Elby Designs MonoWave(X) User manual

MonoWave(X) Build Guide

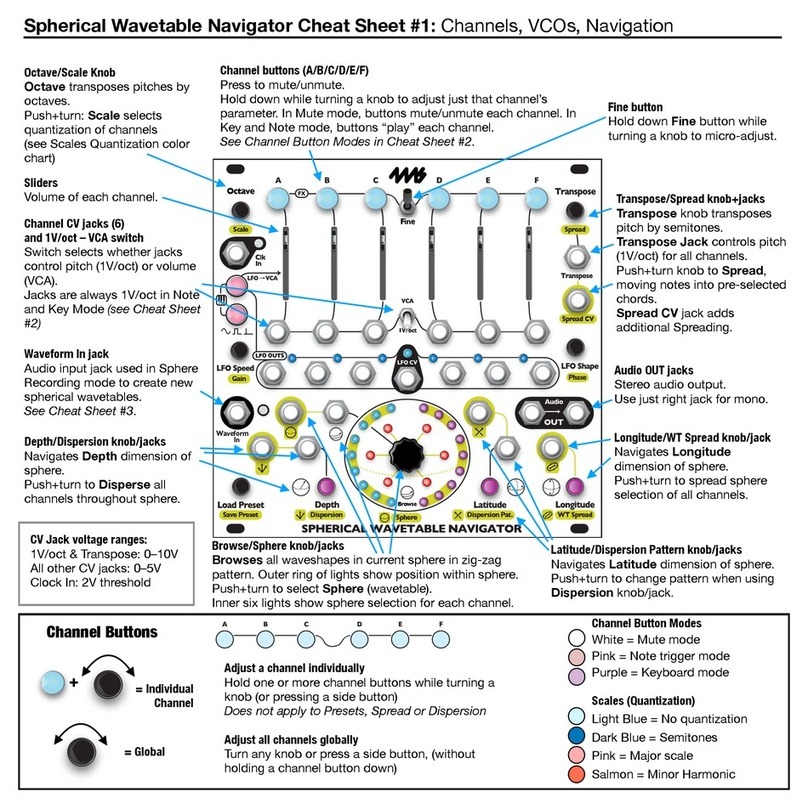

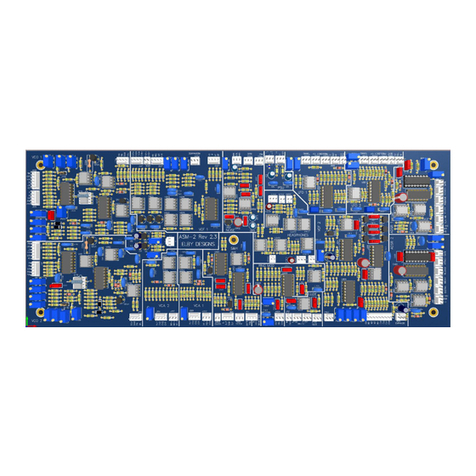

Main PCB Assembl (3D Model)

Install all components as per General Construction Notes.

When installin U4, form its le s first and then mount to the PCB with its heatsink and fixin

hardware. Once securely installed, solder in to place.

R2 should be positioned over the cut-out in the PCB and raised to be about 1-2mm clear of

the PCB.

Refer to the 3D Model for positionin of the wire links in P801 and P1001

Test Points (TPxxx) should be left clear. This will assist with ‘pokin ’ a test probe tip in to

the test point and help prevent the probe from wanderin .

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

2 of 14

MonoWave(X) Build Guide

Displa PCB Assembl (3D Model)

Refer to the PCB overlay and cut the track on the topside to P114_1 (this should already be done

in the factory).

Install all components except the 8x pushbutton switches, P120, 3x LEDs and 1x LCD plus header.

We recommend placin all the pots in to place without solderin . Then place the Front Panel over

the controls to ensure that all the pots are correctly ali ned on the Display PCB. Carefully turn the

assembly over and solder the pots in to place.

Repeat with the 2x rotary switches. Check that the switch stops are correctly located in the ‘STOP

5’ position and secure usin the nuts supplied. The nuts for these are purely to secure the ‘STOP’

plate and are not used to secure the switches to the panel.

Install P120 and check that the front set of le s on P120 are not touchin the rear set of le s. Once

satisfied, solder in to place.

Refer to the PCB overlay and fit a wire link between P114_1 and C2_1.

To help reduce the cost of the MonoWave (X) we are no lon er usin push-button switches fitted

with ‘V-brackets’.

