ELAU PacDrive M User manual

PacDriveTM M

- Field Bus PROFIBUS-DP -

PDM_OpMaPROFIBUS_us0206

Article number: 17130067-001

Operating Manual

PDM_OpMaProfi_00_us.FM

page 2 field bus PROFIBUS-DP PacDrive™M

Korrekturausdruck

Imprint

© All rights reserved to ELAU AG, also in case of patent right

applications.

No part of this documentation and the related software and firm-

ware may be reproduced, rewritten, stored on a retrieval system,

transmitted or translated into any other language or computer lan-

guage without the express written consent of ELAU AG.

Any possible measure was taken to ensure the that this product

documentation is complete and correct. However, since hardware

and software are continuously improved, ELAU makes no repre-

sentations or warranties with respect to the contents of this product

documentation.

Trademarks

PacDrive is a registered trademark of ELAU AG.

All other trademarks mentioned are the exclusive property of their

manufacturers.

ELAU AG ELAU Inc.

Dillberg 12 4201 W. Wrightwood Ave.

D-97828 Marktheidenfeld Chicago, IL 60639

Phone: +49 (0) 93 91 / 606-0 Phone: 773 342 8400

Fax: +49 (0) 93 91 / 606-300 Fax: 773 342 8404

Internet: www.elau.de www.elau.com

PDM_OpMaProfibus_usIVZ.fm

PacDrive™ M field bus PROFIBUS-DP Seite 3

Contents

Korrekturausdruck

Contents

1 Safety 5

1.1 Depiction of Safety Notes ...................................................................... 5

1.2 Use as Directed ..................................................................................... 6

1.3 General Safety Instructions ................................................................... 6

2 Use of This Operating Manual 7

2.1 Target Group ......................................................................................... 7

2.2 Depiction Conventions ........................................................................... 7

3 Overview 9

3.1 In General .............................................................................................. 9

3.2 PROFIBUS-DP .................................................................................... 10

4 Diagnosis 13

4.1 In General ............................................................................................ 13

4.2 Example for a Diagnosis Message ...................................................... 14

5 Transportation, Storage, Unpacking 15

5.1 Transportation ...................................................................................... 15

5.2 Storage ................................................................................................ 15

5.3 Unpacking ............................................................................................ 16

6 Configuration, Parametrization 17

6.1 In General ............................................................................................ 17

6.2 Overview .............................................................................................. 17

6.2.1 System Structure ................................................................................. 17

6.2.2 Data Consistency ................................................................................. 19

6.2.3 Information on the WAGO Bus Coupler ............................................... 20

6.3 PROFIBUS-DP Master ........................................................................ 21

6.3.1 Configuration ....................................................................................... 21

6.3.2 Parametrization .................................................................................... 36

6.4 PROFIBUS-DP Slave .......................................................................... 47

6.4.1 Configuration ....................................................................................... 47

6.4.2 Parametrization .................................................................................... 51

7 Maintenance 59

7.1 Spare Parts, Components ................................................................... 59

7.2 Repair .................................................................................................. 60

PDM_OpMaProfibus_usIVZ.fm

Seite 4 field bus PROFIBUS-DP PacDrive™M

Contents

Korrekturausdruck

7.3 Service Addresses ............................................................................... 60

7.4 Exchanging Units ................................................................................. 61

7.4.1 Procedure for PROFIBUS-DP master module ..................................... 62

7.4.2 Procedure for PROFIBUS-DP slave module ........................................ 64

8 Technical Data 67

8.1 In General ............................................................................................. 67

8.1.1 RS-485 Transmission for PROFIBUS-DP ............................................ 67

8.1.2 PROFIBUS-DP Master ......................................................................... 69

8.1.3 PROFIBUS-DP Slave ........................................................................... 70

8.2 Electrical Connections .......................................................................... 71

9 APPENDIX 73

9.1 Contact ................................................................................................. 73

9.2 Contract on the Use of Software Products ........................................... 74

9.3 Further Literature .................................................................................. 80

9.4 Product Training ................................................................................... 82

9.5 Modifications ........................................................................................ 83

9.6 Index ..................................................................................................... 85

9.7 Form for Error Report ........................................................................... 87

PDM_SicherhStd_us.FM

PacDrive™ M page 5

1.1 Depiction of Safety Notes

Korrekturausdruck

1 Safety

This chapter describes the general requirements for working safely.

