Ekso Bionics EksoVest User manual

EksoBionics,Inc.

EksoVest

Operator Manual

Ekso Bionics, Inc.

© February 2018 106892A

Ekso Bionics, Inc.

EksoVest Operator Manual

2

106892A

This Page Intentionally Left Blank

Ekso Bionics, Inc.

EksoVest Operator Manual

3

106892A

Copyright

© 2018 Ekso Bionics, Inc.

Part Number

106892A2

All Rights Reserved

No part of this publication may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or any computer language, in any

form or by any third party, without the prior written permission of Ekso Bionics, Inc.

Trademarks

Ekso®, Ekso Bionics®, Ekso Works®, EksoWorks™, Amplifying You™, and DEFY

GRAVITY®are trademarks of Ekso Bionics, Inc.

Patents/Patents Pending

The EksoVest is U.S. patent pending.

Disclaimer

Ekso Bionics, Inc., its affiliates and vendors (collectively “Supplier”) shall not be

liable for any injury or damage suffered by any person, either directly or

indirectly, as a result of the use or repair of the EksoVest in violation of its

intended use. Supplier does not accept any responsibility for any damage

caused to its products, either directly or indirectly, as a result of use and/or

repair by unauthorized personnel.

Contact Information

Ekso Bionics, Inc.

1414 Harbour Way, South

Suite 1201

Richmond, CA 94804

Office: 510-984-1761

Fax: 510-927-2647

Customer Service: 888-869-7683

www.eksoworks.com

Ekso Bionics, Inc.

EksoVest Operator Manual

4

106892A

Standard Limited Warranty Against Defects in Materials and Workmanship

Ekso Bionics, Inc. warrants the EksoVest to be free of manufacturing defects in

material and workmanship for a period of one year from the original date of

purchase. Consumable parts including all soft goods (arm cuffs, arm straps, hip belt,

hip belt extender, shoulder straps, mesh back, neck roll, and compression arm

sleeves) with a demonstrable defect are covered by this same one-year warranty.

Damage caused to these consumable parts due to normal wear and tear during the

course of normal use is not covered by this warranty. The Standard Limited Warranty

does not cover any repairs required as a result of user errors, accidents, misuse,

neglect or operation outside of the device’s intended use. The Standard Limited

Warranty is void if the EksoVest is altered in any way or has not been used in

accordance with the operator manual. Please review all product documentation for

important product care and maintenance requirements.

Ekso Bionics, Inc.

EksoVest Operator Manual

5

106892A

Table of Contents

MEASUREMENT AND FITTING INFORMATION ........................................................ 7

VEST HARDWARE .............................................................................................10

VEST SOFT GOODS ............................................................................................11

CUSTOMIZING SIZE WITH VEST COMPONENTS ..................................................... 12

ON/OFF SWITCH.............................................................................................. 17

INSTALLING/CHANGING ACTUATOR SPRINGS ..................................................... 19

ADJUSTING VEST ACTIVATION ZONE................................................................... 21

DONNING AND DOFFING THE EKSOVEST............................................................ 23

MAINTENANCE AND TROUBLESHOOTING ........................................................... 26

APPENDIX A: COMPONENTS AND ACCESSORIES ..................................................27

Ekso Bionics, Inc.

EksoVest Operator Manual

6

106892A

This Page Intentionally Left Blank

Ekso Bionics, Inc.

EksoVest Operator Manual

7

106892A

MEASUREMENT AND FITTING INFORMATION

Measurement Recommendations: Another person must take your measurements

using a tailor’s tape; do not measure yourself. When measuring, tape should be kept

as perpendicular or parallel to the ground as possible. Stand straight; wear normal

work clothes.

Hip Belt Measurement Information

Position: Standing straight, arms relaxed at sides

Instructions: Measure torso circumference at top of the

pelvic bones (the iliac crest). Keep measuring tape even at top

of pelvic bones; measure over work clothes.

Torso Tubes Measurement Information

Position: Standing straight; arm away from waist with palm

back

Instructions: Measure from the top of the pelvic bones to the

top of the shoulder. The top of the shoulder is typically where

the seam lines of a shirt intersect.

Measurement:

Measurement:

Ekso Bionics, Inc.

EksoVest Operator Manual

8

106892A

Arm Cuff Length Measurement Information

Position: Standing straight, one arm raised with elbow flexed

Instructions: Measure from armpit to edge of the elbow. Do

not measure above or beyond elbow bend.

Arm Cuff Diameter Measurement Information

Position: Standing straight, one arm raised with elbow flexed

Instructions: Measure circumference of upper arm at bend in

elbow. Keep measuring tape even and vertical.