Install but do not solder the 8x switches, ensurin that the markin s ‘C NO NO’ are visible at the

front (nearest bottom ed e of the Display PCB), and carefully offer the PCB up to the front panel.

With the panel sittin squarely to the pots (you mi ht like to fit 2 or 3 nuts to ensure the panel

remains in place) raise each switch one by one and fit a nut to the switch. Do the nut up so that it is

JUST flush with the top of the panel, the le s of the switches should still be in the Display PCB and

should finish flush with the bottom of the Display PCB. Repeat for the other 7 switches. Turn the

assembly over and rest on a suitable support to allow easy fin er access to the switches. Start at

the switches furthest from you, push a switch up until the le s are in their Display PCB locations

and the switch nut is firmly a ainst the panel. Solder tack the middle pin of the switch and repeat

for the other 7x switches. Check that all switches are suitably mounted and then solder all the

remainin le s, and finish off by reflowin the tacked centre le s.

Install the LCD as follows:-

1. Install the 4x 8mm spacers usin the 4x M2.5x16mm bolts.

2. Install, but do not solder, the header for LCD1.

3. Install LCD1 and secure usin the 4x M2.5 Nuts.

4. Check that the header is seated properly on the Display PCB and solder in to place startin

with the pads on the LCD and then movin to the pads on the Display PCB

Fit the lens mounts to the Front Panel. Install, but do not solder, the 3x LEDs.

Turn the assembly over and position the LEDs in to their respective mounts. Solder in to place.

We recommend fittin the front panel to the enclosure BEFORE mountin the Panel PCB to allow

easier access to the securin bolts.

