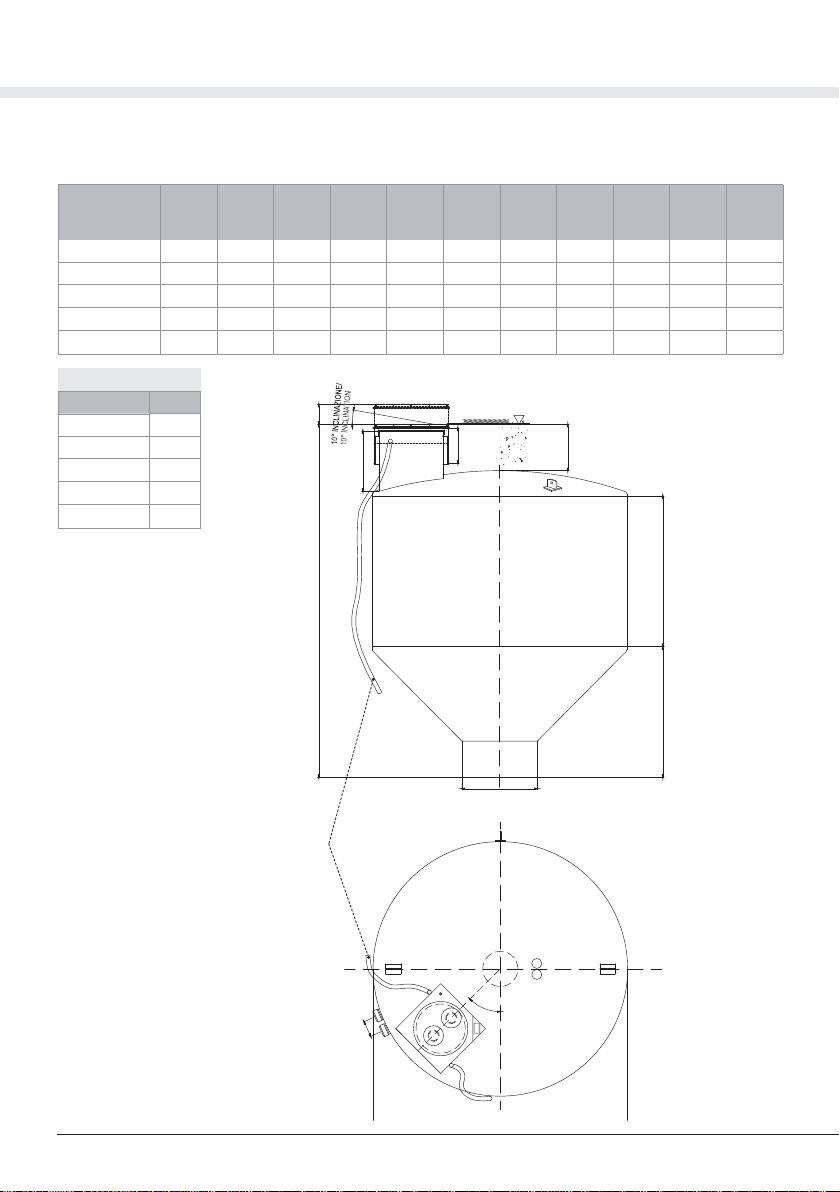

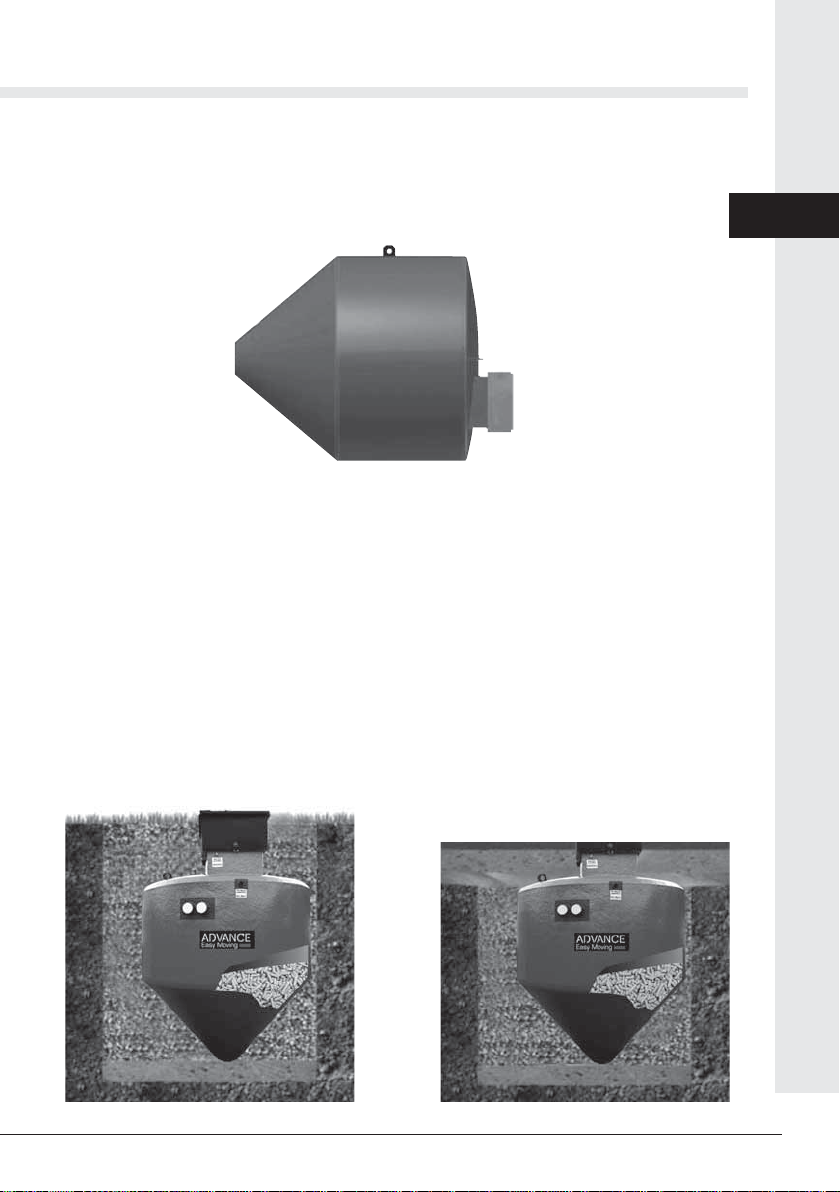

Underground storage tank

13/06/22 Rev:1.0.3

4

1 INTRODUCTION

Dear customer,

the manufacturer would firstly like to thank you for the choice you made in buying an our product, whose

technical features will certainly meet Your needs.

Our products have been designed and manufactured in total compliance with the current regulations, by

choosing the best materials to obtain durability and ease of use of the product.

We ask you, therefore, to read this manual carefully and completely, following strictly the instructions

contained herein.

1.1 Use of this manual

The instruction manual is a document drawn up by the manufacturer and is part of the product: it

integrates the specific rules of application and general rules for people, animals and objects safety. In the

event that the product is resold, handed over, rented or sold to others, it must always be accompanied

by this manual; therefore, it is recommended to use and keep it with care for the entire operative life of

the product.

The main objective of this manual is to make known the proper and safe way to use the equipment.

No part of this manual may be reproduced, copied, or shared in any way, without the written permission

of the manufacturer.

The manufacturer reserves the right to make improvements or modifications to this manual

and to the equipment at any time, without obligation to advise third parties.

2 Warnings

• Do not use the product for improper uses.

• This product must not be used by children or persons without the appropriate knowledge.

• Only use original spare parts.

• In order to be able to operate the product easily, it must be installed leaving a space around it

completely free of any obstructions.

• This product can be installed on pneumatic conveying systems for granular fuels derived from biomass for

other uses ask your seller for advice.

• Before first ignition, check that it is carefully installed.

• Never use the structure of the product as a supporting or fixing element for any other support or equipment.

• It is essential to ventilate the room where the product is installed when loading fuel into the tank.

• Remove the inspection doors only to carry out repairs and maintenance after disconnecting the power supply.

• The manufacturer disclaims all liability or warranty if the purchaser or anyone on his behalf makes any changes

or adjustments, however slight, to the product purchased.

2.1 Installer’s responsibilities

To ensure proper operation of the product, follow these guidelines:

• Only perform the activities described in these instructions

• Perform all activities in accordance with applicable regulations

• Explain to the user the operation and use of the product

• Explain to the user how to maintain the product

• Report to the user the potential dangers related to the use of the product