Elbi DXT Series User manual

___________________

1-Part #7051230-11/04 Rev. 2

“DXT” SERIES

THERMAL EXPANSION ABSORBERS

OWNER’S MANUAL

INSTALLATION INSTRUCTIONS AND GENERAL SPECIFICATIONS

This product has been designed for use with hot water supply system equipped with a back-flow

preventer and for water heaters (both direct and indirect fired). Its function is to absorb the

increased volume of the water when the system heats up.

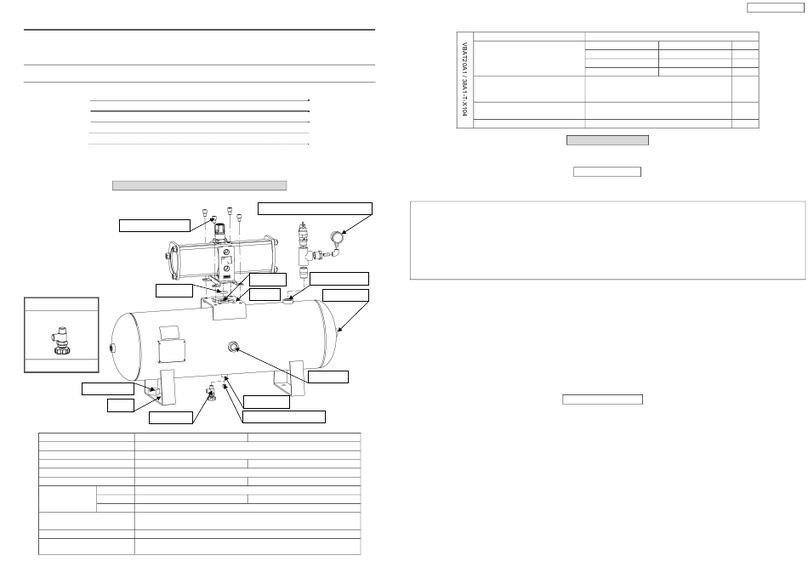

PRODUCT DIMENSIONS

Model No. Capacity

(US Gallons)

Connection

NPTM

Diameter Height Weight

(lbs)

DXT-8 2.1 ¾” 8 11 ¾ 5

DXT-18 5.0 ¾” 10 ½ 16 8 ½

DXT-24 6.5 ¾” 12 ¾ 14 10

DXT-35 9.0 1” 15 ¾ 15 ½ 16

DXT-50 13.5 1” 15 ¾ 20 19

Maximum pressure: 150 PSI – Maximum temp. 200GF

Factory pre-charge: 40 PSI

WARNINGS-

NThis product is designed for water storage at 200 degrees Fahrenheit and 150 PSI

NDo not exceed 80 PSI pre-charge pressure in this tank.

NThe pressure relief valve must be sized and installed according to Local Plumbing Codes and

must be set at 150 PSI maximum.

NSince the tank may eventually leak, make sure not to install without adequate drainage

provisions.

NAlways observe local plumbing codes. This equipment must be installed and/or serviced by

qualified professionals only.

NManufacturer does not accept any liability or other responsibility for personal injury or property

damage resulting from improper use, wrong installation and/or operation of this product or the

system where it is installed.

NInitial under-sizing or increasing temperatures from original settings may cause tank structure

damage and/or internal coating damage. Exceeding the recommended temperature and

pressure limits for this product voids any and all warranties.

NWe strongly recommend the use of a dielectric union when connecting to dissimilar

metals.

INSTALLATION-

1. Read this manual carefully before attempting to install this tank. Tank must be sized correctly

by a licensed plumber before installing. Under-sizing tank can lead to instances of over-

pressurization of tank and potential damage to tanks structure and internal coatings.

2. Inspect the tank for any damage. If the tank appears damaged or dented, return the tank where

you originally purchased it and ask for its substitution with another tank.

3. Determine the system pressure, then remove the plastic cap on the air valve and use a pressure

gauge to verify the pre-charge pressure of the tanks. Adjust if required.