Upper Arm Strap Measurement Information

Position: Standing straight, arm relaxed at side

Instructions: Measure circumference of upper arm at armpit.

Keep measuring tape even and horizontal.

Measurement:

Measurement:

Measurement:

Ekso Bionics, Inc.

EksoVest Operator Manual

9

106892A

For each table or matrix, circle the size that matches the operator’s measurements.

If one or more of the measurements fall outside of the listed ranges, please note the

measurement(s) next to the specific chart and contact Ekso Bionics for advice.

These measurements are provided as recommendations. Personal comfort and

preference should always guide individual component size choices.

Hip Belt

Size

S/M L/XL

Inches 26in – 36in 36in – 46in

Centimeters 66cm – 92cm 92cm – 118cm

Torso Tubes Size

B1 to B6 A1 to A6

Inches 14.5in – 19in 18.5in – 23in

Centimeters 37cm – 49cm 47cm – 59cm

Arm Cuffs

Upper Arm Length

8in – 10in 10in – 12in 12in – 14in+

20cm - 25cm 25cm - 30cm 25cm - 30cm+

Bicep Diameter

9in - 11.5in S S S

23cm - 29cm

11.5in – 14in S S or M M

29cm - 35cm

14in - 16.5in M M L

35cm - 42cm

Upper Arm

Strap

Size

S M L

Inches 9in – 11in 11in – 14in 14in – 17in

Centimeters 23cm – 28cm 28cm – 36cm 36cm – 44cm

Ekso Bionics, Inc.

EksoVest Operator Manual

10

106892A

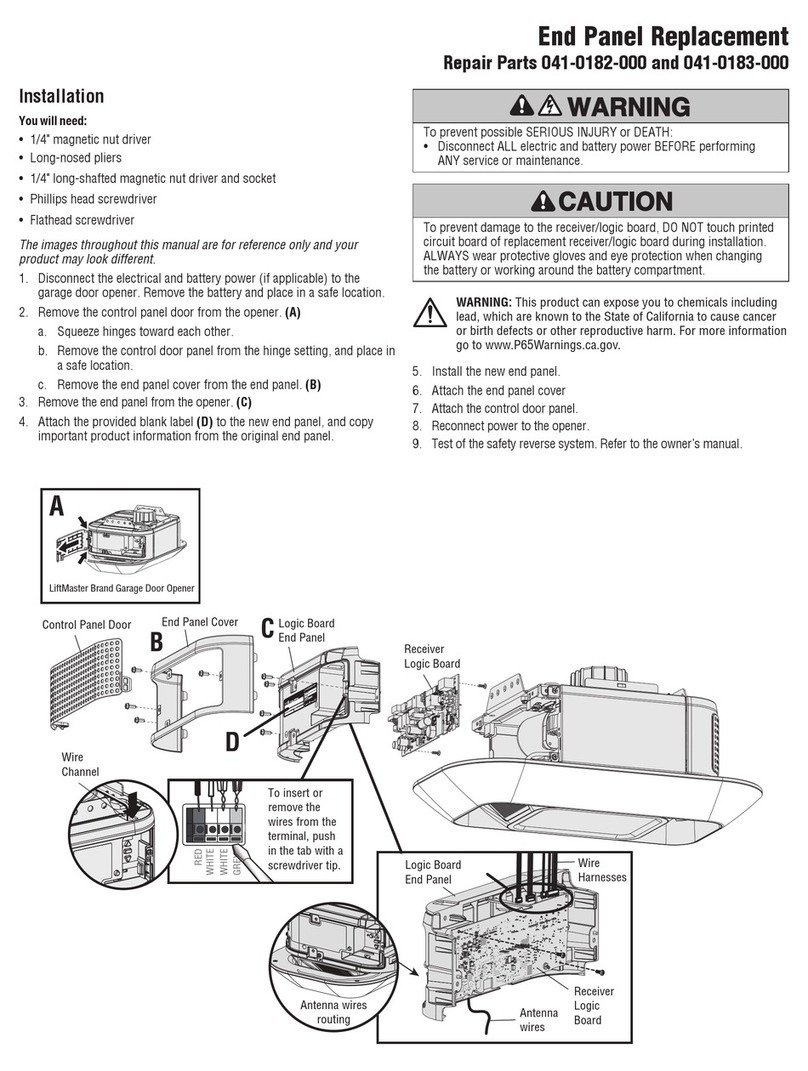

VEST HARDWARE

The mechanical and hardware components of each EksoVest are identified in the

following drawing and table.

Component

Identifier Component Name

A Arm Cuff Plate

B Actuator Spring

C ON/OFF Switch and Tether

D Actuator Activation Zone Indicator

E Actuator

F Link Assemblies

G Torso Plate and Mesh

H Torso Tubes (bottom, middle, top)

I Waist Plate

Ekso Bionics, Inc.

