VBA-OM-S002-A

OPERATIONMANUAL VBAT-M36A

AIR TANK

VBAT20A1-T-X104 VBAT38A1-T-X104

Chinese Pressure Vessel Code Compliant Product

INDEX

- Description and specifications of the components

- Cautions for operation

- Connecting Air tank and Booster regulator

- Regular check

Thank you for choosing this SMC product. This operation manual provides essential information to ensure its optimum performance and

lifespan. Please read it before using the product. Keep this manual accessible and refer to it if problems occur. Please refer to the latest

catalogue, drawings and maintenance procedures for product configuration and specifications.

- Description and specifications of the components

Table 1 Specifications

Model VBAT20A1-T-X104 VBAT38A1-T-X104

Max. operating pressure 1.0 MPa

Material Q235B

Tank capacity 22 L 38 L

Temp. range 0 to 75oC

Tank mass 15 kg 26 kg

IN 1/2

OUT 1/2 3/4

Port size

Drain 1/4

Painting - Outer surface: Baking finish - Painting: Silver gray

- Inner surface: Phosphate coating film treatment

Applicable booster regulator VBA2 / VBA4

Applicable standards TSG R0003-2007

Supervision Regulation on Safety Technology for Simple Pressure Vessels

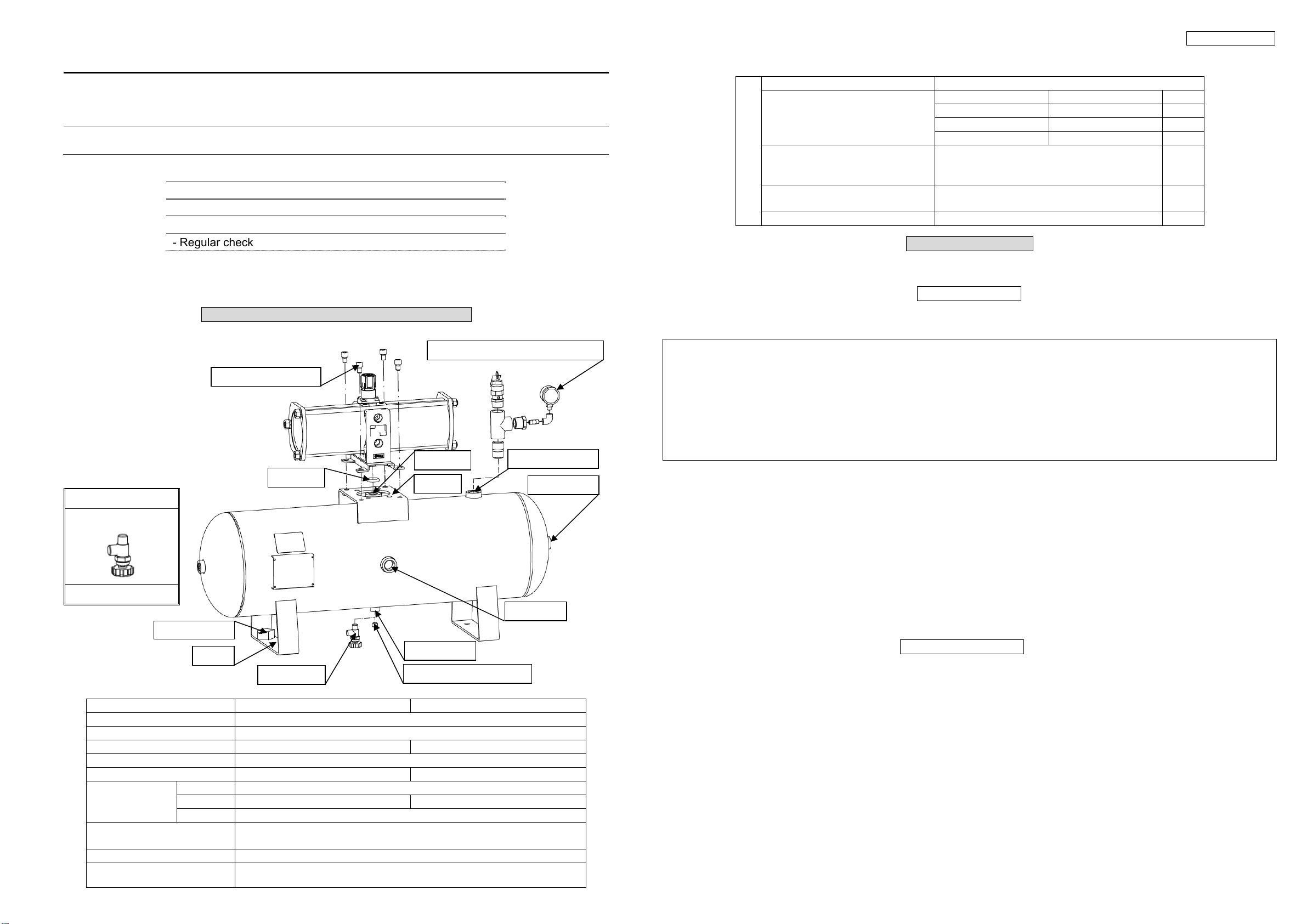

Table 2 Accessories

Part name / Part No. Components

Anchor bolt, nut For VBA2 / 4 mounting 4 pcs.

