Elceram NITRIDE 1/10 User manual

User Manual - Full

Version

for Electronic Speed Controller NITRIDE 1/10

Dated: 23.10.2023

T e latest version of manual you will find ere

ttp://www.elceram-rc.cz/download/

Datum of Revision Description

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

MANUAL

CONTENTS

1. Introduction

2. Warning and Safety

3. Key Features and Specifications

4. Installation

5. Compatible Devices

6. Connections

7. Main Screen Description and Basic Control of ESC

8. Programming and Screens Sc ema

9. RX Calibration

10. Temperature and Voltage Calibration

11. Zero Timing / Blinky / Stock Mode

12. T e Motor C oice

13. Troubles ooting and EVENTs Description

14. Display and Maintenance

15. Option parts

16. Recycling

17. Conformity and Declarations

1.

Introduction

T ank you for purc asing NITRIDE 1/10 and for your trust in ELCERAM product. By t is decision, you ave c osen

a new generation electronic speed controller (ESC) for brus less motors developed especially for 1/10 RC cars,

endowed wit many unique features and functions.

Using t e advanced tec nologies, NITRIDE is a ig -performance device requiring a professional approac .

Improper usage and unaut orized modification to our product is extremely dangerous and may damage t e

product and related devices. We, ELCERAM, are not responsible for any damages occurred by unprofessional or

unsuitable way of using our product.

Please, take your time and read t e following instructions carefully before you start using your ESC!

We ave t e rig t to modify our product design, appearance, features and usage requirements wit out notification.

2.

Warning and Safety

Please read all instructions carefully before using t e

product!

To avoid s ort circuits, ensure t at all wires and

connections are well insulated before connecting t e

ESC to related devices. Ensure all devices are well

connected to prevent poor connections and avoid

damage to your electronic devices.

Read t roug t e manuals of all power devices and

c assis and ensure t e power configuration is

rational before using t is unit.

Please use a soldering iron wit t e power of at least

60W to solder all input/output wires and connectors.

T e device as to be disconnected from battery if not

used!

It is t e ig -power electronic device, please double

c eck t e polarity of battery interconnection! We

are not responsible for a product damage caused by

t e incorrect connection to t e battery.

It is professional top level racing product and it is

extremely important to double c eck t e setting

before use!

T is product is not a toy and it is not intended for

c ildren. Users under 18 years s ould use t is

product only wit t e direct supervision of a

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

responsible and knowledgeable adult. Keep t is

product away from t e reac of small c ildren.

Do not touc t e device Immediately after using, it

can generate ig temperatures. If t e temperature

of ESC is ig er t an 70°C, t e buttons can be ot.

Please, wait until it cools down to 50°C before you

switc it off by button, or switc t e ESC from t e

battery for switc off.

Stop t e usage immediately once t e temperature of

t e ESC exceeds 130°C, as t is may cause damage to

bot t e ESC and motor. We recommend setting t e

“ESC T ermal Protection” to 130°C (t is refers to t e

internal temperature of t e ESC).

Never leave t e device unsupervised w ile it is

switc ed on, in use or connected wit a power

source. If a defect occurs, it could cause a damage or

fire of t e product or t e surroundings.

Never wrap your product in plastic film, metal foil or

similar, if it is switc ed on.

Never allow t is product to come in contact wit

water, oil, fuels or ot er electroconductive liquids.

Never place t is product near t e source of fire or

very ig temperatures.

Never switc t e device off from t e battery w ile

pressing t e t rottle.

We recommend to use NITRIDE toget er only wit

t e compatible devices listed t e c apter 4. Usage

NITRIDE wit ot er devices was not tested yet and

we are not responsible for any disfunctions or

damages caused by using NITRIDE toget er wit

unaut orized devices.

3.

Key Features and Specifications

Developed especially for 1/10t professional RC cars.

TFT LCD color display wit resolution 160 x 80 pixels.

Size: 38,3 (L) x 34,3 (W) x 24,5 (H) mm.

Weig t: 50 g wit out wires / 90 g wit wires AWG13

- 180 mm.

70 % of weig t located in bottom side of ESC.

Power supply: 2S LiPo.

Current cont. / pulsed: 180 A / 1500 A.

BEC: 7,4 V fixed, 4 A cont. / 10 A peak at 125 °C.

Extreme low internal resistance based on silver

conductive layer.

Advanced Cooling Tec nology based on Aluminium

Nitride Ceramic Cooler.

Designed for ig level RC racing.

Zero Timing (Blinky Mode) supported.

For sensored BLDC motors from 4.5T up.

Designed and produced in Czec Republic.

Revolutionary easy Rx calibration.

Realtime monitoring: battery voltage, ESC and motor

temperatures.

Self-diagnostic before t e race: motor temperature,

sensor cable, battery.

Post-race data evaluation.

Easy programming: t rottle, brake, boost and turbo

timing, all angle and many ot er functions.

Race data logging, temperature and ot er curves,

istograms and more.

Adjustable maintenance reminder for easy c eck.

No programming interface needed.

4.

Compatible Devices

We recommend to use NITRIDE toget er only wit t e compatible devices listed below. Usage NITRIDE wit ot er

devices was not tested yet and we are not responsible for any disfunctions or damages caused by using NITRIDE

toget er wit unaut orized devices.

Transmitters

Receivers

Motors

Sanwa MT

-

17

Sanwa Rx 493

-

i

Hobbywing

Sanwa MT

-

4

Sanwa Rx 482 FH4

Trinity

Sanwa MT

-

44

Sanwa Rx 492 FH5

LRP

Sanwa MT

-

5

Futaba Rx R304SB

Muc more

Futaba T4PM Plus

Futaba R202GF

-

E

Yokomo

Flysky Noble Pro

Futaba

R203GF

-

E

Konect

Flysky FGr4v2 micro

Das

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

5.

Installation

T e first way ow to install t e ESC into your car is by using t e NITRIDE Installation Kit - ELC003, included in t e

package - a small grap ite plate and two screws M3x5mm suitable to screw to t e ceramic cooler at t e bottom

side of ESC.

! WARNING ! Do not over tig ten t e screws M3x5!

T en you can stick t e installation plate directly on t e c assis of your car using t e double-sided tape.

An example of NITRIDE installation into 2WD An example of NITRIDE installation into 4WD

Anot er way of installation is to use grap ite plates w ic can be screwed directly to t e c assis of t e car. T is

way of installation brings more stable position of t e ESC in t e car. You can use for example t e option part ELC004

– Universal Grap ite Plate (c apter 15).

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

Illustrative pictures of installation into t e c assis of t e cars:

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

6.

Connections

! WARNING ! Please, double c eck t e polarity of battery interconnection! Make sure, t at positive (+) of ESC is

connected to t e positive (+) of battery. If polarity is reversed, t e ESC will be damaged!

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

7.

Main Screen Description and

B

asic

C

ontrol of ESC

Basic Description of ESC Using

T e using of ESC is very simple and t ere is no ot er programming interface needed.

Turning on

After s ort pressing of ON/OFF/ENTER button, t e ESC will be switc ed on.

Turning off

If you press ON/OFF/ENTER for about 3 seconds t e ESC will be switc ed off. T e ESC can be switc ed off also by

disconnecting from t e battery.

! IMPORTANT ! T e t ree buttons are multifunctional. Above buttons, t ere is t e elp text about w at will appen

if you press t e button. You can move in t e loop around using left or rig t buttons. T e text above t e ENTER

button is underlined sometimes. T at means you ave two possibilities depended on ow long you press t e

button. For example: reset/next. S ort press = reset, Long press = next.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

8.

Programming and Screens sc ema

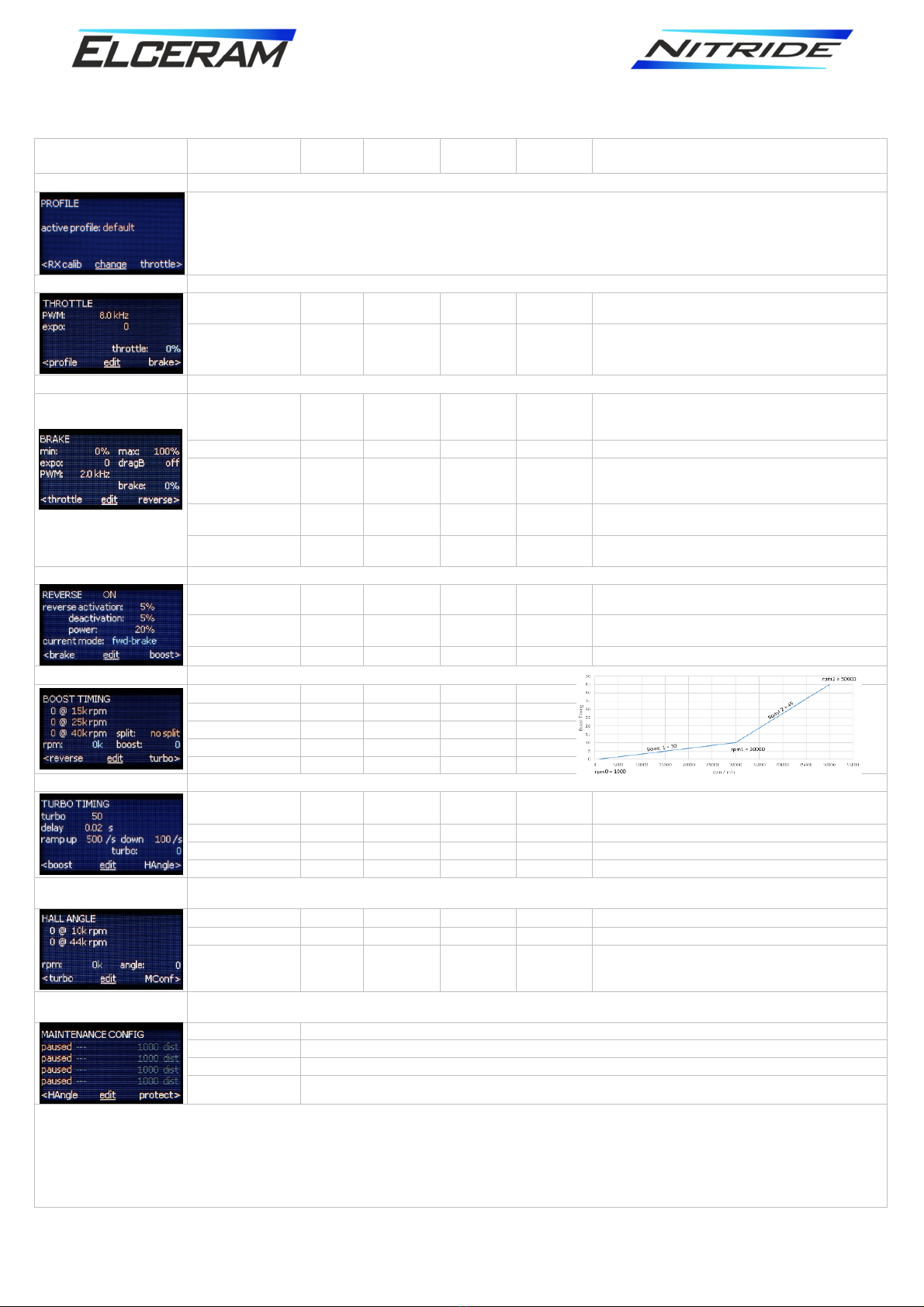

T ere are 3 Menu loops available - picture below:

1) Race data loop - LCD backlig t Black

In t is menu loop you can monitor race data and events before race, adjustment of ESC is not possible. You can

move in t e Race data loop using left or rig t buttons. For any action on t e screen press ENTER button - see t e

elp above t e button. T e most of race information will be reset after t e ESC is switc ed off. Exceptions are

maintenance and total runtime wit ESC.