If the work involves any remaining risk, we will

point this out in the respective passages,

warn you of any possible danger and

describe how the danger can be avoided.

1.1 Depiction of Safety Notes

Risk categories

We differentiate between different categories of safety notes. The

table below shows which danger and possible consequences the

symbols (pictographs) and keywords point out.

Notes

Information and notes are marked by a symbol (pictograph) and a

signal word as well.

Pictograph Keyword Definition

DANGER!

Indicates an immediately dangerous

situation that will result in death or very

serious injuries if the safety rules are

not observed.

WARNING!

Indicates a possibly dangerous situa-

tion that can result in serious injuries or

large material damage if the safety

rules are not observed.

CAUTION!

Indicates a possibly dangerous situa-

tion that might result in material

damage if the safety rules are not

observed.

Pictograph Keyword Definition

NOTE

Tips for usage and other important or

useful information and notes

PDM_SicherhStd_us.FM

page 6 PacDrive™ M

1 Safety

Korrekturausdruck

1.2 Use as Directed

The components of the PacDrive™ system may only be used for

the applications described in this manual and only in combination

with third-party devices and components recommended or appro-

ved by ELAU.

Any other application is not regarded as "Use as directed".

WARNING!

Risk of injury due to use other than directed!

If the components of the PacDrive™ system are used in a different

way than described above or modified without ELAU’s approval,

persons may be injured and material damage may occur.

"Use as directed" includes that you

observe the Operating Manual,

observe the instructions for inspection and maintenance.

1.3 General Safety Instructions

In addition to this manual, please observe

the prohibiting, warning and mandatory signs as well as the

warnings on the components in the switching cabinet,

the corresponding laws and regulations,

the legal requirements concerning accident prevention,

the operating instructions for the other components.

Always keep the operating manuals close to the machine.

PDM_VerwendStd_us.FM

PacDrive™ M page 7

2.1 Target Group

Korrekturausdruck

2 Use of This Operating Manual

2.1 Target Group

This operating manual is aimed exclusively at technically qualified

staff with detailed knowledge in the field of automation technology.

Only qualified staff can understand the significance of the safety

notes and act accordingly.

This operating manual is aimed primarily at design and application

engineers specializing in mechanical and electrical engineering, at

programmers, service and commissioning engineers.

NOTE

Should you not be able to solve problems with the help of this

manual, please contact

ELAU AG

- Abteilung Kundendienst -

Postfach1255

D-97821 Marktheidenfeld

Telefon: 09391/606-142

Fax: 09391/606-300

2.2 Depiction Conventions

Table 2-1: Depiction conventions

Symbol Meaning

Marks the first level of an enumeration.

– Marks the second level of an enumeration.

¾Marks instructions for an action.

normal Normal text.

italics Marks a special term (e.g. parameter).

Code Program code

PDM_VerwendStd_us.FM

page 8 PacDrive™ M

2 Use of This Operating Manual

Korrekturausdruck

PDM_OpMaProfi_03_us.FM

PacDrive™ M fieldbusPROFIBUS-DP page 9

3.1 In General

Korrekturausdruck

3 Overview

3.1 In General

PROFIBUS

PROFIBUS is a manufacturer-independent open field bus standard

for various applications in production, process and building auto-

mation. The international norm EN 50 170 guarantees that

PROFIBUS is manufacturer-independent and open. PROFIBUS

enables the flawless communication between appliances from dif-

ferent manufacturers without requiring any special interface

modifications. PROFIBUS is suitable for quick, time-critical data

transfer as well as for complex communication jobs. PROFIBUS

consists of a family of three compatible variants, with 90% of appli-

cations preferring PROFIBUS-DP.

