Elastimold 164FTV Manual

IS---0377

IS---164FTV

January 2010

Page 1 of 4

Installation & Operating Instructions

164FTV

FEED-- THRU/GROUNDING DEVICE

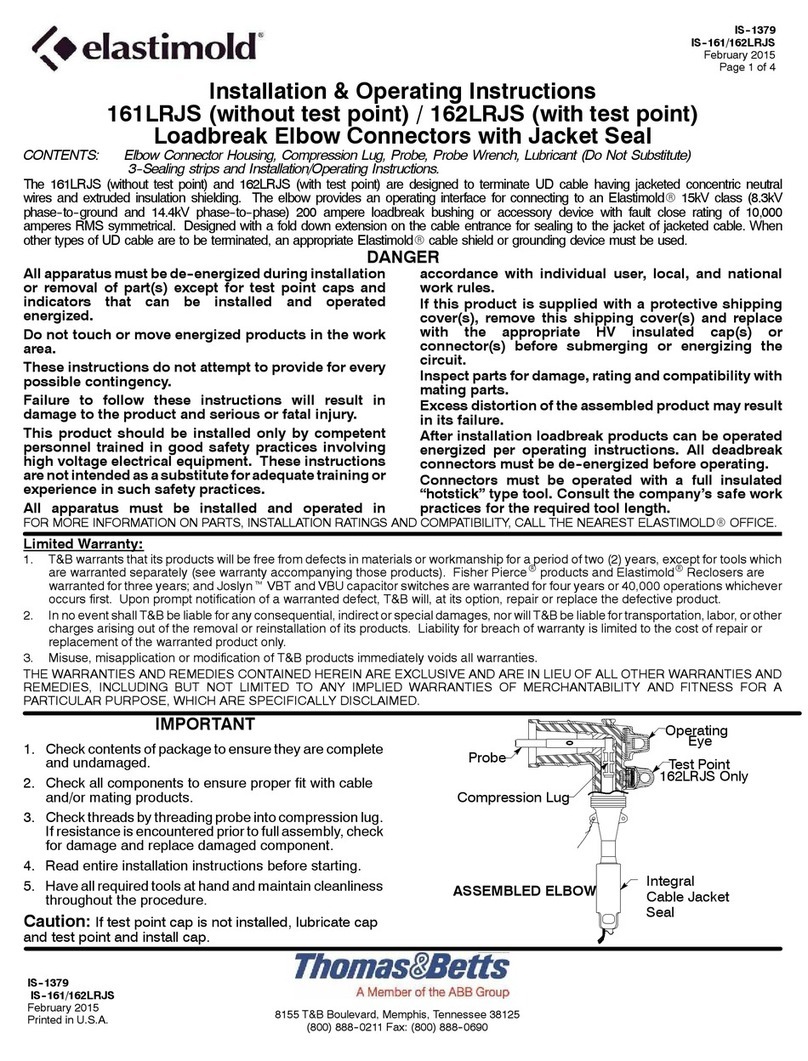

CONTENTS: Feed---thru Body Complete with Mounting Hardware, Lubricant (DO NOT SUBSTITUTE), Operating Instructions.

IMPORTANT: Read these instructions and the Loadbreak Elbow Operating Instructions (IS-- 167/168LR,

Pages 3-- 4) COMPLETELY before operating connectors.

The feed--thru can be used for the following functions: A) A junction point, B) A grounding point. To use the feed--thru as a

junction point, follow steps 1 to 7. To use the feed--thru as a grounding point, follow steps 1 to 5 and 8 to 9. A yellow band

provides indication of full elbow seating. This product is identified by a yellow ID washer attached to the eyebolt.

DANGER

All apparatus must be de--energized during installation

or removal of part(s) except for test point caps and

indicators that can be installed and operated

energized.

After installation loadbreak products can be operated

energized per operating instructions. All deadbreak

connectors must be de--energized before operating.

All apparatus must be installed and operated in

accordance with individual user, local, and national

work rules. These instructions do not attempt to

provide for every possible contingency.

Do not touch or move energized products.

“Loadbreak connectors must be operated with a full

insulated “hotstick” type live-- line tool.” Consult the

company’s safe work practices for the required

live--line tool length.

Excess distortion of the assembled product may result

in its failure.

Inspect parts for damage, rating and compatibility with

mating parts.

This product should be installed only by competent

personnel trained in good safety practices involving

high voltage electrical equipment. These instructions

are not intended as a substitute for adequate training or

experience in such safety practices.

Failure to follow these instructions will result in

damage to the product and serious or fatal injury.

If this product is supplied with a protective shipping

cover(s), remove this shipping cover(s) and replace

with the appropriate HV insulated cap(s) or

connector(s) before submerging or energizing the

circuit.

FOR MORE INFORMATION ON PARTS, INSTALLATION RATINGS AND COMPATIBILITY, CALL THE NEAREST ELASTIMOLD OFFICE.

IMPORTANT

1. Check contents of package to ensure they are complete

and undamaged.

2. Check all components to ensure proper fit with cable

and/or mating products.

3. Read entire installation instructions before starting.

4. Have all required tools at hand and maintain cleanliness

throughout the procedure.

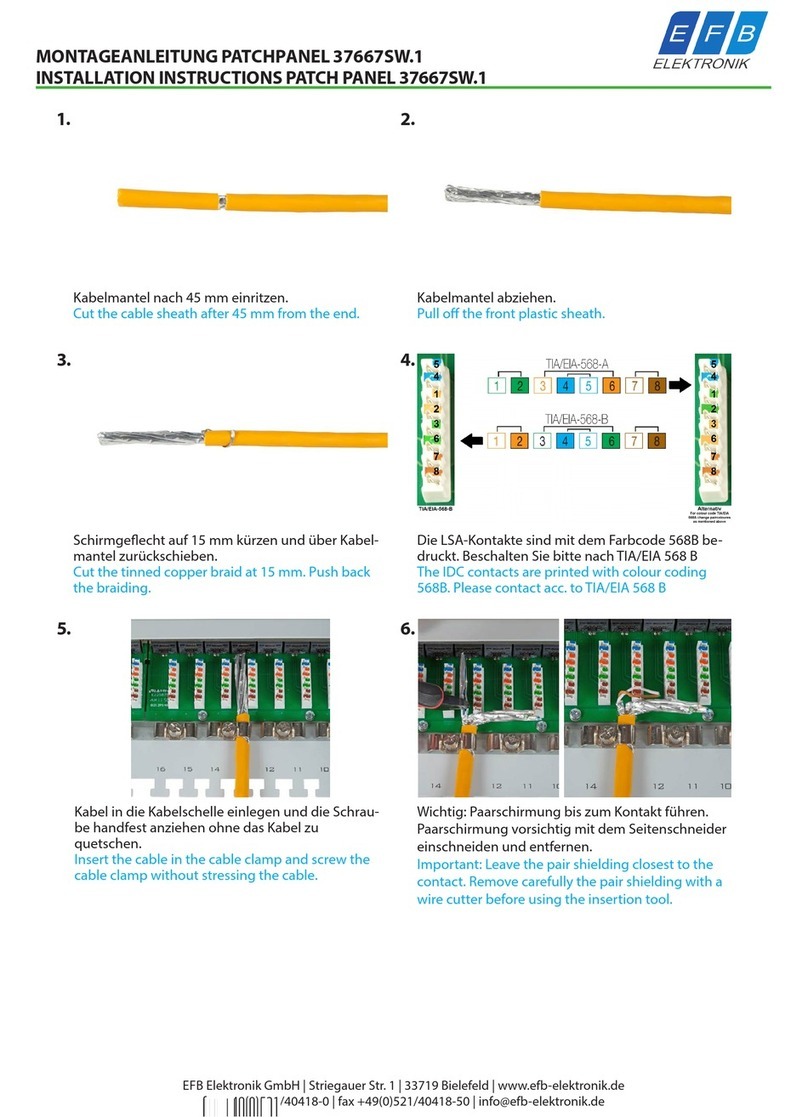

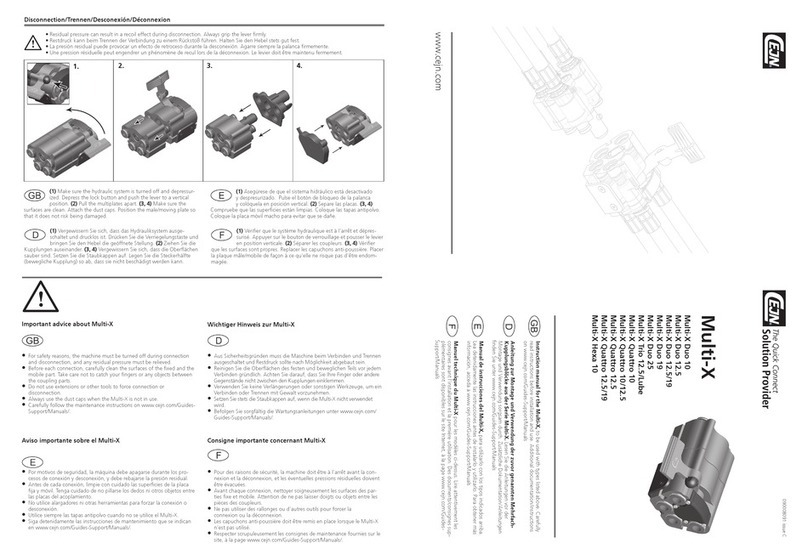

STEP 1

Bracket Grounding

Insert ground lead into the grounding lug provided on the

mounting hardware and tighten lug. Ground lead should be

equivalent to No. 14 copper wire or greater. Connect the

opposite end of the ground lead to ground, leaving enough

slack to operate with a hotstick.

IS---0377

IS---164FTV

January 2010

Printed in U.S.A.

8155 T&B Boulevard, Memphis, Tennessee

38125 (800) 888--0211 Fax: (800) 888--0690

To Ground

Protective

Covers

No. 14 Copper Wire Ground Lug

Yellow ID Washer

IS---0377

January 2010

Page 2 of 4

STEP 2

Remove the protective covers from the bushings of the

feed--thru.

WARNING: PROTECTIVE COVERS MUST NOT BE ON

THE BUSHINGS OF THE FEED--THRU WHEN THE

FEED--THRU IS BEING USED. When the feed--thru is not

in use, the protective covers should be placed on the

bushings of the feed--thru to protect them from dirt and other

contaminants.

Clean the bushing surfaces and lubricate them with the

lubricant supplied. DO NOT SUBSTITUTE. Other lubricants

may be harmful to this product and its mating product(s).

Clean &

Lubricate

Remove

Protective Covers

STEP 3

Attach feed--thru eye firmly to hotstick. Eye

Hotstick

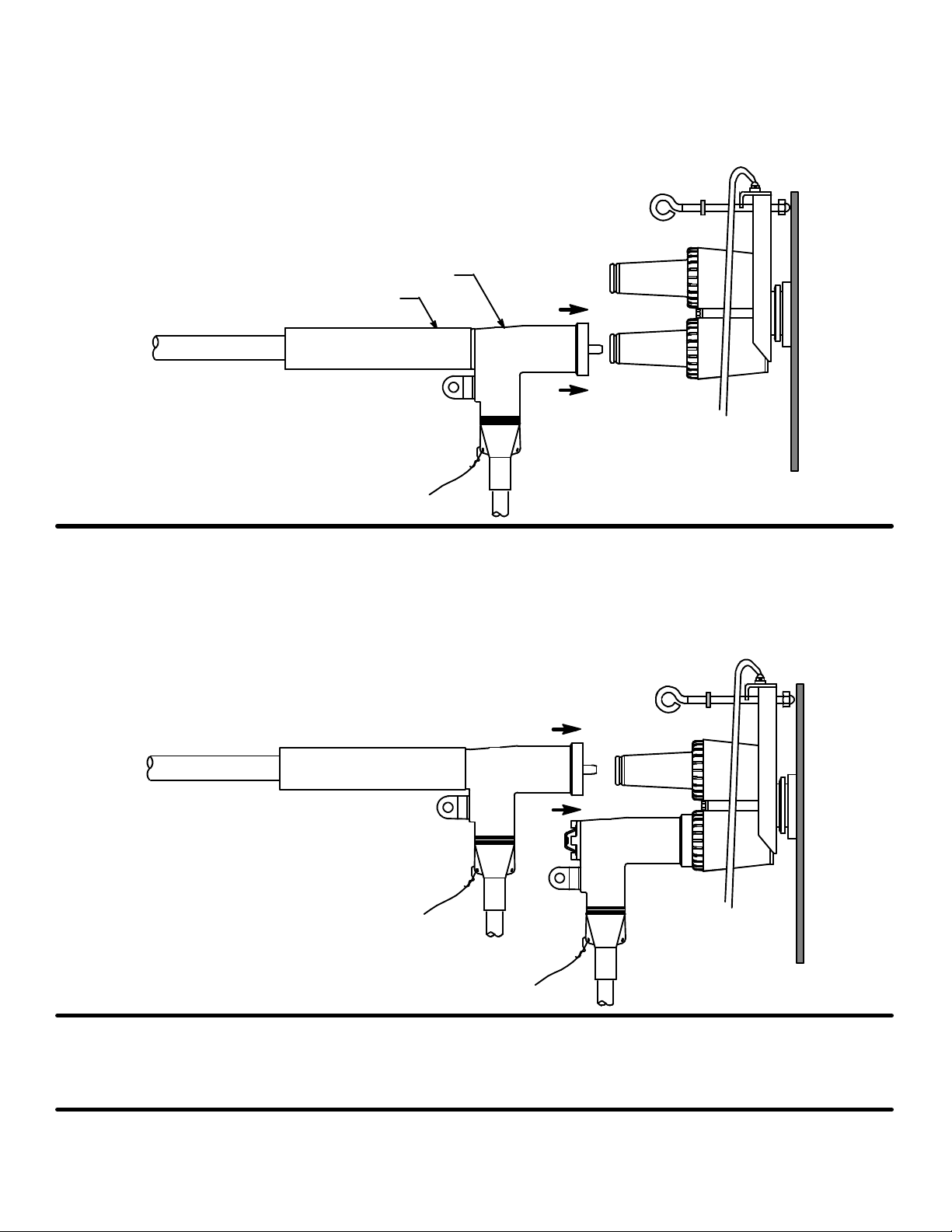

STEP 4

1. Using a hotstick, slide feed--thru onto parking stand.

Unlock hotstick and back off, to allow space for eyebolt

to be tightened. Tighten eyebolt by rotating

hotstick clockwise until snug. DO NOT OVERTIGHTEN.

Release hotstick.

2. Position the ground lead near the bracket so it does

not come in contact with the bushing interfaces or

mating devices.

F

R

O

N

T

V

I

E

W

Parking

Strand

Parking

Stand

SIDE VIEW

Eye

Hotstick

IS---0377

January 2010

Page 3 of 4

STEP 5

Remove one loadbreak elbow from its apparatus loadbreak bushing following the applicable loadbreak operating instructions

(IS--167/168LR, pages 3--4). Using a hotstick, firmly attached to the elbow, insert the probe tip into one feed--thru until the first

slight resistance is felt. Immediately push the elbow home with a fast, firm straight motion which will engage the internal lock on

the mating interfaces.

Hotstick

Elbow

FOR JUNCTION POINT APPLICATION FOLLOW STEPS 6 AND 7

STEP 6

Remove second loadbreak elbow, following the applicable loadbreak operating instructions (IS--167/168LR, pages 3--4).

Using a hotstick, firmly attached to the elbow, insert the probe tip into the remaining feed--thru until the first slight resistance is

felt. Immediately push the elbow home with a fast, firm straight motion which will engage the internal lock on the mating

interfaces.

STEP 7

When it is desired to re--connect the elbow(s) to the apparatus bushing(s), first make certain no faults exist on the system. To

return the loadbreak elbow to the apparatus bushing, reverse the operational sequence, following the applicable

loadbreak--loadmake operating instructions.

IS---0377

January 2010

Page 4 of 4

FOR GROUNDING POINT APPLICATION FOLLOW STEPS 8 TO 9

IMPORTANT: DO NOT INSERT GROUNDING ELBOW INTO FEED--THRU UNLESS CIRCUIT HAS BEEN TESTED

AND SHOWN TO BE “DE--ENERGIZED”.

STEP 8

Ensure that the system is de--energized with either of the following procedures.