2) Setting 1 loop - LCD backlig t Blue

For entry to t is Setting old rig t and left button simultaneously for about 2 s. For return, old t e buttons again

for 2 s.

In t is loop you can set all t e most important parameters of your ESC for t e race.

! Warning ! It is professional product for top racing and features are accessible for setting in real-time. During setting

of parameters, you ave to be careful and ave on your mind t at it can cause destruction of some components.

3) Setting 2 loop - LCD backlig t Orange

For entry to t is Setting old rig t and left button simultaneously about 4 s. For return, old t e buttons again for

2 s.

T is loop you will probably use not so frequently like Setting 1. Here you can set basic parameters like temperature

calibration and so one.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

SETTING 1

Parameter Name Default

value

Typical

value Min. value Max.

value Comments

Profile

Here you can set t e profile. For every profile t e parameters below will be saved and you can c ange it very easy and quickly.

T rottle

PWM 8 kHz 8 kHz 0.1 kHz 45 kHz

Less PWM frequency, more current t roug motor and

more aggressive t rottle response

expo 0 0 -64 +64

Zero = linear / line

More expo = exponential curve = slower beginning

Less expo = logarit mical curve = quicker beginning

Brake

min 0 % 5 % 0 % 50%

Initial brake force if you move wit

t rottle from neutral

position to t e brake. If Drag brake is activated, min

brake = drag brake

max 100 % 95 % 1 % 200 %

Max. brake force

expo 0 0 -125 125

Zero =

linear

/

line

More expo = exponential curve = slower beginning

Less expo = logarit mical curve = quicker beginning

dragB off off on off

If

dragB is on, t e car will be braking in neutral position

of t rottle

PWM 2 kHz 2 kHz 0.1 kHz 45 kHz

Less PWM frequency, more current t roug motor

during braking, and brake will be more aggressive

Reverse

activation 5 % 5 % 1 % 50 %

Percentual position of t rottle for activation of reverse

deactivation 5 % 5 % 0 % 50 %

Percentual

position of t rottle for deactivation of

reverse

power 20 % 20 % 1 % 100 %

More power more speed during reverse

Boost Timing

rpm 0 15000 5000 1000 48000

rpm 1 25000 20000 2000 49000

rpm 2 50000 50000 3000 50000

boost1 0 0 0 63

boost2 0 0 0 63

Turbo Timing

turbo 0 40 0 63

If full t rottle (100 %), turbo will be activated

More value = more top speed

delay 0.2 s 0.03 s 0.00 s 1.00 s

Delay from full t rottle to activated turbo

ramp up 100 / s 300 / s 10 / s 1000 / s

More Ramp up = More turbo increase

ramp down 100 / s 300 / s 10 / s 1000 / s

More Ramp down = More turbo decrease

Hall Angle

S

i

milar function like

mec anical timing by motor but in specific rpm range

using software

. It brings more

power

efficiency

for y

our

power

system.

rpm 0 10000 30000 5000 49000

Start of Hall Angle increase

rpm 1 44000 45000 6000 50000

End of Hall Angle increase

all angle 0 0 0 63

T is value of mec anical timing = Hall angle will be

progressively reac ed between rpm0 and rmp1. T e all

angle value will be kept above rpm1 at constant level.

Maintenance

Using t is

function,

you can c eck t e wear out of components of your car. You can set eit er time (minutes) or distance of your car. 1

distance = 100.000 turns of your motor = 100 k turns of your motor. 5 min of race ave approx. 100 k of turns of your motor.

Maintenance A

Maintenance B

Maintenance C

Maintenance D

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

Protection

voltage warning 3.6 V 3.4 V 3.1 V 4.1 V If battery voltage reac ed t is value ESC starts to

limit max. power

voltage cutoff 3.4 V 3.3 V 3.0 V 4.0 V If battery voltage reac ed t is value ESC power

will be reduced to t e minimum

motor limit 100 °C 100 °C 70 °C 150 °C If motor temperature reac ed t is value ESC

starts to limit max. power

ESC limit 125 °C 125 °C 125 °C 150 °C If ESC temperature reac ed t is value ESC starts

to limit max. power

Rx Calibration Pus calibrate button and old ca 1s. Pus full t rottle, full brake and leave neutral. Pus Ok button.

! WARNING ! Keep t e sensor cable disconnected during t e first power on until ESC is calibrated wit your radio system, to avoid

unexpected motor start!

Press calibrate button and old it for approx. 1s. Pus full t rottle, full brake and return to neutral. T en press t e Ok button. T e

calibration is done.