Hex. socket head bolt For VBA2 / 4 mounting 4 pcs.

O-ring For VBA2 / 4 mounting 1 pc.

Accessory set

VBAT20A-Y-3

Hex. socket head plug For Drain port 1 pc.

Pressure gauge and safety valve set

VBAT-T

Safety valve

Pressure gauge

Piping components for tank connection

1 pc.

1 pc.

1 pc.

Operation Manual/VBAT-M36

Operation Manual/VBAT-M36C

Operation Manual (Japanese)

Operation Manual (Chinese)

1 copy

1 copy

VBAT20A1 / 38A1-T-X104

Product certificate Certificate 1 pc.

- Operating precautions

- To ensure safety and optimum operation, confirm the product’s specifications before use. Operating product out of the scope of its

specifications may cause failure or accident.

△

! WARNING Design precautions

(1)Applicablestandard

- This air tank conforms to laws and regulations in China.

When this tank is used in countries outside of China, confirm that it is compliant with the laws and regulations of those countries.

Astheairtankiscompliantwith"RegulationsonSafetySupervisionofSpecialEquipment",thefollowingproceduresare

requiredwhenusingtheproduct.(Referto"RegulationsonSafetySupervisionofSpecialEquipmentChapter3"fordetails.)

(1) To confirm that the pressure is set at the set value, submit the safety valve for air tank to the nearest Safety Inspection Bureau, and

store the safety valve together with the Check ticket.

(2) Before installing the air tank, inform the nearest Special Equipment Safety Supervision Department in writing.

(3) When installing the air tank, it should pass the inspection performed by the Inspection and Measurement Agency authorized by the

Special Equipment Safety Supervision Department based on the safety technical standard. [Documents supplied with the air tank, the

Check ticket of the safety valve and the certificate supplied with the pressure gauge are necessary.]

(4) Register the product and related documents with the Special Equipment Safety Supervision Department before using the device or

within 30 days after starting to use the device.

(2)Operatingpressure

- Use this air tank at maximum operating pressure of 1.0 MPa or less.

(3)Connection

- Install a filter or mist separator on the OUT side of the air tank.

Although phosphate coating film treatment is applied to the inner surface of the VBAT∗A1-∗-X104, rust may be generated if the product is

used for a long time.

△

! CAUTION

- Consider the operating conditions, and use this air tank within the specification range.

- Do not supply or discharge air suddenly. This will cause the temperature to decrease due to air expansion, and the temperature may

exceed the operating temperature limit of the air tank. If flow speed becomes faster, a loud noise may be generated by the friction inside the

tube.

- When a booster regulator is used, select the appropriate product model according to the selection procedure of the energy saving program

or How to Order in the catalog.

△

! CAUTION Installation precautions

(1)Accessories

- Accessories are supplied attached to the foot of the tank. Once removed, take care not to lose any of the parts.

(2)Installation

- Operate the air tank fixed.

- To mount the air tank on a floor surface, use the four holes of φ13 to secure the tank with bolts (order separately) or anchor bolts (supplied

with the product).

- Mount the air tank horizontally. If the tank is mounted vertically, the load will be concentrated on one foot, leading to breakage.

- If the air tank is used where there is vibration, it may lead to breakage of the foot and the body. Do not use it where there is vibration.

- A lot of energy builds up if high pressure is applied to the air tank. If the air tank breaks and air is discharged, a large blast of air will be

generated and is very dangerous. Install the air tank where operations or equipment will not be affected.

- When connecting a booster regulator with an air tank, refer to the procedure “Assembling the air tank and the booster regulator”.

(3)Piping

- Connect piping so that the piping load and vibration are not applied to the tank socket.

(4)Safetyvalve

- Pressure setting cannot be changed as it is fixed.

(5)Drainvalve

- The drain valve needs to be prepared by the user. SMC related product VBAT-V1 is available.

Related products

VBAT-V1

Drain valve

Order it separately

O-ring

IN port

Stand

Air tank

OUT port

Spare port

Accessory set

Drain port

Foot

Hex. socket head bolt

Hex. socket head plug

Drain valve

Pressure gauge and safety valve set

Safety valve port