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

3 of 14

MonoWave(X) Build Guide

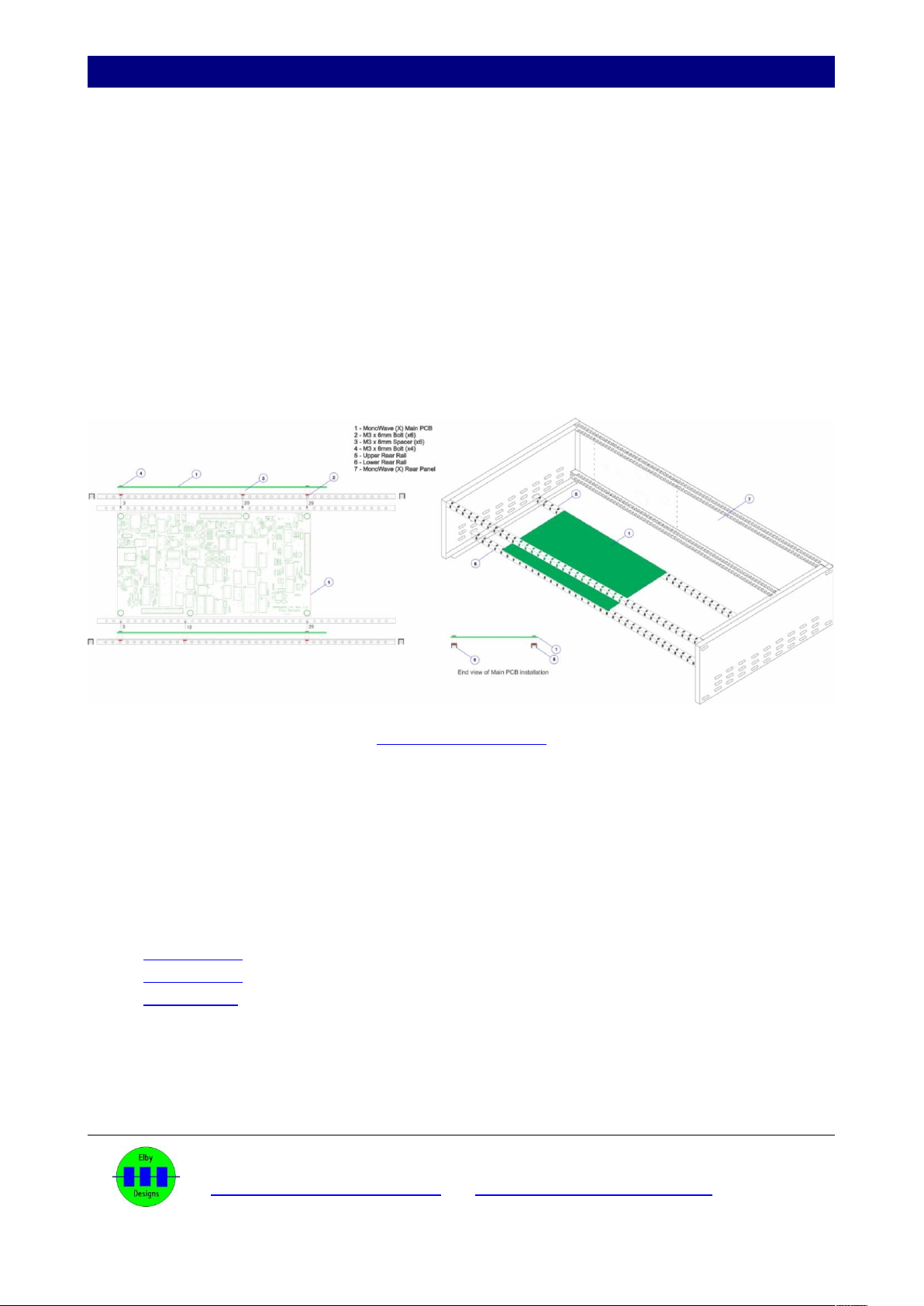

Enclosure Assembl

NB: We recommend usin the 2 carry

handles supplied to attach the front panel

as they help provide protection to the

panel controls. However, fittin these front

handles will mar inally restrict access to

the two ri ht-most panel controls. If this is

not desired or you prefer a more open

front panel, then secure the panel usin

the M5 bolts and M5 nuts, mountin the

bolts from the front panel side.

Attach 2x Support Rails to the Rear Panel usin M6x 10mm Bolts and M3 nuts

Rear Panel Pre-assembly

Mount the assembly on to the 2 side panels usin 4x M3 Flan e Screws. Ensure that the

3 rows of slots on each Side Panel are at the bottom of the case. You can either mount the

flush to the outside ed e of the Side Panel or to the back of the slots, this will help protect

connectors from bein squashed and provide more clearance at the back of the unit.

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

4 of 14

MonoWave(X) Build Guide

Countin from the left, fit M3x8mm Spacers usin M3x6mm Screws at positions 3 and 29

on both Support Rails

.

Fit M3x8mm Spacers at the 12th position on the front Support Rail and 20th position on the

rear Support rail and secure usin M3x6mm Screws.

.

Fit the Front Panel usin your chosen method. Before finally ti htenin the securin bolts,

ensure that the Front Panel is centred vertically to the enclosure.

Install the main board and secure usin 4x M3x6mm Screws.

Mount the Main PCB assembly and secure to the side panels usin 4x M3 Flan ed

Screws. We recommend usin the 4th and 8th slots from the front as this will ive

clearance to work on the front panel.

Main PCB Assembly

Attach the Panel PCB to the Front Panel.

Fit the 3x IDC cables between the main board and the panel board. The central and ri ht-

hand cables should be folded to allow them to sit neatly in the chassis.

Drawin s for the 3 cables:

Cable J101

Cable J102

Cable J103

Fit the Rear Panel component assemblies and plu on to their respective headers on the

main board.

The MonoWave(X) should now be calibrated after which the top and bottom covers can be

fitted.

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

5 of 14

MonoWave(X) Build Guide

CALIBRATION

Initial Setup

Set the followin controls to maximum (CW):-

OSCILLATOR-1 OZ

OSCILLATOR-1 SUB

OSCILLATOR-2 OZ

OSCILLATOR-2 SUB

VCF-EG SUSTAIN

VCA-EG SUSTAIN

Set the followin controls minimum (CCW):-

TUNE

VCF ENVELOPE

VCF NOTE

VCF VELOCITY

VCF Q

VCF-EG ATTACK

VCF-EG DECAY

VCF-EG RELEASE

VCA-EG ATTACK

VCA-EG DECAY

VCA-EG RELEASE

VCA-EG VELOCITY

VOLUME

Set the followin controls ‘0’

DETUNE

OSCILLATOR-1 OCTAVE

OSCILLATOR-2 OCTAVE

Set VCF CUTOFF to its centre position ‘5’

Connect a MIDI Controller to MIDI IN

Connect AUDIO to a suitable amplifier

LCD Contrast

Apply power and adjust P1301 for optimum contrast.

MIDI-CV Module

Trimmer Module Function

P401 MIDI-CV V/Octave Scalin

Monitor TP401 and adjust P401 for an output of -10.667V

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

7 of 14

MonoWave(X) Build Guide

Voltage Controlled Amplifiers (VCA1 and VCA2)

Trimmer Module Function

P1111 VCA1 – Velocity Offset

P1201 VCA2 – Main Offset

Adjust P1201 full CCW

Play and release a MIDI Note near Middle C.