1. ELBOW TEST POINT

a. Remove test point cap with a hotstick. When removing cap, PEEL OFF AT AN ANGLE rather than pulling directly in

line with the test point assembly.

b. WARNING: THE VOLTAGE TEST POINT IS A CAPACITANCE DEVICE, IT IS NOT DIRECTLY CONNECTED TO

THE CONDUCTOR. Do not use conventional voltage measuring equipment. Follow the manufacturer’s directions for the

meter that is used. Test with a suitable sensing device, made for use with separable connectors manufactured with

capacitive test points, to determine if cable is energized. Contamination, moisture, dirt, etc. around the test point or use of

the wrong measuring equipment can provide a false “no voltage” indication on an energized elbow. To prevent serious or

fatal injury treat the elbow as energized until the “no voltage” test point indication is confirmed by other means.

c. After voltage detection has been made, clean and lubricate the inside surface of the cap with silicone grease and replace it

on the test point.

2. DIRECT TEST

Remove existing elbow or insulated cap from the bushing with a hotstick following the applicable loadbreak operating

instructions (IS--167/168LR). Firmly tighten a hotstick to the 370TR test rod operating eye. Insert the test rod into the

bushing. Using a meter capable of DIRECT READING the system voltage, check thetest rod disc for voltage. Remove test rod.

The hotstick eye and disc of the test rod are not insulated; be careful to keep them clear from ground until tested “de--energized”.

IMPORTANT: If voltage is indicated by either of the two preceding procedures, do not proceed without de--energizing

the system.

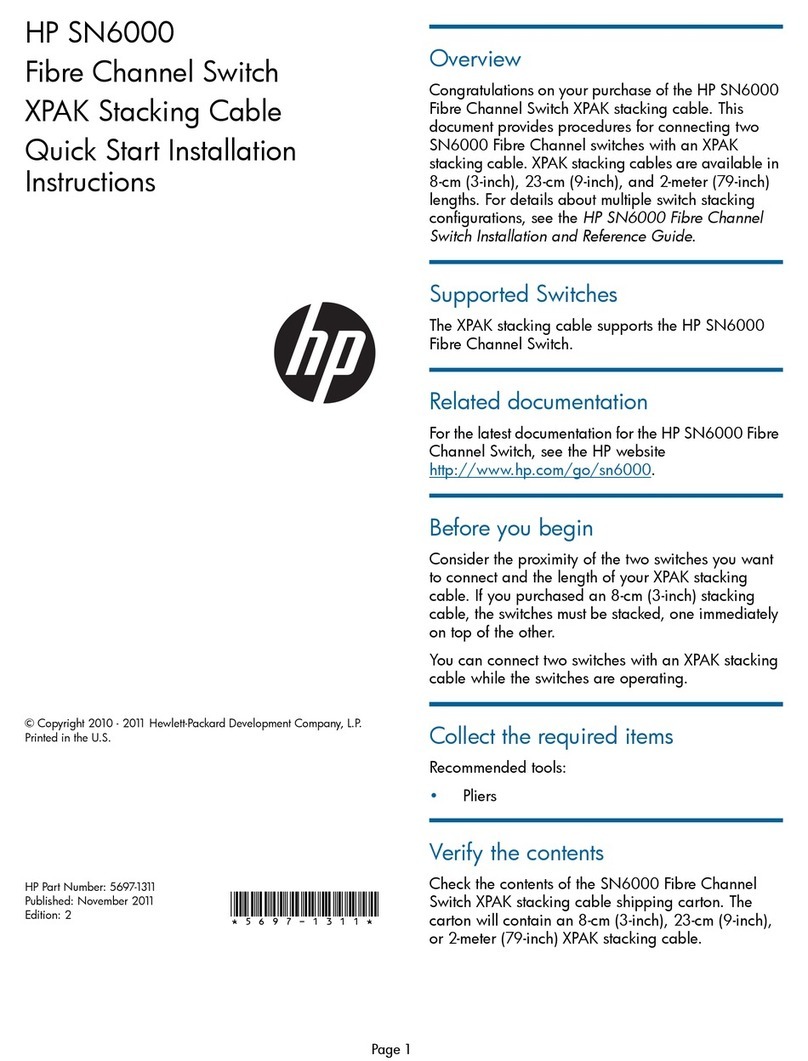

STEP 9

Install ground elbow into the second plug of the feed--thru,

following the grounding elbow operating instructions

(IS--160/370GLR, steps B thru D).

STEP 10

Complete assembly of an insulated cap or elbow is indicated

by no portion of the yellow band being visible when viewed

from the side

Hotstick

370TR

Test Rod

Test Rod

Disc

Operating Eye

2.

Table of contents

Other Elastimold Cables And Connectors manuals