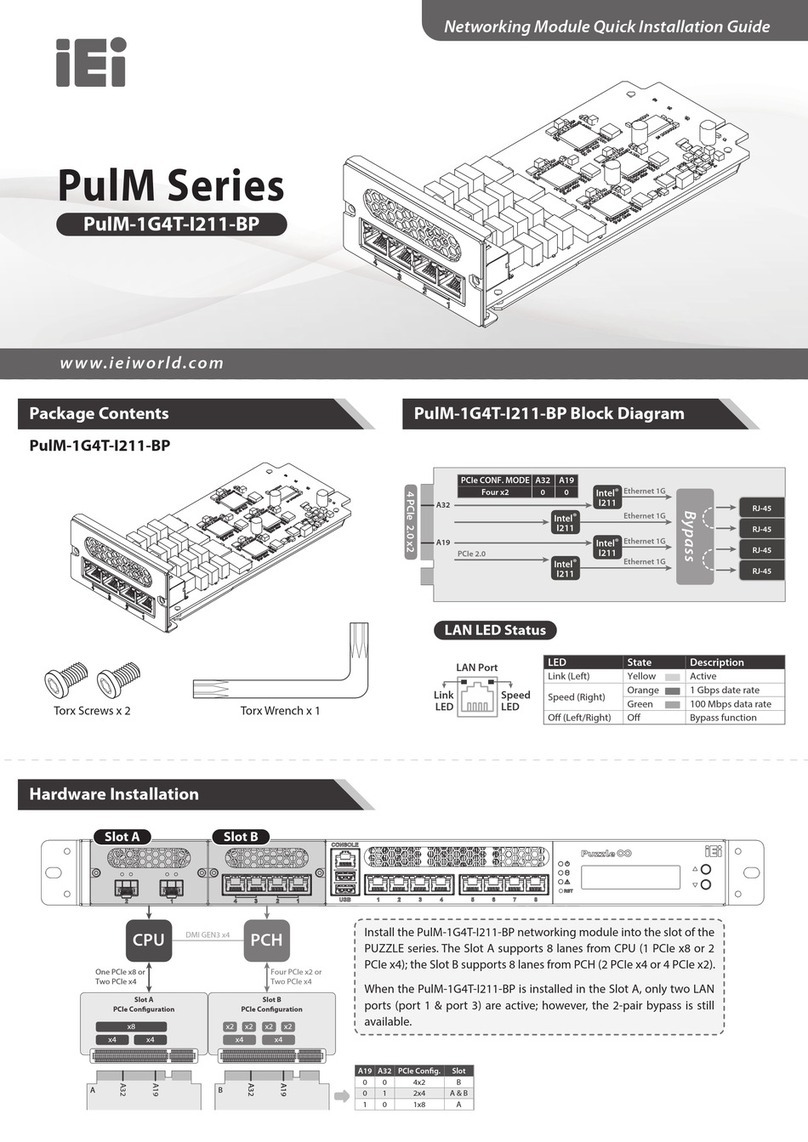

Fig. 3-1: Automation concept for food and packaging machines

PDM_OpMaProfi_03_us.FM

page 10 field bus PROFIBUS-DP PacDrive™ M

3 Overview

Korrekturausdruck

PROFIBUS-DP

This PROFIBUS variant, which is optimized for speed and low con-

nection costs, is designed especially for the communication

between automation systems and decentralized peripherals on field

level. PROFIBUS-DP is suitable as a substitute for conventional

parallel signal transmission with 24 Volt or 0-20 mA.

Basic features

PROFIBUS determines the technical and functional features of a

serial field bus system in which automation appliances located in

different places can be networked from field level to cell level. PRO-

FIBUS differentiates between master and slave units.

Master units determine the data transfer on the bus. A master may

send messages without external request if it has a bus token. In the

PROFIBUS protocol, masters are also called active participants.

Slave units are peripherals. Typical slave units are input/output

devices, valves, drives and measuring transducers. They have no

bus token, i.e. they can only acknowledge received messages or

transmit messages to the master on request. They require only a

small part of the bus protocol, which makes the implementation

fairly simple.

The MAx-4 PacController can be a master and/or slave.