Setup s eet

Parameter

TC Car

modified

carpet

TC Car

modified

asp alt

TC Car

Stock

carpet

2WD

modified

carpet

2WD

stock

carpet

4WD

modified

carpet

4WD

stock

carpet

Default

value

Motor

Rotor (mm) 5T

12.3 / 12.5

4.5T

12.3 / 12.5 13.5T 6T-6.5T 13.5T 5T-5.5T 13.5T -

Motor Timing (°) 30 30-35 - 30 - 30 - -

Active FAN No Yes No No No No No -

T rottle

Less PWM frequency, more current t roug motor and more aggressive t rottle response

PWM 8 kHz 7-8 kHz 2-4 kHz 6-8 kHz 2-6 kHz 6-8 kHz 2-6 kHz 8 kHz

expo 0 0 0 0 0 0 0 0

Brake

Less PWM frequency, more brake torque, more aggressive brake response

min 10 % 15 % 10 5 5 5 5 0

max 90 % 85 % 85 % 125 % 125 % 90 % 90 % 100 %

expo 0 0 0 0 0 0 0 0

dragB on on on off off off off off

PWM 6 kHz 4-6 kHz 6 kHz 1 kHz 1 kHz 2 kHz 2 kHz 2 kHz

Boost Timing

More boost timing, more power in rpm range, less efficiency of power system

rpm 0 15000 15000 - 1000 - 1000 - 15000

rpm 1 25000 30000 - 25000 - 25000 - 25000

rpm 2 40000 45000 - 50000 - 50000 - 40000

boost1 0 10 - 0

- 0 - 0

boost2 0 20 - 0

- 0 - 0

Turbo Timing

More turbo value, more Top speed. More Ramp up = faster turbo increase

turbo 25 40 - 45 - 50 - 0

delay 0.02 s 0 s - 0.02 s - 0.02 s - 0.2 s

ramp up 300 / s 400 / s - 450 / s - 500 / s - 100 / s

ramp down 300 / s 400 / s - 350 / s - 350 / s - 100 / s

Hall Angle

Hall Angle = SW controlled Mec anical timing. More all angle, more rpm, less torque, less efficiency of power system

rpm 0 - - - - - - - 10000

rpm 1 - - - - - - - 44000

all angle - - - - - - - 0

Protection

! Warning if voltage cutoff is below 3,5 V, it can cause damage of your battery

voltage

warning 3.2 V 3.2 V 3.2 V 3.2 V 3.2 V 3.2 V 3.2 V 3.6 V

voltage cutoff 3.1 V 3.1 V 3.1 V 3.1 V 3.1 V 3.1 V 3.1 V 3.4 V

motor limit 100 °C 100 °C 105 °C 105 °C 105 °C 105 °C 105 °C 100 °C

ESC limit 130 °C 130 °C 130 °C 130 °C 130 °C 130 °C 130 °C 125 °C

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

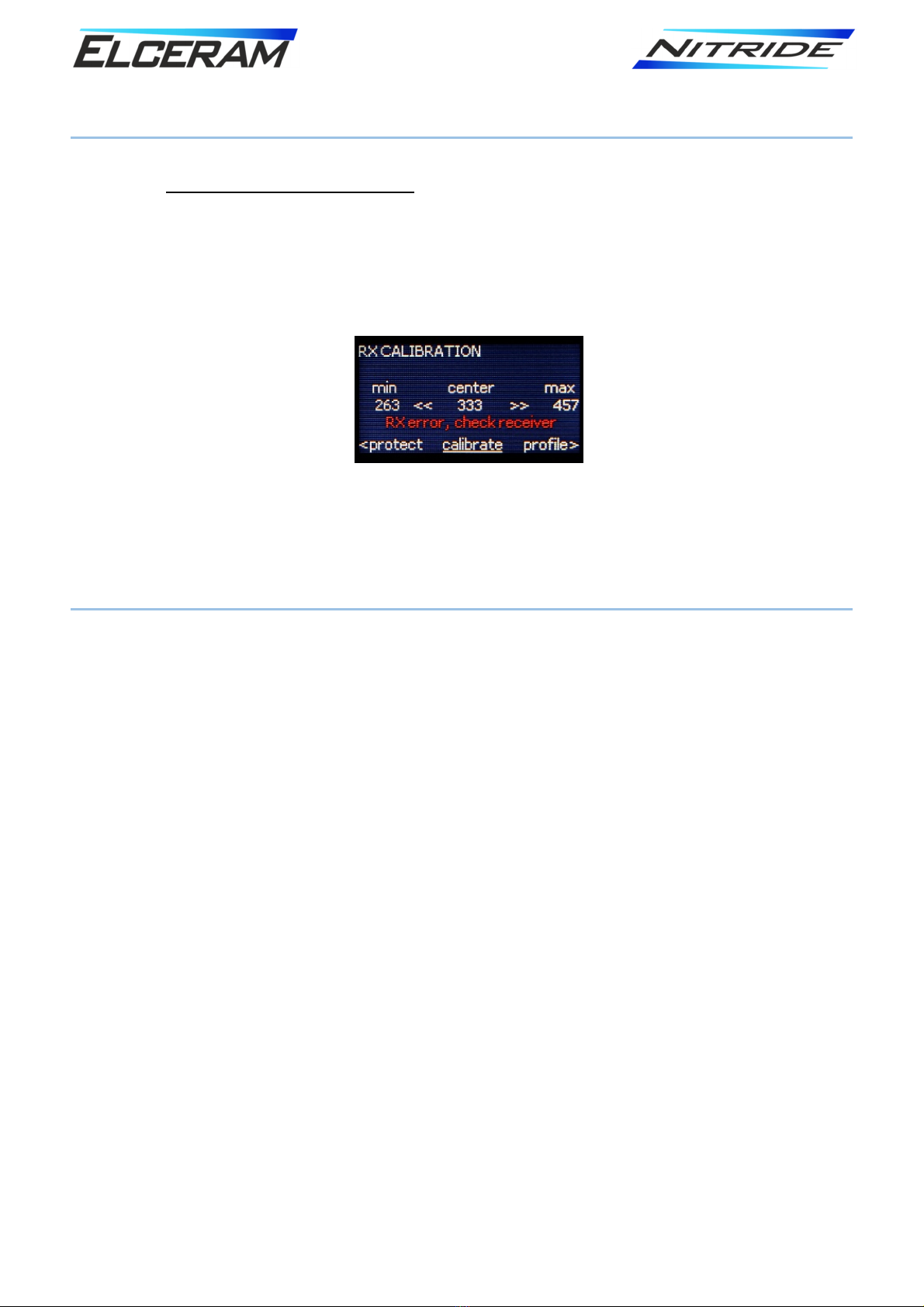

9.

RX Calibration

! WARNING ! Keep t e sensor cable disconnected during t e first power on until ESC is calibrated wit your radio

system, to avoid unexpected motor start!

! WARNING ! We recommend to use one of t e radio control systems compatible wit NITRIDE – listed in c apter

4. T e table will be extended during t e time.

! WARNING ! If you ave Futaba Radio system, please reverse t rottle on t e transmitter before first turn on!

For radio system calibration, c oose t e RX CALIBRATION in t e Blue menu (picture above) using t e buttons. Press

calibrate button and old it for approx. 1s. Pus full t rottle, full brake and return to neutral. T en press t e Ok

button. T e calibration is done.

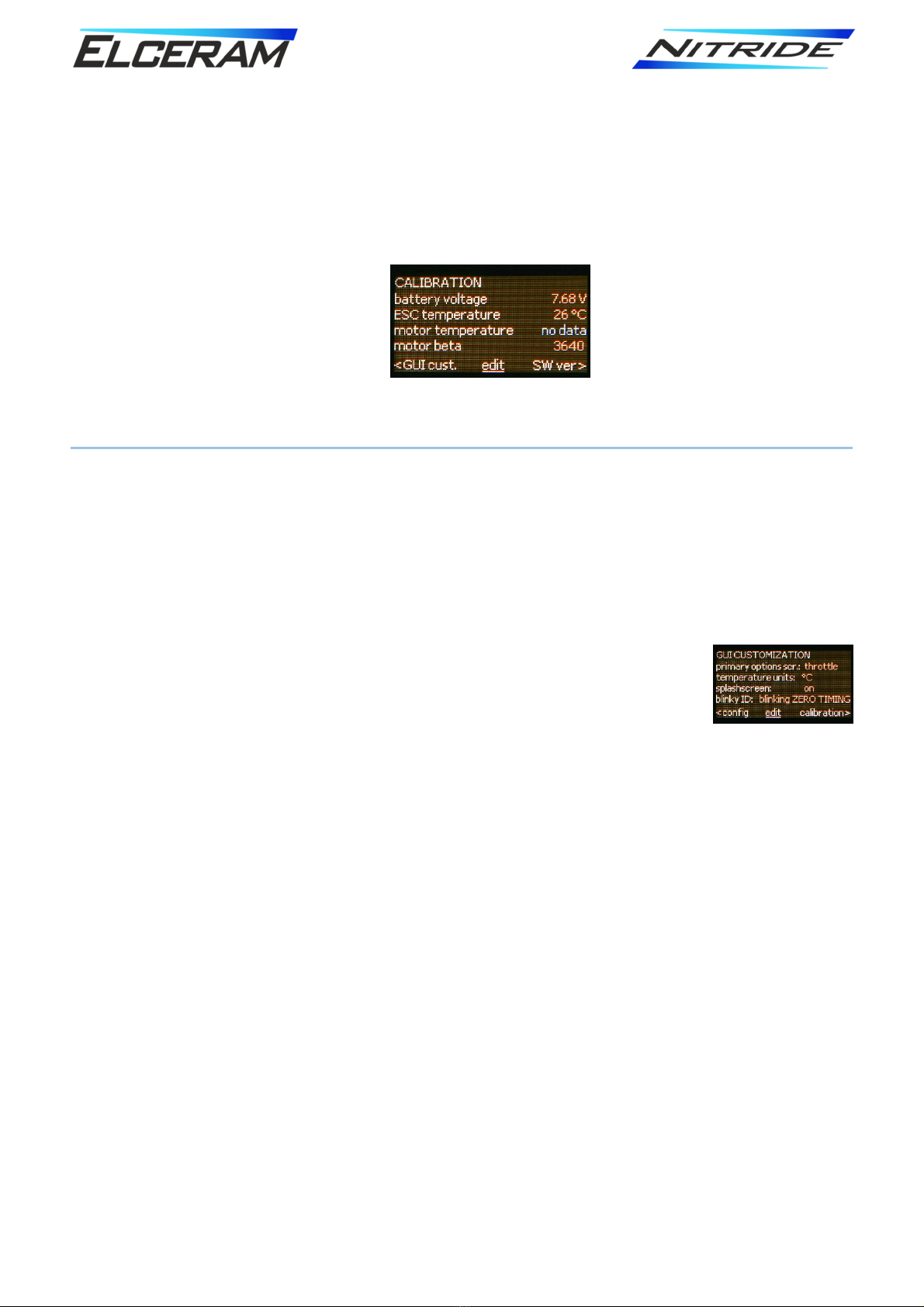

10.

Temperature and Voltage Calibration

ESC Temperature Calibration

T e temperature of your ESC was calibrated in factory. If needed you can re-calibrate it.

For t is case use t e t ermometer for ensuring t e ambient temperature. T en c oose t e CALIBRATION in t e

Orange menu (picture below) using t e setting buttons. Set t e ESC temperature according to t e ambient

temperature using edit button and t en +/- buttons and press Ok. T e temperature calibration is done.

! TIP ! T e calibration s ould be finis ed s ort time after switc ing on of ESC, because ESC generates some warming

itself.

Motor Temperature Calibration

If temperature NTC sensor is included in your motor, t e motor temperature as to be calibrated.

