ELAN DIGITAL SYSTEMS HD717 User manual

Elan Digital Systems Ltd. 1 HD717 USER’S

GUIDE

ELAN DIGITAL SYSTEMS LTD.

LITTLE PARK FARM ROAD,

SEGENSWORTH WEST,

FAREHAM,

HANTS. PO15 5SJ.

TEL: (44) (0)1489 579799

FAX: (44) (0)1489 577516

e-mail: support@elan-digital-systems.co.uk

website: www.pccard.co.uk

HD717 PC-CARD USER’S GUIDE

ALSO COVERS HD712,HD713

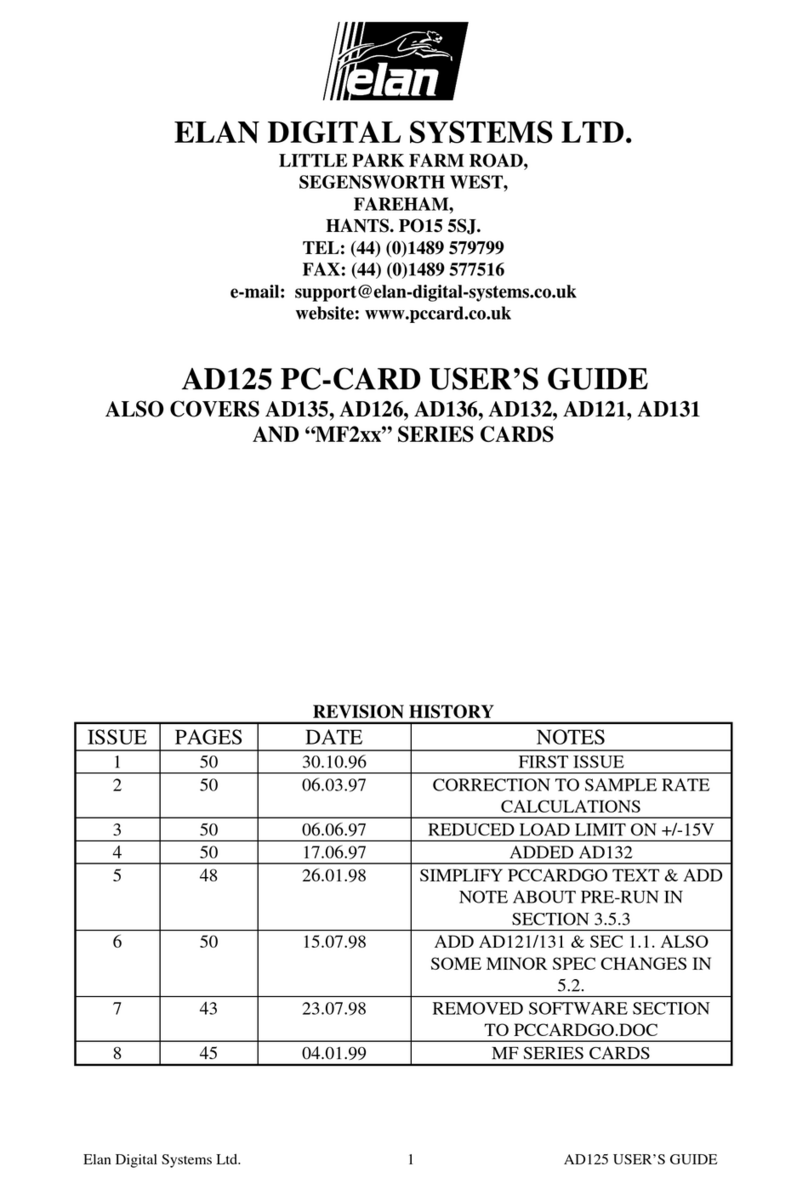

REVISION HISTORY

ISSUE PAGES DATE NOTES

1 59 11.04.97 FIRST ISSUE

2 60 28.04.97 NEW FEATURES

3 60 09.09.97 SCC DATA/CLK TIMING NOTE p15

4 58 28.01.98 SIMPLIFY PCCARDGO TEXT

5 58 25.03.98 RS422 ENABLE BIT (GSR2)

