10/2010 - Art. Nr. 4200 1030 7600A 13

- Pre-ventilation,

- Return to ignition position,

- Ignition of electrodes,

- Valves open,

- Burner stops due to lack of gas

pressure or control unit locks because

flame is extinguished.

- If unsure, redo the above test.

The unit can only be fired once this very

important operating sequence check

has been performed.

Firing

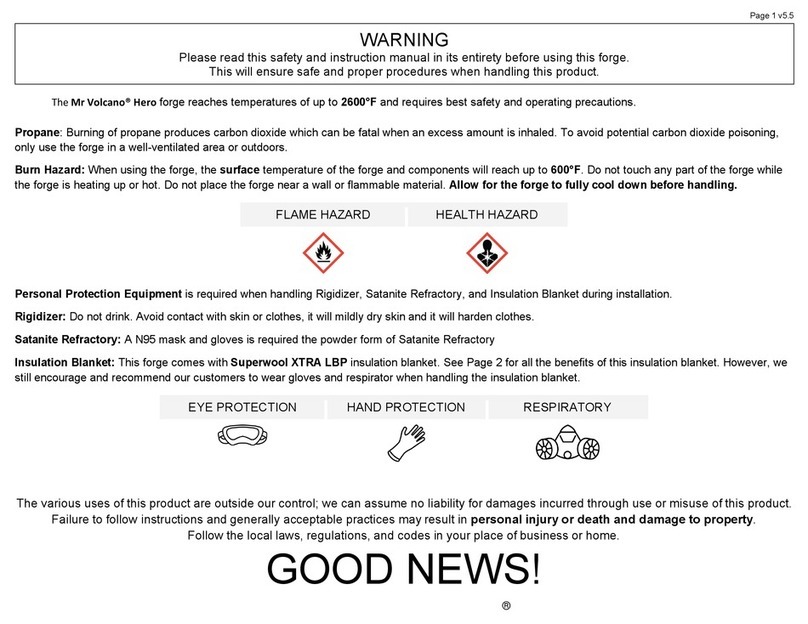

Warning:

The burner may be only fired when

all the requirements listed in

previous sections have been met.

• Open the quarter-turn hand-operated

fuel valve.

• Close the thermostatic circuit.

The leak tester is charged. After running

the test (30 s), the control unit

programme will relaunch. After pre-

ventilation, the burner comes on and

operates at minimum power.

• Check the following:

- the combustion

- the overall leak tightness of the gas

train using foam designed for this

purpose.

No leaks should be detected.

• Measure the gas flow shown on the

counter.

• Slowly increase the power to nominal

output, controlling the combustion

throughout. If necessary, adjust the

combustion by adjusting the

Pair:Pgas pressure ratio ( ,

Screw R).

• Adjust the servomotor control cam I

(Nominal output) to limit the maximum

opening of the air flap to the position

reached for nominal output.

• Slowly reduce the power to the

nominal output required, checking the

combustion values throughout; if

necessary, at minimum power, adjust

the combustion via parallel shifting of

the characteristic ( , Screw D).

• Adjust servomotor control cam III

(Minimum output) to limit the minimum

opening of the air flap possible during

operation to the position reached for

minimum output.

•Precautions: On principle, the

nominal output must only be modified

by adjusting the Pair:Pgas pressure

ratio ( , Screw R), and the

minimum output must only be

modified by offsetting in parallel to the

characteristic e ( , Screw D).

• After any modification to the minimum

output settings, check the combustion

at nominal output and adjust if

necessary.

• After any modification to the nominal

output settings, check the combustion

at minimum output and adjust if

necessary.

• To complete the adjustment process,

restart the burner and check the

power and the combustion. If

necessary carry out adjustments as

described above.

• Check the leaktightness of the gas

train.

• No leakage should be detected.

• Check the safety devices.

• Setting and checking the safety

devices

Gas pressure switch

• Set it to the minimum distribution

pressure.

• The burner operates at minimum

output.

• Slowly close the 90° manual shut-off

valve.

• The burner must stop due to a lack of

gas pressure.

• Open the 90° manual shut-off valve.

• The burner restarts automatically.

• The pressure switch is set.

• Fix and screw on the cover.

Air pressure switch

• See the paragraph entitled

"Determining the differential pre-

ventilation pressure and setting the

differential pressure switch" (page

16).

Leak testing device VPS:

• Open pa on the device.

• Restart the burner. After 30s the tester

should enter safety mode (red light

on).

• Reclose pa.

• o Unlock the tester safety catch by

pressing the red indicator.

The test cycle is relaunched.

The burner will be working.

• Check the leaktightness.

• Disconnect the measurement devices.

• Re-close the pressure tap.

• Reset the unit.

The burner will be working.

• Check:

- the seal between the flange and the

boiler front,

- the opening of the control circuit

(limiter and safety),

- the current on the motor relay.

• Check the combustion under actual

working conditions (doors closed,

cover in place, etc.) and check all

circuits for possible leaks.

• Establish a measurement protocol.

• Start-up automatic operation.

• Provide all the data required for proper

operation. (Inform the boiler room

operator).

• Place the boiler plate in a visible

location.

Commissioning

Working cycle test

Firing

Safety unit settings and checks

e

Important!

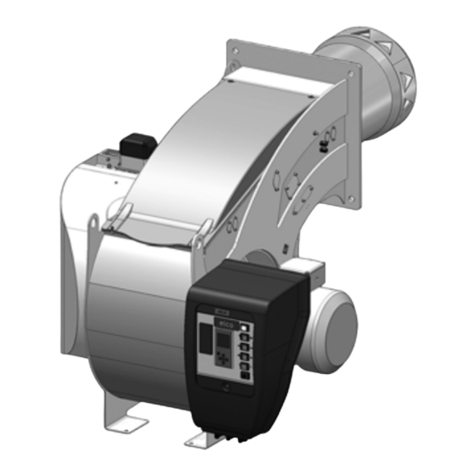

Before firing, to ensure the gas train

operates correctly, the position of the

gas flap must be checked. The table

below shows the recommended setting

depending on the burner.

• If a correction is necessary, proceed

as follows:

• Loosen screw S.

• Manually move lever Hto the

recommended position (setting

according to the table above).

• Lock into position using screw S on the

housing mounting bracket.

Pre-setting the SKP 75 according to

the table below: (these values are

given as a guide only)

Pre-setting the pressure switches on

the burner and the gas train

See the "Commissioning, Gas pressure

switch/air pressure switch" section.

Checking the operating sequence

• Open the quarter-turn hand-operated

fuel valve, then immediately close it

again.

• Switch the burner on.

• Select manual operation mode on the

control cabinet.

• Close the thermostatic circuit.

The VPS 504 S02 leak tightness test

device is switched on. After 30 s if the

test is validated, the amber light will

come on. The control unit is now

powered on.

The program should function in the

following way:

- Air flap opens to the servomotor

nominal output position,

Burner Setting (°)

N6.2400 G-VF3 90

N6.2900 G-VF3 90

N7.3600 G-VF3 90

N7.4500 G-VF3 90

Burner Gas

pressure

[mbar]

Shift from

origin

(screw D)

Pressure

ratio

(screw R)

N6.2400

G-VF3 90 2,9...4,0 2,2...2,3

N6.2900

G-VF3 90 2,9...3,7 2,2...2,3

N7.3600

G-VF3

90

N7.4500

G-VF3

90