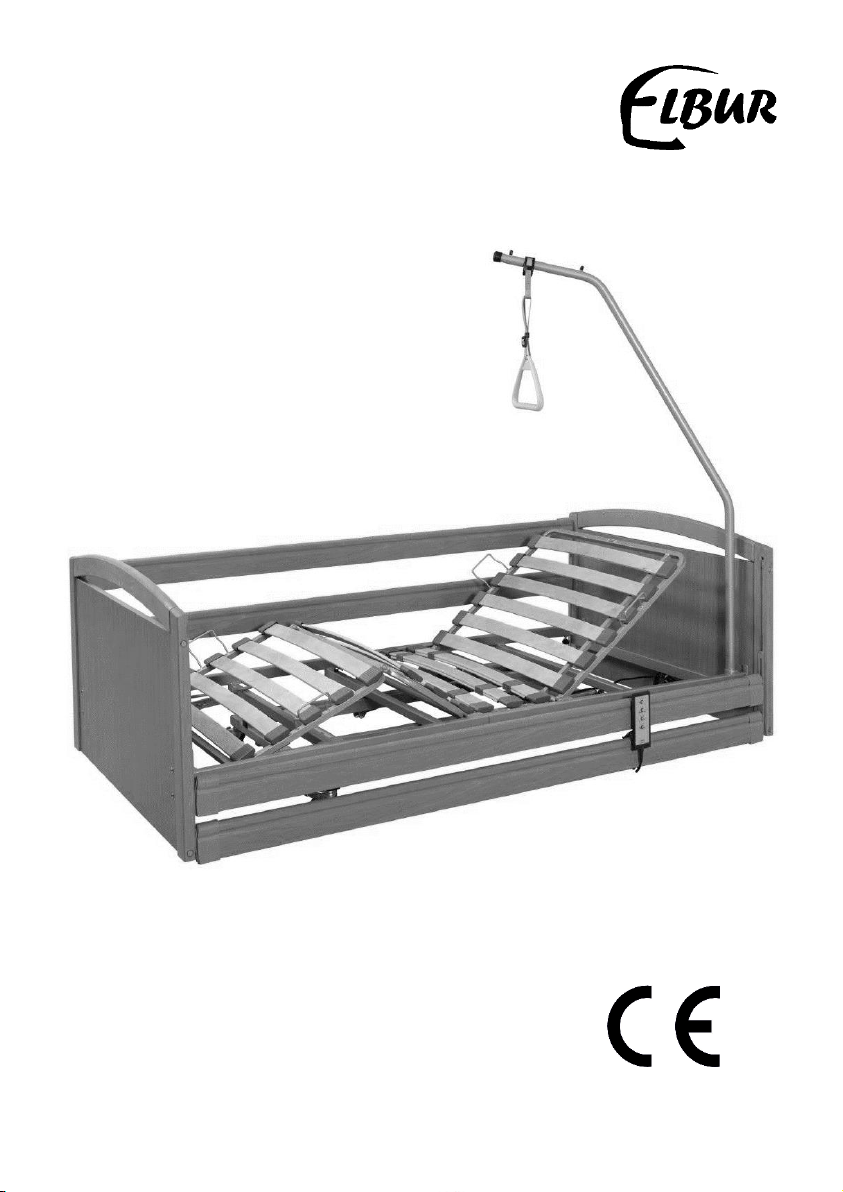

Elbur PB 636 IV User manual

INSTRUCTION FOR USE

ELBUR Nursing Beds:

PB 636 IV,

PB 636 IV with axional brake

Dear Customer,

Congratulations on having chosen a quality ELBUR nursing bed which will

certainly fully meet your expectations. We would like to take this opportunity

to thank you for showing such confidence in our company and purchasing one

of our products.

Due to designing and manufacturing in accordance to the latest

technological development at the time of delivery, PB 636 IV nursing bed is

very durable and ensure essential performance. It is used to alleviate

and compensate injuries and disabilities for older, frail and handicapped

people. It also combines modern design and technical accuracy with

user-friendly handling. PB 636 IV nursing bed meets the varying needs

of patients and professional caregivers.

Based on great experience of Elbur company, we can guarantee high

quality and reliability of our products. In order to meet customer

expectations we provide wide range of bed height-adjustment. We also care

about attractive design, as well as matching furniture systems

and accessories, which can be chosen depending on the individual needs.

This instruction manual provides important information regarding safe

operation for patient, user and operator. It will help to learn about all

functions of our products and also describes: assembling, care

and maintenance of the nursing bed and operating of the adjustment

controls. Read these instructions carefully and follow them exactly in order

to provide reliable service and avoid damage or incorrect operation.

Remember to keep it for future reference.

We reserve the right to change technical specification to the ELBUR

nursing bed detailed in this instruction, without obligation to update or

replace the product.

If you have any questions, please do not hesitate to contact your local

distributor or Elbur customer service through our website. We will do our

best to fulfil your needs.

Team Elbur

Table of contents

1.0. Product description..................................................................... 6

1.1. Purpose and range of application ............................................... 6

1.2. Technical specification.............................................................. 7

1.3. Labelling of nursing beds .......................................................... 8

1.3.1. Name plates...................................................................... 8

1.3.2. Information labelling .......................................................... 8

1.3.3. Explanation of symbols used on name plate ........................... 9

2.0. Safety information ..................................................................... 9

2.1. Definitions of involved people.................................................... 9

2.2. Marking and safety signs .........................................................10

2.3. General advice and limitation of use..........................................10

2.4. Potential risks and warning messages........................................10

2.4.1. General information ..........................................................10

2.4.2. Electrical components information .......................................11

2.3.3. Information for care personnel............................................12

2.3.4. Assembly information ........................................................13

2.3.5. Service information ...........................................................13

3.0. Scope of delivery ......................................................................14

4.0. Electric components ..................................................................15

4.1. The scissor lift drive unit .........................................................15

4.2. Back rest / foot rest drive units ................................................15

4.3. Control box ...........................................................................15

4.4. Hand switch...........................................................................16

5.0. Accessories and spare parts........................................................16

6.0. Assembly .................................................................................17

6.1. Location requirements.............................................................17

6.2. Preparation ...........................................................................17

6.3. Assembly of mattress support platform on the scissor lift .............17

6.4. Location of drive units and control box for mattress support platform

..................................................................................................18

6.5. Assembly of mattress support platform drive unit –adjustment of

foot rest section ...........................................................................19

6.6. Assembly of mattress support platform drive unit –adjustment of

head rest section ..........................................................................19

6.7. Connecting electric components ...............................................20

6.8. Cable routing .........................................................................20

6.9. Testing of adjustment functions................................................21

6.10. Assembly of the end boards ...................................................21

6.11. Assembly of side rails............................................................21

6.12. Assembly of the lifting pole ....................................................22

7.0. Operating of the nursing bed ......................................................22

7.1. Electric mattress support adjustment ........................................22

7.2. Side rails operating.................................................................24

7.3. Setting the springiness of mattress support platform ...................24

7.4. Castors operating ...................................................................24

7.5. Movements of nursing beds .....................................................25

7.6. Emergency lowering of the back rest .........................................25

8.0. Maintenance.............................................................................26

8.1. Disinfecting ...........................................................................26

8.2. Cleaning and care...................................................................26

9.0. Service ....................................................................................27

9.1. Troubleshooting .....................................................................31

10.0. Transport and storage..............................................................33

11.0. Disposal.................................................................................33

12.0. Warranty ...............................................................................33

13.0. Notes

.....................................................................................33

Table of contents

Other Elbur Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual