www.tti.com.au Freecall: 1800 816 277www.tti.com.au Freecall: 1800 816 277

5

TransLoc™& InterLoc™

PRODUCT HANDBOOK

General Safety Instructions

1. The TransLoc unit is designed and manufactured solely to carry water or benign fluids. Under no

circumstances should it be used for any other purpose. It must never be used for transporting fuel or

harsh chemicals.

2. The InterLoc unit is designed and manufactured solely to carry water or other fluids. Under no

circumstances should it be used for any other purpose. It must never be used for transporting fuel.

Confirm suitability with the TTi Compatibility Chart.

3. Only authorised and trained personnel are to operate this equipment. Operators must have read and

fully understood this manual before operating the TransLoc/InterLoc modules.

4. Do not operate this equipment while under the influence of alcohol or any drugs that could impair your

capabilities in any way.

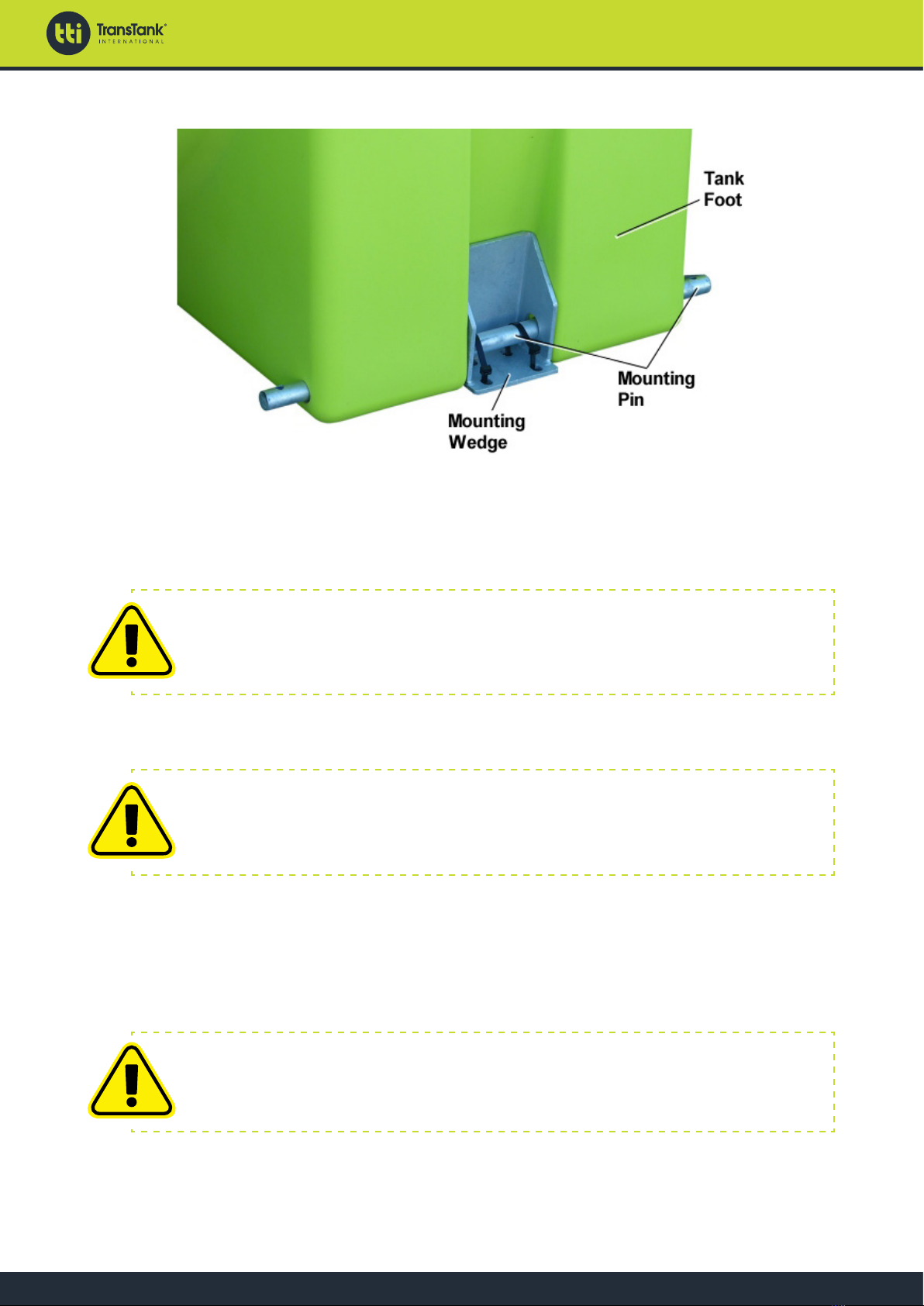

5. The TransLoc/InterLoc must be supported and secured on a flat surface, as specified in this manual.

In particular, each InterLoc module must be correctly supported, ensuring the sump does not take any

weight. The unit must be secured on a flat surface, as specified in this manual.

6. Personal Protection Equipment (PPE) must be worn when refuelling or operating a pump associated

with transferring fluid to or from your TransLoc/InterLoc. Exposure to excessive noise over an extended

period can cause impairment or loss of hearing.

7. Avoid diesel or unleaded petrol contact with skin and eyes, and avoid breathing vapours or mists. Refer

to the relevant Safety Data Sheet (SDS).

8. Ensure the capacity of the vehicle is suitable for the loaded mass of the TransLoc/InterLoc. Refer to the

vehicle’s operator manual for safe working loads and relevant safety instructions. Do not exceed the

carrying and braking capacity as specified by the vehicle manufacturer. As a guide, one litre of water

weights one kilogram (kg), therefore a full 12,000 litre TransLoc four-module unit will weigh in excess of

12,500kg.

9. The TransLoc/InterLoc tank is a confined space. Ensure compliance with OH&S requirements if entering

the tank.

10. Be aware of the height of the TransLoc/InterLoc when mounted on a vehicle. Keep clear of overhead

obstructions, such as bridges, low-hanging tree limbs and power lines.

11. Appropriate working at heights OH&S requirements must be followed if accessing the top of the tank is

required.

12. TTi recommends the LiquidLocker baffle system be used in TransLoc/InterLoc tanks.

13. All hoses and pipes attached to the TransLoc/InterLoc tanks must be flexible, to prevent damage due to

vibration from pumps and motors. Rigid pipes must not be coupled directly to the tank.

14. For TransLoc/InterLoc tanks fitted with 3” outlets, additional venting is required to prevent internal

negative pressure. This can be achieved by loosening or opening the tank lid.

15. The TransLoc/InterLoc must never be left unattended while being filled.

16. Care should be taken at all times, particularly when operating on rough or steep terrain. Drivers should

be aware of fluid surge affecting the centre of gravity.

17. The TransLoc/InterLoc has safety labels affixed to various locations on the unit. These labels should be

kept clean and legible, and replaced if damaged.

18. Any unauthorised modifications to this equipment may affect its function and create a serious safety

risk. Any unauthorised modifications will void any warranty on the unit.

19. Failure to observe the above safety precautions could void your warranty.