Adjust VOLUME for a suitable listenin level.

Adjust P1201 CW until the note just cannot be heard.

Monitor U1102_14 and adjust P1111 for 5VDC.

VCF CV Scaling

Trimmer Module Function

P901 VCF CV Scale

P902 VCF EMPHASIS Trim

Set the followin controls minimum (CCW):-

OSCILLATOR-1 SUB

OSCILLATOR-2 OZ

OSCILLATOR-2 SUB

Play and hold a MIDI Note and adjust P902 until the output just starts to self-oscillate.

Repeat to check for consistency across a ran e of MIDI Notes.

Set the followin controls to their mid-position:

VCF CUTOFF

VCF Q

Set the followin controls minimum (CCW):

VCF VELOCITY

VCF-EG SUSTAIN

Set VCF ENVELOPE to maximum (CW).

Adjust VCF-EG ATTACK and VCF-EG DECAY to ive an envelope control of the filter so

that you can hear it sweepin throu h it filter ran e.

Play and hold a low MIDI Note (e C2)

Adjust P901 so that after the envelope has complete you can just hear the note

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

8 of 14

MonoWave(X) Build Guide

Set CUTOFF FREQUENCY control to 4.

Rotate EMPHASIS control clockwise.

Filter re eneration should start with the EMPHASIS control is between 7 and 8.

If it does not, adjust the REGEN CAL trimmer

Set CUTOFF FREQUENCY control to 4.

Set EMPHASSIS to 10

Compare output with A440Hz and adjust RANGE trim for zero beats

Turn of A440 and rotate CUTOFF FREQUENCY fully clockwise

Amplitude should be fairly stable and frequency should increase to 16kHz

Rotate CUTOFF FREQUENCY and check that frequency reaches 400Hz before

re eneration stops.

Turn on A440

Adjust CUTOFF FREQUENCY for 1760Hz (2 octaves above A440)

Adjust Filter Scale trim for zero beat at A220

ELBY Designs - Laurie Biddulph

3 Therese Street, Bridport, TAS 7262, Australia

elby-desi ns@bi pond.com http://www.elby-desi ns.com

12 of 14

Other manuals for MonoWave(X)

1

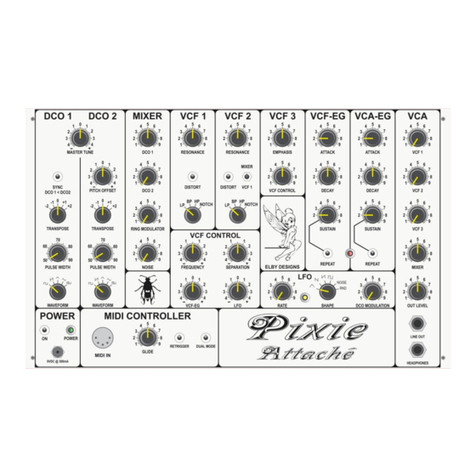

Other Elby Designs Synthesizer manuals

Elby Designs

Elby Designs CGS738 Instructions for use

Elby Designs

Elby Designs EURO STAGE ES30 Instructions for use

Elby Designs

Elby Designs EURO SERGE ASM301 Instructions for use

Elby Designs

Elby Designs ASM-2 Instructions for use

Elby Designs

Elby Designs EURO-SERGE User manual

Elby Designs

Elby Designs Pixie Attache EDP WASP User manual

Elby Designs

Elby Designs MonoWave(X) User manual

Elby Designs

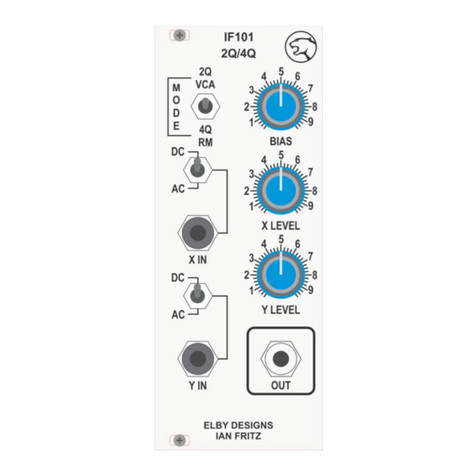

Elby Designs IF101 2Q/4Q Instructions for use

Elby Designs

Elby Designs ASM321 Instructions for use