For motor temperature calibration let t e car wit motor to stabilize in ambient temperature for approx. 20

minutes wit out using. C oose t e CALIBRATION in t e Orange menu (picture below) using setting buttons. Set t e

motor temperature according to ESC temperature using +/- buttons. T en press Ok. T e temperature calibration is

done.

! TIP ! In some cases, you will need to c ange motor beta dependence according to temperature sensor used by

motor producer. At t e beginning start wit default value 3640.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

Battery Voltage Calibration

For battery voltage calibration measure battery voltage using any multimeter. T en c oose t e CALIBRATION in t e

Orange menu (picture below) and set t e measured value using edit button and +/-. T en press Ok. T e battery

voltage calibration is done.

11.

Zero

T

iming / Blinky / Stock

M

ode

NITRIDE also supports t e Zero timing / Blinky / Stock mode.

Switc ing to Zero Timing Mode

If all of t ese parameters - Turbo Timing, Boost Timing and Hall Angle in Blue menu (Setting 1) - are set to 0, t e

ESC is switc ed to Zero Timing Mode. In t is case, t e inscription “ZERO TIMING” is blinking green on t e main

screen.

Alternatively, t e user can c ange t is sign for t e inscription “BLINKY” or “STOCK” and

c oose, if t e inscription will be static or blinky. T e option can be made in Orange menu

(Setting 2): Setting 2 → Gui Customization → blinky ID

C anging of inscription does not affect t e function of Zero Timing Mode, it´s just anot er name, but t e function

is t e same.

Switc ing t e Zero Timing Mode Off

If any of t ese parameters - Turbo Timing, Boost Timing or Hall Angle - are set to a different value t an 0, t e Zero

Timing mode is switc ed off and t e inscription “ZERO TIMING” disappears from t e display.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

12.

T e

M

otor

C

oice

NITRIDE was tested wit t e most of sensored motors available on t e market, wit or wit out temperature sensor.

If motor as no temperature sensor, “no data” will be displayed.

NITRIDE as very linear and smoot t rottle c aracteristics especially if boost timing is set to zero. From t is point

of view consider carefully t e c oice of your Motor Turns.

For example, you can get better feeling wit Motor 5.0T and boost timing zero compared to 5.5T and activated

boost timing. Some of our recommendations are summarized in t e table below:

2WD

dirt

2WD

carpet

2WD

astro

4WD

dirt

4WD

carpet

4WD

astro

TC

carpet

stock

TC carpet

modified

TC

asp alt

stock

TC asp alt

modified

Motor 7.5 T

8T

6T

6.5T

6.5T

7T

7T

7.5T

5T

5.5T

6.5T

7T 13.5T 5T-5.5T 13.5T 4.5T

5T

Active

FAN No No No No No No No No No Recommended

for 4.5T

T e above recommended values strongly depend on t e Drive Ratio as well.

For use in off-road cars and also for on-road wit t e motor wit more t an 4,5T, t ere is no active cooling needed.

For use in on-road car wit t e motor 4,5T on asp alt, especially in ot summer weat er, we recommend to use

an additive active cooler, t at can be simply installed using t e small plate and screwed toget er wit NITRIDE

directly to t e c assis of t e car. Examples of installation you can see on pictures bellow.

Example of NITRIDE installation into on-road car using t e fan for use wit t e motor 4,5T on asp alt

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

13.

Troubles ooting and EVENTs

D

escription

NITRIDE as revolutionary self-diagnostics and you can see t e event notifications before and after race

immediately on t e display.