4. Replace and tighten the plastic cup.

___________________

1-Part #7051230-11/04 Rev. 2

LIMITED WARRANTY

Elbi of America, Inc., warrants its DXT Series Thermal Expansion Absorber against manufacturing

defects in materials and workmanship for a period of 90 days from the date the DXT Series Thermal

Expansion Absorber is installed. This warranty only applies to Elbi of America's products when used

for their intended purpose and will be voided by misuse or improper installation. This product should

only be installed by a qualified plumber who is acquainted with the proper procedures for installing

Thermal Expansion Absorbers as well as applicable local regulations and/or building codes. This

Warranty is the sole warranty of the manufacturer. Any other Warranties express or

implied, including warranties of merchantability or fitness for use, are specifically

disclaimed and excluded. Manufacturer's sole obligation under this warranty is to repair or

replace those products found to be defective. Products repaired or replace under the terms of this

warranty shall be warranted for period of 90 days. In no event shall Elbi of America, Inc., be

responsible for: a) consequential, collateral or incidental damages; b) Labor costs associated with

product replacement; or c) lost profits associated with product replacement.

No employee, agent, dealer of distributor of Elbi of America, Inc., has any authority to change or

enlarge the terms of this warranty or to bind Elbi of America, Inc., to any obligation beyond the

limited warranty set forth above.

Warranty Handling Procedures

1. The warranty claim form must be filled out in its entirety.

2. Tanks claimed defective may be required returned to the factory, freight collect, for inspection.

3. All tanks returned for inspection must be intact.

4. PRIOR to returning any tanks to the factory a Returned Good Authorization number (RGA) must

be secured from Elbi Of America, Inc. Tanks returned without prior authorization will not be

accepted.

5. Manufacturer will not consider nor is responsible for any tanks lost in transit.

___________________

1-Part #7051230-11/04 Rev. 2

THERMAL EXPANSION TANKS – QUICK SELECTION TABLE

ENDING TEMPERATURE

System Max. Desired 110°F 120°F 130°F 140°F 150°F 160°F 170°F

Content press. (PSIG)

90 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8

30 100 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8

120 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8

90 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18 DXT-18

40 100 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18

120 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8

90 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18 DXT-18 DXT-18

50 100 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18 DXT-18

120 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18

90 DXT-8 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-18

75 100 DXT-8 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-18

120 DXT-8 DXT-8 DXT-8 DXT-8 DXT-18 DXT-18 DXT-18

90 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-24 DXT-24

100 100 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-18 DXT-24

120 DXT-8 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-18

90 DXT-18 DXT-18 DXT-18 DXT-18 DXT-24 DXT-24 DXT-35

120 100 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-24 DXT-24

120 DXT-8 DXT-18 DXT-18 DXT-18 DXT-18 DXT-18 DXT-24

90 DXT-18 DXT-24 DXT-35 DXT-50 DXT-50 DXT-50 2 x DXT-35

250 100 DXT-18 DXT-24 DXT-35 DXT-35 DXT-50 DXT-50 2 x DXT-35

120 DXT-18 DXT-18 DXT-24 DXT-35 DXT-35 DXT-50 DXT-50

For supplying minimum pressure 45 – 50 psig - Thermal Expansion Absorber must be pre-charged to 40 psig.

For relief valve setting: 125 psig – use 100 psig minimum pressure, 150 psig – use 120 psig minimum pressure;

Initial temperature 60°F.

We strongly recommend the use of a dielectric union when connecting to dissimilar

metals.

___________________

1-Part #7051230-11/04 Rev. 2

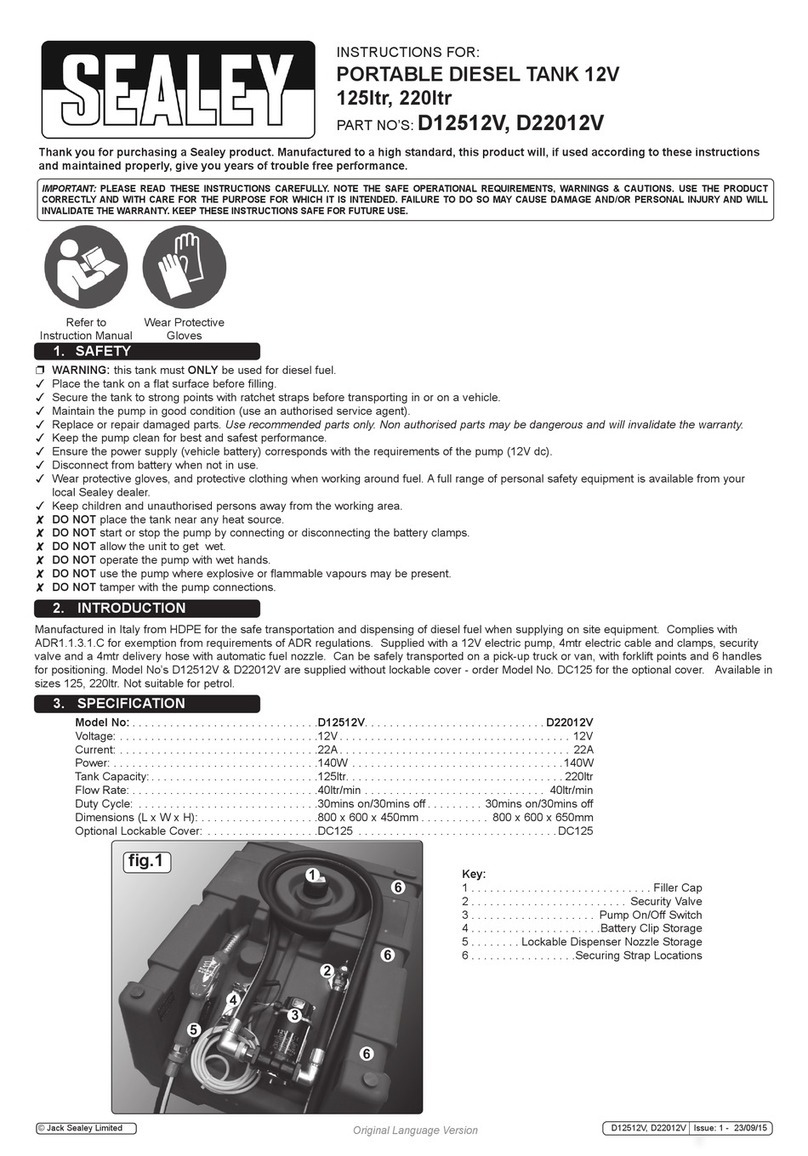

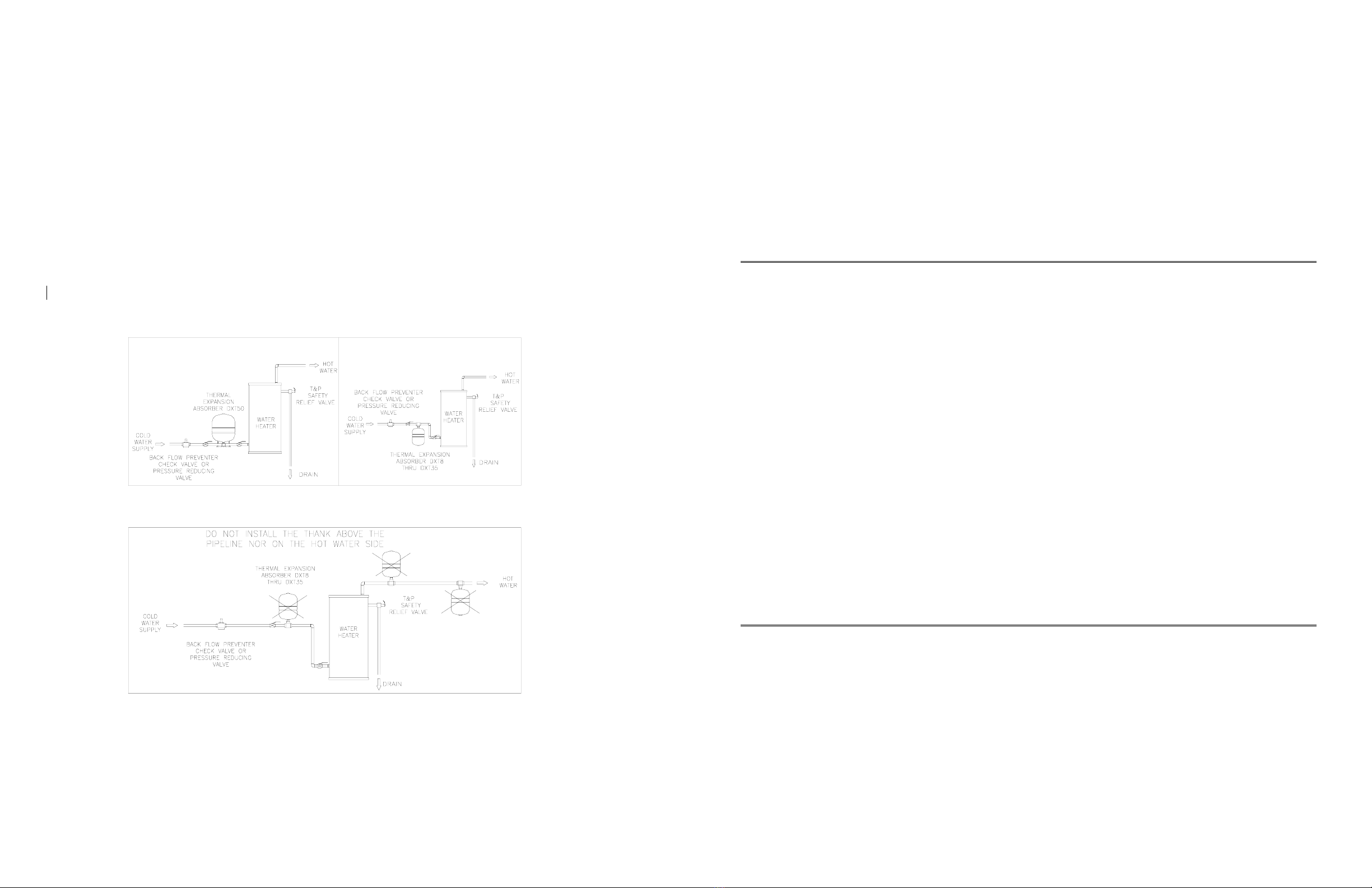

5. Connect the tank to the cold water inlet line to the water heater between the heater itself and

the back-flow preventer and/or any valve. Tank must be installed in vertical position with water

fitting facing up for optimum performance (see figure). If installed with water fitting facing

down, air can be trapped in tank and reduce performance of tank.

6. Draw water from the system until all air is removed, then turn the system on until it reaches the

desired temperature (see water heater manufacturer’s instructions).

7. Slightly open a hot water fixture and allow system to reach its operating temperature. Then

close the fixture. The DXT tank is now operational.

WARNING: Dielectric fitting must be installed between the water heater cold

water line and the expansion tank to assist in preventing electrolysis within the

Thermal Expansion Tank. This is not a requirement if PVC pipe is used to plumb

the hot water tank’s cold water line.

MAINTENANCE-

Periodic maintenance inspections of the complete heating system, by a professional licensed

installer, is required at least once a year. During such inspection, correct pre-charge of this tank

should be verified and adjusted if required. Failure to perform maintenance will void warranty.

CORRECT INSTALLATION

WRONG INSTALLATION

We strongly recommend the use of a dielectric union when connecting to dissimilar

metals.

This manual suits for next models

5