EIP 585B Operation manual

DIGITALY REMASTERED

OUT OF PRINT- MANUAL SCANS

By

Artek Media

18265 200th St.

Welch, MN 55089

www.artekmedia.com

“High resolution scans of obsolete technical manuals”

If your looking for a quality scanned technical manual in PDF format please visit

our WEB site at www.artekmedia.com or drop us an email at

manuals we have available.

If you don’t see the manual you need on the list drop us a line anyway we may

still be able to point you to other sources. If you have an existing manual you

would like scanned please write for details. This can often be done very

reasonably in consideration for adding your manual to our library.

Typically the scans in our manuals are done as follows;

1) Typed text pages are typically scanned in black and white at 300 dpi.

2) Photo pages are typically scanned in gray scale mode at 600 dpi

3) Schematic diagram pages are typically scanned in black and white at 600

dpi unless the original manual had colored high lighting (as is the case for

some 70’s vintage Tektronix manuals).

4) Most manuals are text searchable

5) All manuals are fully bookmarked

All data is guaranteed for life (yours or mine … which ever is shorter). If for ANY

REASON your file becomes corrupted, deleted or lost, Artek Media will replace

the file for the price of shipping, or free via FTP download.

Thanks

Dave & Lynn Henderson

Artek Media

lEllElFl u,u",u,,,

Warranty

EIP Microwave warrants this product to be free from defects in material and workmanship for three

years* from the date of delivery. Damage due to accident, abuse, or improper signal level is not covered

by the warranty. Removal, defacement, or alteration of any serial or inspection label, marking, or seal

may void the warranty. EIP Microwave will repair or replace, at its option, any components of this product

which prove to be defective during the warranty period, provided the entire unit is returned to EIP or an

authorized service facility. In-warranty units will be returned freight prepaid; out-of-warranty units will be

returned freight COLLECT. No warranty other than the above is expressed or implied.

Certification

EIP Microwave ceftifies this instrument to be in conformance with the specifications noted herein at time

of shipment from the factory. EIP Microwave further certifies that its calibration measurements are traceable

to the United States National Institute of Standards and Technology.

Instruments Covered by This Manual

The information in this manual applies to EIP Models 25B and 28B with the CCN number(s) listed on

the cover. The CCN is the configuration control number. lt is a four digit number which is either shown

separately as the "CCN" on the serial number tag of the instrument, or as the first four digits of the

serial number. The serial number tag is located on the lower rear frame. Please inspect the serial number

tag of the instrument and verify the CCN is listed among the CCN numbers covered by this manual.

Manual Updates

The CCN of the instrument will change any time a part or assembly of the instrument is changed to the

e)dent that it is no longer interchangeable with the earlier part or assembly. When changes occur, either

a new manual is printed incorporating the changes or the manual is shipped with a Manual Update. To

ensure the technical accuracy of the manual, please be sure to incorporate new information as instructed

in the Manual Update.

Supplied Accessories

The EIP Models 25B and 28B are supplied with an operations manual, an ac line cord, and a protective

front cover. Other available options and accessories are listed in Section 1.

Gustomer Suggestion Form

A mail-in form at the end of this manual provides an easy way for you to tell us about any additions,

corrections, or changes that would improve this publication. Your suggestions are a valuable part of the

input used in revising our manuals and developing the structure and format for new manuals.

| . Products shipped prior to October 1992 had a standard one year warranty.

REV.7/20/93 UPDATE 5580486-00 C

Scans by Artekmedia => 2010

ilE]mm sssB/s888

SAFETY

The EIP Models 258 and 288 have been designed and tested according to international safety requirements,

but as with all electronic equipment, certain precautions must be observed. This manualcontains information,

cautions, and warnings that must be followed to prevent the possibility of personal injury and/or damage

to the instrument.

SAFEW SYMBOLS

WARNING The WARNING sign denotes ahazard.lt calls attention to a procedure or practice, which,

if not correctly per{ormed or adhered to, could result in personal injury.

CAUTION The CAUTION sign denotes a hazard. lt calls attention to an operating procedure or

practice, which, if not correctly pedormed or adhered to, could result in damage to or

destruction of part or all ol the product.

OVERALL SAFEW CONSIDERATIONS

WARNING

Before thls instrument is switched on, the protective earth terminals of this instrument

MUST be connected to the protective conductor of the ac power cord. The mains

plug shall only be inserted in a socket outlet provided with a protective earth

tonlact. The protective action must not be negated by the use of an extension

cord (power cable) without a protective earth (grounding) conductor.

WARNING

Only fuses with the required rated current, voltage and specified type should be

used. DO NOT use repaired fuses or short-circuited fuseholders. To do so could

cause a shock or fire hazard.

CAUTION

Before connecting power to the instrument, check to insure that the correct fuse

is installed and the voltage select switch on the rear panel of the instrument is

set properly. Refer to Section 2, Installation.

CAUTION

Excessive signals can damage these instruments. To prevent damage, do not exceed

specified damage level. Refer to specifications listed in Section 1.

REV.7/20/93 UPDATE 5580486-00 C

Scans by ArtekMedia => 2010

TABLE OF CONTENTS

TABLE OF CONTENTS

Page

Warranty

Certif ication

Manual Change lnformation

Qafotrr ....,,.t

Section 1 - GENERAL INFORMATION

Iniroduction

Operating Conditions

Ventilation

Storage

Specifications . . .