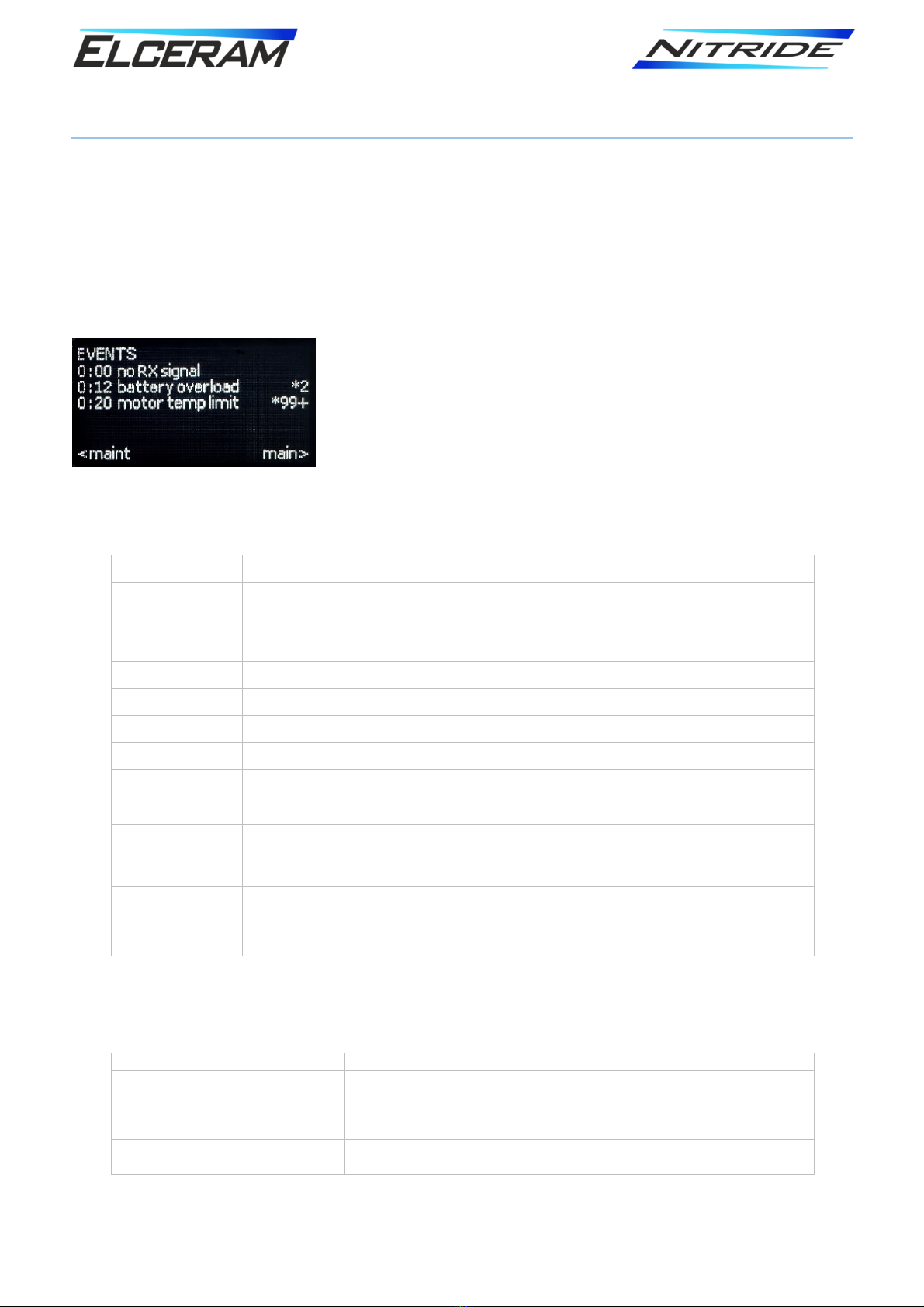

T e example of t e events you can see in t e picture bellow:

T ese events inform you t at:

In t e time 0:00 t e ESC as no Rx signal from your Receiver.

In t e time 0:12 was your battery overloaded wit ig current consumption

2 times.

In t e time 0:20 you reac ed maximum temperature limit of your motor

more t an 99 times.

Description of Possible Events:

Displayer Event Description and Recommendation

no Rx signal

T e ESC does not see t e signal from your receiver - Rx.

It can be displayed if you switc ed ESC on first before t e Transmitter.

Transmitter and Receiver not paired. Bind your radio system.

sensor cable Data from motor sensors are invalid - c eck your sensor cable connection

motor temp limit Motor reac ed “motor limit” temperature - ESC starts to limit max. power

motor temp over Motor temperature exceeded “motor limit” + 5 °C - Motor power will be reduced to t e minimum

ESC temp limit ESC reac ed “ESC limit” temperature - ESC starts to limit max. power

ESC temp over ESC reac ed “ESC limit” + 5 °C - ESC power will be reduced to t e minimum

battery empty Battery was disc arged below “voltage cutoff” level

low battery Battery was disc arged below “voltage warning” level

battery overload Current flow was too ig for your battery - reduce boost timing, use motor more

turns, new battery

unexpected reset Current flow was extremely ig for your battery and subsequent voltage drop caused ESC reset

maintenance

interval At least one of your maintenance counters reac ed 100 %

MAINTACE

INTERVAL At least one of your maintenance counters reac ed 200 %

Additional Troubles ooting

Problem Cause Solution

Display is frozen

Dirty connector or

s ort connector contacts loose during

strong cras

- Hold settings buttons for display

reset.

- C eck and clean t e connector.

- Use new cover.

Motor is tugging and ECS temperature

rise up Wrong p ase connection C eck t e cables.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

14.

Display and

M

aintenance

Display is very resistant and does not need any maintenance. We

suggest cleaning using microfiber clot – see picture on t e rig t

side.

! TIP ! For unscrewing use t e allen key screwdriver 0,05 “ / 1,27 mm

Please be informed, t at t e cover wit display and

buttons is replaceable in case of any incident – spare

part number ELC002.

T ere is very reliable connector in your ESC. During

mounting you ave to avoid any dust contamination

or damage of t e female part on control board – see

picture on t e left.

T ere is very small probability t at t e image on

display will be frozen after very big car cras . T is can

appen because of display connector losing contact

for a s ort time. In t is case you can reset display by

olding settings buttons t e same way as to switc to

Blue Setting.

High power electronics for professional RC racing Advanced Cooling Technology for RC Cars 1/10

________________________________________________________________________________________________________________________________________________

15.