6 52 24.07.98 REMOVED SOFTWARE SECTION

TO PCCARDGO.DOC

7 52 10.08.98 HD712 ADDED

8 52 16.04.99 HD713 ADDED

9 52 29.01.01 LOOPBACK CONNECTIONS

10 52 11.04.02 LOOPBACK CONNECTIONS

11 55 23.04.02 Figure 3.1.3-1 Added

Elan Digital Systems Ltd. 2 HD717 USER’S

GUIDE

CONTENTS

1. OVERVIEW..................................................................................................5

2. ABOUT THE HD717 ....................................................................................6

2.1 THE SERIAL COMMS CONTROLLER........................................................6

2.2 LOW RATE DATA INTERFACES.................................................................7

2.3 DIGITAL I/O INTERFACE..............................................................................9

3. CONTROLLING THE HD717.....................................................................10

3.1 SCC....................................................................................................................10

3.1.1 SCC I/O PORTS...........................................................................................10

3.1.2 SCC BASIC CONFIGURATION................................................................11

3.1.3 SCC TX/RX CLOCK SELECTION............................................................14

3.1.4 SCC TRANSMIT PROCEDURE................................................................17

3.1.5 SCC RECEIVE PROCEDURE....................................................................21

3.1.6 RS485 SUPPORT (Issue 2(+) HD717 & HD712,713 Cards Only).............23

3.2 LOW RATE DATA..........................................................................................24

3.2.1 TRANSMIT..................................................................................................24

3.2.2 RECEIVE.....................................................................................................28

3.3 HANDLING INTERRUPTS............................................................................31

3.4 USING THE DIGITAL I/O PINS...................................................................35

4. HD717 REGISTER INTERFACE ...............................................................36

4.1 SCC CONTROL (IOBASE+0).........................................................38

4.2 SCC DATA (IOBASE+1).....................................................................38

4.3 IPR READ / IMR WRITE (IOBASE+2).....................................39

4.4 LRD RX LO READ / TX LO WRITE (IOBASE+3)..............40

4.5 LRD RX HI READ / TX HI WRITE (IOBASE+4)................40

4.6 SUB REG DATA (IOBASE+5).........................................................41

4.7 SUB REG IDX WRITE ONLY (IOBASE+6)............................41

4.8 RX 4K FIFO READ / TX 4K FIFO WRITE (IOBASE+7).43

Elan Digital Systems Ltd. 3 HD717 USER’S

GUIDE

4.9 PCR (SUB REG 0)..................................................................................44

4.10 LBG (SUB REG 1)................................................................................45

4.11 SCS (SUB REG 2).................................................................................46

4.12 DIDI READ / DIDO WRITE (SUB REG 3)............................47

4.13 DIR (SUB REG 4).................................................................................47

4.14 SCR (SUB REG 5)................................................................................48

4.15 MSR READ ONLY (SUB REG 6)................................................49

4.15 IMR READ ONLY (SUB REG 7).................................................50

5. HARDWARE SPECIFICATION..................................................................51

5.1 PINOUT.............................................................................................................51

5.2 POWER CONSUMPTION..............................................................................53

5.3 MECHANICAL................................................................................................53

5.4 ENVIRONMENTAL........................................................................................53

5.5 LOOP BACK CONNECTIONS FOR TEST SOFTWARE.........................53

6. SOFTWARE...............................................................................................54

6.1 UNIVERSAL DRIVER....................................................................................54

6.2 C SOURCE CODE...........................................................................................54

7. OPERATIONAL PRECAUTIONS .............................................................55

Elan Digital Systems Ltd. 4 HD717 USER’S

GUIDE

Disclaimer

This document has been carefully prepared and checked. No responsibility can be

assumed for inaccuracies. Elan reserves the right to make changes without prior notice

to any products herein to improve functionality, reliability or other design aspects.

Elan does not assume any liability out of the use of any product described herein;

neither does it convey any licence under its patent rights not the rights of others. Elan

products are not authorised for use as components in life support services or systems.

Elan should be informed of any such intended use to determine suitability of the

products.

Source code supplied with Elan PC-Cards is provided “as-is” with no warranty, express

or implied, as to its quality or fitness for a particular purpose. Elan assume no liability

for any direct or indirect losses arising from use of the supplied code.

Copyright © 1996,1997 Elan Digital Systems Ltd.

Elan Digital Systems Ltd. 5 HD717 USER’S

GUIDE

1. OVERVIEW

Before using the HD717, take some time to read the section

“OPERATIONAL PRECAUTIONS”.

