5

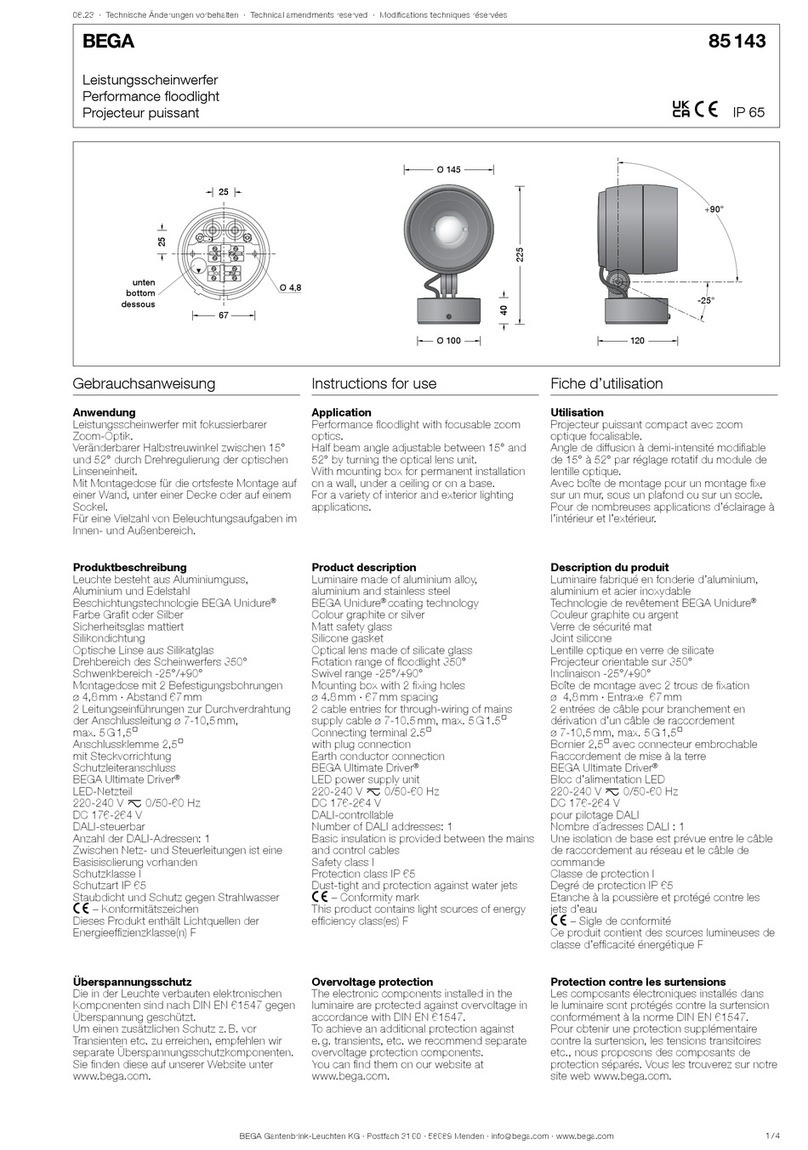

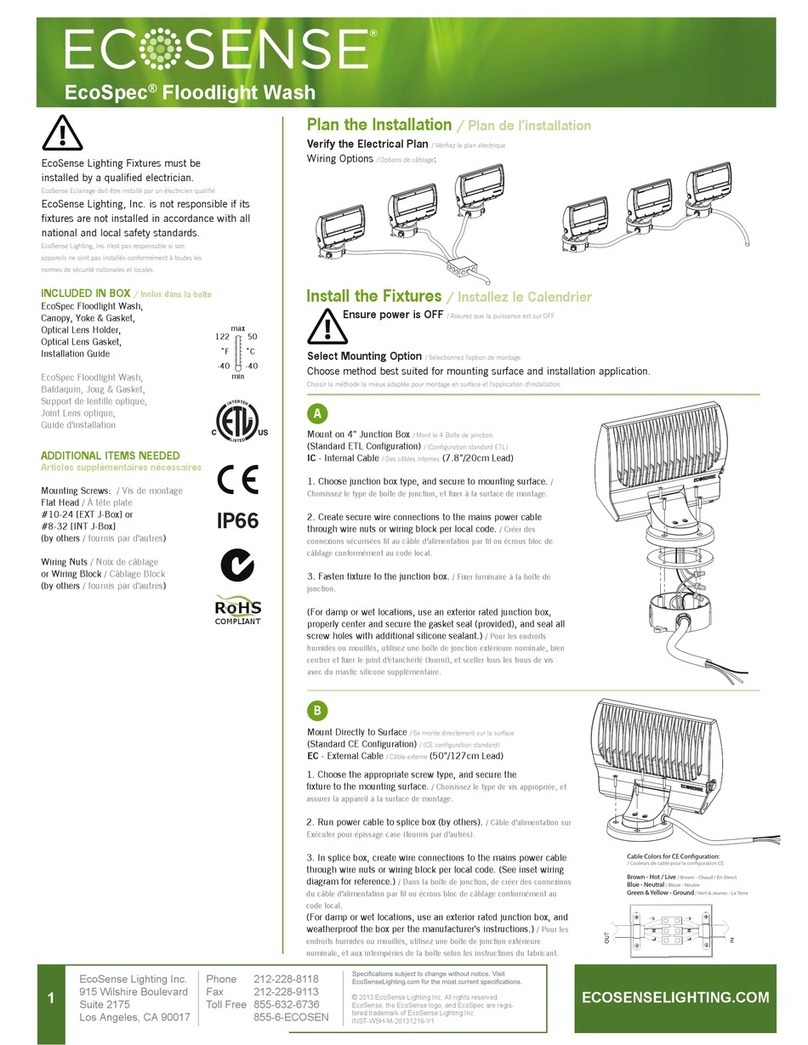

IP65 RATED

The International Protection (IP) rating system is commonly expressed as “IP” (Ingress Protection) followed

by two numbers (i.e. IP65), where the numbers dene the degree of protection. The rst digit (Foreign Bodies

Protection) indicates the extent of protection against particles entering the xture, and the second digit (Water

Protection) indicates the extent of protection against water entering the xture. An IP65 rated lighting xture

is designed and tested to protect against the ingress of dust (6), and low-pressure water jets from any direction

(5).

NOTE: THIS FIXTURE IS INTENDED FOR TEMPORARY OUTDOOR USE ONLY!

Maritime/Coastal Environment Installations: A coastal environment is seaside adjacent, and caustic to

electronics through exposure to atomized salt-water and humidity, whereas maritime is anywhere within 5-miles

of a coastal environment.

NOT suitable for maritime/coastal environment installations. Installing this xture in a maritime/

coastal environment may cause corrosion and/or excessive wear to the interior and/or exterior

components of the xture. Damages and/or performance issues resulting from installation in a

maritime/coastal environment will void the manufactures warranty, and will NOT be subject to

any warranty claims and/or repairs.

Maritime installations require additional preparation, and additional service intervals may be needed given the

maritime use. In general, IP ratings presuppose freshwater conditions VS maritime conditions, which are typically

more “caustic” to IP xtures (both internally and externally). A duty-cycle may also be needed when units are not

in use. During times of high humidity and colder temperatures, condensation may occur internally so the xture

may require a duty-cycle to bring it up to running temperature, allowing any accumulation of moisture to be

expelled via the vent valve. Recommendations can change based on installation environmental circumstances. A

waterproof dome or similar device is recommended for use in permanent outdoor installations. When using a dome,

refer to manufacturer recommendations for duty-cycle.

NOTE: NOT ALL FEATURES LISTED ARE AVAILABLE ON ALL FIXTURES; THE FOLLOWING INSTRUCTIONS MAY

NOT APPLY. CONTACT SUPPORT FOR ADDITIONAL DETAILS.

Exterior Maintenance: Inspect the exterior every 30-days. The unit must be powered o/disconnected. The

