, which represents the

measurement period, is actually making a measurement

of the signal which appeared at the input connector 60

nanoseconds earlier. If the SIGNAL THRESHOLD output

is used as an indication of input signal, then it occurs

40 nanoseconds prior to measurement. Figure 3-6 shows

the relative timing of these signals for a pulsed input

signal. Timing however, is not a function of input sig-

nal characteristics.

FIGURE 3-6. INTERNAL TIMING DELAYS

3-24. ACCURACY

3-25. In a CW frequency counter, measurement accuracy

is generally specified as time base accuracy ± 1 count".

This means that the frequency measurement is in error by

the same percentage as the time base reference oscillator.

The maximum error in the time base is the sum of various

possible errors, such as aging rate, temperature, etc.

3-26. The second type of errrate. 1 count, is derived

from the relative timing of gate acount.

nal. Simply stated,

if an event occurs every 400 ms (F = 2.5 Hz), a counter

could measure either 2 or 3 events in a one second interval.

3-27. There is a third possible source of error in a CW

counter: gate error. A gate is supposed to represent a

precise number of reference oscillator cycles. Due pri-

marily to differences in the rise and fall times of various

circuits, the actual gate will usually be a fixed am

circuits.

r or narrower than desired. If this error is less than

one period of the maximum input frequency, no counter

error will occur. Thus a 300 MHz counter needs a gate

accurate to about 3 nanoseconds,

3-28. Each of these three sources of error can contribute

to the overall error in pulse frequency measurements. In

fact for narrow pulses, the second and third sources of

error which pulses.

ally ignored in a CW counter, become

the dominate sources of error in a pulse counter.

3-29. Time Base Errors

3-30. A frequency error in the time base reference os-

cillator, results in a proportional frequency meaos-

cillator.

or. Two main sources of time base error are: aging

rate, and temperature. Aging rates of <13 x 10

- 7

1

rate.

h,

and temperature stability of <13 x 10

- 5

1 over the range

of 0 to +50° C, are standard on the 451. An optional tem-

perature compensated crystal oscillator (TCXO) reduces

temperature instability to <12 a 10

- 6

1.

By calibration

against a frequency standard,this error can be made less

than one one count, and thus becomes insignificant.

3-31. Averaging Error

3-32. In order to obtain high resolution, the frequency of

a number of measurements is averaged. Each-individual

measurement has a ± 1 count uncertainty as previously

noted. If N measurements are made, then an uncertainty

of ± N counts is possible, but very unlikely. The result-

ant averaged measurement will follow the rules of sta-

tistics, in that successive measurements will vary ran-

domly to a certain degree. In fact, most of the readings

(63%) will fall between ±

✓

IT]

.

counts — this is called the

RMS averaging error. N is the number of gates required

to accumulate 100 ms (or 1 es) of gate time. The gate is

typically 30 ns narrower than the input pulse, se the RMS

averaging error is:

Averaging Error (RMS) = 100 (or 30) kHz*

PW - .03

PW = Pulse width in ms. * 30 kHz with 1 ms gate, 200

(or 60) kHz for Band A. NOTE: Since Band A gate times

are expanded by 4,

7

--

N

increases by 2,

3-33. Gate Error

3-34. When narrow pulses are counted, the gate is open-

ed many times in order to obtain a high resolution meas-

urement. Each time the gate opens and closes, there will

be a small but finite error. The closes.

rror is proportional

to the number of times the gate is cycled during a meas-

urement, and is thus inversely proportional to the gate

width. This error is also related to both temperature and

3-5

AVERAGE READING

cw rsTo.

MEASUREMENT

LEAST

SIGNIFICANT

DI

However.this

TPUT

07

-

P

,

P

CHART

RECORDER

/

ANALOG

OUTPUT

DIGITAL

TO

ANALOG

CONVERTER

MICROWAVE

PULSE

COUNTER

input frequency. In the 451, the worst case error includ-

ing all variables. is specified as:

Max Gate Error =

40 kHz

PW - .03

where PW = pulse width in microseconds.

Unlike averaging error which is random, gate error is

systematic, and is not reduced by frequency averaging.