The HD717 card is a general purpose Serial Comms PC-Card with

the following features:

•Z85233 Serial Comms Control device (SCC) capable of both

synchronous and asynchronous protocols. SDLC mode can

operate at up to 4MBits / sec (also known as HDLC mode)

• 16MHz base clock rate to SCC (12MHz:HD712, 13MHz:HD713)

•Flexible clock routing network for synchronous modes, including

card generated 4,2,1 or 0.5MBits/sec clock to SCC’s TX and RX

clock pins (12,3,1.5,0.75MBits/s on HD712 or 16,4,2,1,0.5MBits/s on Iss2.01+

HD717, 13,3.25,1.625,0.8125MBits/s on HD713).

•RS422 interface drivers and receivers for SCC

•Issue 2+ HD717 and all HD712,713 cards have support for

RS485 shared data bus scheme

•4Kx8 transmit and receive FIFOs to decouple PC from high

speed transfers

•Bipolar RZ input and output to ARINC 717 spec with bit rates

from 768 to 6144 bits/sec

•Harvard Biphase (or “FM1”) input and output to ARINC 717

spec with bit rates from 768 to 6144 bits/per sec

•8 digital I/O lines with programmable 47K pull up-down.

This guide aims to familiarise you with the way that the HD717

works and so will help you to maximise its performance in your

application.

Elan will be happy to quote for either customisation of the HD717 if

its exact specifications do not quite meet your needs, or to create

complete application software.

Elan Digital Systems Ltd. 6 HD717 USER’S

GUIDE

2. ABOUT THE HD717

2.1 THE SERIAL COMMS CONTROLLER

The HD717 uses the “industry standard” 85233 Serial Comms

Controller chip (or SCC). This device contains all the logic required

to handle a variety of synchronous and asynchronous serial

protocols. Its operation is not detailed in this document due to its

complexity and the possibility of data book transcription errors.

Instead the reader is strongly advised to obtain the latest User’s

Guide for the generic family of controllers from Zilog Inc. The full

title of the guide is:

“SCC USER’S MANUAL, Zilog Inc, Part No. DC-8293-02”

This is referred to as [REF 1] in this document.

In the UK, Zilog can be reached at (44) (0)1628 39200.

The HD717 maps the SCC directly into the PC’s IO space and so the

device appears just as it would if it were on say an ISA card or PCI

card. The only fundamental difference in the way the SCC operates

on the HD717 is that the data for TX and RX is buffered by 4096 x 8

FIFOs. On an ISA card, it is common to use the SCC in DMA

mode, where two DMA channels are used (one for TX and one for

RX data paths). This is precluded in PCMCIA as only one physical

DMA channel is possible. To overcome this, the HD717 uses

control logic in the card to act like a DMA controller to the SCC.

This means that the SCC must be set to operate in DMA mode even

though the source and destination for the DMA requests never leave

the PC card itself. Instead the data transfers operate transparently (to

the PC) into and out-of the FIFOs. The PC is notified by interrupt

when either the TX FIFO falls below half full or the RX FIFO rises

above half full or the SCC signals a “special condition” e.g. End Of

Message in synchronous modes.

The 4K FIFO buffers effectively shadow normal SCC operations: it

is still possible for the PC to directly read and write the SCC’s own

internal data buffers although doing so must be considered carefully

as accessing the SCC data registers directly may cause missed DMA

Elan Digital Systems Ltd. 7 HD717 USER’S

GUIDE

cycles to the 4K FIFOs (the read or write acts as the DMA

acknowledge).

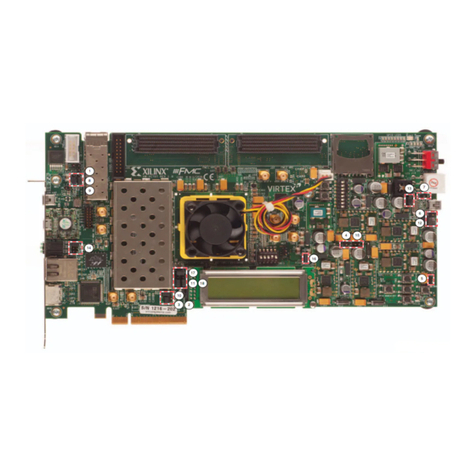

The following block diagram may help to clarify the role of the 4K

FIFOs in the system:

OSC:

16MHz HD717

12MHz HD712

TRxC PIN

OSC÷4,8,16,32MHz

TXClkExt

TX CLK IN

RX DATA

TX DATA

TX CLK OUT

RXClkExt

RTxC PIN

RX CLK IN

RX CLK OUT

SCC

4K

FIFO

RX

4K

FIFO

TX

LOGIC

PIO

PIO

DMA

DMA

PC

RS422

PCLK PIN

Rterm=220ohms

TRxCEn

HD712/Iss2.01+HD717

OSC÷4,8,16,32MHz

Figure 2.1-1 Functional Block Diagram of SCC + FIFOs

2.2 LOW RATE DATA INTERFACES

The HD717 provides inputs and outputs for two of the common

ARINC 717 serial data protocols, namely Bipolar Return-to-Zero

and Harvard Biphase (or FM1). The input and output circuits

function independently except that i) the encoding mode applies to

both input and output at the same time (i.e. can’t send BRZ and

receive Biphase simultaneously). ii) the input and output data rates

are derived from the same clock so that the send and receive circuits

always run at the same bit rate.

Data rates are software programmable and cover the “commonly”

used bit/sec settings of 768,1536,2304,3072,6144.

Elan Digital Systems Ltd. 8 HD717 USER’S

GUIDE

The waveshapes for the two protocols are summarised below. Refer

to the ARINC specification for a more complete definition.

BIPOLAR R-Z

LINE A to LINE B +10V

-10V

0V

1 10 0 0

+5V

-5V

0V

+5V

-5V

0V

LINE A to GND

LINE B to GND

BIT-CELL

HARVARD BIPHASE

LINE A to LINE B +5V

-5V

0V

1 10 0 0

+5V

-5V

0V

+5V

-5V

0V

LINE A to GND

LINE B to GND

BIT-CELL

As can be seen, there is sufficient clocking information in both

waveforms to allow complete asynchronous reception without the

source clock present. The BRZ code is inherently simple to decode

due to its “transition-per-bit” nature. Harvard Biphase is more

complex to decode and relies on there being at least one zero in the

data stream to ensure the receiver is correctly in sync with the

transmitter. The HD717 provides a status bit and various control

Elan Digital Systems Ltd. 9 HD717 USER’S

GUIDE

signals to control how it will behave when it first receives Biphase

data.

Note that the transmitter circuits in the HD717 are also capable of

operating in NRZ and FM0 modes. The receiver can cope with FM0

input data but cannot receive NRZ data (NRZ is simply generated as

“A-B”=5V ⇒Logic ‘1’, “A-B”= -5V ⇒Logic ‘0’).

The output drivers used for the Low Rate Data are slew rate limited

as required by ARINC specifications (typical 10-20us 10-90%).

Additionally, they are series terminated (in both A and B circuits)

with 22ohm resistors. This aids in driving highly capacitative loads

(i.e. very long cables).

2.3 DIGITAL I/O INTERFACE

8 Digital I/O drivers are provided on the HD717 to use as general

purpose control outputs and/or status monitoring inputs. The I/O

pins are logically grouped together in clusters of 1,1,2,4 I/O pins

(i.e. total = 8). These groupings define how the pins are set to inputs

or outputs. The groupings allow for any number of inputs or outputs

by using the correct combination of clusters. Additionally, each I/O

pin is “pulled” via a 47K resistor to a global control signal called

“DIOPull”. This signal can be set low or high in software to affect a

pull up or a pull down. The default (power-on) state is down.

The I/O pins are clamped to the internal Vcc and ground rails using

fast schottky diodes. This affords a good level of protection against

static damage.

Elan Digital Systems Ltd. 10 HD717 USER’S

GUIDE

3. CONTROLLING THE HD717

3.1 SCC

3.1.1 SCC I/O PORTS

The control registers of the SCC are mapped for read and write at

IOBASE+0. The data registers (i.e. TX and RX data buffers) are

mapped at IOBASE+1. It is not recommended to directly access the

SCC data registers unless you intend to run the serial data at very

low rates. It is far easier to allow the SCC to DMA its data to/from

the 4K FIFOs and configure the SCC to create interrupts to notify

the PC to collect or deposit data to the FIFOs as required.

The SCC control registers use a two access process. The first access

to IOBASE+0 is a write, which contains the “pointer” to the SCC

internal register to read or modify. The second access will be a read

or write to IOBASE+0 to read or write to the register pointed to by

the first access. The two access sequence must be maintained by

software to ensure that incorrect accesses to internal registers are not

made. The only exception is when the first write cycle is to execute

one of the “commands” that are controlled by WR0 (Write Register

0 in Zilog terms). Here, no second cycle is required as the data is

essentially implicit in the command. Refer to [REF 1] for details.