Options and Accessories .

Section 2 . INSTALLATION

iii

iii

iii

t-l

t-l

11

ll

t-l

t-z

t-I

Unpacking . . 2-l

Installation . . 2-j

VoltageSelection ..2-1

Fuse Replacement .......2-2

lncoming Operational Checkout . . 2_2

Servicelnformation ,...,.2-3

PeriodicMaintenance... ....2_3

Counter ldentification,,,. ....2-3

FactoryService ......2-3

Shippinglnstructions ..2_3

Section 3 - OPERATION

Introduction .......3_1

Front Panel Controls, Indicators, and Connectors . . . , . 3_1

Status Display .......3-2

GPlBStatuslndicators ....3-3

Signal InputConnectors .....3*3

Rear Panel Control and Connectors .. ... 3-4

InstrumentDefaultSettings ......3-s

KeyboardOperation ......3-s

Numeric Entry Keys ... 3-6

TerminatorKeys. ,,,..3-6

Clear Display and Clear Data . , . . 3-6

One-ShotActionKeys ....,.3-6

Parameter Call Keys .. 3*7

ParameterCallKeysUsedWithoutTerminator ..."... 3-7

Parameter Call Keys Used With Terminator ... 3-10

Signal Measurements . .. . 3-13

AutomaticFrequencyMeasurements .....3-13

MultipleSignal Measurements ,.^..3-13

Pulse Profiling ... . ... 3-15

VCO Settling Time Measurements .. ...... 3-16

Scans by Artekmedia => 2010

TABLE OF CONTENTS

TABLE OF CONTENTS (Continued)

Page

Section 3 - OPERATION (Continued)

FrequencyAgilePulseMeasurements... ..3-17

Timing Considerations ,. .... 3-17

Measurement WindowWidth ...3-17

. Internal Timing Delays . . . 3-17

Accuracy ., 3-18

CW Measurement Accuracy . 3-18

Pulse Measurement Accuracy . . .. . 3-18

Time Base Error , 3-18

AveragingError. .3-19

GateError .,....3-20

DistortionError ..3-20

TechniquesforlmprovingAccuracy .,..3-20

TimeBaseOalibration ...,..3-20

Reducing AveragingError. ..3-20

Reducing Gate Error . 3-21

ReducingDistortionError, ..3-22

Calculating Measurement Accuracy .... 3-22

Measurement Accuracy Worksheet . .. , 3-24

Special Function Directory .,...,3-25

Activation of Soecial Functions ....3-25

Operation Verification Functions ....3-25

Calibration and Troubleshooting Functions . 3-27

Capability Enhancement Functions . 3-31

ErrorMessages ..3-36

Section 4 - PROGRAMMING

Remote Programming ... .... . .. 4-1

General PurposelnterfaceBus.. '...4-1

GPIB Functions lmplemented .. '.. . . 4-1

Device-Dependent Messages (Listener Features) . . 4-2

Control Messages '.'....4-3

ModeMessages .'4-3

ParameterMessages ."' 4-4

OutputControl Messages ...'...4-5

Output Setup Command .. 4-6

SyntaxDefinition ..4-6

Output and Format ExamPles . . . 4-8

Output Messages (Talker Features) ... ' . . 4-10

Status Byte . .. 4-11

ServiceRequestMask. .'..' 4-11

Configurationlnformation... ......4-13

Default State (Device Clear Features) . . . . 4-14

Scans by ArtekMedia => 2010

Eilffim sssB/sBBB TABLE OF CONTENTS

Page

4-14

4-15

4-16

4-16

4-16

4-17

6-1

6-1

6-2

6-2

6-3

6-3

7-1

7-3

7-3

7-3

7-3

7-4

7-4

7-5

7-5

7-5

7-6

7-7

TABLE OF CONTENTS (Continued)

Section 4 - PROGRAMMING (Continued)

GPIB Address Selection

Talk Only Modes

Data Input and OutPut SPeed

.lnput Speed

Output Speed

Reading Measurements

Section 5 - OPERATIONAL VERIFICATION TESTS

lntroduction .."""5-1

Equipment Requirements 5-1

Sourcelockingsetup .. " " 5-2

Operational Verification Test Procedures " . 5-3

Band 0 Range and Sensitivity Test (CW Only) . . . " . 5-3

Band 1 Range and Sensitivity Test . . . 5-4

Band 2 Range and Sensitivity Test ' " . 5-5

Band2AmplitudeDiscriminationTest .. " " " 5-7

Band 3 Subband 1 Range and Sensitivity Test (5888 Option 5804 Only) " ' . 5-8

OperationalTest Record 5-10

Section 6 - THEORY OF OPERATION

Introduction

Basic Counter

RF Converters

Band 0 RF Converter (CW OnlY)

Band 1 RF Converter

Band 2 Microwave Converter

Section 7 - ADJUSTMENT AND CALIBRATION

lntroduction

Equipment Required

Preliminary Operations

Cover Removal

Memory Protect Feature

Adjustments

Power SupPlY Adjustment

Display I ntensitY Adjustment

Calibration

Timebase Calibration

YIGDAC Automatic Calibration - Special Function 91 . .