3-35. TECHNIQUES FOR IMPROVING ACCURACY

3-36. In most cases, specified accuracy of the 451 will be

more than sufficient to meet measurement requirements.

If greater accuracy is required, all three sources of error

can be minimized by a combination of error calibration

and long term averaging. It is recommended that if very

high accuracy is required, the counter include Options P1

(TCXO) and P4 (BCD Output/Remote Programming).

3-37. Time Base Calibration

3-38. A frequency error in the time base oscillator results

in the same percentage error in the frequency reading for

either. CW or pulsed signals. By directly measuring the 10

MHz time base frequency at the 10 MHz OUTPUT connector

using a standard of known accuracy, this error can be

determined and corrected. As an example, suppose the

measured time base output is 10.0001 MHz. The time base

is thus 1 x 10

- 6

high in frequency, and all readings will

be 1 x 10

- 6

low in frequency -- a reading at 10 GHz will

be 10 kHz low. Instead, of correcting the

reading

for this

error, a better technique is to set the time base oscillator

precisely on frequency. The advantage of a 451 equipped

with a TCXO is improved settability and temperature

stability.

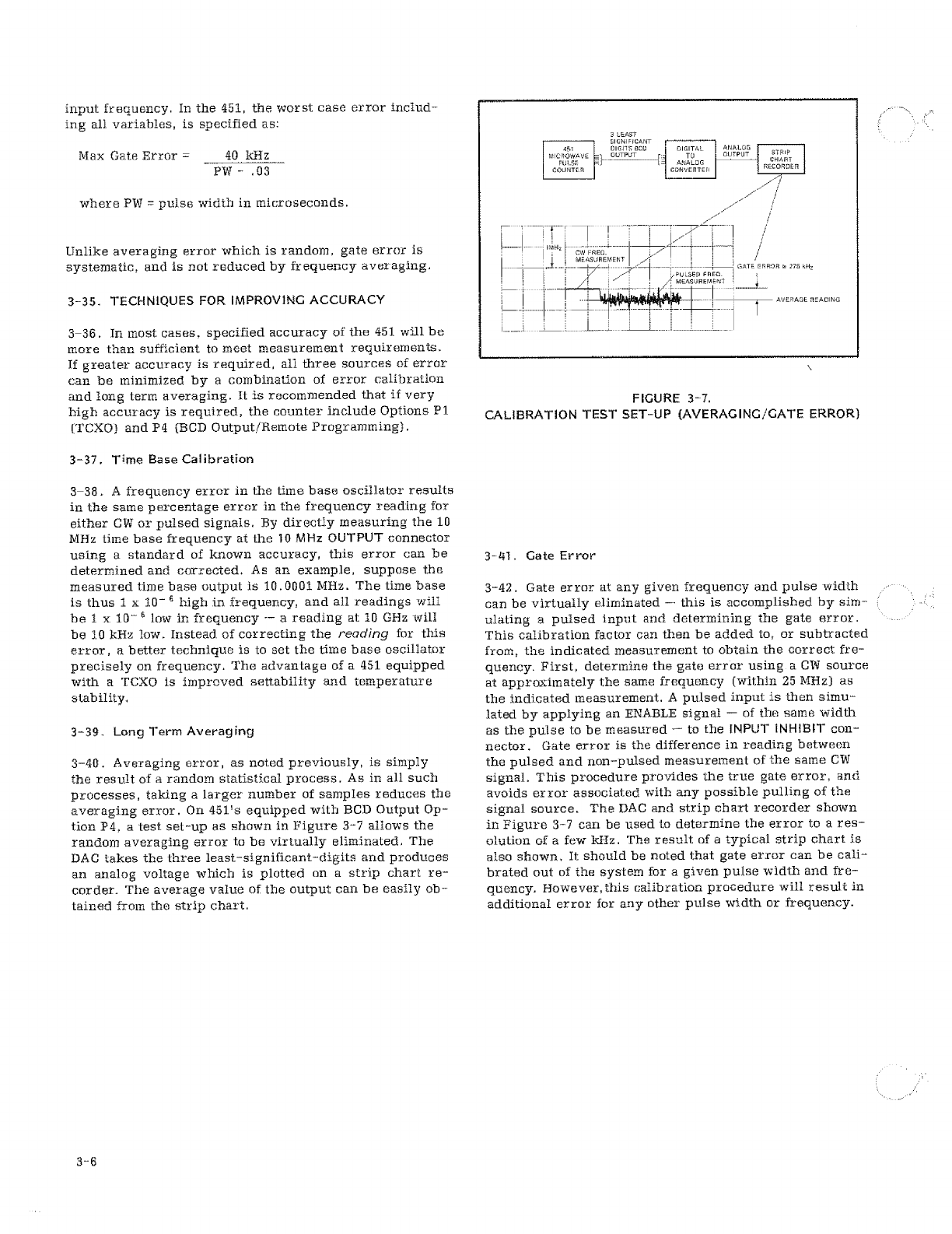

3-39. Long Term Averaging

3-40. Averaging error, as noted previously, is simply

the result of a random statistical process. As in all such

processes, taking a larger number of samples reduces the

averaging error. On 451'8 equipped with BCD Output Op-

tion P4, a test set-up as shown in Figure 3-7 allows the

random averaging error to be virtually eliminated, The

DAC takes the three least-significant-digits and produces

an analog voltage which is plotted on a strip chart re-

corder. The average value of the output can be easily ob-

tained from the strip chart.

FIGURE 3-7.

CALIBRATION TEST SET-UP (AVERAGING/GATE ERROR)

3-41. Gate Error

3-42. Gate error at any given frequency and pulse width

can be virtually eliminated — this is accomplished by sim-

ulating a pulsed input and determining the gate error.

This calibration factor can then be added to, or subtracted

from, the indicated measurement to obtain the correct fre-

quency. First, determine the gate error using a CW source

at approximately the same frequency (within 25 MHz) as

the indicated measurement. A pulsed input is then simu-

lated by applying an ENABLE signal — of the same width

as the pulse to be measured — to

the INPUT INHIBIT

con-