Elan Digital Systems Ltd. 11 HD717 USER’S

GUIDE

3.1.2 SCC BASIC CONFIGURATION

The following table shows the required SCC set-up to enable the

HD717 to operate correctly. Bits marked as ‘0’ or ‘1’ must be as

such, those marked as ‘x’ can take a state appropriate to the

configuration needed. Underlined bit states are recommended

recognising that other modes of operation are possible.

REGISTER REQUIRED STATE

(binary MSB...LSB)

76543210

WR1 11111x01 = F9h

Ext/status MIE = ON

TX int en = OFF

RX int on special conditions

DMA on RX = ON

Select RX DMA mode

Master RX DMA en = ON*1

*1 Set to on when s/w is ready to

RX...see also HD717 PCR for DMA

enabling.

WR2 xxxxxxxx = xxh

WR3 xxxxxxx1 = x1h

RX en = ON*1

*1

Set to on when s/w is ready to

RX...see also HD717 PCR for DMA

enabling.

WR4 xxxxxxxx = xxh

WR5 xxxxxxxx = xxh

WR6 xxxxxxxx = xxh

WR7 xxxxxxxx = xxh

WR7’ 0x010x11 = 13h

Auto TX flag (SDLC) = ON

Auto EOM reset = ON

RX DMA every char

DMA deassertion is fast

TX DMA every char

Must be 0

Elan Digital Systems Ltd. 12 HD717 USER’S

GUIDE

WR8 xxxxxxxx = xxh

WR9 xx1x1x1x = 2Ah

No vector on INTACK

MIE = ON*1

Software INTACK mode = ON

*1

Set to on when s/w is ready to

service interrupts from the SCC...see

also HD717 PCR, IPR & IMR f

or

interrupt enabling / acknowledging,

status and masking.

WR10 xxxxx0xx = x0h

Send Flag on TX underrun

WR11 000010xx = 08h

Set TRxC pin as an INPUT

Select TRxC pin as TX clock

Select RTxC pin as RX clock

RTxC is NOT a crystal osc

NB: The TRxC pin on the SCC is wired

to a logic driver circuit (the output

of the TX clock select MUX on the

card). Therefore it MUST be set to an

input on the SCC if SCS2 is high in

the SCS register.

NB: The sources for the TX and R

X

clock can also be set to the BRGen or

DPLL of the SCC. The SCC does not

have to use the external clock

sources. When using DPLL, observe the

maximum data rates (Zilog data sheets)

for the SCC to be able to recover the

clock from the data stream.

See a

lso the HD717 SCS register for

the external clock selection options.

WR12 xxxxxxxx = xxh

WR13 xxxxxxxx = xxh

Elan Digital Systems Ltd. 13 HD717 USER’S

GUIDE

WR14 xxxxx1xx = x4h

Select TX DMA mode

WR15 11000101 = C5h

Use to access WR7 or WR7'

No zero count int on BRGen

Enable status FIFO in SCC

No DCD int

No SYNC/hunt int

No CTS int

Enable int on TX underrun/EOM

Enable int on RX break/abort

Elan Digital Systems Ltd. 14 HD717 USER’S

GUIDE

3.1.3 SCC TX/RX CLOCK SELECTION

As well as being able to select various clock sources for the SCC via

WR11, the HD717 also pre-muxes both the TX and RX clocks to

allow even greater flexibility on how the card is used in synchronous

systems. Refer to Figure 2.1-1 for a block diagram showing the

clock routing.

Various HD717 control registers effect the clock selection, they are

summarised here:

REGISTER BIT FUNCTION

SCS0 Together form a 2-bit selection code for the

frequency applied to the SCC’s TRxC & RTxC

pins when the HD717 derived clock is selected

(SCS6/7):

SCS1 SCS[1:0]=00: 4MHz (default)

SCS[1:0]=01: 2MHz

SCS[1:0]=10: 1MHz

SCS[1:0]=11: 0.5MHz

SCS2 TRxCEn. This bit allows the HD717 driver

connected to the SCC’s TRxC pin to be tri-

stated. When set high, the HD717 drives the

SCC. When low, the SCC can be programmed

to output on its TRxC pin if required e.g to

output its internal baud generator or DPLL clk.

SCS3 EdgeSel. This bit allows the HD717 clock

divider to use either the +ve or -ve edge of the

master 16MHz clock supplying the SCC. The

default state is 0: +ve edge. This bit should be

left at the default state.

SCS4 SCCPClkEn. This bit acts as a master enable

for the SCC’s master oscillator (PCLK). The

default state is 0: DISABLE PCLK. When

enabled, the SCC is clocked at 16MHz. UNTIL

THIS BIT IS SET, NO OPERATION WITH

THE SCC WILL BE POSSIBLE.