Two Point YIG DAC Automatic Calibration - Procedure 1 " " '

Multi-PointYlcDAOAutomaticCalibration-Procedure2 .. " . .7-7

Gate Error Calibration - Special Function 92 - . 7'8

Section 8 - PERFORMANCE VERIFICATION TESTS

lntroduction ... 8-1

Equipment Requirements 8-4

REV.7/20/93 UPDATE 5580486-00 C

Scans by Artekmedia => 2010

lElEilEjl ,,u,,,,,, 'o"'o, "on,,,*,.

TABLE OF CONTENTS (Continued)

Page

Section 8 - PERFORMANCE VERIFICATION TESTS (Continued)

Special Equipment . ' 8-5

TestProcedures .. 8-6

Band 0 Range/Sensitivity Tests (CW Only) . . . 8-6

BandlRange/SensitivityTests .....8-7

Band2Range/SensitivityTests ... ". 8-8

BandlAmplitudeDiscriminationTest ..... 8-9

Band 2 Amplitude Discrimination Test 8-10

Band 1 Gate Error Test 8-10

Band 2 Gate Error Test 8-11

Band 1 Distortion Error Test 8-12

Band 2 Distortion Error Test 8-14

Band 1 Averaging ErrorTest 8-15

Band 2 Averaging Error Test 8-17

Band 2 Frequency Limits Test 8-18

Band 2 Center FrequencY Test 8-19

Band 1 Maximum Video . 8-2O

Band 2 Maximum Video . 8-21

Pulse Width Accuracy Test 8-22

Pufse Period Accuracy Test . 8-23

Section 9 - TROUBLESHOOTING

lntroduction

SignatureAnalysis . . 9-1

Self-Diagnostics . ' 9-3

Keyboard-ControlledOircuitTests. .....9-3

Troubleshooting Trees

SECIION 10. FUNCTIONAL DESCRIPTIONS AND REPLACEABLE PARTS

lntroduction 10-1

Ordering Inlormation 10-1

Reference Designators 10-1

Abbreviations 'lO-2

TopAssembly . . 10-3

A1 Chassis Assembly 10-9

A1A1 Counterlnterconnect ....10-11

42 Power Supply . 10-15

A5Processor/GPIB(2O2O4OO-02) ... ..10-23

A5Processor/GPIB(2020480-02).'. .10-32A

A6CountChain . .10-33

A7 Gate Generator 10-45

A8 Gate Control . . 10-59

AgSignalConditioner ' . .10-65

Al0Band2MicrowaveConverter(2010936-01/2010936-O2) . . . . . .10-81

9-1

REV.7120/93 viii UPDATE 5580486-00 C

Scans by ArtekMedia => 2010

fElU[Ejl urr'urr" ,o"r= o, "o*r=*r,

TABLE OF CONTENTS (Continued)

Page

Section 10 - FUNCTIONAL DESCRIPTIONS AND REPLACEABLE PARTS (Continued)

A10A1 YTFDriver(2020452-03) ... ..10-85

AlOBand2MicrowaveConverter(2010670-0112010670'02) . . . ". 10-90A

A10A1 YTF Driver (2020483-02) . . . 10-90E

A'12 Frcint Panel . 10-91

A12A1 Front Panel Display and Keyboard . . " . 10-95

A12A2 Front Panel Logic 10-103

A'13 Rear Panel '10-1'13

Section 11 - OPTIONS

Option 5804 - Extended Frequency Capability 11-3

Theory of Operation 11-3

Power Amplifier 11-5

Multiplier 11-5

lF Amplifier 11-5

Calibration 11-6

Gate Error Calibration 11-6

Performance Verification Tests 11-8

Range/SensitivityTests . . 11-10

Amplitude Discrimination Test " " 11'12

Gate ErrorTest . 11-13

Distortion Error Test

Averaging Error Test

Troubleshooting

Troubleshooting Tree

Options 5807, 5808, 5809 - AT-Cut Ovenized High Stability Timebases

Power Supply

Calibration

Option 5809 - SC-Cut Ovenized High Stability Timebase

lntroduction

Specifications

Timebase Calibration

Power Supply Theory of OPeration

1 1-15

11-17

1 1-19

1 1-19

11-25

11-25

11-26

11-31

11-31

11-31

11-32

11-33

Appendix A - QUICK REFERENCE LIST OF GPIB COMMAND MESSAGES . . . . A-1

Appendix B - PHYSICAL DESCRIPTION B-'t

REV.7/20193 UPDATE 5580486-00 C

Scans by Artekmedia => 2010

ilEtil]ilFtl 5858/588B LIST OF ILLUSTRATIONS

LIST OF ILLUSTRATIONS

Page

Rear Panel Fuse and Voltage Selection Switch Locations . . 2-1

Figure

2-1

3-1

3-2

3-3

3-4

3-5

J-O

3-7

3-8

3-9

3-10

3-11

3-12

3-13

4-1

4-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

Front Panel Controls and lndicator (Model 5888 Shown) . . .

Status Display

Signal lnput Connectors (Model 5888 Shown)

Rear Panel Control and Connectors .