chassis should be inspected for any signs of contaminants. Inspect optics to determine if the lens is obstructed,

then clean optics and chassis accordingly. Based on initial nding, schedule maintenance accordingly, keeping in

mind that exterior maintenance will be required. Even if the luminaires are NOT in use, maintenance will still be

needed given its location (exterior use). The use of a durable type of wax on the chassis is recommended since

it will help prevent contaminant build up. Inspect both power and data lines for any signs of contaminants or

corrosion. Periodically reapplying di-electric grease, especially in coastal environments. If any signs of corrosion/

contaminants are present, clean thoroughly, and/or replace connectors, then reapply di-electric grease. Typically,

this should be done annually, or any time an opportunity presents itself. As a preventive measure, annual

replacement of both vent valves is recommended. The vent valve membrane can become contaminated and/or

clogged causing improper venting of humidity within the luminaire. Inspect all mounting hardware as a precaution.

Interior Maintenance: Inspect the interior every 30-days. The unit must be powered o/disconnected.

• Inspect zoom/focus mechanism, clean optics, lubricate linear bearings (Krytox oil) as needed, inspect belts

for wear

• Inspect all rotating eect wheels, manually rotate them, note any resistance

• Inspect all remaining rotating belts for any wear

• Inspect all fans, clean as needed, check rotation, check connections

• Inspect CMY module, manually move ags and check for signs of resistance, and if needed, clean guide rods

rst, then reapply a thin layer of grease (moly lube)

• Clean interior with low-volume compressed air, then clean optics prior to reassembly of head covers

Although the base has limited moving parts, the pan belt should also be inspected for wear. Remember to always

perform an IP test anytime a cover is removed.

There is no specic time frame regarding the routine replacement of parts such as belts/stepper motors, PCBs,

or LEDs. These items should only be replaced on an as needed bases, except for cooling fans, which should be

replaced once the luminaries reach 10,000-hours. This is a prophylactic measure intended to keep the unit running

as cool as possible, insuring proper function of all internal components. A complete service breakdown is available,

please contact service@elationlighting.com for any needed parts or manuals.