Elan Digital Systems Ltd. 15 HD717 USER’S

GUIDE

SCS5 SCCTRClkEn. This bit acts as a master enable

for the SCC’s external clocks. The default state

is 0: DISABLE TX & RX clocks to SCC.

When enabled, the TRxC and RTxC pins are

driven from the HD717 derived clock or from

the off-card clock inputs. For the HD712/713

and Iss2.01+ HD717 cards this bit serves an

extra function: when an external source is

selected via SCS6 or 7 setting this bit high will

select the clock connected to T/RXCLKIN+/-

but setting it low will select the master OSC

that is also used to drive the PCLK pin on the

SCC. This allows greater flexibility in the baud

rates available when the SCC is used in async

mode. Note that when SCS5 is low only one of

two states can be selected for either the TRxC

or RTxC pins: disabled or OSC...there is no

way to route OSC to TRxC and an external

clock to RTxC simultaneously. See figure

3.1.3-1.

SCS6 SCCTXClkExt. When low, the TRxC SCC pin

is driven from the HD717 derived clock

(4,2,1,0.5MHz). When high, the SCC pin is

driven from the TXCLKIN+/-RS422 inputs to

the card (Pins 5&6) (For HD712,713 read note

for SCS5 bit)

SCS7 SCCRXClkExt. When low, the RTxC SCC pin

is driven from the HD717 derived clock

(4,2,1,0.5MHz). When high, the SCC pin is

driven from the RXCLKIN+/-RS422 inputs to

the card (Pins 11&12) (For HD712,713 read

note for SCS5 bit)

Elan Digital Systems Ltd. 16 HD717 USER’S

GUIDE

Figure 3.1.3-1 Clock Routing Internal to HD717

Note that the SCC’s TRxC and RTxC pins are buffered to RS422

levels and driven off card as TXCLKOUT+/-(Pins 3 & 4: this is

TRxC), and as RXCLKOUT+/-(Pins 9 & 10: this is RTxC).

It is vital for correct opperation that the timings for the TX/RX clock

and data follow the requirements laid down in the Zilog SCC data

sheets. In a synchronous system there must be sufficient setup and

hold time for the data relative to the clock. In the external clock

case, the HD717 passes clock and data through the same type of

RS422 receiver / transmitter chips. This means that no significant

extra skew between clock and data is added. Typically, 0ns of setup

and 50ns of hold are required at the SCC in receive relative to the

RX clock edges. In transmit, the delay between TX clock edges and

data changing is 80ns.

Be aware that some combinations of data and clock will not work

reliably when used in a loop-back test mode. For example, clocking

the TX and RX clocks from the same source (internal to the card)

and sending the TX data “out” of the card through two pieces of

wire and back “in” to the card may not work properly at 2 or 4MHz.

This is because the RX data is grossly skewed relative to the RX

clock because the data has passed through two RS422 transcievers

but the clock has not.

SCS6

SCS7

SCS5

D0

D1

D2

D3

Y

S1

S0

1

2

3

4

6

7

5

D0

D1

D2

D3

Y

S1

S0

1

2

3

4

6

7

5

Y

1

TXCLKIN

RXCLKIN

TXCLK

RXCLK

16MHZ

16MHZ

0.5/1/2/4MHz

Elan Digital Systems Ltd. 17 HD717 USER’S

GUIDE

3.1.4 SCC TRANSMIT PROCEDURE

The HD717 is intended to operate in a mode where interrupts from

the SCC only occur on special conditions. All data transfers are

performed by the SCC DMAing the data out of the TX 4K FIFO. In

this way the PC is able to load the 4K FIFO with TX data, configure

the SCC, HD717 and finally enable the HD717 DMA controller.

The TX data will automatically be sent without further intervention

from the PC unless the message length is greater than 4K. The

following flow diagram summarises the steps to transmit data:

DISABLE HD717

TX DMA

⇓⇓

CONFIGURE SCC AS

REQUIRED

WITH TX DMA ENABLED

AND

TX ENABLED

⇓⇓

LOAD TX 4K FIFO

WITH

TX DATA

⇓⇓

ENABLE HD717 TX DMA

⇓⇓

⇓⇓

The above process could generate an interrupt request for three

reasons:

1. The SCC signals that it has completed the message (EOM)

2. The HD717 signals that the TX 4K FIFO has fallen below half full

(only applies if original message was 2048 or more bytes long)

3. The HD717 signals that the TX 4K FIFO has fallen to empty

The HD717 will cease to acknowledge TX DMA requests from the

SCC when the TX 4K FIFO is empty. This will force the SCC to

terminate the message and so complete the transfer.