3-'l

3-2

3-3

3-4

3-6

6-1

6-2

o-.,

6-4

6-5

o-o

6-7

7-1

7-2

7-3

| 7-4

| 7-5

8-1

8-2

8-3

8-4

Keyboard

Pulsed Signal 3-13

Frequency Limits 3-14

Pulse Profile Measurement Test Setup 3-15

Pulse Profile Measurement 3-15

VCO Settling Time Measurements 3-16

Time Varying Signal Measurement Test Setup 3-16

InternalTiming Delays 3-17

Logical"AND" Function 3'2O

Status Byte Structure 4'1'l

Allowable Address Codes 4-15

Sourcelockingsetup .....5-2

Band 0 Range and Sensitivity Test Setup (100 Hz to 10 MHz) . . . . 5-3

Band 0 Range and Sensitivity Test Setup (100 MHz to 250 MHz) . . 5-4

Band 1 Range And Sensitivity Test Setup . . . 5-5

Band 2 CW Signal Range and Sensitivity Test Setup . . . . . 5-6

Band 2 Pulsed Signal Range and Sensitivity Test Setup . . . 5-6

Band2AmplitudeDiscriminationTestSetup .. "..5-7

Band 3 Range and Sensitivity Test Setup (Model 5888 Option 5804 Only) . . 5-8

Block Diagram of Basic Counter ' . . . 6-1

BandOBlockDiagram. " . . 6-2

BandlBlockDiagram. '..6-3

Band 1 RF Converter Lock Process Flow Diagram . ' . 6-3

Band 2 Microwave Converter Block Diagram . . 6-4

MicrowaveConverterOperationFlowDiagram '... ' 6-5

Models8sB/sSSBOountersFunctionalBlockDiagram ..... 6-9

AdjustmentControlLocations ..- .7-2

Power Supply Adjustment Setup . - . 7-4

Timebase Calibration SetuP . . 7-5

YIG DAC Automatic Calibration Setup - . . . 7-7

Bandsl and2GateErrorOalibrationSetup . . . . .7'9

PulseModulator '.. 8-6

Band 0 Range and Sensitivity Test Setup (100 Hz to 10 MHz) ' . . . 8-6

Band O Range and Sensitivity Test Setup (100 MHz to 250 MHz) . . 8-7

Band 1 Range and Sensitivity Test Setup . . . 8-8

REV.7/20193 UPDATE 5580486-00 c

Scans by ArtekMedia => 2010

ilElEiFl ,rr'urr, .,., or,rru.r"or,o*,

LIST OF ILLUSTRATIONS (Continued)

Figure Page

8-5 Band 2 Range and Sensitivity Test Setup " " . 8-8

8-6 Band 'l Amplitude Discrimination Test Setup . . . . . 8-9

8-7 Band 2 Amplitude Discrimination Test Setup 8-10

8-8 Band 1 Gate Error Test Setup 8-11

8-9 Band 2 Gate Error Test Setup 8-12

8-10 Band 1 Distorlion Error Test Setup 8-13

8-1 1 Band 2 Distortion Error Test Setup 8-14

8-12 Band 1 Averaging ErrorTest Setup 8-16

8-13 Band 2 Averaging Error Test Setup 8-17

8-14 Band 2 Frequency Limits Test Setup 8-18

8-15 Band 2 Center Frequency Test Setup 8-19

8-16 Band 1 Maximum Video Test Setup 8-20

8-17 Band 2 Maximum Video Test Setup 8-21

8-18 Pulse Width Accuracy Test Setup 8-22

8-19 Pulse Period Accuracy Test Setup 8-23

9-1 Main Troubleshooting Tree " " 9-7

9-2 Program Inoperative Troubleshooting Tree . . 9-8

9-3 100 MHz Self-Test Troubleshooting Tree " " . 9-9

9-4 Band 0 Troubleshooting Tree 9-10

9-5 Band 'l Troubleshooting Tree 9-11

9-6 Band2TroubleshootingTree .: . . 9-13

1O-1 TopAssembly... 10-3

1o-2 Counter Cable Assemblies 10-6

1O-3 Power Entry Interconnect Diagram 1O'7

1O-4 Power Entry Schematic Diagram 10-8

1O-5 Chassis Assembly (Al) Replaceable Parts . 10-10

10-6 Counter Interconnect (A1A1) Component Locator . 10-12

1O-7 Counter Interconnect (A1A1) Schematic Diagram . . 10-13

1O-8 Power Supply Block Diagram . . 10-15

1O-9 PowerSupply(A2)ComponentLocator. ....'10-20

10-10 Power Supply (A2) Schematic Diagram . . . 'lO-21

10-11 Processor/GPlBsimplifiedBlockDiagram(2020400-02)... .. "10-23

10-12 Processor/GP|B(A5)Componentlocator(2o2o4oj-02) ... ...10-30

10-13 Processor/GPlB(A5)SchematicDiagram(2020400-02) . . . . " " 10-31

1O-13A Processor/GPlBSimplifiedBlockDiagram(202O48O-O2)... '.10-32A

1O-13B Processor/GP|B(A5)Componentlocator(2020480-02)... ..10-32H

1o.13cProcessor/GP|B(A5)SchematicDiagram(2o2o48o.o2)'..