EksoVest Operator Manual

11

106892A

VEST SOFT GOODS

Each EksoVest consists of the hardware components described in the previous

section combined with appropriately sized soft goods. Each operator uses the sizing

charts and matrix to select the soft goods that complete his/her vest. The operator

attaches the customized soft goods to the vest’s torso plate, waist plate, and the

arm cuff plates. All vest-related soft goods are identified in the following drawing

and table.

Note: The General Configuration Vest kit includes all items/sizes identified in the

table; the Specific Worker Vest contains only the specific sizes and number of

components selected for an individual operator. (See APPENDIX A for more

information.)

Component

Identifier Kit-Included Items Number Sizes

A Hip Belt 2 S/M, L/XL

B Hip Belt Extender 1 n/a

C Arm Cuffs 3 sets S, M, L

D Upper Arm Straps 3 sets S, M, L

E Neck Roll 1 n/a

F Compression Arm Sleeves* 2 sets S/M, L/XL

* Ekso Bionics recommends that compression arm sleeves are always worn on arms during vest use.

Ekso Bionics, Inc.

EksoVest Operator Manual

12

106892A

CUSTOMIZING SIZE WITH VEST COMPONENTS

The EksoVest is designed to be customized for each operator (see MEASUREMENT

AND FITTING INFORMATION beginning on page 7). Select the sizes that match the

operator’s measurements; assemble and attach or install the customized

components as described in this section.

Torso Tubes

Vest Customized to A4

Vest Customized to B4

1. Based on operator’s measurement, determine if torso tube

setting size is in the A or B range.

2. If A, press lower detent button on the bottom tube and

slide upper tubes until the middle tube is seated at the A

button setting.

3. Once adjusted for A or B, press the highest detent button

and slide top tube until button is seated at the appropriate

number (1 to 6) setting.

Ekso Bionics, Inc.

EksoVest Operator Manual

13

106892A

Hip Belt (S/M or L/XL)

1. Working from the front of vest, slide one side of the hip belt over waist

plate. Position the waist plate side and hip belt so that the plate aligns with

and “sits” completely in the hip belt’s attachment pocket.

2. Press to connect the waist plate and

hip belt’s hook-and-loop fasteners on

chosen side.

3.

Attach hip belt to opposite side

of waist plate, bending plate as

needed to attach belt and secure

hook-and-loop fasteners.

4. Buckle both straps around the waist

plate.

5. Connect each shoulder strap to

hip belt with buckle.

Ekso Bionics, Inc.

EksoVest Operator Manual

14

106892A

Hip Belt Extender

The hip belt extender expands the width of the hip belt, if needed.

1. Put one hip belt strap

through the elastic strap

on the hip belt extender

and fasten buckle.

2. Wrap hip belt with

attached belt extender

around waist and repeat

step 1 on opposite side.

Extender sits inside hip

belt, secured by the elastic

straps and buckles (see

picture).

3. Pull hip belt straps to cinch for a tight but comfortable fit.

Arm Cuff and Upper Arm Strap (S, M, or L)

1. Fit arm cuff onto arm cuff plate and

work plate into arm cuff pocket until the

three snaps line up. Snap in place.

Note: Action will require extra force

until arm cuff pocket is broken-in.

2. Install upper arm strap to plate with

snap.

3. Repeat steps 1 and 2 on opposite side.

Ekso Bionics, Inc.

EksoVest Operator Manual

15

106892A

Link Assemblies Adjustment

Rarely, an operator may need to adjust the

placement of the link assemblies to improve

his/her range of motion. When an operator’s

range of motion is hampered, the links don’t

move freely around the operator’s back and

shoulders. Instead, the links press into the

operator’s back (see photo). This restriction

would be particularly felt when an operator

reaches in front with his/her arms.

Each side of the torso plate has three sets of top-and-bottom holes for link assembly

attachment (these holes are circled in the picture on the left). The vest’s default setting (the

middle pair of holes) is shown in the picture on the right. When range of motion is impeded, the

link assemblies must be shifted to the widest adjustment (i.e., the outermost set of holes).

If such an adjustment is needed, reposition each link assembly to a different hole pair as

described in the following procedure. Note: Both the left link assembly and the right link

assembly must be adjusted to the same placement.

Ekso Bionics, Inc.

EksoVest Operator Manual

16

106892A

1. Using a 4-mm hex key, remove the two (2)

button head socket cap screws from the

torso plate’s (oval) front washer plate.

2. Remove link assembly from torso plate and

retain all parts. Repeat on the other link

assembly.