nector. Gate error is the difference in reading between

the pulsed and non-pulsed measurement of the same CW

signal. This procedure provides the true gate error, and

avoids error associated with any possible pulling of the

signal source. The DAC and strip chart recorder shown

in Figure 3-7 can be used to determine the error to a res-

olution of a few kHz. The result of a typical strip chart is

also shown. It should be noted that gate error can be cali-

brated out of the system for a given pulse width and fre-

quency. However,this calibration procedure will result in

additional error for any other pulse width or frequency.

SECTION 4

GENERAL THEORY OF OPERATION

4-1. GENERAL

4-2. The EIP Model 451 Microwave Pulse Counter auto-

matically measures and displays the frequency of a CW

or pulsed signal in the range of 925 MHz to 18 GHz (Band

B). An optional Prescaler (Option P2} extends this range

downward to 300 MHz (Band A). In addition to fully auto-

matic measurements. it is possible to utilize the 451 with

accessory equipment to make dynamic frequency measure-

ments — the frequency of any repetitive signal can thus

be measured at any point in time. Measurement windows

as narrow as 20 nanoseconds are achievable.

4-3. Measurements in Band B (925 MHz - 18 GHz) are

achieved by heterodyning the input signal with a known

harmonic of 200 MHz. The resulting difference frequency

is then processed by a 350 MHz Direct Counter. The

counter gate is enabled by the input itself in a manner

such that the gate is open only when a signal is present.

4-4. In the Direct Counter, obtainable resolution is in-

versely proportional to the measurement time. For exam-

ple: a 1 microsecond gate time will yield 1 MHz resolu-

tion. To achieve 10 kHz resolution, the 451 automatically

averages as many input pulses as necessary to obtain a

total gate interval of 100 ms (or 1 us). The required

number of pulses is thus a function of the input pulse

width. (A more comprehensive discussion of this will be

found beginning with paragraph 4-27.)

4-5. In the optional Band A (300 MHz - 950 MHz), the in-

put frequency is divided by four. The divided frequency

is then counted in the Direct Counter for a 400 us (or

4 ms) period to obtain a readout with 10 kHz resolution.

As in Band B. gating is controlled by the input signal.

4-6. The system operation of the 451 is best described

by separating the instrument into its two main functional

blocks: the Microwave Converter. and the Direct Counter.

