Page Number - 2 Form 404308

BEFORE CONNECTING

EJECTOR TO AIR LINE

Airline lubrication is necessary for the

proper performance and life of this ejector

Be sure that the proper airline filter.

lubricator and regulator can supply the

volume of air necessary to operate the

ejector at the speed required.

OPERATING PRECAUTIONS

Use Lincoln replacement parts to assure

compatible pressure rating.

Heed ALL warnings.

ALWAYS check equipment for proper

operation before each use, making

sure safety devices are in place and

operating properly. DO NOT alter or

modify any part of the equipment as

this may cause a malfunction and

result in serious bodily injury.

DO NOT OPERATE Ejector in excess of

recommended pressure range.

NOTE: A 24” length of 1/2” I.D. hose

must be used at the material inlet to

prevent hydraulic lock which may

occur if rigid piping is used.

ALWAYS read and follow the

uid and solvent manufacturer’s

recommendations regarding the

use of protective clothing and

equipment.

To reduce the risk of serious bodily

injury or property damage. NEVER

exceed the maximum air or uid

working pressure of the lowest

rated system component.

OPERATION

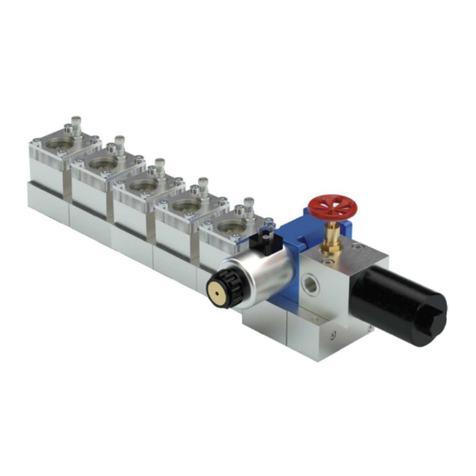

Model 85250 Ejector incorporates an inline

double povver air cylinder which produces

a 35:1 ratio during the dispense cycle. This

is achieved through special porting through

the upper piston rod which allows air to ow

and pressurize the top sides of the pistons.

When the Ejector is pressurized to dispense

material, air should also be vented from the

bottom of the lower piston. The bottom of the

upper piston is never pressurized because

of a small hole in the upper cylinder wall

which exposes it to ambient pressure. As

the Ejector continues its dispense stroke,

it’s travel is limited by the adjustment screw.

When the Ejector is retracted, air is

vented from the tops of the two cylinders

and pressure builds under the lower

piston. When the Ejector is fully retracted,

pressurized material enters the material

inlet and rells the void of the pumping

chamber just in front of the plunger.

The Ejector is now ready for another

dispense stroke.

SERVICE AND

DISASSEMBLY PROCEDURE

Always disconnect air supply to

Ejector and relieve pressure before

checking, servicing, or repairing

any part of Ejector.

TOOLS REOUIRED

1.7/16 Open End Wrench

2. 1/2” Open End Wrench

3. 5/8” Open End Wrench

4. 3/4” Open End Wrench

5. 7/8” Open End Wrench

6. 1-1/2” Open End Wrench

7. Pliers

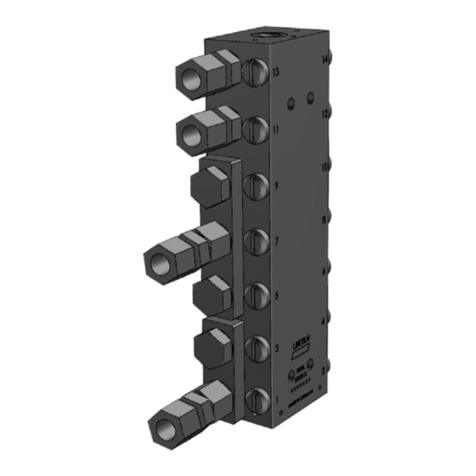

Disassembly of

Air Components

1. Remove the four Bolts and Lock-

washers (Items 2 & 3).

2. Lift the Top Plate and Gasket off

(Items 4 & 5) Gasket must be

replaced.

3. Remove the top Air Cylinder

(Item 6).

4. Hold the top of the Plunger (ltem 21

with a 1/2” wrench through the slot ted

holes in the Cylinder (Item 16) while

removing the top piston Bolt (Item 1).

5. Remove the Spacer (Item 8).

6. Remove the top Piston and 0-ring

sub-assembly (Items 7, 9 & I 0).

7. Hold the center Cylinder (Item 30)

while lifting off the center divider

Plate and 0-ring subassembly

(Items 11 & 12) and upper Piston

Rod (Item 13).

8. Remove the upper piston rod from the

center divider plate.

9. Remove the center Cylinder (ltem 30)

which will include the lower Piston

and 0-ring sub-assembly (Items 7,9 &

10).

10. Remove the lower Gasket (Item 5)

for replacement.

11. Remove the lower divider Plate,

Piston Rod and Connector (Items

14,29 & 15). At this point the entire

air unit is disassembled and all

seals can be replaced if necessary.

Disassembly of

Wetted Components

1. Remove the Packing Nut and Gasket

(Items 17 & 18).

2. Remove the Bottom Plate (Item 19).

3. Remove the Packing Retainer and

U-cup (Items 28 & 20).

4. Remove the Cap (Item 27).

5. Remove the Lock Nut (Item 25).

6. Remove the Nose Adapter, Adjusting

Screw and 0-ring Sub-Assembly (Items

23. 26 & 24).

7. Turn the adjusting screw all the way in

(clockwise direction) to access the

0-ring for replacement.

8. Finally remove the Gasket (ltem 22). At

this point the wetted components should

be completely disassembled.

REASSEMBLY

To reassemble the Ejector reverse the

Disassembly Procedure.

IMPORTANT: The small holes in the upper

Piston Rod (Item 13) and the upper CyIinder

(Item 6) must be positioned towards the

Body & Plunger assembly (ttem 21) for

proper function of the Ejector.