Model

5315

A/ B

General Informati

on

1-1.

INTRODUCTION

SECTION I

GENERAL

INFORMATION

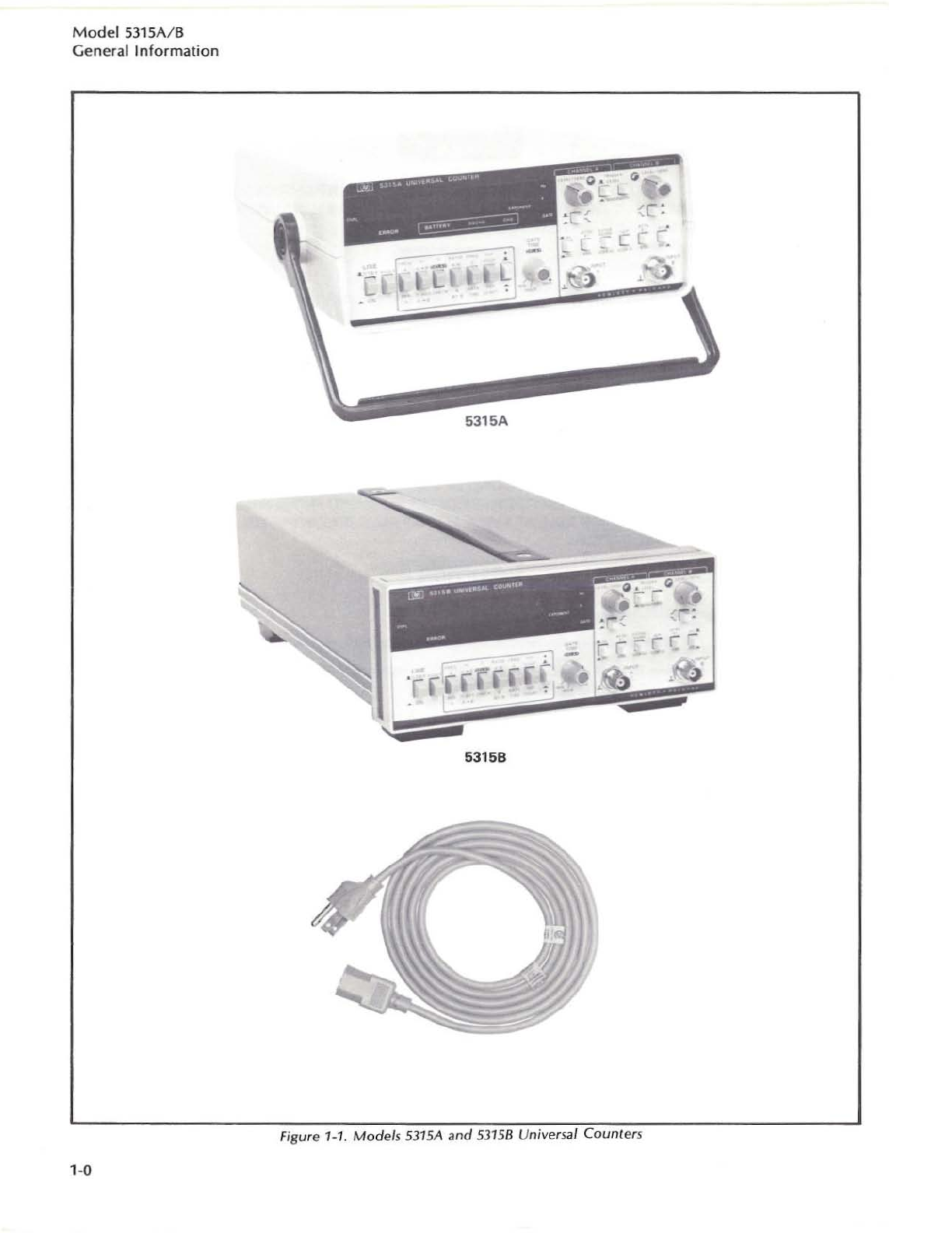

1-2. This manual provides information pertaining to

the

installation,

operation,

testing, adjust-

ments, and maintenance of

the

HP

Mode

l

53

1

5A

and 53158 Universal

Co

unters, shown

in

Figure 1-1.

1-

3.

This

manual is divided into eightsections, each covering a particular topic for

the

operating

and service of the

HP

Model

S31SA

/ 8. The top

ics

by

section

number

are:

Sedion

Topic

General Information

II

Installation

lit

Operation

IV

Performance Tests

V Adjustments

VI Replaceable Parts

V

II

Manual Changes

VIrI Service

1-4. DESCRIPTION

1-5. The Hewlett-Packard Model

5315A

and 53158 are universal

co

unters, measuring signals

over a range from

0.1

Hz to

100

MHz.

Th

e

5315A

/ B measures

Fr

e

qu

ency, Period, Time Interval,

Time Interval Ave

ra

ge, Time Inter

val

Holdoff (Delay), and Ratio. ATotalize functi

on

with manual

or external gating is al

so

provided. A

ll

measurements except Totalize are displayed

in

engineer-

ing notation with up to eight digits of resolution.

1-6. Two

independent

input channels are prOVided for time interval measurements.

Each

input

channel has an attenuator (Xl,

X20

), trigger slope sel

ecto

r, tr

igg

er

level/sensitiv

it

y control, and

ac-dc coupling. A switchable low-pass fitter

on

Channe

l A and 3-state trigger lights are also

provided.

1-7. The

53

158

is

functionally identical to

the

53

1

5A.

The major differ

ence

is

that

the

53

15

B

is

designed for rack mounting or stacking and features a metal cabinet to minimize

EM!.

1-8. OPTIONS

1-9.

Th

e options

ava

il

able with the

5315A

/ 8

are

described

in

Table 1-1.

If

an

option

is

included

in

the

initial

order

, it

will

be

installed at

the

factory and ready for operation

upon

receipt.

If

an

option

is

ordered

for field installation,

it

w

ill

be

supplied

as

a retrofit kit. For field installation of

Option

001

and

002

, refer to paragraph 2-29.

1-10. SPECIFICATIONS

1-1

1.

Th

e inst

rument

specifications are listed

in

Table 1-1. Thesespecifications are

the

perform-

ance standards

or

limi

ts

aga

in

st

which

the

instrument may

be

tested.

1

-1