Option parts

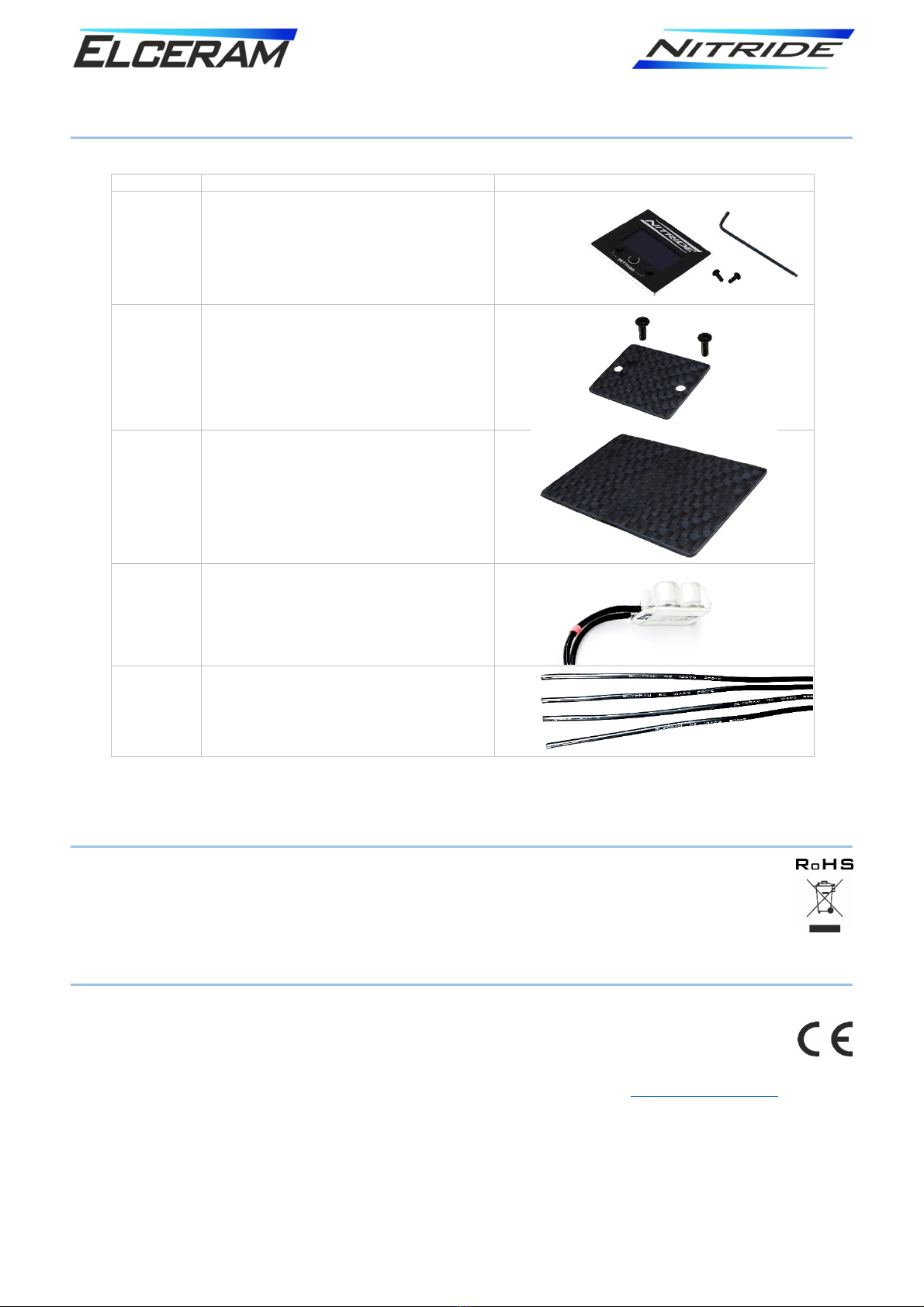

Part number Description Picture

ELC002

New aluminium cover wit display and buttons.

Allen key Tool 0,05 ‘’ (1,27 mm) and new screws

included

ELC003 Installation kit - Grap ite plate wit screws

ELC004 Universal Grap ite plate

50 x 60 x 1 mm

ELC005 External low ESR capacitors soldered on t e

ceramic PCB wit t ick silver layer

ELC006 ELCERAM RC cables 1 m

16.

Recycling

Electronic devices marked wit t e crossed-out dustbin symbol must not be disposed of in normal

ouse old waste, but must instead be anded in at a specialized collection and recycling facility.

17.

Conformity and Declarations

T e producer, company ELCERAM a.s., ereby declares t at Electronic Speed Controller NITRIDE 1/10

complies wit t e requirements of relevant directives, regulations and armonized European standards.

T e full text of t e EU Declaration of Conformity is available at following website: www.elceram-rc.com.

Table of contents

Popular Controllers manuals by other brands

Kohzu Precision

Kohzu Precision KOSMOS series user manual

National Instruments

National Instruments PCI-8212 Getting started

Mitsubishi Electric

Mitsubishi Electric AnyWire ASLINK user manual

Inovance

Inovance H3U Series user guide

Emerson

Emerson Fisher FIELDVUE DVC6200 SIS Instruction manual supplement

FATEK

FATEK FBs Series user manual

Allen-Bradley

Allen-Bradley PowerFlex 755TL Product information

Sentera Controls

Sentera Controls DRPUM Mounting and operating instructions

Lovato

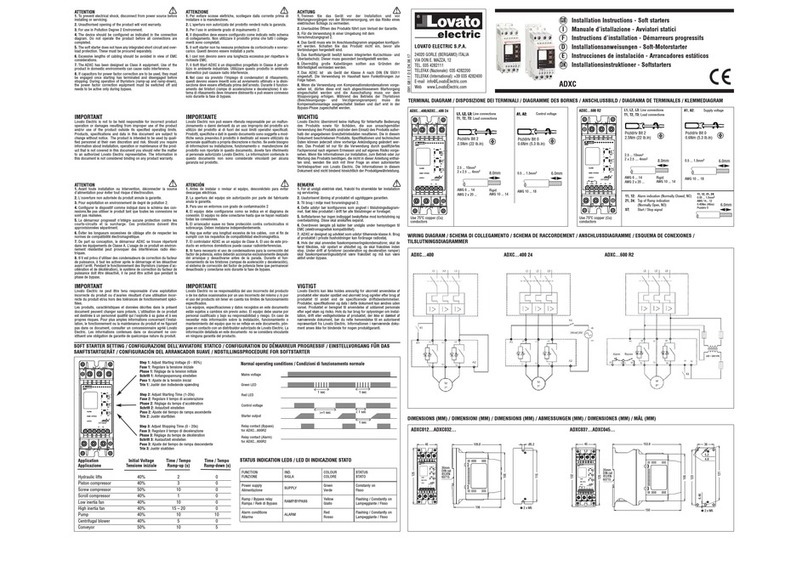

Lovato ADXC 012 400 installation instructions

National Instruments

National Instruments cRIO-9030 user manual

Danfoss

Danfoss EKC 102C instructions

marklin

marklin Central Station 3 60216 Operation