The PROFIBUS module is plugged into the MAx-4 PacController

and served from there.

3.2 PROFIBUS-DP

PROFIBUS-DP is designed for fast data exchange on field level.

The central control units, such as PLC/PC, communicate with

decentralized field units such as I/O, drives and valves via a fast

serial connection. The necessary communication functions are

determined by the PROFIBUS-DP basic functions according to EN

50 170.

For parameter setting, diagnosis and alarm handling while cyclic

data transfer is in progress, additional acyclic communication

functions are needed for intelligent field units. They are defined in

the PROFIBUS directive no. 2.042 and will be explained in chapter

3.2.

Basic Functions of PROFIBUS-DP

The central control (master) cyclically reads the input information

from the slaves and writes the output information to the slaves.

Besides the cyclical transfer of useful data, PROFIBUS-DP also

features efficient functions for diagnosis and commissioning. Data

PDM_OpMaProfi_03_us.FM

PacDrive™ M field busPROFIBUS-DP page 11

3.2 PROFIBUS-DP

Korrekturausdruck

transfer is monitored by monitoring functions on the sides of both

master and slaves.

table 3-1 summarizes the basic functions of PROFIBUS-DP.

Transmission technology:

RS-485 twisted two-wire circuit or beam waveguide

Baud rates of 9.6 kbit/s up to 12 Mbit/s

Bus access:

Master-Slave method

master and slave units, max. 126 participants per bus

Communication:

point to point (useful data) or multicast (control commands)

cyclic master-slave useful data transfer

Operating states:

Operate: cyclic transmission of input and output data

Clear: inputs are read, outputs remain in safe state

Stop: only master-master data transfer possible

Synchronization:

control commands enable synchronization of inputs and out-

puts

Sync mode: outputs are synchronized

Freeze mode: inputs are synchronized

Functionality:

cyclic transfer of useful data between DP master and DP

slave(s)

configuration check for DP-Slaves

efficient diagnosing functions,3 graduated diagnosis message

levels

synchronization of inputs and/or outputs

max. 244 bytes input and output data per DP slave

Protective functions:

all messages are transmitted with hamming distance HD=4

response monitoring at DP slaves

access protection for inputs/outputs of DP slaves

monitoring of useful data transfer with adjustable monitoring

timer in master

PDM_OpMaProfi_03_us.FM

page 12 field bus PROFIBUS-DP PacDrive™ M

3 Overview

Korrekturausdruck

Table 3-1: Basic functions of PROFIBUS-DP

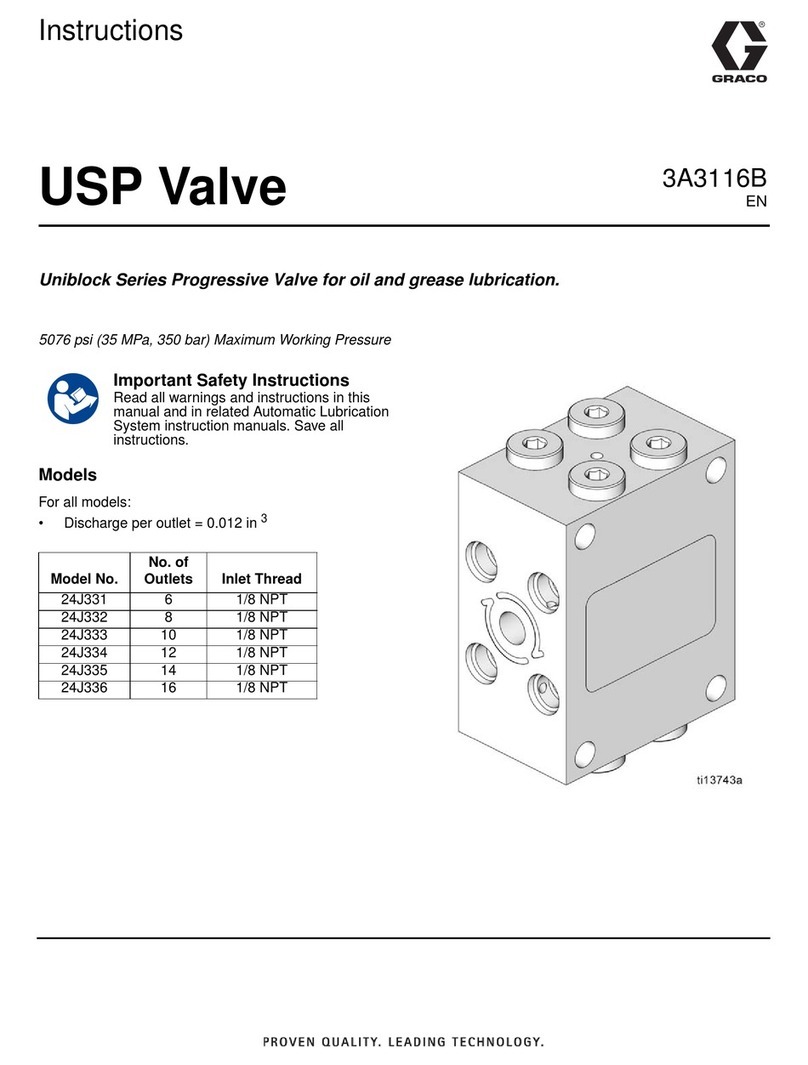

Fig. 3-2: Bus cycle time of a PROFIBUS-DP mono master system

Note on figure 3-2

Marginal conditions: each slave ahs 2 bytes input and 2 bytes out-

put data; the minimum slave interval time is 200 microseconds;

TSDI = 37 bit times, TSDR = 11 bit times

Device types:

DP masters class 1 (DPM1), e.g. central automation devices

such as PLC, PC ...

DP slaves, e.g. devices with binary or analog inputs/outputs,

drives, valves

18

14

10

6

2

5 10 20 30 DP-Slaves

bus cycle time

[ms]

500kBit/s

1.5 Bit/s

12 Bit/s

PDM_OpMaProfi_04_us.FM

PacDrive™ M field busPROFIBUS-DP page 13

4.1 In General

Korrekturausdruck

4 Diagnosis

4.1 In General

The PacDrive™ system supports the user with its extensive dia-

gnosis system.

The diagnosis messages can be read out with the Windows pro-

gram EPAS-4. The PacDrive™ M system also contains a powerful

message logger, which records additional diagnosis messages.

Normally the diagnosis messages are shown via an operating unit

on the machine.

In case of an error, read this diagnosis message and contact your

machine producer.

NOTE

For further details on the diagnosis, see the Programming Manual -

Reference - for the PacDrive™ M system.

PDM_OpMaProfi_04_us.FM

page 14 field bus PROFIBUS-DP PacDrive™ M

4 Diagnosis

Korrekturausdruck

4.2 Example for a Diagnosis Message

The diagnosis message 4731 „automatic bus deactivation“ is

shown.

Meaning of the diagnosis message:

class 4 error

diagnosis code 731

The meaning of the diagnosis code is further explained in the Pro-

gramming Manual - Reference - as shown below.

731 automatic bus deactivation

The Auto Clear bit in the master is set and at least one slave is

not exchanging cyclic I/O data. The error code entered after

"Err=" is equivalent to the error code of the parameter ErrorCode.

Cause:

Handling: Slave was switched off.

Reactivate slave.

Cause:

Handling: Faulty configuration of at least one slave.

Check configuration.

Cause:

Handling: Wiring error: Cable problem in the bus.

Check cable

Cause:

Handling: Wiring error: Faulty bus topology.

Check terminations,stubs, ...

PDM_OpMaProfi_05_us.FM

PacDrive™ M field busPROFIBUS-DP page 15

5.1 Transportation

Korrekturausdruck

5 Transportation, Storage, Unpacking

5.1 Transportation

¾Avoid shocks.

¾Immediately check units for transport damage and inform your

transport company, if necessary.

5.2 Storage

¾Store units in a clean, dry place.

Storage conditions:

air temperature between - 25 °C and + 70 °C.

temperature fluctuations max. 30 K per hour.