10-14 Count Chain Block Diagram . 10-33

10-15 CountChain(A6)Componentlocatot . ... -10-42

10-16 Count Chain (46) Schematic Diagram . . . 1H3

10-17 Gate Generator Block Diagram . " . 10-46

10-18 Gate Generator (A7) Component Locator . . 10-54

10-19 Gate Generator (A7) Schematic Locator . . 10-55

10-20 Gate Control Block Diagram . . . . 10-59

xi

REV.7/20193 UPDATE 5580486-00 c

Scans by Artekmedia => 2010

lElfllEil ,rur,rrr, ,'r, or,rru.r*or,o*,

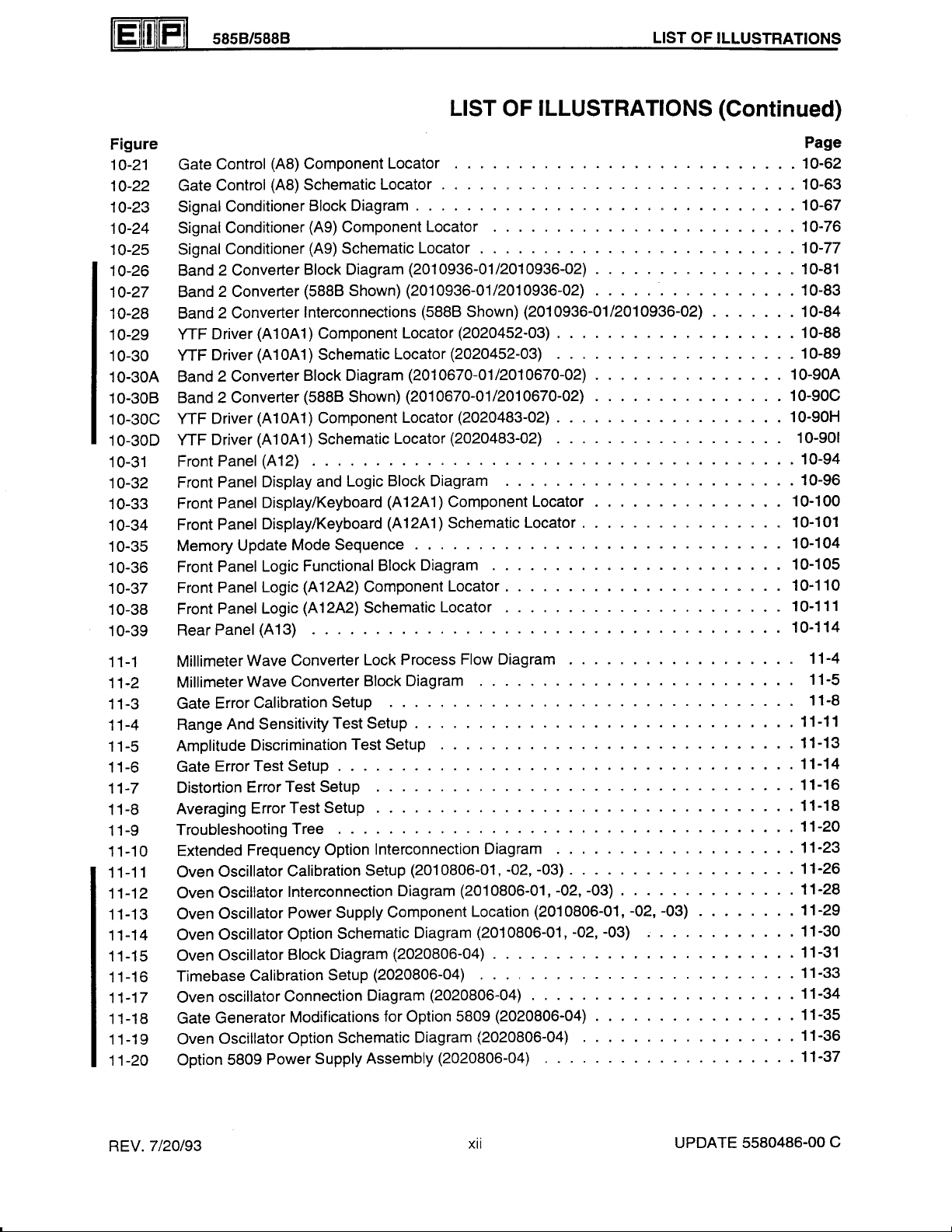

LIST OF ILLUSTRATIONS (Continued)

Figure Page

10-21 Gate Control (A8) Component Locator . . . 10-62

10-22 Gate Control (A8) Schematic Locator . . . . 10-63

10-23 SignalConditionerBlockDiagram ...10-67

10-24 Signal Conditioner (A9) Component Locator . 10-76

10-25 Signal Conditioner (A9) Schematic Locator . 'lO-77

10-26 Band 2 Converter Block Diagram (2010936-01/2010936-02) . . . " 10-81

10-27 Band 2 Converter (5888 Shown) (2010936-01/2010936-02) . . . . 10-83

10-28 Band2Converterlnterconnections(5888Shown) (2010936-01/2010936-02).......10-84