Elan Digital Systems Ltd. 18 HD717 USER’S

GUIDE

Remember that before re-loading the TX 4K FIFO with the next

message to send, the HD717 TX DMA must be disabled. If this is

not done the HD717 will start honouring TX DMA requests as soon

as the FIFO holds data and there is a possibility (at high bit rates)

that the SCC will empty the TX 4K FIFO faster than it is being filled

by the PC. This could lead to a TX Underrun at the SCC causing the

premature termination of the message.

For messages longer than 4096 bytes, the Interrupt Service Routine

in the PC must detect that more data must be loaded to the TX 4K

FIFO (i.e. the next block of the message). It should use the 8086

“REP OUTSB” command to rapidly copy the TX data from its local

buffer to the TX 4K FIFO. The amount of data to copy depends on

the message length remaining, but at most 2048 bytes at a time can

be transferred (remember that the IRQ occurs when the TX 4K FIFO

is less than half full). For even greater efficiency, the ISR can also

inspect the TX 4K FIFO Full, Half Full and Empty flags. This

would allow the ISR to decide to write more data if required in an

attempt to better fill the TX 4K FIFO. If this technique is used

remember that once the initial 2K block has been written by the ISR,

every subsequent byte write must made conditional on the Full flag

being high (else the ISR could write “beyond” full). At high data

rates, this extra flag check could lead to the ISR filling the FIFO

more slowly than it is being emptied by the SCC which could

ultimately lead to a FIFO empty condition and the ISR getting

“stuck” trying to fill an ever emptying FIFO ! In such a case, use

only the single 2K block write and then exit the ISR.

HD717 control / status registers that relate to an SCC TX are listed

below:

REGISTER BIT FUNCTION

PCR0 MIRQEn: Set to ‘1’ to allow any interrupt

through to the PC

PCR1 IRQInService: Use this bit in the ISR routine

to lock the IRQ state, so indicating that an IRQ

is being serviced by software. Set the bit to ‘1’

to lock the IRQ state as the first action of the

ISR. Return it to ‘0’ as the last action of the

ISR (this may immediately re-activate the IRQ

to the PC).

Elan Digital Systems Ltd. 19 HD717 USER’S

GUIDE

PCR2 TXDMAEn: Set to ‘1’ to allow the HD717 TX

DMA controller to honour SCC TX DMA

requests. The TX DMA controller will only

“run” if the TX 4K FIFO contains >0 bytes of

data.

IMR0 MaskSCCInt: Set to ‘1’ to mask interrupts

from the SCC. Set to ‘0’ to allow them.

IMR3 MaskTXFIFOHInt: Set to ‘1’ to mask

interrupts from the TX 4K FIFO as it falls

below half full. Set to ‘0’ to allow them.

IMR5 MaskTXFIFOEInt: Set to ‘1’ to mask

interrupts from the TX 4K FIFO as it falls to

empty. Set to ‘0’ to allow them.

IPR0 SCCIntPending: Reads back as a ‘1’ when

there is an interrupt pending from the SCC.

The SCC must be set to use a software

INTACK mode (WR9) so that the SCC’s

interrupt line is de-asserted when RR2 is

accessed to determine the reason for the SCC

interrupt.

Elan Digital Systems Ltd. 20 HD717 USER’S

GUIDE

IPR3 TXFIFOHIntPending: Reads back as a ‘1’

when there is an interrupt pending due to the

TX 4K FIFO falling below half full. The

interrupt is cleared by a PC write to the TX 4K

FIFO. If this is not appropriate (i.e. there is no

more data to TX) then IMR3 should be set to

‘0’ ‘1’ ‘0’ to clear the interrupt. If messages

are always less than 4096 bytes then it is best to

always mask these interrupts (IMR3=‘1’).

IPR5 TXFIFOEIntPending: Reads back as a ‘1’

when there is an interrupt pending due to the

TX 4K FIFO falling to empty. The interrupt is

cleared by setting IMR5 to ‘0’ ‘1’ ‘0’.

MSR0 TXFIFOEmpty: Status of the TX 4K FIFO’s

empty flag (active low).

MSR1 TXFIFOHalf: Status of the TX 4K FIFO’s half

full flag (active low).

MSR2 TXFIFOFull: Status of the TX 4K FIFO’s full

flag (active low).