PDM_OpMaProfi_05_us.FM

page 16 field bus PROFIBUS-DP PacDrive™ M

5 Transportation, Storage, Unpacking

Korrekturausdruck

5.3 Unpacking

¾Check whether the delivery is complete.

¾Check all units for transport damage.

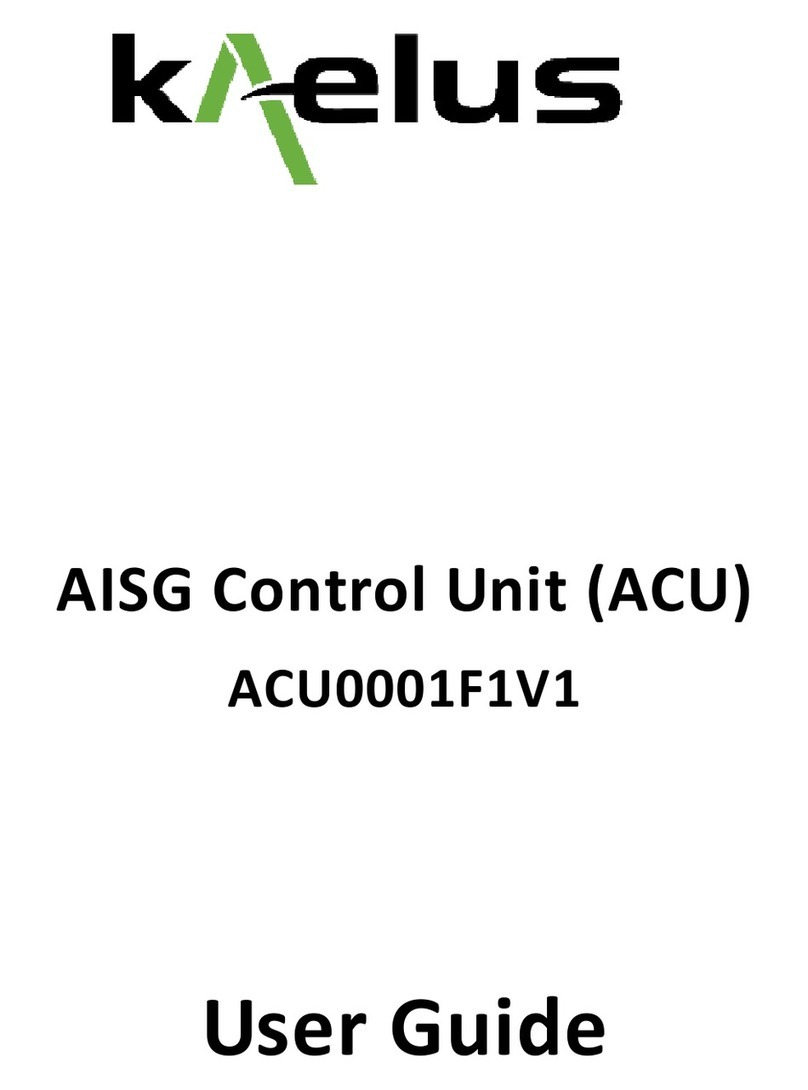

Type plate

The type plate contains all necessary information:

Fig. 5-1: Type plate of a MAx-4 PacController

Fig. 5-2: Type plate of a PROFIBUS-DP master optional module

PDM_OpMaProfi_06_us.fm

PacDrive™ M field busPROFIBUS-DP page 17

6.1 In General

Korrekturausdruck

6 Configuration, Parametrization

6.1 In General

The PacDrive M system is adapted to your task with the help of

ELAU’s programming and archiving software EPAS-4.

In EPAS-4, the system is configured and programmed according to

IEC 61131-3.

ATTENTION!

Detailed knowledge of the system and the IEC program is required

to make changes in the PacDrive M system. Therefore changes

should only be made by your machine supplier or ELAU staff.

6.2 Overview

6.2.1 System Structure

The image below shows the correlation of the individual

components (parameters, IEC program, field bus card, external

PROFIBUS-DP assembly group).