10-29 YTFDriver(A10A1)Componentlocator(2020452'03). . . ....10-88

10-30 YTFDriver(A10A1)SchematicLocator(2020452-03) ... ....10-89

1O-30A Band 2 Converter Block Diagram (2010670-0'112010670-02) . . . 10-904

1O-3OB Band 2 Converter (5888 Shown) (2010670-0112010670-02\ . . . 10-90C

1O-3OC YTF Driver (A10A1) Component Locator (2020483-02) . . . . . . 10-90H

1O-3OD YTF Driver (A10A1) Schematic Locator (2020483-02) . . . '10-901

10-31 Front Panel (A12) . . 10-94

10-32 FrontPanel DisplayandLogicBlockDiagram . . .10-96

10-33 Front Panel Display/Keyboard (A12A1)Component Locator . . . 10-100

10-34 Front Panel DisplayKeyboard (A12Al) Schematic Locator 10-101

10-35 Memory Update Mode Sequence . . . 10-104

10-36 Front Panel Logic FunctionalBlock Diagram . . ' 10-105

10-37 Front Panel Logic (A12A2) Component Locator . . 10-110

10-38 Front Panel Logic (A12A2) Schematic Locator . . 10-111

10-39 Rear Panel (A13) 10-114

1 1-1

11-2

11-3

11-4

1 1-5

11-6

11-7

11-8

11-9

1 1-10

1 1-1 1

11-12

1 1-13

11-14

1 1-15

1 1-16

11-17

1 1-18

1 1-19

11-20

Millimeter Wave Converter Lock Process Flow Diagram 11'4

Millimeter Wave Converter Block Diagram 11-5

Gate Error Calibration Setup 11-8

Range And Sensitivity Test Setup ' . 1 1-11

AmplitudeDiscriminationTestSetup ....11-13

GateErrorTestSetup . . ' .11-14

Distortion Error Test Setup ' 11-16

Averaging Error Test SetuP . 11-18

TroubleshootingTree ....11-20

Extended Frequency Option Interconnection Diagram - . . 11-23

Oven Oscillator Calibration Setup (2010806-01, -02, -03) - . 11-26

Oven Oscillator Interconnection Diagram (2010806-01, -02, -03) . . 11-28

Oven Oscillator Power Supply Component Location (2010806-01, -02, -03) . ' . . 1 1-29

OvenOscillatorOptionSchematicDiagram(2010806-01,-02,-03) ; . . . . . . .11-30

Oven Oscillator Block Diagram (2020806-04) . . . . 11-31

Timebase Calibration Setup (2020806-04) . 1 1-33

OvenoscillatorConnectionDiagram(2020806-04) ... ..11-34

Gate Generator Modifications forOption 5809 (2020806-04) . . . . 11-35

Oven Oscillator Option Schematic Diagram (2020806-04) . . . . . 11-36

Option5S0gPowerSupplyAssembly(2020806-04) .. . .11-37

REV.7/20193 xil UPDATE 5580486-00 C

Scans by ArtekMedia => 2010

lElEilFl u,u,,,,,, ,,,, o,,o".=,

Table

LIST OF TABLES

Page

Band 3 Remote Sensors 1-8

Options 5807, 5808, and 5809 - Ovenized High Stability Timebases (AT-Cut) 1-8

Option 5809 - Ovenized High Stability Timebase (SC-Cut) 1-8

EquipmentRequirements .... 5-1

Adjustment and Calibration Procedures . " 7-1

EquipmentRequired . .7-3

PerformanceVerificationTestMethods . . ... 8-1

RecommendedEquipmentRequirements. .. "..8-4

ProcessorFree-RunningSignatures " " ". " 9-2

KeyboardTestCoordinates . . . . 9-4

TroubleshootingTestEquipment ".. 9-5

Cable ldentification Guide 10-5

Calibration Equipment Required 11-6

Performance Verification Test Methods 11-8

Equipment Required 11-9

Subband Frequency and Power Ranges " " 11'12

Equipment Required for Troubleshooting . . 1 1-19

Oven Oscillator Option Specifications . 11-25

Recommended Equipment . 11-32

1-1

lii

5-1

7-1

7-2

8-1

8-2

9-1

9-2

9-3

1 0-1

1 1-1

11-2

1 1-3

11-4

1 1-5

I 11-6

a 11-7

REV.7120/93 xill UPDATE 5580486-00 C

Scans by Artekmedia => 2010

fElEIFil u,u,,,,,, .,", o,,o".-,,

This Page Intentionally Left Blank

REV.7/20193 UPDATE 5580486-00 C

Scans by ArtekMedia => 2010

1/GENERAL INFORMATION

)SECTION 1

GENERAL INFORMATION

INTRODUCTION

The EIP Models 5858 and 5888 Pulsed Microwave Frequency Counters are microprocessor-

based multifunction instruments used for both CW and pulsed microwave measurements. They

can automatically measure the frequency of repetitive pulse signals as narrow as 50 ns. Both

models can also automatically measure pulse widths from 50 ns to 1 second and pulse periods

from 250 ns to 1 second, to a 10 ns resolution. Additionally, through the lNHlBlT lN connector,

the 5858 and 5888 can profile pulsed or chirped signals with measurement windows as narrow

as 15 ns. No manual switching is required to measure CW or pulsed signals.

The frequency range of the 5B5B is 100 Hz to 20 GHz. The frequency range of the 5BBB is

100 Hz to 26.5 GHz, and is ertendible, by option, up to 170 GHz. Band 0, 100 Hz to 2SO MHz,

is for CW measurements onlv.

All major functions are controlled through the 21-button, functionally grouped keyboard.

Information is presented for viewing on a nine-digit sectionalized frequency display, a

three-digit floating point pulse parameter display, and a 2O-message annunciator bank.

Microprocessor control and the unique architecture employed offer all the malor counrer

functions, such as frequencyoffsets, frequency range limits, and averaging capabilities, plus a

variety of special functions including internal diagnostics, calibration and test aids, and

sophisticated operational enhancements.

All front panel controls (except the POWER switch) and all background functions are externally

programmable via the IEEE 488 - 1978 standard GPIB (General Purpose Interface Bus) port.

The instrument output status and all displayed information are accessible via the GPIB.

