Replacing a plastic gear

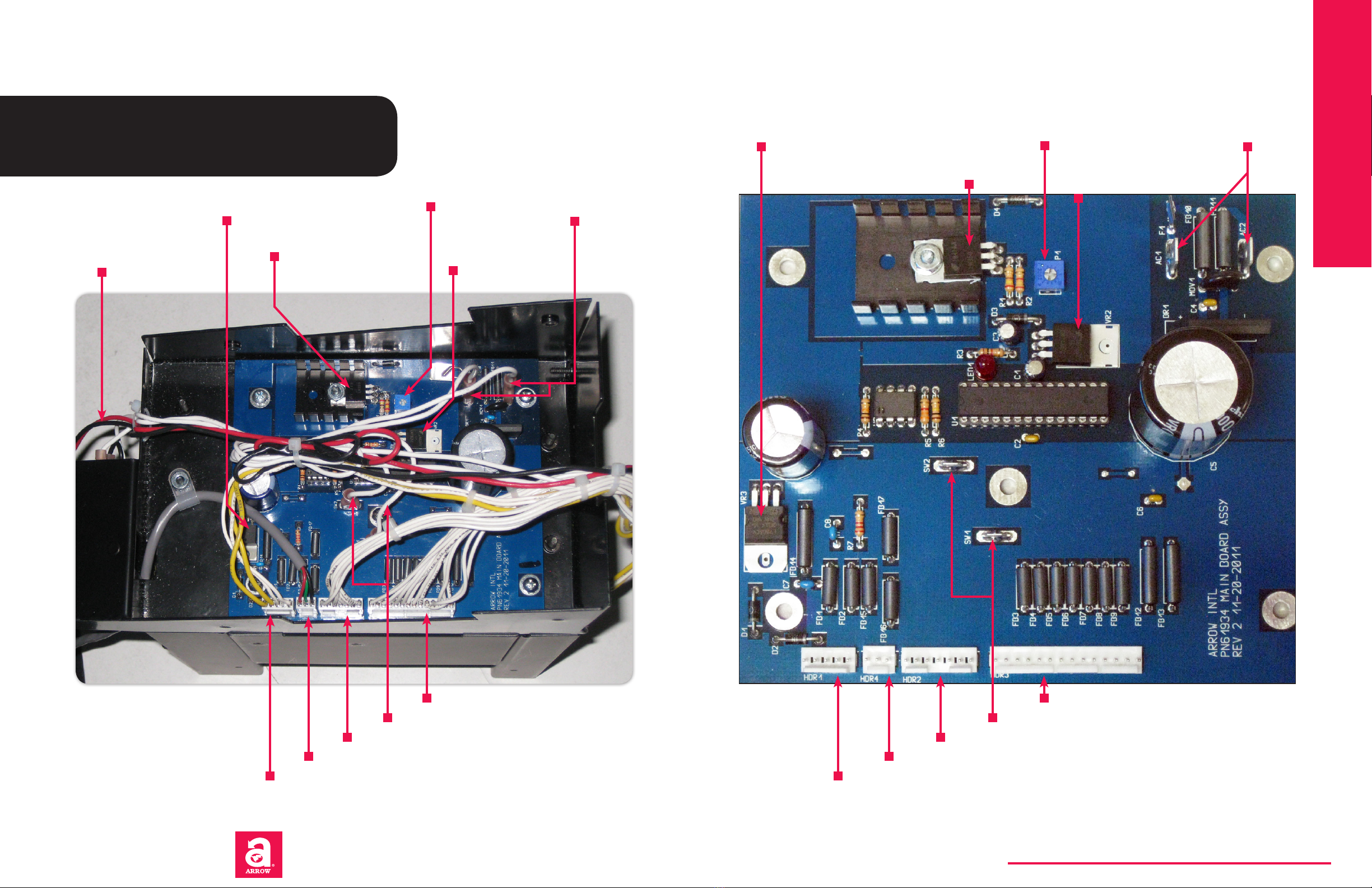

Harness for the square pushbutton switch: 2 variants may exist in the field. Both variants uti-

lize 2 wires for sending the switch signal, and those 2 wires connect to SW1 and SW2 on the

Main PCB (it doesn’t matter which wire connects to which connector). The 1st variant consists

of just the 2 wires connecting to the pushbutton switch. The 2nd variant, utilizes a 5-prong

plug to connect to the pushbutton switch. This 5-prong plug, has 3 extra prongs for possible

expanded functionality in future models of the ticket counter

7-pin harness for the keypad - Connects to HDR2 on the main PCB (underneath the ticket coun-

ter). The header which connects to the keypad itself is not keyed. Prior to removal, it is recom-

mended that both the header and connector on the keypad be marked in some way to ensure

correct re-attachment: in the diagram, the header has a black mark indicating the location of

PIN 1 ... the keypad connector (not visible) has a similar marking

Power wires for the motor - they go underneath the ticket counter, across the main PCB, and

connect to the motor on the other side of the ticket counter (see p.10-11)

Motor Board PCB

Plastic Gear - 60 Tooth. It is mounted on the transfer shaft (which does not contain any rollers)

Plastic Gear - 96 Tooth. It is mounted on the shaft with the two visible rollers

The optical sensor responsible for counting tickets includes these 4 wires pre-attached (con-

sisting of 2 braids [red/black & orange/black]). The other ends of the wires are soldered to the

motor board PCB (which is visible on this page)