PDM_OpMaProfi_06_us.fm

page 18 field bus PROFIBUS-DP PacDrive™ M

6 Configuration, Parametrization

Korrekturausdruck

Fig. 6-1: Overview of PROFIBUS-DP communication

Access to IO data

The cyclic IEC program exchanges data with the IO range (direct

reading and writing).

The IO server matches this IO range against the field bus card.

When this matching takes place it is controlled via the parameter

IOTrigger. The matching is done with every trigger signal.

The field bus card exchanges data with the respective nodes in the

Profibus cycle. The Profibus cycle is influenced via the parameter

DataExMode. The Profibus cycle runs as fast as possible with

DataExMode = 0 or 1. With DataExMode = 2 the Profibus cycle

runs with the IOTrigger.

Ax-4

IEC program

Pr aTrigger();

call in IEC prg cycle

wTmpIn : WORD;

wIn : AT I%B0;

wOUT : AT Q%B0;

wTmpln := WIn;

wOUT := 1234;

IO range

IO Server

exchange in trigger cycle

IOTrigger

2

1

3

sercos cycle

field bus card

bus

cycle

in IO

trigger

cycle

IO data

exchange in

Pb bus cycle

internal

buffer

PB Bus

controller

input

output

control signals

IO data IO clamp

PROFIBUS-DP

bus coupler

clamps

DataEx ode

2

0

1

Buszyklus fertig

PDM_OpMaProfi_06_us.fm

PacDrive™ M field busPROFIBUS-DP page 19

6.2 Overview

Korrekturausdruck

6.2.2 Data Consistency

In case of access via the IO range, observe the following in terms of

data consistency:

Data consistency by priority control

To achieve data consistency across the entire IO range, the priority

of the IEC program task must be lower than that of the IO server(IO

map update). By default, the IO server has the priority 4.

Moreover, IOTrigger must be standing on 2 (IO matching by IEC

program) and DataExMode must be on 1 (synchronous buffered

firmware access to PB data) or 2 (synchronous direct firmware

access to PB data with cycle control).

NOTE

The data consistency can only be achieved for the IEC program

task that controls the triggering of the IO server.

Data consistency by checking the IO server state

To achieve data consistency across the entire IO range, you have

to use the function PrMaGetServerState or PrSlGetServerState.

Proceed as follows:

Trigger IO server.

Check IO server state.

If the IO server is waiting for the trigger, then data can be written

and read in the IEC program.

Moreover, IOTrigger must be standing on 2 (IO matching by IEC

program) and DataExMode must be on 1 (synchronous buffered

firmware access to PB data) or 2 (synchronous direct firmware

access to PB data with cycle control).

NOTE

The data consistency can only be achieved for the IEC program

task that controls the triggering of the IO server.