OPERATING CONDITIONS

This instrument is designed to be operated at temperatures not exceeding 0 to 50 oC at

relative humidity not to exceed 95o/" (75o/o over 25 oC; 45/" over 40 oC). This instrument will

perform to specifications at altitudes not exceeding 10,000 ft (3050 m) and wiil toterate

vibration not exceeding 2 g. lt is fungus resistant. The chassis is not designed to provide

protection from mechanical shock or falling water particles and is intended for normal bench

use in an environmentally uncontaminated area.

VENTILATION

Air circulates through the vents in the rear panel of the counter. These vents must not be

obstructed or the temperature inside the counter may increase enough to reduce counter

stability and shorten component life.

STORAGE

Store the instrument in an environment that is protected from moisture, dust, and other

contaminants. Do not expose the instrument to temp€ratures below -55 oC or above 75 oC,

nor to altitudes above 40,000 ft (12,000 m).

1 -'l

Scans by Artekmedia => 2010

5858/5888

SPECIFICATIONS

1/GENERAL INFORMATION

GENERAL

SIZE 3.5 in H x 16.75 in. W x 14 in. D

(8,9 cm H x 42.6 cm W x 35.6 cm D)

WEIGHT 35 lb (1 5.9 kg)

SHIPPING WEIGHT 41 lb (18.6 kg)

OPERATING TEMPERATURE 32 to 122 oF (0 to 50 'C)

POWER 100t120t140t200t220t240 Yac +10% 50-400 Hz,

100 VA, typical

MINIMUM PULSE WIDTH 50 ns

MAXIMUM PULSE WIDTH CW

MINIMUM PULSE PROFILE '15 ns

MINIMUM PRF lHz

MINIMUM OFF TIME 200 ns (will count CW)

MINIMUM ONiOFF RATIO 15 dB

RESOLUTION 1 kHz to 1 GHz (100 Hz to 100 MHz in Band 0)

GATE TIME 10 ms to I !.s (dependent upon resolution)

BAND O

FREQUENCY RANGE 100 Hz to 250 MHz (CW onty)

CONNECTOR BNC

IMPEDANCE 50 ohms nominal

SENSITIVITY -15 dBm

MAXIMUM INPUT +7 dBm

DAMAGE LEVEL +20 dBm

MAXIMUM VIDEOl N/A

MAXIMUM FM Carrier frequency must remain within band

(See notes on page 1-7.)

1-2

Scans by ArtekMedia => 2010

5858/s888

SPECIFICATIONS (Continued)

1/GENERAL INFORMATION

BAND 0 (Continued)

AVERAGING EFROR lN Hz N/A

GATE ERFOR lN Hz N/A

DISTORTION ERROR N/A

TOTAL ERROR TE = time base error +1 count (excluding noise effects)

ACQUISITION TIME N/A

MEASUFEMENT TIME

1OO Hz RESOLUTION

1 kHz RES AND ABOVE 200 ms

(1/FES) + 85 ms

BAND 1

FREQUENCY RANGE 250 MHz to I GHz

CONNECTOR BNC

IMPEDANCE 50 ohms nominal

SENSITIVITY -15 dBm

MAXIMUM INPUT +7 dBm oeak

DAMAGE LEVEL +24 dBm peak

AMPLITUDE DISCRIMINATION 10 dB for signals separated by <100 MHz

MAXIMUM VIDEO1

VIDEO FREQUENCY <250 MHz MV = SL

VIDEO FREQUENCY >250 MHz MV = SL

(SL FREQUENCY MUST BE >250 MHz)

- [10 log (250 MHztFV)4] - 20 dB

-20d8

MAXIMUM FM/CHIRP2 Carrier frequency must remain within band

AVERAGING ERROR lN Hz1 AE=+2x

GATE ERROR lN Hzt GE = +0.07/GW

DISTORTION ERROR lN Hz1 DE=+0.03/(PW-3x10-8)

TOTAL ERROR (PULSE)1 TEp = +AE +GE +DE lTime Base Error

TOTAL ERROR (CW) TEcw = Time Base Error i1 count

(Based on averaging 10 measurements.)

ACQUISITION TIMEl AQ = (1/MINPRF) + 55 ms

MEASUREMENT TIME (PULSE)1 Mr = 11(4) (PP)) / ((Gw) (RES))] +0.1

MEASUREMENT TIME (CW1I Mr = [4 / ((GW) (RES))] +0.1

(See notes on page 1-7.)

1-3

Scans by Artekmedia => 2010

s85B/5888 1/GENERAL INFORMATION

SPECIFICATIONS (Continued)

BAND 2

FREQUENCY RANGE 950 MHz to 20 GHz (5858), 26.5 GHz (5888)

CONNECTOR Precision N (5858), APC 3.5 (5888)

IMPEDANCE 50 ohms nominal

SENSITIVITY -20 dBm (950 MHz to 20 GHz)

-10 dBm (20 to 26.5 GHz, 58BB Only)

MAXIMUM INPUT +7 dBm oeak

DAMAGE LEVEL +45 dBm CW, +53 dBm oeak

(<1 psec pulse width, 0.1Vo duty cycle)

AMPLITUDE DISCRIMINATION 15 dB. lf <15 db, will count one signal accuratety if

separated by >200 MHz.