3. Properly position one of the torso’s

(rectangular) back washer plate on the two

bosses of the link base pivot housing. Each

back washer plate must be positioned as

shown in the adjacent pictures.

Right Arm Link Left Arm Link

4. Position one of the assemblies so that the

two link bosses align with the correct torso

holes for the desired adjustment. Insert link

bosses into these correct holes.

(Note: Picture shows the default adjustment

placement for the link assemblies.)

5. Position (oval) front washer plate on

bosses. Use a 4-mm hex key to install the

two (2) button head socket cap screws

attaching link assembly to torso.

6. Repeat steps 1 to 5 on the other link

assembly.

Ekso Bionics, Inc.

EksoVest Operator Manual

17

106892A

ON/OFF SWITCH

Each EksoVest arm has an ON/OFF switch (with tether) located on the actuator

housing. Switching the vest ON activates the spring support of the actuator. This

spring support triggers the actuator and arm cuff plate to move upward with great

speed and power unless the arm cuff plate is secured. The arm cuff plate is secured

in two ways:

When wearing the vest, the operator

secures the arm cuff plates by

properly wearing the arm cuff safety

straps and buckling the arm cuffs

and upper arm straps around his/her

arms. The operator must also keep

his/her arm fully down (i.e., directly

at his/her side) when flipping the

switch ON/OFF. See adjacent

picture.

When the vest in not being worn, the

arm cuff plate must be firmly held to

secure the plate and actuator as the

arm moves up. See adjacent

pictures.

Ekso Bionics, Inc.

EksoVest Operator Manual

18

106892A

WARNING: High-Pressure Spring

Secure arm cuff plate before turning ON to avoid injury.

The ON/OFF switch and labels

(shown in the OFF position).

Switch is Up and is in the

ON position.

Switch is Down and is in

the OFF position.

Note: The arm cuff plate is being secured.

Ekso Bionics, Inc.

EksoVest Operator Manual

19

106892A

INSTALLING/CHANGING ACTUATOR SPRINGS

The EksoVest has four sets of actuator springs that control the level of assistance

(“the spring support”) in each arm. Each spring level matches an approximate

amount of lift support.

The support level is labeled on each spring’s cap. Level 1 provides the least arm

support and Level 4 provides the most. The following table shows the different

spring labels and the approximate lift support offered by each of the four different

actuator springs.

Spring Cap Labels and Approximate Spring Support (lb./kg)

Support Level 1 Support Level 2 Support Level 3 Support Level 4

5 – 7 lb. 7 – 9 lb. 9 – 12 lb. 12 – 15 lb.

(2.2 – 3.1 kg) (3.1 – 4.0 kg) (4.0 – 5.4 kg) (5.4 – 6.8 kg)

Ekso Bionics ships all General Configuration Vests with four (4) sets of springs; each

Specific Worker Vest is shipped with the selected set of support level springs. When

first using or when sizing the EksoVest, Ekso Bionics recommends beginning with

Level 1 and changing to a spring set with a higher level of support as needed and/or

desired by the operator.

Ekso Bionics, Inc.

EksoVest Operator Manual

20

106892A

WARNING: Actuator contains high-pressure spring. Secure arm cuff plate as you

turn switch lever ON and guide arm cuff plate to full vertical (up) position. Failure

to secure the arm cuff plate may result in injury. Changing the actuator spring

should be done when the vest is not being worn.

The EksoVest is shipped with protective caps covering both actuator cylinder

chambers. These caps must be removed before installing actuator springs for the

first time.

Installing/changing the actuator springs must be done when the vest is not being

worn. To change the actuator springs:

1. If protective cap is present on

actuator, remove cap and store

for future use.

2. Secure an arm cuff plate in the

down position and then enable

that actuator by flipping switch

to the ON position.

3. Continue to secure arm cuff

plate while carefully guiding the

plate to the full vertical (up)

position.

4. Unscrew and remove the spring

from actuator cylinder

chamber.

5. Select the desired spring and

insert into actuator cylinder

chamber.

6. Screw in the spring, tightening

fully by hand.

7. Secure arm cuff plate and then

carefully guide the plate to the

down position.

8. Flip the switch to the OFF

position.

9. Repeat steps 1 to 8 on opposite

side, if needed.

Table of contents

Other Ekso Bionics Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Lafferty

Lafferty VC-1016 Installation & operation instructions

HBM

HBM Genesis ISOBE5600 user manual

Elgo

Elgo LIMAX2M Series operating manual

Hubbell

Hubbell KILLARK UGFI 2P Series INSTALLATION, OPERATION & MAINTENANCE DATA SHEET

Jorc

Jorc NUFORS-CR Maintenance instructions

Novexx Solutions

Novexx Solutions LA-SO operating manual