PDM_OpMaProfi_06_us.fm

page 20 field bus PROFIBUS-DP PacDrive™ M

6 Configuration, Parametrization

Korrekturausdruck

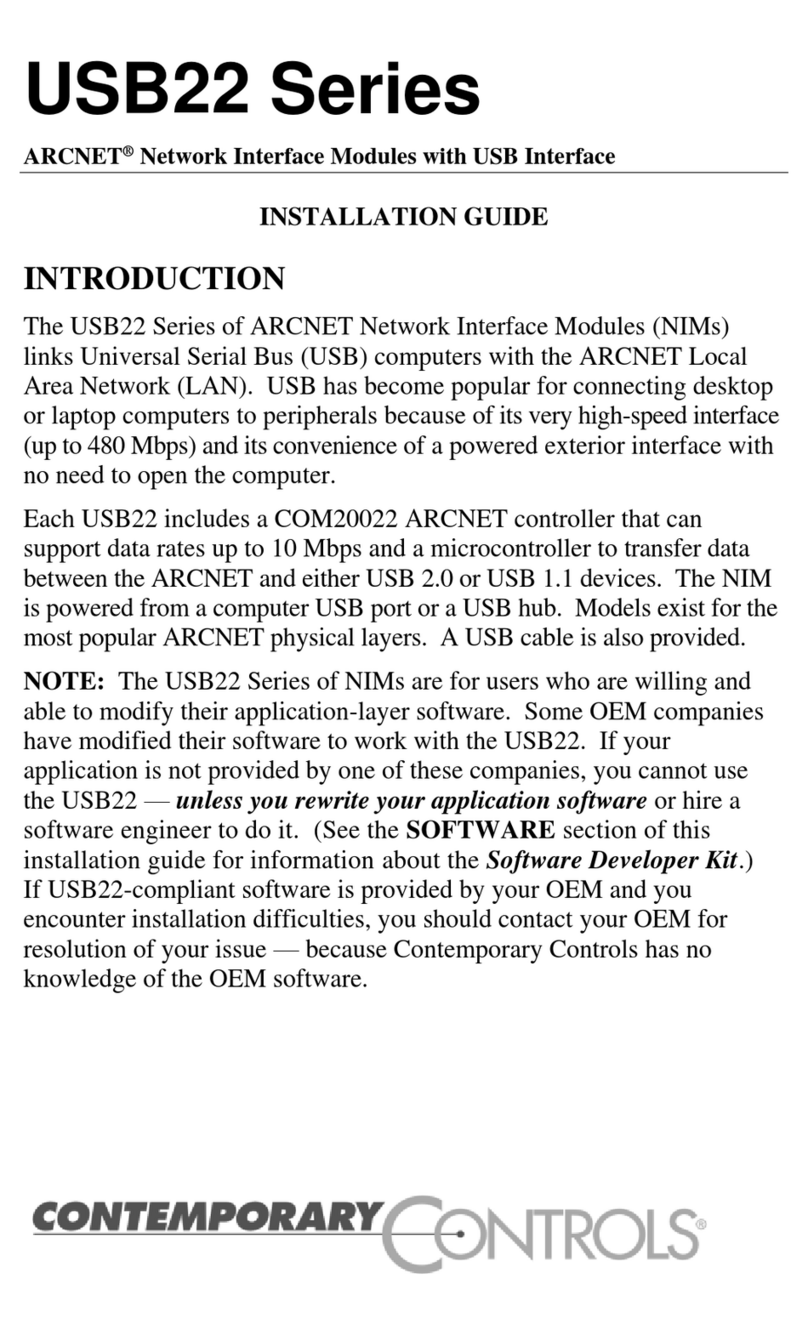

6.2.3 Information on the WAGO Bus Coupler

System structure

Fig. 6-2: Structure of a WAGO connector block

There are two cycles in which a data exchange is taking place.

The data are exchanged between the IO clamps and the bus

coupler via the internal K bus. This bus runs with a cycle time of

typically 2 ms with purely digital IO clamps. With analog clamps,

this cycle takes at least 5 to 10 ms. In addition, the cycle time rises

with the number of configured clamps on the bus coupler. The cycle

of the K bus can be synchronized with the Profibus cycle by means

of the Profibus parameter Process image update = “cycle

synchronous“.

The Profibus cycle is given by the master.With each Profibus cycle,

the data of the output clamps are received and the data of the input

clamps are sent.

Example on reaction time

In synchronous mode at least three Profibus cycles are necessary

to bring a reaction of an output value via a bridge to an input back

input

output

IO data

IO clamp

PROFIBUS-DP

bus coupler

clamps

K-Bus

Table of contents

Popular Control Unit manuals by other brands

Parker

Parker 221 Series owner's manual

DMP Electronics

DMP Electronics ITI 738I Installation and programming guide

MG

MG R30NCIT1 instruction manual

Telit Wireless Solutions

Telit Wireless Solutions DE910 Series Hardware user's guide

Contemporary Controls

Contemporary Controls USB22 Series installation guide

DOMIQ

DOMIQ Base Installation leaflet

Xycom

Xycom XVME-951 manual

Inovance

Inovance GL20-0016ETN user guide

Emerson

Emerson ACE95jr instruction manual

Philips

Philips LBB 2521/10 Installation and user instructions

Acorn

Acorn CONTROLS ST7017 Installation, operation and maintenance instructions

WEG

WEG SSW900-CMB-TCP-N Installation, configuration and operations guide