Cleaning the ticket-count optical sensor

Plastic Gear - 35 Tooth. It is mounted on the motor shaft

5-pin harness for the motor board PCB - Connects to HDR1 on the main PCB (underneath the

ticket counter). This harness has a keyed header on both ends that snaps into place when

inserted correctly

Replacing the ticket-count optical sensor

14-pin harness for the LCD assembly - Connects to HDR3 on the main PCB (underneath the

ticket counter). This harness has a keyed header on both ends that snaps into place when

inserted correctly

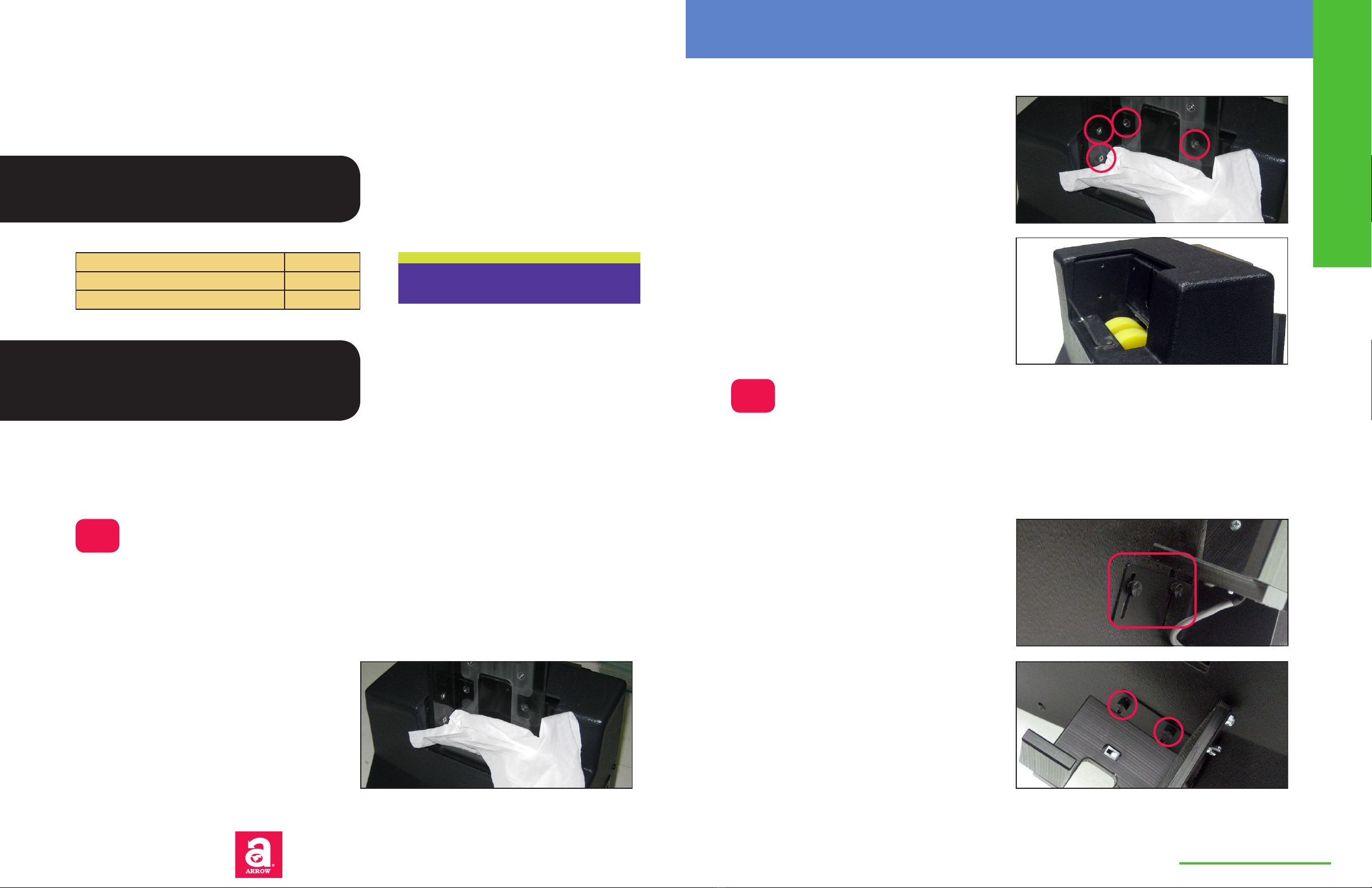

There is an interlocking mechanism between

the header on the harness and the header on

the PCB. This results in a very solid connec-

tion, but, it can also make it seem difficult to

disconnect the harness from the PCB

The following notes should be followed when

disconnecting the harness from the PCB

• make sure there is enough room to

comfortably grip the harness header

• grip the harness header from the left

and right plastic sides of the connector

(not from the wires) and pull the con-

nector straight backwards (red arrow)

OVERVIEW OF PARTS AND PROCEDURES CHAPTER 1

www.arrowinternational.com

8

© 2012 Arrow International, Inc.

9900 Clinton Rd. Cleveland, OH 44144 • Toll Free: 800.321.0757

Technical Assistance Center (8 AM - 12AM EST): 800.277.6214

This service manual is only authorized for use by Arrow Distributors

ARROW INTERNATIONAL

9