While the HD717 is transmitting data from the TX 4K FIFO via the

SCC, the PC can still access the SCC’s registers. A bus arbitrator in

the HD717 makes sure that the PC and SCC accesses to the

HD717’s internal bus do not clash. However, do not access the SCC

“too often” whilst TX DMA is enabled because the HD717 will

simply run out of time trying to arbitrate both sources (which will

make the SCC underflow and terminate the frame prematurely).

Accessing (reading) one SCC register every 50us is OK; every 1us is

not ! Also bear in mind that the situation gets worse if the HD717 is

both transmitting AND receiving data at the same time. Again the

arbitrator is working to share the bus between all sources and so the

potential to “run out of time” is greater in this instance (still the 50us

holds good).

Table of contents

Other ELAN DIGITAL SYSTEMS Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Adaptec

Adaptec RAID 6805Q datasheet

Kontron

Kontron CP6012 user guide

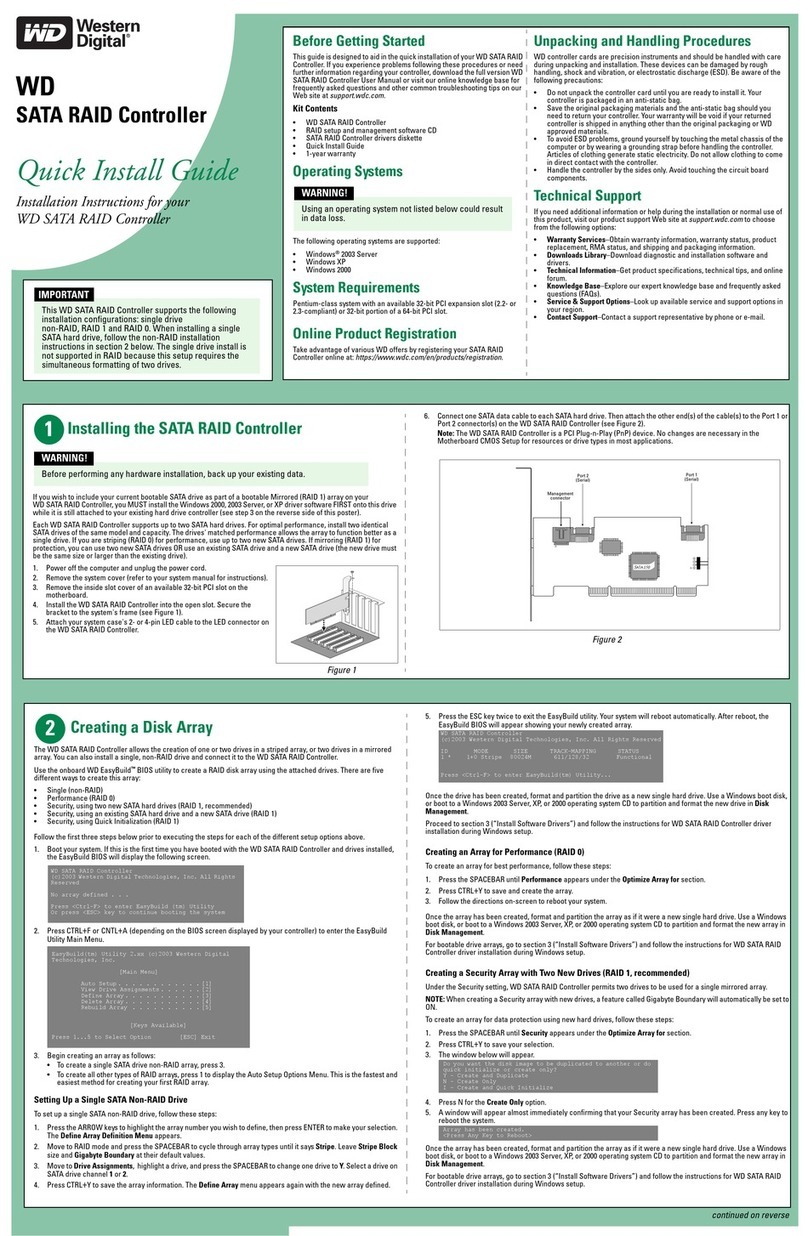

Western Digital

Western Digital WD Serial ATA RAID Controller Quick install guide

National Instruments

National Instruments Compact FieldPoint Mounting Accessories... quick start guide

Fife

Fife CDP-01 Additional instruction manual

Radiant

Radiant DIAGNOCODE SM 20015 instruction manual