4-7. Figure 4-1 shows a simplified block diagram of the

entire 451. Figure 4-2 shows a more complete block dia-

gram of the Microwave Converter section, while Figure

4-3 diagrams the Direct Counter. Detailed circuit descrip-

tions of all PC boards are given in Section 9.

4

-

8. MICROWAVE CONVERTER

4-9, The Microwave Converter is a self-contained assem-

bly which performs the function of translating the input

microwave frequency downward into the range of 100 to

350 MHz. This translation is accomplished by mixing the

incoming signal with a known reference frequency and

then amplifying the difference. The input frequency is

determined by counting this difference frequency and ad-

ding it to the known reference frequency (see Figure 4-2).

4-10. The reference frequency is an integral harmonic of

200 MHz. generated within the FIG Comb Generator (A207).

This unit is an integrated assembly containing a harmonic

(or comb) generator,and a two-stage FIG filter. The comb

generator converts the 200 MHz sine wave input into a

train of narrow pulses containing all the harmonics of 200

MHz up to 18 GHz. while the FIG filter selects the desired

harmonic. Tuning of the FIG filter is accomplished by

varying the current through a pair of coils, which in turn,

varies a magnetic field within the structure. (A more com-

prehensive description of the operation of a FIG-tuned

device is given tater in this section.)

4-11. The 200 MHz reference is generated within Source/-

Amplifier A201 by an LC oscillator which is phase-locked

to the 10 MHz Time Base Oscillator (A108) within the 451.

This reference is amplified to produce up to one watt of

output power to drive the comb generator section of A207.

A second output at 200 MHz is used to generate the gate

and test functions within the Direct Counter.

4-12. The RF input signal to the Converter section first

passes through a Limiter/Attenuator (A206). The limiter

portion of this module is a passive diode whose main func-

tion is to protect the Mixer (A205) against excessive input

power. Protection at levels up to one watt peak or average

is provided.The attenuator section contains a multistage.

matched PIN diode serving two functions: (a) to provide a

means of controlling the RF signal level to the Mixer. and

(b) to act as a switch which shuts off the input signal dur-

ing certain portions of Converter operation.

4-13. The Mixer (A205) is another integrated microwave

circuit assembly, containing a hybrid coupler, termina-

tion, mixer diode, and a DC return. The Mixer produces

two output signals on a common line: (a) an IF signal

equal in frequency to the difference between the RF sig-

nal and the reference signal; (b) a Video signal resulting

from rectification of either the RF or reference input.

4-14. The IF and Video signals are separated in the IF

Processor (A204). This assembly contains an IF amplifier,

video amplifiers. threshold circuits, and LOCK circuitry.

The output of the IF amplifier is the signal actually meas-

ured by the Direct Counter. It is also used by the LOCK

circuitry to determine the correct reference frequency

(comb line). The Converter is considered to be locked

when a particular comb line mixes with the applied RF

signal to produce an IF signal of proper amplitude and

frequency.

4-15. The amplified Video output is used to generate three

separate signals: two threshold, and one analog output.

One signal — SIGNAL THRESHOLD — is used to detect the

presence of sufficient RF signal to initiate operation of the

Converter and enable the gate of the Direct Counter. The

4-1

FIGURE 4-1. BLOCK DIAGRAM - 4S1 MICROWAVE PULSE COUNTER

SALO

IKOLJT

_L

Iuvur

— FzEF

SIGL1AL

THRESHOL4>

0A1.42 S

THKESHOLD

> LOCK

can3vETe TE2 K.3ASLE

POP LIMIT

>

MSC

,

P2tSET

FIGURE 4-2. BLOCK DIAGRAM - 451 PULSE COUNTER - CONVERTER (A2)

4-2

Table of contents

Other EIP Cash Counter manuals

Popular Cash Counter manuals by other brands

Gemini

Gemini BPM-1 Service manual

MULTISPAN

MULTISPAN LC-2046 quick start guide

MEI

MEI Cashflow SC Series Operation & maintenance manual

Nautilus Hyosung

Nautilus Hyosung MONiMAX5600 Service manual

Measurement Computing

Measurement Computing CB-7080 user guide

advantest corporation

advantest corporation TR5821 Operation manual