MAXIMUM VIDEO1 MV=SL-20d8

MAXIMUM FM/CHIRP2 2a MHz peak-to-peak

AVERAGING ERROR lN Hz1 AE =V RES/[(GW) (AVG)]

GATE ERROR lN Hzl GE = +0.01/GW

DISTORTION ERROR lN Hzt Pg=10.03/(PW-3x10-8)

TOTAL ERROR (PULSE)

TOTAL ERROR (CW)

TEp = +AE +GE 1DE tTime Base Error

TEcw = Time Base Error t1 count

(Based on averaging 10 measurements)

ACQUTSTTTON T|ME (PULSE)

FREQ, LIMITS

. CENTER FREQ

ACQUTSTTON T|ME (CW)

FREQ. LIMITS

CENTER FREQ

AQ = 2(FH)[(4 x 10-12) + (4 x 1O+/MINPRF)] +

60/MINPRF +[(2 x 10-5) (PP)]/GW + 0.35

AQ = 72|MINPRF + [(2 x 105)(PP)]iGW + 0,2

AQ = 2(FH) [(4 x 1g-tz) + (4 x 1O-VM|NpRF)] +

60/MINPRF + 0.25

AQ=72/MINPRF+0.1

MEASUREMENT TIME

MEASUREMENT TIME

MT = [(PP) / ((cw) (RES))] + 0.2

MT=(1/MINPRF)+0.2

(PULSE)

(cw)

FREQUENCY LIMITS Instrument will ignore signals outside of limits. 1O MHz

resolution, +50 MHz accuracy. Unwanted signals

must be greater than '100 MHz from either limit.

CENTER FREQUENCY Will lock on signals <50 MHz from the entered

frequency at sensitivity. 10 MHz resolution.

(See notes on page 1-7.)

1-4

Scans by ArtekMedia => 2010

5858/5888

SPECIFICATIONS (Continued)

1/GENERAL INFORMATION

BAND 3 (Option 5804)

FREQUENCY RANGE 26.5 to 170 GHz. see Table 1-1

CONNECTOR Depends on remote sensor, see Table 1-'1

SENSITIVITY -20 dBm (-25 dBm Typ)

MAXTMUM |NPUT (TYP) +5 dBm peak

DAMAGE LEVEL +10 dBm peak

AMPLITUDE DISCRIMINATION 20 dB

MAXIMUM VIDEO1 MV = 15 mv oeak-to-oeak

MAXIMUM FM/CHIRP2

AUTOMATIC

CENTER FREQ 20 MHz peak-to-peak

150 MHz peak-to-peak

AVERAGING ERROR lN Hz1 AE = +2 r Vnevt(owl(nvG)f

GATE ERROR lN Hz1 GE = +0.03/GW

DISTORTION ERROR lN Hz1 Pg=10.02l(PW-3x10-8)

TOTAL ERROR (PULSE)

TOTAL ERROR (CW)

TEp = +AE +GE 1DE +Time Base Error

TEcw = Time Base Error +N2 counts

N = freq/20 GHz

ACQUTSTTTON T|ME (PUI-SE)t

AUTOMATIC

CENTER FREQ

ACQUTSTTON T|ME (CW)

AQ = 7o/MTNPRF + [t(e r''g-s1(pp)l/GW] + 0.25

Ae = 7O/M|NpRF + [t(9,. .'g-r;1pp)l/Gw] + 0.25

AQ=70/MINPRF+0.25

MEASUREMENT TIME (PULSE)

MEASUREMENT TIME (CW)

Mr = [(4)(PP)]/t(GW) (RES)l + 0.15

(4/MINPRF) +0.15

CENTER FREQUENCY Instrument assumes any signal present to be in the

range of +2 GHz from the specified center frequency

and calculates the harmonic number based on this

assumption.

(See notes on page 1-7,)

1-5

Scans by Artekmedia => 2010

5858/5888

SPECIFICATIONS (Continued)

1/GENERAL INFORMATION

PULSE PERIOD

ACCURACYl +(20 ns + time base error x PP)

DISPLAY RESOLUTION 3 digits, floating point, 10 ns maximum (Special function

available for 10 ns)

RESOLUTION TO GPIB 10 ns

MIN/MAX PULSE PERIOD 250 ns/1 s

MEASUREMENT POINTS 6 dB t1.5 dBc

PULSE WIDTH

ACCURACYl +(20 ns + time base error x PW)

DISPLAY RESOLUTION 3 digits, floating point. 10 ns maximum (Speciat function

available for 10 ns on all measurements)

RESOLUTION TO GPIB 10 ns

MIN/MAX PULSE WIDTH 50 ns/1 s

MEASUREMENT POINTS 6 dB +1.5 dBc

TCXO T|ME BASE (STANDARD)

FREQUENCY 10 MHz

AGING RATE <11 x 19 -zl / mo

SHORT TERM STABILITY <1 x 10 -e RMS for one second averaging time

TEMPERATURE STABILIW <11 x 10 -61 over the range 0 to 50 "C

LINE VARIATION <11 x 10 -zl (110o/o line voltage change)

WARM-UP TIME 30 minutes

OUTPUT FREQUENCY 10 MHz, square wave, 1 V peak-to-peak minimum into

50 ohms

EXTERNAL TIME BASE Requires 10 MHz, 1 V peak-to-peak minimum into

300 ohms

PHASE NOISE -95 dBc/Hz at 10 Hz from carrier

(See notes on page t-7.)

1-6

Scans by ArtekMedia => 2010

This manual suits for next models

1

Table of contents

Other EIP Cash Counter manuals